-

Posts

291 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Mocivnik

-

New to stamping, first project help need

Mocivnik replied to Mocivnik's topic in Floral and Sheridan Carving

Well, i would too, but unfortunally, I dont have that kind of artistic touch to just add depth freely by feeling. -

New to stamping, first project help need

Mocivnik replied to Mocivnik's topic in Floral and Sheridan Carving

Thank you for your reply. I tried to google and search youtube for videos/tutorials, but either i gave up too fast (and I did some research) or I just missed mostly of them. Would you be so kind to paste the link to it? It seems, I cannot find it though.. -

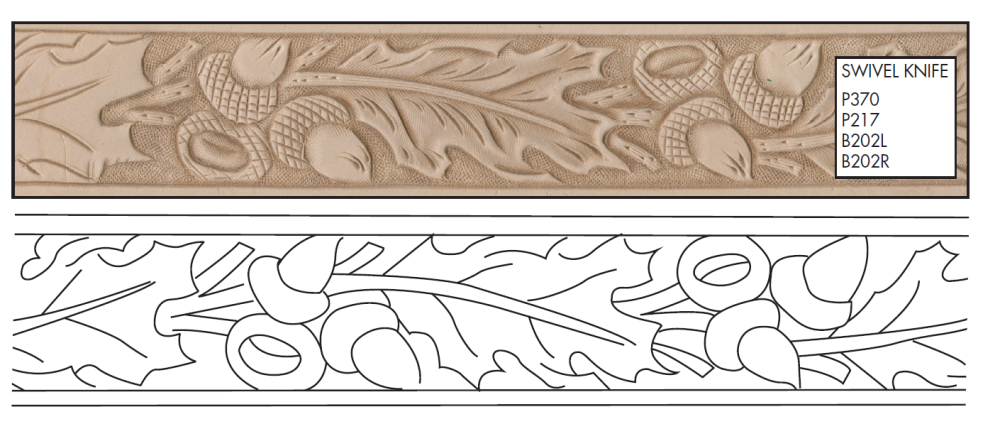

So, I think I came to the step in my leathercrafting journey, where I can "afford" to start carving. My first (and most common I believe) idea is carving oak leaves on knife sheaths. There isn't much to add, there are a lot of things about carving oak leaves on the internet, but I cannot find THE ONE tutorial, that would take me to final product. Now, I have two things: Tandy's "BELT STRIP TIP SHEET by GEORGE HURST" where there's an oak leaf, which is a good pattern, but doesn't show where to use which stamp and list of stamps, that I own (list will be lower in this post). And since I'm completely new to using any stamps, beside pattern stamps, its difficult for me to even start. Is there a pattern for this kind of oak leaf and acorn, that has: 0. List of tools needed (this one has it) 1. Order for use of tools 2. Where to use which tool (preferably with ones, that I have) List of stamps that I have: 701001 A104 BW1 BW2 BW3 BW4 B803 B936 B701 B60 C431 C431 D444S D447S D616 E684 F916 G508 G548 M887T P217 S706 U851 V407 V407 X510S X595 Z-X511

-

So, as I got only a few photos to make certain bag (for the missus), does anyone have a pattern simmilar to this bag perhaps? Or can give me a hint or two on how to make a pattern for this kind of a bag? Appriciate any help.

-

Okay, might be slightly annoying, but im glad noone knows anything :D i cant really remember, where I've read it, but I remember people were "stocking on dies" and just to be on the safe side, I asked others aswell. Thanks all for the information!

-

Somewhere I've read, that Fiebings being discontinued to work since 31.12.2023. Anyone knows anything about this, is this the real deal or just gimmick?

-

@fredk: yeah, that make sense (on how to wrap it and stuff). Might try some day. @Samalan: i get you. But I dont want to give this away as my invention, but to use it as a part of my creation.

-

That cut-out didnt apply to all comments.

-

Well, I believe this thread turned wrong turn somewhere very soon, as it wasn't an idea to either discuss copyrights either copy the original author. I am well aware, that there are some things/ways, that people spent a lot of time to understand/make/achieve and include a lot of anger, dissapointment and failure. But as long as I can see the "How do I do that" on Leatherwork board, I feel free to ask things as such, because I also asked which dye should I use for my leather projects (years ago, when I joined this forum). Well, I got the reply that Fiebings pro dye works best. Now, was either that a copy because I use same technique as someone else? Or is asking on how to do these funky shaped edges a simple asking for a direction? If anyone does know how to do that and doesn't want to share this "from God hidden secret", I'm totally fine with it. It's every person's right. It's can be taken as sacred trick from Penn & Teller, I get it. But instead of receiving a lecture on "how not to copy anyone" I'd rather skip that tutorial. Now, back on topic: -I wasn't able to talk to the leathercrafter, who did that, becuase he has no information to reach, neither lives in my country. -I don't want to copy that, I'm 80% interested in this as "how the hell is that even possible" and 20% on "oh yeah, I might use it someday" on some project. Depends also on many many other factors, but that's not the topic. -I got already my own edge work (not a big deal, but it's slightly more round than everyone else's I believe), so I don't need an inspiration for that. I'm searching for more and more creative ways on how to "decorate/finish off" items as many options availible.

-

Well, that didnt help much about the welt, since it's not folded (if I got you right), but it was (probably) tied up? And about the bottom pic: not sure what you thought a mystery for me was, but it's the "extruded" leather near the edge of the holster. Not sure if you looked at it. Exactly. Love it. I was considering of using ropes, straps, leather belts etc. But can't come up with simmilar effect tho. Was wondering if anyone ever made it before.. My intensions are such. But I was hoping on some tips before I even start to try it out.

-

I couldnt find their website, thanks for it. But it's penny plus, it's this one: https://www.ctpoint.it/en/products/twisted-yarns/penny-plus/

-

How is possible to do 2 things here: i) burnish edges then "mold" them? As seen small black sheath on the top. To me, it looks like it was done with some sort of string or thread and that it was tied down from left to the right...anyone knows anything better? On the brown sheath on red background, it's even more diverse, so I'm confused on how THAT was done.. ii) How it's done that "carving" on leather on lower pictures? It's like leather have different depth, but not cut out, rather pressed in? Although, this guy is making different shapes every time, I kinda doubt he makes specific tool for each sheath.. Any help would be appriciated!

-

YES!! THIS SOLVED 99% OF THE PROBLEM. I wasn't aware, that the foot pressure needs to be higher so the machine doesnt skip the stitch. Here's the product now, i've only had 1-2 skips during the red area. (those big blobs are burnt thread, so the stitch stay together) I've also spent quite some time for setting pressure on top 2 screws (top of the machine, nr.1 and nr.2) and both screws under the bobbin (left for pressure, right screw for fixing it). IDK how they are set now, but the machine is working and I'm nearly 100% satisfied. ALSO, the needle I'm currently using is 180, and there is 0% of difference between 180 and 200. It just skips 1-2 stitches per 50 stitches and I'm quite OK with this. I'm a bit bothered about seeing a knot in the hole (that brown ball), but I hope somehow will be solved this one day aswell. Thanks everyone for help, it means a lot to me. And if anyone knows how to solve 1-2 missed stitches per 50 stitches, I'm more that thrilled to find out

-

Hello Dwight, I changed needles from 180 to 200 and back, but didn't help at all tho. Now: Needle flew easily on even a shorter piece of string, I did that trick already. The needle was looking away from the machine, ALTHOUGH it was a bit tilted, maybe for like 15 degrees, so I fixed that, THANK YOU. I would actually like to give my boss to the company back for a week just to make sure it will work for next decade..But still might send an email for details and buying center Presser Foot (i really hate the STAMP that tippmann does on leather and leaves deep markings). i) So, I was always wondering about the thread, what it is, but I never got much on the data, since I got it shipped from Italy. Here's the sticker, that's on the bottom of the thread: ii) I believe that V138 (#20) thread isn't availible for me. I would somehow prefer using different threads aswell, but local leathershop doesn't offer much of a choice tbh. It's pretty bad down here about leathercrafting in general. iii) I understand, and I believe, this wasnt much of a problem, I believe there's enough space in the groove for the thread. iv) Needle aligned. v) Yes, the needles are pointy ones (7x3), not the dull ones. They are properly sharp and can very easily hurt you. vii) I've used 180 and 200 needle, same effect tho. Im using either 2.4mm (6oz) or 3.6mm (9oz) veg tan leather for the 99% of the time on my machine.

-

So, my machine didnt sew for months now so I set it aside. Now, when I got projects (thanks God, not in a rush!) for the machine, I decided to either make it work or sell it. Depends on time/cost. So, the problems were/are: -skipping stitches, -when the needle was exiting leather (way out), the needle jumped up front, -clenching and clogging thread. Now, I opened the machine up, cleaned and oiled up a bit some parts, put it back together, and it's working better, but I still have some problems with skipping stitches. I think I set the timing correct (please se first two pictures), I did it by Tippmann Tutorial on how to set timing correct. I've read about the possible issues, why the machine is skipping stitches, but I'd say so: -I think timing is OK. If not, please let me know what's wrong, I believe it's seen on 1st and 2nd picture. -the needle is 180, -the thread is /10 (European size, it's the thickest I can get, but i think US size would be simmilar to 246). It's polyester. The needle slides freely on the thread, if I hold it with both hands and needle hangs through the hole on it. -Needle is oriented as such, that the vertical U-groove is pointing AWAY from the machine, -Needle is new, -Tension on presser foot: no idea how strong it should be, but I try to keep it slightly lighter, so it doesn't damage leather much (although, still skipps stitches even if I "add or take" the pressure) Now, this is the "new" outcome. Also, the bobbin is having a bit too much space. Am I missing a part in here or is that normal? Link to IMGUR for the video on how much space there is around the bobbin. If anyone has idea of what I'm doing wrong, I'd be very grateful.

-

Cleaning polyester/polyurethane leather (faux leather)

Mocivnik replied to Mocivnik's topic in How Do I Do That?

Those are hell of an advices, but the thing is, she aint my gf :D -

Cleaning polyester/polyurethane leather (faux leather)

Mocivnik replied to Mocivnik's topic in How Do I Do That?

nope, dont have any. Neither it's white, so...hardly can do anything about it. -

Cleaning polyester/polyurethane leather (faux leather)

Mocivnik replied to Mocivnik's topic in How Do I Do That?

Tried warm water, warm water + detergent, zippo lighter fluid...nothing works at all. Im slowly giving up. -

Cleaning polyester/polyurethane leather (faux leather)

Mocivnik replied to Mocivnik's topic in How Do I Do That?

Yeah, that's why I used acetone on swab and on small piece at the edge, so I wouldn't ruin it whole. Never heard of Naptha, but I have some Zippo lighter fluid at home, resting. Deff. will try (swab test at first for sure). Also, a bit concerned of how to get rid of the odor smell? Well, ofcourse....I forgot about the easiest thing Deff. will try today! Thought of it, but I think it's not. It was supposed to be resting against some trousers/jacket, no idea what exactly. I asked, but was told "some other clothes". Asked aswell, she said no. And it's been too long already so she could return it to the store, so that's the reason I got involved into this. -

So I got this girl, who brought me brand new skirt she bought, and got stained "without doing anything". Her statement was, that she just folded it over a coathanger and store it in the closet, when she wanted to take it off, it was stained like this. Now my question: what are those stains and how am I supposed to remove them? Material is faux leather (face-dirty: polyurethane, inside is polyester). I tried: isopropanol, 70% alcohol, acetone. First two did nothing, while acetone made a huge mess (thank got I tried on a small piece at the edge).

-

Well, to be honest, I plan to make stacked handle mostly from natural color, while using a few black pieces by the end of the handle in between to add the contrast. But I find it difficulty to burnish it because of the shape, as it's not a good shape for wooden slicker tho. @chuck123wapati: thank you for tips!

-

Are you interested in shipping overseas? (Europe)

-

@PastorBob and @chuck123wapati: thank you, both of you! And just a question about finishing touch: what to use to finish the leather? I assume, when I glue it together, I sand it with some 240 grit sandpaper (dremmel), and then use...what? Usually I finish my edges with water + burnished, after it's dried, I just apply Fiebing's pro dye/edge kote and that's it.

-

it's not exactly white, it's more like yellow-transparent. Gets very tacky quick and I use it for most of my leather projects. @chuck123wapati I appriciate this info, but to be honest, I don't even know what exactly a contact cement is. In Europe, we dont use this term. The blue "MOVI Multikol" glue, I attached earlier, is super simmilar to this glue. If anything helps, tho.. https://www.kemostik.com/neostik-en/products-adhesives/universal-glues/neostik-universal-en/