jeeperaz

Members-

Posts

195 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by jeeperaz

-

western boot making classes

jeeperaz replied to 41hammer's topic in Special Events, Contests and Classes

The best option would be to find someone local to teach you.... an apprenticeship or a variation of it. From my experience, most Bootmakers love to talk, help and teach their craft to 'newbies'. You just have to reach out and ask if you can come by for a visit.... and build a relationship from there. It takes more than a two week course to learn to build quality boots.... and much longer if you expect to make & sell them to others. That is not to say that coursework is a waste of time. It is a great foundation if you cannot apprentice full-time. I took a two week course with a master bootmaker (who no longer teaches) but also found someone local who was willing to help me out with everything he could. Short of a full-time apprenticeship, I feel this was a great way to learn and gain some valuable experience. good luck. here is a list of bootmakers in Ca: http://www.dimlights.com/boots/custom/ca.html Also, here is a list of bootmakers who offer course work: http://www.dimlights.com/boots/features/schoolin.htm -

Might want to try this place.... http://www.pilgrimshoemachine.com/

-

http://haleandco.com/ The website needs serious work... but it does link to his ebay store.

-

http://www.ohiotravelbag.com/ I'm not sure they have the exact same finish but they carry that style clasp. page 27

-

Question About English Style Strap End Punches

jeeperaz replied to jeeperaz's topic in Leather Tools

Everyone, thanks for your time replying to this post. Some good ideas for me to try. -

I want to make some belts in various sizes ranging between 1" and 2". Because the punches are so expensive, I would rather not buy a separate punch for a 1", one for a 1- 1/4", a 1-1/2"... all the way to 2". For example, I was curious what type of end a 2" punch would leave on a 1.5" belt? Hope that makes sense. Do I just need to bite the bullet and order the all of the sizes or can I get by with a bigger punch on a smaller strap? Thoughts? Also, anyone have opinions on best bang for the buck when it comes to buying a specific brand (other than craftool)? Thanks

-

I did receive an invoice from them on friday or saturday and in tiny print at the bottom, it did have a fedex tracking number... which indicates that I should have it today. I can't wait!

-

How fast is there shipping? Earlier last week, I ordered from them for the first time and haven't received any type of shipping confirmation. Do they even do that?

-

Do you have a hardware store close by? Typically all of them sell wood bleach which is usually plain Oxalic Acid (check the label before purchase). example of the most popular brand: http://www.highlandwoodworking.com/savogranwoodbleach12oz.aspx

-

oh the music on that site.... just awful. But with that said, it is a great resource.

-

I wonder if you still have the wrong needle(s). The singer 31-15 uses system 134 needles. These systems will also work: 135x5, 135x7, 135x8, 797 and DPx5. Make sure it is a leather point needle. Go to an industrial sewing supplier in your area and they should have the correct items. Also, get some size #69 bonded nylon thread to go with size 18 needles (like Luke said). Often times, the machine will behave better if there is a slightly lighter thread in the bobbin but #69 will be fine top and bottom. Tell us more about the needles you are using? What other numbers/letters are on the package? Joann's fabrics likely would not have had the proper items needed for that machine or your project. Also, when starting to sew, hold both threads back behind the project for the first few stitches. You can sew without the motor but why? Just practice for a bit and you'll get the hang of the motor speed. Get some old manilla folders or card stock and practice without thread. You can also put a tennis ball under the foot of the machine to help control the speed. I know what you are going through because I was there not too long ago. I bought a 31-15 and had never sewn a stitch in my life. It took me a while to figure out the machine, the needles, the thread, tension and timing. Now it sews beautifully.

-

Do vendors typically offer better prices at the shows than their normal phone or internet sales?

-

Does anyone have a possible source for spots like in these 2 examples? I've looked at tandy, standard rivet and timco.... no luck The pictures don't show the size but I'm looking for small spots... in the 3/16" to 1/2" neighborhood.

-

Tooling/carving is not where my interests are... but I like it. I like anything with a chiefs head. What type of artifacts are you into? I used to collect prehistoric southwestern pottery but got out of it about 10 years ago

-

That's a pretty good price. Did you put it on your local craigslist? I would think it would sell pretty quickly there if you advertised "industrial, leather sewing machine". 31's are great machines.

-

You understood right. These are the type of ideas I was looking for. Thanks. Fortunately, I have a Tandy about 1 mile away. I'll see what they have.

-

All, I need help with laying out spots. Just trying to eyeball where the next spot goes is not working for me. I'm trying to layout your basic decorative shapes like diamonds and circles... or even a straight row of spots, but my spacing and alignment is crap. I'm a noob at this so any tips or advice(no matter how basic) is most appreciated. Also, is there a good tool to mark where to punch or slice the slots for the prongs of the spots? Regards, from Phoenix, Lars

-

Magnesium Maker/Embossing Stamp Makers?

jeeperaz replied to cumberlandhighpower's topic in Suppliers

I got this link from someone earlier this year... http://evergreenengravers.com/ I have no first hand knowledge of their work. -

Does anyone know how many tanneries are left in the US? Hermann Oak?? Wickett & Craig??

-

Just placed my very first order with them earlier in the week. Good experience so far.

-

Looks good. I had a peek last night and felt the whole site was a little small. Had another look today and it seems better but still small to my eyes.

-

Lippy, did you send him a PM? I was always bummed that the links above were old and the pics never worked. Now that he is here... it would be a tremendous resource to have him post something again.

-

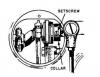

If not a timing issue then quite likely you are using the wrong needle or an improperly installed needle... but needle/shuttle timing is my guess. As far as the manual online, I believe you are talking about this one: http://www.tpub.com/...s/14218_183.htm which is where most of the info below comes from. There are two distinct timing operations for the 31 series machine. One operation times the needle with the shuttle; the other times the feed dog with the needle. Timing the Needle with the Shuttle. Insert the needle in the needle bar as far as it will go. Next compare the needle stroke to the shuttle stroke. To do this, remove the throat plate. Turn the balance wheel toward you until the point of the shuttle on its forward stroke reaches the center of the needle while the needle is on the upstroke.At this time, the needle bar should have risen 1/10 inch and the point of the shuttle should be 1/16 inch above the eye of the needle. If the needle eye is not in this position, loosen the needle bar connecting stud screw and move the needle bar up or down as needed; and then tighten the screw. Timing the Feed Dog with the Needle: If the feed mechanism is properly timed, the feed dog should be on its down stroke and level with the throat plate when the point of the needle reaches the material. To adjust the feed timing, first lower the stitch regulator to the lowest position so the machine forms its longest stitch. Turn the balance wheel until the feed dog is on its down stroke and is flush with the throat plate. Move to the rear of the machine and take off the arm side cover. Turn the balance wheel away from you until the feed eccentric collar setscrew is visible (see attached image). Hold the collar with your left thumb.Loosen the screw and rotate the balance wheel away from you until the needle, on its down stroke, reaches the material. Tighten the setscrew.Rotate the balance wheel to check the timing. Recheck the timing of the shuttle point with the needle. When you time the feeding mechanism, you may throw the needle out of time with the shuttle.

-

If the masses begin to equate leather with cruelty then bad things are on the horizon for leatherworkers. 'Slaughter free leather' is a first step in that direction. I won't buy from Siegel as long as they 'push' this product.

-

Singer 31-15's can routinely be had for $75-$150 on ebay.. plus maybe $50 for shipping. Roller presser and single dog feed another $50. These machines are very common and are frequently found on craigslist as well. There cannot be an easier machine to work on as far as cleaning and tuning. I would not hesitate buying a used one as long as it looks decent.