Jack142

Members-

Posts

92 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Jack142

-

had the same thing happen to me.

-

Battery bag

Jack142 replied to the gafer's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

I don't know if this will help you, but I did a cell phone pouch to sit on the front of my belt. I used chicago screws. way easier than stitching. 9 oz or thicker leather. lots of grooving/skiving on the flesh side... -

Next one I make will be slightly wider and have stitching.

-

very cool

-

-

-

I just finished a wallet for my daughter. I thought I would post it here. I only get to punch leather about 4 hours a week, I got a business, a family, and a ranch, that keep me busy. I have been looking at the work you guys do and its fantastic stuff, I know mine is not as good but I'm still proud of it. The wallet didn't come out as planned. It's thicker and not as flexible as I wanted. And I know there are mistakes on it. But she's getting it anyway.

-

hi guys, I walk with a cane, with a Crook handle ( kinda 1/2 circle ). I want to cover just the handle in leather. I just don't know how to work the shape of the leather. I am assuming I wet mold the leather, and cut some kind of slots or slices to relieve the lower part of the circle ? Has any one done something similar ? Any suggestions ? Any help ?

-

I have made a couple of strops, on one I use a mouse pad for a backing. I am wondering why the flesh side of leather to strop on ? from what I read in my knife mags we should only use the skin side

-

Texas possibles bag

Jack142 replied to dhaverstick's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

very nice work. -

ok, thanks

-

I'm working on a wallet for my daughter. I have been experimenting on washing the veg tan leather with Barkeepers friend, letting it dry ( it gets real stiff ) Then I rub on a decent amount of neetsfoot oil , I let it soak in for a few days and then stamp and tool it. So far, I think it stamps and tools easier. And the leather is a lot less stiff. I did notice, that I have to bend the leather to get it "softer " which is the feel I want for her wallet. I'm curious, what do you guys do ?

-

Can Bison hide be stamped and tooled ? Is it like veg tan ? or Chrome tan ? ?

-

Scout carry sheath

Jack142 replied to battlemunky's topic in Gun Holsters, Rifle Slings and Knife Sheathes

I discovered that grinding my awl narrow for about a inch of so up the awl helps me push the awl completely though all the leather pieces. As long as I keep the awl straight, my backside hole is where it should be. -

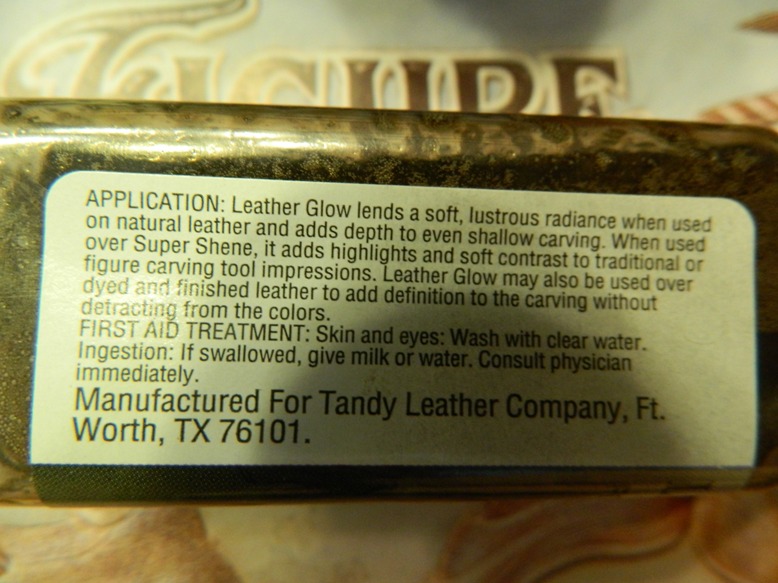

I had a old bottle of tandy leather glow,, maybe 10 to 15 years old. I tried to use it to highlite my lines on my snake, but it didn't take at all, I left it on for a couple of minutes and it wiped right off. I did use satin sheen as a resist on the snake. I you look at the snakes mouth, hopefully you will see a " green pigment " in the snakes mouth, I think this was the leatherglow trrying to work ? I don't know ? any comments or suggestions ... I am going to buy a new "highlighter" eitherway pics of leathglow

-

I should of put my no oiled piece for comparison but oh well. you can see the difference. and some pics on the snake stained and colored.. I should of mentioned that the snake did not to take stain very well, I left the stain on for a couple of minutes , that surprised me

-

-

-

I have so leather 3-4 oz from tandy, not a very good grade, but good enough to play with. I washed two pieces in Barkeepers friend, let then dry, and then carved a snake in one piece and left the other blank. I then put some neetsfoot oil on them and waited, and I mean 4 weeks waited for the oiled pieces to lighten up. I took a bunch of pics so here goes. I might have to do this in 2 or 3 threads so bear with me please first 3 pics are just washed no oil, second 2 pics are just oiled. a no oiled piece is there for comparison

-

here is a pic of 2 strops I made and use. I put white of green rouge on them. I really don't see a difference in them. one strop has a rubber backing ( mouse pad ) This is to strop my knives with a convex edge. the other I glued right on the wood. I used a softer leather, from what I have read you want a little "give" in the leather so it curves a bit on the edge. You don't want the leather to strop over the edge or it will dull it. Now the key is keeping soft pressure, ( I have read about the same pressure and you use when you shave ) and keeping the correct angle. which is pretty narrow.... Of course, I built these for my knives, and for touch up they work really well. I can shave with most of my knives. PS.... this is a custom Stek knife I purchase a couple of years ago

-

Here is a card/ money clip I made for my kid, its designed to hold his license and a couple of cards, with a money clip on the back. He is a fitness instructor and wears those nylon gym shorts with no back pocket.