-

Posts

1,801 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Chief31794

-

I don't like taking the chance of dye bleed on shirts, and I've never liked the look of dyed flesh side of leather, I like it better when it looks like leather. If I double layer the strap then both sides are dyed, but then the backsides are glued together and don't show. Just me, but there is an option to have the back dyed when they order and I've not had very many take that option. I'll dye it and seal it if they want but most don't want it. Chief

-

What a nice compliment. I have a video out on you tube concerning the arrowhead basket weaving technique, hadn't thought about the others since they are pretty standard and there's lots of folks out here that do basket weave better than I. I will try to get in the shop and do some techniques on video and get it posted. Chief Standard width for guitar straps is 2-1/2 inches but I've made them from 1-1/2 to 3-1/2" wide for different folks. Thanks, Chief

-

I use Fiebing's Aussie, I coat both the front and back then heat with a heat gun until it liquifies, then wipe off the excess. This provides shielding against perspiration and also conditions the leather. Then I put 1 or 2 coats of Resolene on the front side. The Aussie is like "Sno Seal" it acts as a moisture prevention. Instrument straps that are used a lot get subjected to sweat. Hope that helps.

-

Using Acrylic Resoline and cracking!

Chief31794 replied to PrimroseHandmade's topic in How Do I Do That?

Are you cutting the Resolene, most people cut it 50/50 with distilled water and then you should make sure that you only apply one or two very light coats, most cracking results from applying too much resolene. Your picture looks like there is a fairly substantial build up of finish. There are other finishes, but Resolene is a staple in the leather working world, with Clear Lac being another. Some folks use Mop and Glo floor polish cut 50/50 with distilled water. I have used it and it seems a lot like Resolene and I don't think your results would be any better. Chief -

Thanks, I don't get up to Kentucky, I do the ones in Georgia, and a few in Florida and Alabama. I make Resogat every year in Wilkesboro, NC. Wish I could get up to KY, I used to live in Clarksville just south of Hopkinsville back in the 70's and played around there some then.

-

Thanks, Thanks for the nice comments about my tutorials. Good luck on your first guitar strap. Chief

-

Thanks, Thanks, Chief

-

I do these kind of things, you can reach me at chief31794 {at} yahoo DOT com. Chief

-

More stuff for a festival next month. 2 Attachment type banjo straps, a cradle type banjo strap and 2 mandolin straps for F-style mandolins. Chief

-

Absolutely Beautiful!!! Excellent craftsmanship.

-

Thanks Chris, yep, I had a big show in North Carolina for dobro pickers last month and a couple of Bluegrass Festivals coming up, so I'm running pretty hard, and about next month will kick off Rifle Sling Season (beginning of hunting season through Christmas). Chief

-

Thanks, yeah I know a lot of them too. I get a double benefit from selling at Bluegrass Festivals, I get to sell some straps and I get to pick some too. Chief

-

Thanks Rohn, Chief

-

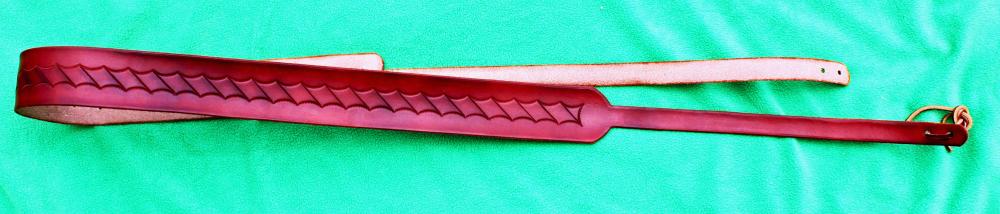

Getting ready for a Bluegrass festival next month, put these out over the last 4 days, I still have to do some banjo and mandolin straps, had some dobro straps left over from Resogat last month. Made from Hermann Oak 7/8 oz. Chief

-

Neatlac

Chief31794 replied to Handstitched's topic in Dyes, Antiques, Stains, Glues, Waxes, Finishes and Conditioners.

Neatlac is still made, it is no longer called neatlac it is called Clear Lac, it is available from Springfield Leather Company and other places. It is produced by LCI which is who marketed it under Neat Lac back in the day. Chief -

-

The Big Red swivel knife sharpening jig will hold Barry's or Tandy's one end is smaller diameter inside than the other. It also comes with a device for setting the correct angle. Best sharpening tool I've found for swivel knives. Chuck Smith makes them, several places sell them. Chief

-

I've been wondering about the versa groover they sold, I have one and love it but have replaced the blade once (after about 1 year), I don't have anymore replacement tips and don't know of a source for them, does anyone have any idea?

-

It is normal to replace the oils in the leather after dying by applying Neetsfoot oil or some other conditioner. I use Neetsfoot oil most of the time and Feibings Aussie on projects that need perspiration or weather resistance. There are other products and probably other ideas about how to condition leather but most leather workers I know do some kind of conditioning after the dying process. I normally apply a finish after the conditioner has migrated appropriately (for me 12-24 hours).

-

Mandolin Strap And 3 More Dobro Straps This Week.

Chief31794 replied to Chief31794's topic in Guitar Straps

Style of the mandolin. A style is the "Pear" shaped mandolins you see while an F Style has a scroll at the top. F-Style first then an A-Style As pictured here. -

Mandolin Strap And 3 More Dobro Straps This Week.

Chief31794 replied to Chief31794's topic in Guitar Straps

PM Sent Chief -

Never seen 1-1/2" or 2" sets, once it gets over 1" I carve the letters. Chief

-

Mandolin Strap And 3 More Dobro Straps This Week.

Chief31794 replied to Chief31794's topic in Guitar Straps

PM Sent Chief