Clintock

Members-

Posts

314 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Clintock

-

You can get the same results with a dauber. Load it up, and pass straight lines I get that effect inadvertently when I try to get an even color. Just be sure not overlap the passes too much. And don’t oil the leather before you give a go.

-

Patriotic knife sheath for a Kabar

Clintock replied to corkscrew's topic in Gun Holsters, Rifle Slings and Knife Sheathes

That's a good looking sheath! -

Been down this road. I shoulda listened to folks when they said start with the good leather for carving and stamping. I'm still new to carving too but can tell ya that an inferior leather is HARDER to carve than the good stuff. I only buy from wickett & craig now. Straight from the tannery. Talk with Cindy. Once you use it you'll notice the difference immediately. And WC will split it down to what oz you need. Down to 2 oz I believe.

-

@JLSleather same way down here in south Alabama. At least you don't have heat index of 112° f today. Sweat pooling in yer boots. Have I mentioned it's hot?? Look there at demopolis. Swear I seen a lizard toting a leaf fer shade.

-

Got a little scale on the "weigh". Pretty sure the tensions are around 5-6 hammers but we'll see. Being swamped in leatherwork isn't really a bad thing. At least you're inside. Being swamped in dirt work is a different story.

-

Whatever works! Always more n one way to skin a cat! I'm checking eBay now. Found one but not very good reviews. And my nephew wants his fish weighed right. I put a fish in a bag and threw it on bathroom scales. He said "that ain't the way the pros do it". Where these kids come up with stuff like that???

-

@RockyAussie 3 pounds is more like it. Or more on my machine. Plan on getting some scales just outta curiosity. And I been catching some pretty good size sun perch lately too. So win both ways. Thanks for the reference. My tension might be a "tad" over. Seriously will cut your finger when pulling slack if not held right. Now let's talk about them hammers. You got a bit of redneck in your blood? That's something we'd do down here in the south

-

@Wizcrafts I tried to move that loop as you suggested but it only moved maybe a 32nd of an inch. But it's working now so it's all good! As bugstruck mentioned, I did learn some things to check for in the future and during this ordeal I learned some pretty good info. @RockyAussie don't take what I said to heart. Reading back over it looked like it may have been a smart ass remark. It was all in good humor. @JLSleather I knew I'd get a response outta you! Again THANKS TO ALL THAT HELPED GET THIS THING BACK SEWING!!

-

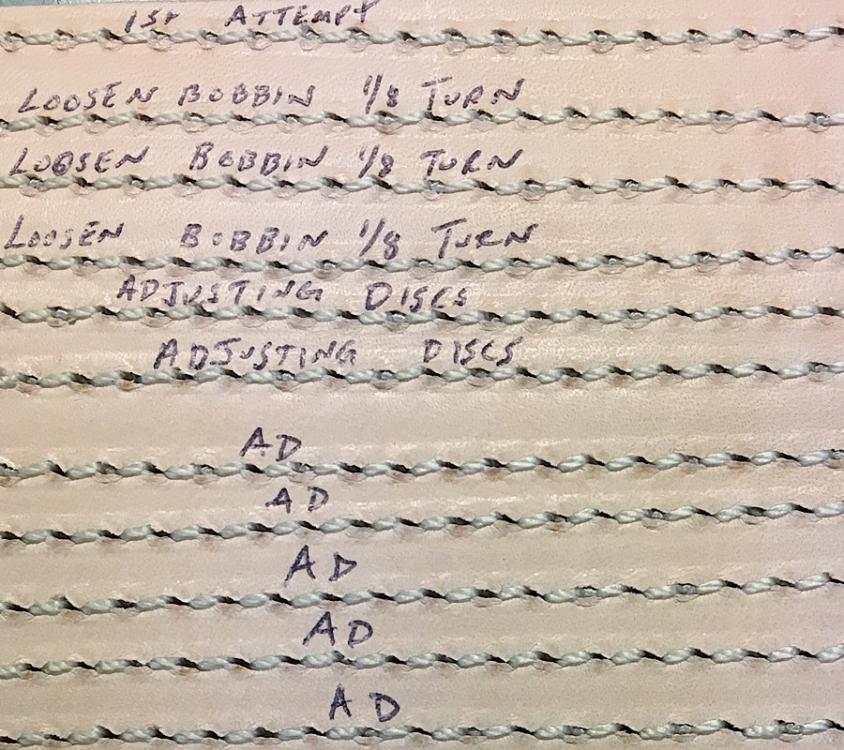

@RockyAussie tension on these threads would break your scales aims be honest with ya, ifn I gotta do all that polishing then it'd be quicker to handstitch everything I do. But I do see what you're talking about and can understand the reasoning. Nothing catching so far just for some reason machine got out of tension. I'm slowly but surely learning more about it. @JLSleather yep. That's exactly what I did. And fiddled with tension some more. And that pig might self identify as a bear. pic turned for some reason but you can still get the jist of it.

-

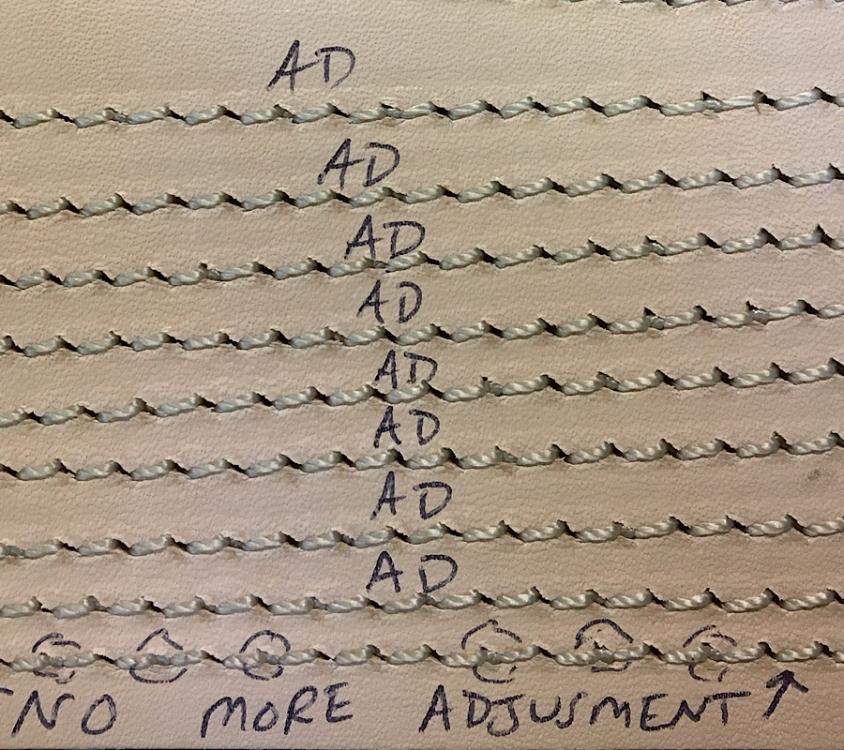

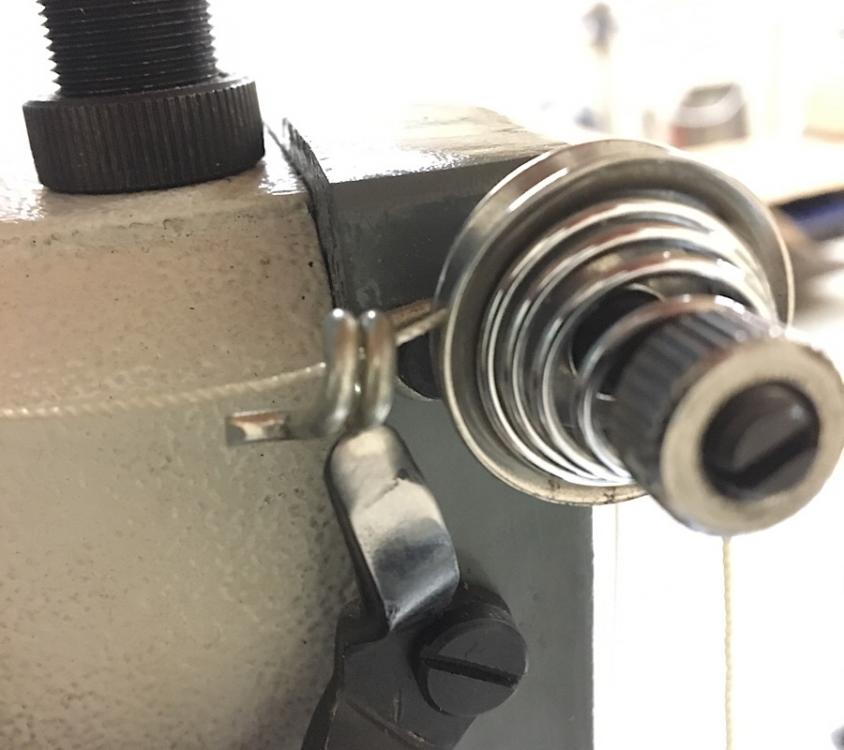

Did what y'all talked about. Cussed a little. Laughed a little to keep from crying. Cried a little anyway. Stare at it. Cuss it some more. Looked for hammer. Only thing I did do differently this time was wrap the thread 180 degrees around top disc tensioner. Don't ask how that makes a difference but it did. Then followed yalls suggestion. Min all seriousness y'all have saved me a big headache. A big thank you!!!

-

Ok. I've went through with some of fergs and some of jeffs suggestions and came up with this. Thread is tight as a banjo string and kinda hard to pull slack when finished stitching. Backstitches look like crap but that's prolly me. I really appreciate all the comments and suggestions! Thank you all!

-

Oh yea definitely. He's alright for a northerner. Yes. Enough to make the leather curve or cup After it's stitched. Just can not seem to get the top tension to do right. I'll give your logic a try in an hour or so. Maybe two. I do wanna stay stay with the LL needles. I really like the way the stitch looks compared to straight or S needles

-

I'm using cowboy brand thread (277) from bob with a 24 LL needle. Maybe one more 1:8 turn will help straighten it out. Gonna redo it this afternoon after work.

-

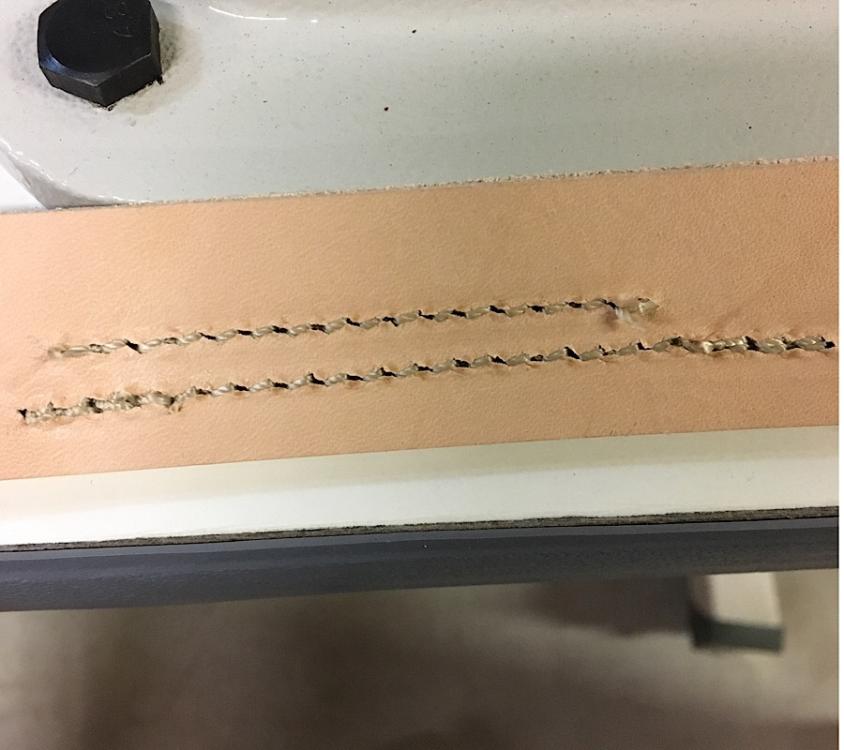

Ok. So I've done all that you mentioned @Ferg still no luck. I'm out of disc adjustment. Included a pic Is the top tensioner supposed to be harder to turn than the main? I would assume the main supposed to be harder due to the fact it s the main. Anyone close to Alabama that can come fix it? I've been tinkering with it over a week Think I'm gonna start that procedure over and back off the bobbin spring another 1/8. And I may have overshot that sweet spot it was close on a couple runs but still had one or two knots on bottom.

-

@Bugstruck I've checked the tail. It's sucked back into bobbin. Tried that with 4 different bobbins now. Regarding 4/5 oz I was just referencing I've tried to stitch it. Never would do right for me. Mostly what I stitch now is 7/8 doubled or 7/8 with a 3 oz liner. So I know there's plenty of room for the knot to be centered. I'm half bald now and with this machine I'll be completely bald in a week or two. But I'm not gonna give up on it. @Ferg completely understand about wanting to know how things work. I've been that way for years. Went to trade school for automotive technician and went through apprenticeship for journeyman electrician. Have my nceer card for electrical now. Oh yea. Back to the machine. I'm not gonna bet ya cause I have no idea about it yet but I am gonna give those steps a try. Only thing I really haven't done yet is hit with a hammer. If this don't work Ima start with the biggest hammer I can find. Will definitely let ya know how the results turn out.

-

Those look pretty darn good! On another note... made no adjustments and machine started doing it again. Keeps it up and I'll have a cowboy 3200 for sale!!

-

I don't wanna see daylight through my stitchi holes. Some folks like that but not me. Any daylight with 207 on bottom?

-

I've tried 138. Could never center the knot in 4/5 oz single layer. I mighta been asking too much of the machine. Now it's just 277 top and bottom. I see lots of folks doing 207 on bottom. I don't know the purpose of that. You'd still have to use a bigger needle for 277. So... the smaller thread on bottom wouldn't fill the hole. Is that correct? Smaller thread buries deeper in the leather? Knot harder to center? There's still so much I don't know about the machine.

-

I usually test on scraps. A pretty leather worker told me to do that before each piece. As a newbie I have no idea when good is good and bad ain't. I just try get it to look good and not any slack in it. Chevk it out evo and let's see. Hell im curious now

-

My firm may be different than somebody else's firm. Guy told me one time on a mower part to tighten the bolt till its firm. Well it snapped. So tugging on string my firm would be a least 4-5 pounds. But I reckon if it's too firm it'd bunch the leather up and you could tell. Or if it's not firm enough it'll just lay on top of the leather. Correct me if I'm wrong.

-

@JLSleather didn't think about that. Was caught up in the excitement of getting the tensions just right.

-

@chrisash Thanks!! Not a bad idea to have one. Make sure you get the same tension on certain projects. Would hate to have to adjust that many threads @RockyAussie Appreciate ya looking that up and giving us links.

-

UPDATE: found a piece of thread between what looks like a race behind the bobbin. So far so good except on corners but that's prolly me. Any advice on what to do to correct that would be great THANKS TO ALL THAT GAVE INFO ON THE MATTER!! I really do appreciate the time you took to help me.

-

@Wizcrafts tried just going through one hole in top post. Changed the angle of the loop you were talking about. The loop bottoms out on the disc separator. It did move about a 32nd. Had to completely remove top discs and spring to access screw. Reinstalled and it's better. In a run of about 4 inches I had that crazy knot only twice. I do have a wrap anna half around the main tensioner before overlapping side post. You can see in the pic.

-

@Bugstruckthat spring with the loop holding the thread coming off check spring does rest on the stainless seat. I tried to wrap the thread around the upper disc tensioner but I don't see how it can be done with the tension release hits it when you raise our foot. It puts my thread at an angle that it'll glide over the end of that "disc splitter"? Changed out bobbin again. So I'm on the 4th one. Still the same. Is there a way to reset all tensions on machine and start over? There has to be. But where would one start?