councilman24

Members-

Posts

86 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by councilman24

-

Frustrated by Consew 199 - Timing Issues

councilman24 replied to spotty's topic in Leather Sewing Machines

Put on a bigger needle. The thread hast to hide in the long groove of the needle from all friction from the material being sewn. It make work with no material but once you try to sew the thread no longer moves freely in the long groove.to make loop for the hook to pick up. -

You may think it's threaded right but the path all the way from the cone to the needle matters. As above cone directly below first guide, through the right guide holes in the right path before the tension disks, etc. Needle size may also be the issue as mentioned.

-

If that class 7 in the OP has reverse (labeled 7-33r would say it does and it looks like it does) it may also have high lift added. Either with or without hi lift $1600 with reverse is very fair. I have 2 and wish I'd been able to get one with reverse.

-

You've gotten some advice about new machines and very heavy machines but I haven't seen an answer to what you want to do? I just bought a very good condition consew 206rb-2 needing a little adjustment and a 206rb-3 running well a little more used each for $300 with tables and clutch motors. I have one machine (lighter) with a servo. I also have two servos in boxes that I haven't decided which machine to put them on. In the mean time I keep sewing with the clutch motors I've been using for 20 years. One of the 206s I sat down at to try out before I bought it and could run it at a out 200spm (actually likely less) with the clutch. That being said a servo can be added to any machine for $135. I've bought sewing Songer 111 walking foots for $100. A Pfaff 145 compound feed similar in capacity to 206 for $35. To start you don't need new, no offense to the dealers here. The ONLY machines that I paid more than a $750 for out of 8 industrial zig zags, 5 or 6 compound feeds, 2 walking foot machines, 2 29-4s and an Adler 30-1, a 132k6, 2 7 class singers and an electronic bartacker was the bartacker and one of the 7 class. A couple needed a new take up spring a screw or two or adjustment. Oh, I forgot the Brother double needle cylinder arm that is all there but does need some work adjustment, cleaning and tuning for $300 with NIB hooks and lots of other parts. Granted I watch the ads, are familiar.with a lot of machines and willing to work on them myself. You can get a lot for $1000. If you need the heaviest cylinder arm compound feed they are rare used (the Brother is medium weight and and a steal) and command a high used price. Otherwise tell us what you want to sew and the forum can guide you to the proper used machines.

-

I just found this file somewhere last week. This should help. Prices range from $100 to $1000 around the country and depending on whether a good working machine, a spotless show piece or both. singer29classcomparisonsv02.pdf

-

Transporting American Straight needle.

councilman24 replied to councilman24's topic in Leather Sewing Machines

Thanks for the advice. I wouldn't likely have considered laying it down. I've hauled a gun safe in the middle of my trailer. I tie a net/cap with 4000lb webbing.and use 4 heavy ratchet straps. Key is having it in the middle so even length on all straps. But if I think I can manage to get it down and up I try that. I worry about stress bolts somewhere. -

Question is can an American Straight needle come apart easily for transport or does it need to move as one piece? Have trailer to move it intact and upright but hope a can make it a couple of pieces. Thanks.

-

The idea that this has given me is to use a long stand I got with a parts 29-4 for one of my complete 29-4s that has a standard stand so I can have a bigger table than the standard stand allows.

-

Need help timing a double needle machine

councilman24 replied to Kd0afk's topic in Leather Sewing Machines

I also use my phone, not only for close but also as telescope. But I also have one of the flexible stand magnifying glasses with circular light around it. Usually use it for picking.out bartacks on parachutes I repair but works for close up look at machines too. Range from $35 to.$350. Mine is 35 years old. -

I've never heard of one cracking. See post on 7-33 needles for very good manuals.

-

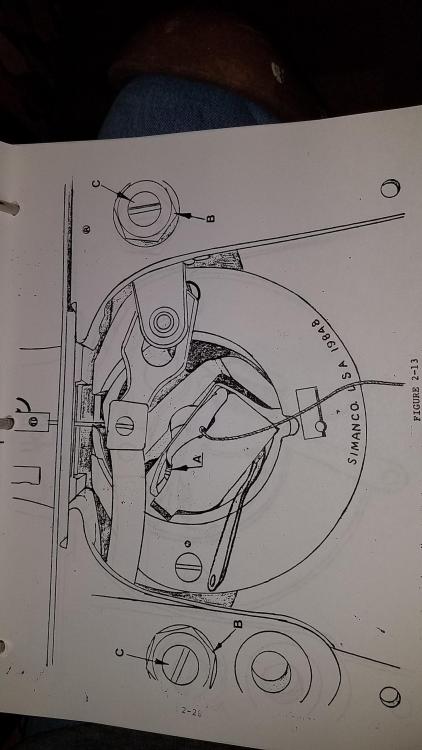

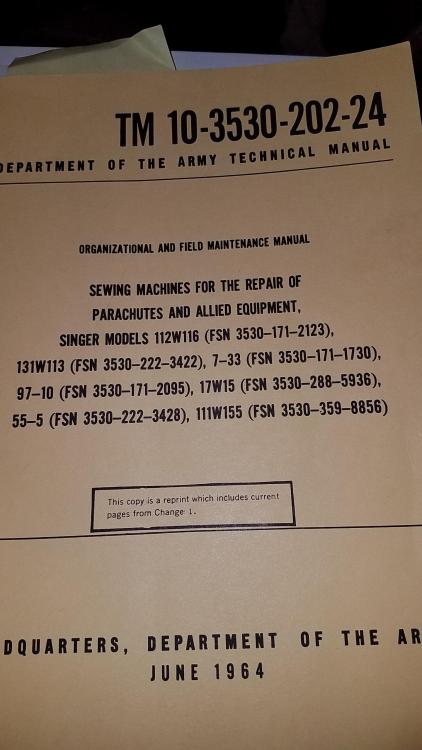

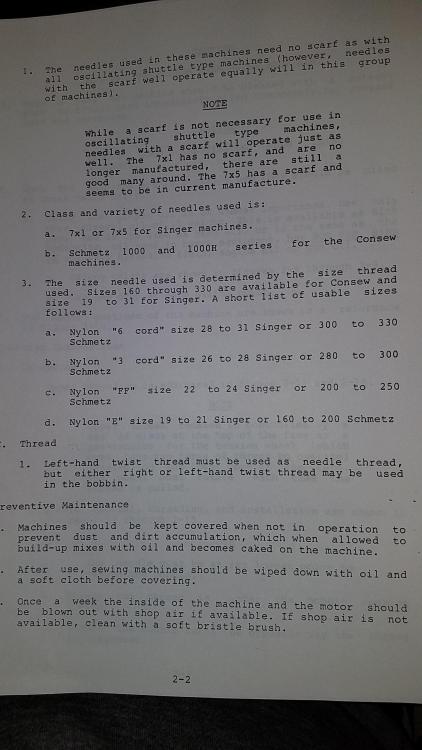

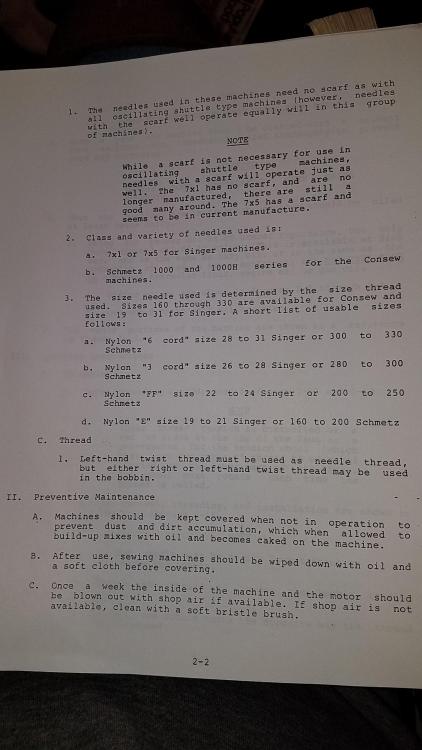

The Navy Equipmentman manual 3 and 2 is very good for 7 class as well as 31-15, 111 w 150 through 155, 112 w 140, 143 w 2. But the Cal's manual is by far the best. A user wrote very good detailed instructions for classes 31-15 and similar, 7 class and consew 733, 111 class including consew 225 and juki 562, 211 singer class, consew 199 class, singer 107 class. Here is an example. But I have one of only two copies I've ever heard of. The Technical manual has VERY detailed service instructions also.

-

-

-

-

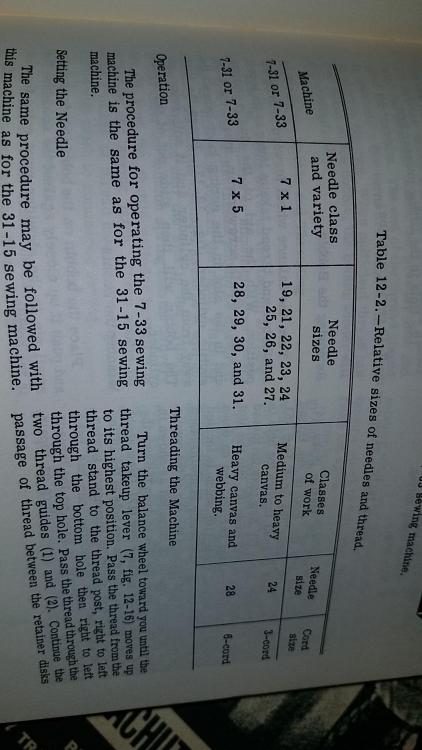

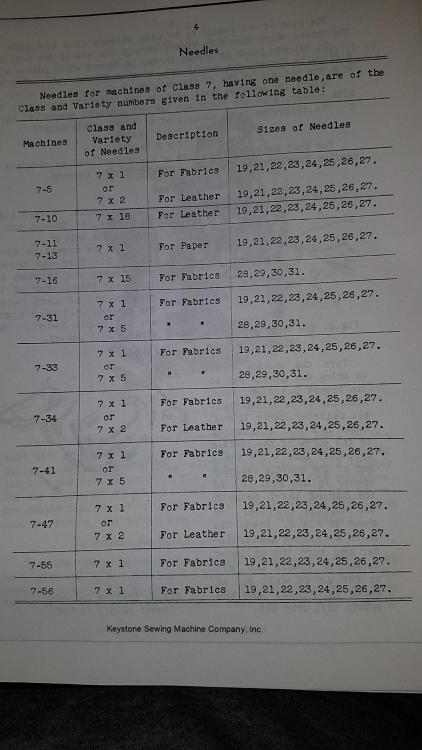

In the thread and needle table above the 7 under government is thread designation. I usually use 5 or 6 cord for parachute harnesses. All my needles for my 7-33 and now 7-34 aee 7-1 fabric needles. I believe 7-3 and 7-4 were later designations of fabric and leather points respectively. Below are a series of photos from various manuals. First the cover, then applicable pages.

-

Need help Identifying this Consew machine

councilman24 replied to tecbuddy1's topic in Leather Sewing Machines

It's also a Supreme DY637 and a Chandler DY347. I have both. It is a Mitsubishi. The DY-359 is a descendant with auto controls. Walking foot only as stated above. I know I've seen at least one other name on them. This is the first time I've seen Consew on it or the Consew documents above. I have only sewn on one of mine testing it when I bought it but seemed like a solid quality walking foot. Mine will likely both be for sale. Mine are both large bobbin so maybe I'll keep one. -

I'll pm later but why not compound feed?

-

-

Are you looking for a display piece or a work horse? I have one I should sell but not sure if it's pretty enough for you.

-

Is there standard for twin needle machines?

councilman24 replied to katit's topic in Leather Sewing Machines

Ebay. Or Henderson -

Is there standard for twin needle machines?

councilman24 replied to katit's topic in Leather Sewing Machines

BTW I am not a sewing machine mechanic. I had to learn how to work on mine because I own 20 industrial machines and no mechanic nearby. Becoming a mediocre machine mechanic based on need. But this change of gauge isn't really that hard. they are meant to be changed in the field. -

Is there standard for twin needle machines?

councilman24 replied to katit's topic in Leather Sewing Machines

It just really isn't that hard. Some of the first detailed sewing machine adjustment I did. But takes a good manual and an understanding of the adjustments needed. Try it for fun. -

Is there standard for twin needle machines?

councilman24 replied to katit's topic in Leather Sewing Machines

No, on a 212 singer it"s not that hard. When I got mine in the mail both hooks were loose and no where near set up. Took 2 to 3 hours with a good manual to set the hooks, the first time I ever moved a hook. Bought a new gauge set and changed it for the first time to a new gauge in an hour or two, again the first time I did it. With a good manual. Parts are widely available. I haven't worked with other than 212 singer series. But if you find a good one of those at a good price buy it no matter what the gauge. You likely will want more than one gauge anyway. Yes it's more convenient to have one in each gauge you want. But if you use one for an occasional project and mostly at one gauge it's not that hard to change. Assuming some medium mechanical ability. Especially if you've timed machine and adjusted hook clearances before. If you can't change your watch battery or the oil in your car then maybe changing one isn't for you. In fact I need to go down stairs and change mine from 1/4 to 3/16. I expect it to take an hour. With interruptions maybe 2 hours. -

Figured it out. Luberto's classic. Other posts on here. Maybe pink is photo artifact

-

https://www.facebook.com/marketplace/item/484665518704132/ I've never sewn this. Info?