-

Posts

382 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by JoeSnuffie

-

I've been getting the best scrap from this guy. The stuff with the most scars and marks has surprisingly been the most requested by customers. http://www.ebay.com/usr/theleatherguyofmn Like this, for example

-

The blade comes very sharp and resharping is really easy. I let the tension bar fall and strop it in place. Also, I no longer use shims. I bought a 10mm steel shaft, bearings and aluminum tube and made a great free spinning drum. this makes splitting up to 4.5" oil tan possible without a lot of muscle. Of course the blade needs to be really sharp. I can also easily split calf skin strips down to .4mm.

-

Pakistani Round Knife

JoeSnuffie commented on JoeSnuffie's gallery image in Gallery- Our Leatherwork

It's hard steel from a guy who makes real knives, not the junk you buy in a flea market. It's has hard as my straight razor and pocket knives. I stacked 8 pieces of 10oz veg tanned and it went through like butter. After I honed it a while and ran it over the stop a few times, of course. I just added a picture that he sent me of the construction. -

From the album: Tools and Supplies

From pictures I received of the round knife construction. -

From the album: Tools and Supplies

From pictures I received of the round knife construction. -

From the album: Tools and Supplies

Ordered this from a Pakistani knife maker. Sent him a picture and he made this. It's 5.5 inch diameter. -

Maybe this would work on a larger scale. I use Mop and Glow 50/50 with water for the holes I make for bracelets that use Sam Brown studs or beads. I soak the flesh side around the hole and when it's dried it's almost as stiff as plastic and the stud or bead fits securely in with a nice snap. I'm wearing a 2 year old bracelet that still snaps in place.

-

A friend who's currently stationed Japan sent pictures of this to me. I know my kids would love this. Now I'm off to locate this product online.

-

Japanese Leather Elephant Craft Project

JoeSnuffie posted a gallery image in Gallery- Our Leatherwork

From the album: Tools and Supplies

-

From the album: Tools and Supplies

-

From the album: Tools and Supplies

Baby wallets -

From the album: Tools and Supplies

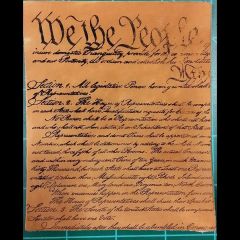

My US Constitution stamp arrived. I've been looking for one for a couple years and it showed up on eBay for an incredible price. This is on a piece that's about 3.75" x 4.75" and the stamp has a lot more on it. I need some more practice to get the amount of dye to use but I am thrilled with the results. The leather was dyed with Fiebing's Tan diluted to about 1 part dye and 3 parts alcohol. Looks a lot like parchment I think. -

Help Sourcing A Good Skiving Knife For Making Watch Bands

JoeSnuffie replied to teddycrafts's topic in Suppliers

For skiving edges I need to fold over on soft calf skin I use the cheap Tandy Safety Skiver. It's really easy to control for small areas and the blades are cheap and can be stropped to a perfect edge over and over before the need to be replaced. The key is to strop a lot. I'll usually give it 20 passes as soon as it doesn't seem to be cutting like I want and I flip the blade every other time I strop it. For larger items I use a round knife that I made from a high speed steel industrial fabric cutting wheel. It holds a fantastic edge. -

Treasure Map Card Wallet

JoeSnuffie replied to JoeSnuffie's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

I used a large rubber stamp and applied black dye instead of ink. It works really well. -

A neighbor said he wanted to treat himself to a Christmas present and this is what I came up with. I was going for an old treasure map theme. He works the flight line at the local Air Force base and they like the card wallets. Actually, most of my card wallets in this style have gone to the Air Force base because they fit in those tiny pockets on the flight suits.

-

From the album: Leather Things

-

From the album: Wallet Cloth Lined Card Pocket Process

-

From the album: Wallet Cloth Lined Card Pocket Process

-

From the album: Wallet Cloth Lined Card Pocket Process

-

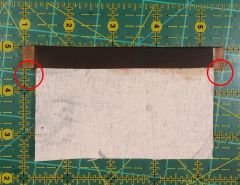

This is how I make cloth lined wallet pockets. I use a chasing hammer on the glues parts and folds. Which is important for good results. Be generous with the glue and make sure you don’t try to stick the pieces together before the glue is ready. I use Weldwood Contact Cement and I refill my tiny bottle from 32oz cans. For thin calf skin, get a rotary fabric cutter and keep the blade razor sharp. I cut 4” wide strips from a sturdy fabric. 2 of them will be 4.5” long while the rest will be 3” long. The 4.5” long pieces will be used with the back most pocket and will extend to the bottom of the forward most pocket. This gives a nice large pocket that can hold cash, vertical credit cards, etc. I cut 2 pieces of calf skin that are 4.5” wide and at least 4” long. These will be the forward most pockets. I cut 2” wide strips of calf skin. I split them to .4mm. You can go thinner, but at .3mm the strips were breaking. For an 8 pocket wallet, you’ll need enough to make 6 pieces that are 4.5” long. I make a couple extra because I usually ruin a piece. After splitting I dye. After the dye dries I cut the strips down to 1.75” wide. I started with 2” wide strips because splitting stretches them and they become uneven. I just cut along one edge, nudging the strip into place under the ruler. After cutting them to 1.75” wide I cut them into pieces that are 4.5” long. Using the straight edge I created in step 6 as the bottom edge, I place the pieces face down and draw a horizontal line .75” above the bottom. This is the line where I fold and where the fabric will be placed. I also draw a line, .25” in from each side, from the horizontal line to the top. Cut out the rectangles in the top corner and glue and fold over when the glue is ready. Hammer it with the chasing hammer until the lines are crisp and glued together. "The areas circled in red were removed." After folded and dried, draw a horizontal line on each side .5” down from the top edge and .25” in. Cut this rectangle out. This gives you the tabs that will fold over in final assembly. This also gives you an easy way to line up the distance between the openings of the pockets. In this case, .5”. On the 4.5” x 4” pieces, I draw a line on the back, top edge of the 4.5” wide side. This line is 1” down from the top. I use a skiver to thin it out to be folded over. If you’re having trouble with your skiver, sharpen it. Properly sharpened, it will cut like butter. When it stops cutting like butter, sharpen it again. I get maybe 10 thin passes before I have to stop it 20 times but this gives really nice results. I use a lot of very shallow cuts to avoid mistakes. After skiving, you’ll find that the thin calf skin as stretched a little. Carefully straighten this up or when you fold it over the edge will not be straight. Glue and hammer this skived edge. This will give you a .5” tall folded edge. Skive .5” in on both vertical sides of the all leather pockets. These edges will be folded over in the final assembly. If you want a crease now is the time to add them. The pieces are ready for assembly. Lay the bottom most cart pocket down and place the next one on top, lining up the tabs so that they are flush against each other. Insert a card to the depth you want it to sit and, holding everything in place, draw a line at the bottom edge. After drawing the line, remove the card and add a line of between the fabric pieces. The glue should be on the line and a little below, BUT NOT ABOVE THE LINE. After the glue dries, stitch the line. Repeat for every cloth lined pocket piece. With all the cloth pieces stitched together, lay the all leather forward post pieces in place and flip everything over, face down. Making sure everything is in place and lined up, apply a generous portion of glue to the tabs, and skived area of the forward most piece. When the glue is ready, carefully fold the tabs over and make sure they all line up. You may have to pull apart and reposition a little so work fast. Once everything lines up, hammer the edges. When the card pocket assembly dries, you need to mark the stitch line on the all leather forward most pocket. Insert a card just a tiny bit deeper than you measured for the others and mark the line with a creaser or folder. The reason you mark it a little lower is because the stitched leather isn’t as forgiving as the cloth and the card will rest just a tiny bit higher than you measured after you stitch. Now I cut off the excess from the bottom. I usually leave 1/8” past the stitch line on the bottom and then trim it a little closer when I’m doing the final fit.

-

From the album: Wallet Cloth Lined Card Pocket Process

-

From the album: Wallet Cloth Lined Card Pocket Process

-

From the album: Wallet Cloth Lined Card Pocket Process