-

Posts

240 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Instinctive

-

I've been making pouch sheaths but a guy asked me to make him a sheath for his Case Cutlery Buffalo Horn handle knife but wanted a snap closure handle retainer (no pouch). This is my first attempt at such a thing. Much harder than I thought it would be. Spent a long time on what looks like a very basic pattern. I was pretty happy to remember to put the snap strap the right way so it would not catch on a branch when walking forward. He wanted me just to cut some slits in the leather to put his belt through but I couldn't bring myself to do that. He liked my solution enough to order another. Triple layer of 9oz leather with the welt. Hand stitched.

-

Time to upgrade form the Xacto. Any opinion on the Vergez Blanchard L'Indispensable Flat Knife?

-

The D ring was a "let's see if it works" thing. It allows the quiver to be worn on the right or left side by letting the front of the shoulder strap slider to the right or left depending on the side it is worn on. I'm going to work on eliminating that for a no metal build. I did use a needle. Perma-lok needle Item #1193-01 from Tandy.

-

Fiebing's have an article on their website for blending up to 6% solution spirit dye with neatsfoot oil. https://www.fiebing.com/tips/mixing-fiebings-leather-dye-and-prime-neatsfoot-oil-compound/ I have done this and it worked very well.

-

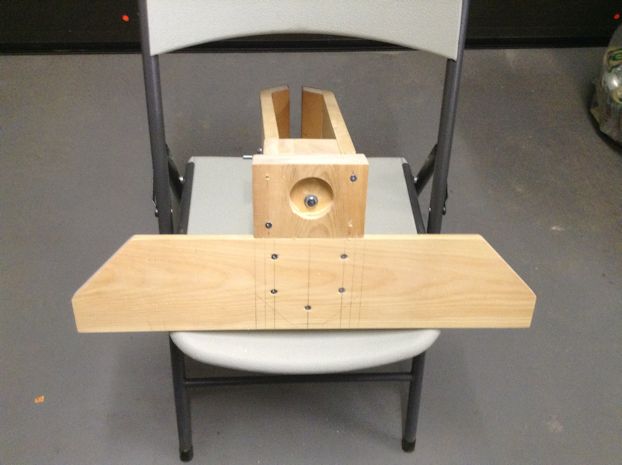

I've been leaning toward Hony as well. The extension is a lot more comfortable, especially if you have a more substantial build like mine, i.e., a beer gut. Picked up the stuff to make that cam closure today. Clear pine from my local Home Depot. Very easy to work with but still provided the strength required.

-

That's a nice job. I especially line the cam closure and am going to need to modify mine now. Personally I built a hybrid between a pony and horse. I extended the location of the arms to provide more working room. The arms can also be rotated to provide a better work angle iof the work requires. The extension is supported by a piece of PVC built-in vacuum cleaner pipe so it remains portable and storable. Built from pine. Still can't decide if I should call it a Hony or a Porse.

-

Doesn't look like there will be any issue with sag on this one. That a 10-12 oz leather. The center is really stiff. I've seen some done with metal stiffeners but they were using much thinner leather. If it looks like it's going to sag, the design with the paracord stitching will allow me to add leather stiffener ribs on the side of the center section.

-

New Shotgun Shell Pouches

Instinctive replied to l2bravo's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Nice inlay work and on my list this year as well. -

Slowly working my way through a pile of 25+ year old veg tan. Back into traditional archery so made myself a prototype rustic traditional side quiver stitched with camo paracord. Question This old leather is really dry and brittle. gave it a treatment of neatsfoot oil. Would saddle soap help rejuvenate the leather?

-

Bear Claw Knife Sheath

Instinctive replied to Instinctive's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Just melted with a lighter. -

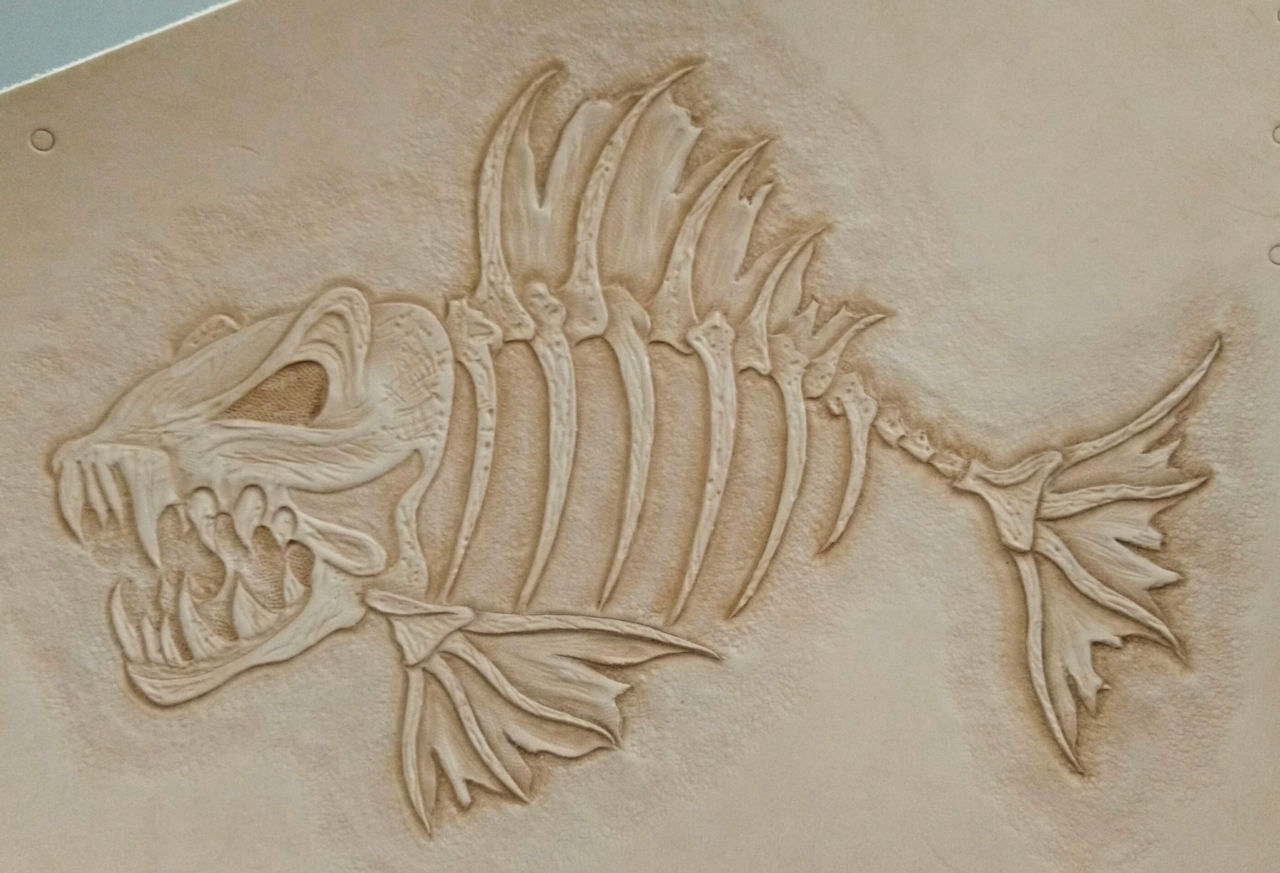

Most recent sheath for a bushcraft knife made from Russian steel. I thought a bear would go well with that steel. Experimenting with paracord stitching and the belt loop technique. The belt loop works really well.

-

Axe Sheath - Copper Rivet Intro

Instinctive replied to eby's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Copper rivets are next on my list too. Scrap bin project coming up. -

I asked my daughter if she would like something made from leather. She asked if I could make a leather tote bag to lug here stuff back and forth to work and sent me a picture and some specifications to go by. Drew a pattern on my computer CAD system and went to a lot of work. Hand cut, dyed and stitched. Because I'm an Engineer I just had to count. 918 saddle stitches that required 1232 stitching holes punched one at a time. I did not count the hours it took. The leather is 5-6 oz mill finished veg tan (she wanted a soft bag). The handle is laminated with the 5-6 oz mill finish backed with 3-4 oz regular veg tan. Not having done this before it was a bit of a design as you go. Internal strap was added with a couple of clip hooks to attach wallets, keys, etc. Not lined because we were not sure if it was going to work out and be usable until the end. It was a keeper but lining the next time.

-

My Best Sheath Yet

Instinctive replied to stu925's topic in Gun Holsters, Rifle Slings and Knife Sheathes

That works for me and I really like the idea of covering the flesh side. It looks great, -

Tooled Belt

Instinctive replied to AndyL1's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Your antiquing technique is simply the best. -

Knife Sheath

Instinctive replied to jstar61's topic in Gun Holsters, Rifle Slings and Knife Sheathes

I like out of the box thinking on the design. I'm thinking the dangler hangs a bit low though. -

i will be waiting on the finished product as well. Just back into tra\traditional archery after 30 years or so and am working on a side quiver of my own.

-

Para-Cord Stitched Knife Sheath

Instinctive replied to Instinctive's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Not sure I like the neck idea either but since it sort of looks like a holster I figure I can put a longer cross body cord on it and tuck it under my arm. The pieces are glues with water based contact cement. All the holes were punched before gluing.