-

Posts

289 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Mocivnik

-

Decided to sell most of my rivets due to lack of use. Bought them couple of months ago, but I barely used any of them. All rivets are unused, they come with settling dye and holder aswell. Will send them in PVC boxes from photos. EVERYTHING COMBINED IS ABOUT 850 SETS OF DOUBLE CAP RIVETS AND SNAP BUTTONS. There are 4 colors of the rivets and snap buttons (GOLD, SILVER, ANTIQUE BRASS and BLACK). Here's the full list of DOUBLE CAP RIVETS: 6x6mm 6x8mm 6x10mm 7x8mm 8x6mm 8x8mm 9x8mm 10x8mm 12x10mm 12x12mm 8x10mm 8x12mm EACH SIZE OF EACH COLOR IS 10 PCS OF RIVETS, EXCEPT: ANTIQUE BRASS - 6x8mm - 100pcs GOLD - 12x10mm - 25pcs SILVER - 6x6mm - 100pcs SNAP BUTTONS 15mm dia., 4 colors (ANTIQUE BRASS, GOLD, SILVER, BLACK): Antique brass: 60sets Gold: 20sets Silver: 50 sets Black: 20 sets Selling for 100 USD OBO + shipping. Including PVC boxes.

-

Everything is seen from the photo, here is the pricelist: strap cutter - 10€ head knife - 15€ wooden slicker - 1€ 3x skiver - 10€ 2x multitool (edge bevveler, crease, groover, etc. both comes with all tools that belongs) - 15€ crease tool - 3€ Ivan Leather strap end strap punch 1 3/4" - 30€ radius end chisel 20mm - 2€ small scissors - 2€ oblong punch 26x5mm - 8€ edge beveler nr. 2 - 3€ edge beveler Movi Italia - 12€ (unused) wooden round edge slicker - 1€ U and V gauge - 2€ 2x bone folder - 2€ 7 stamps - 7 € (bottom photo) All together for 80€ OBO. Shipping worldwide, 15€ anywhere.

-

Ordered both. Thanks God I really HAD to finish my order - otherwise the tool list would never find end :D

-

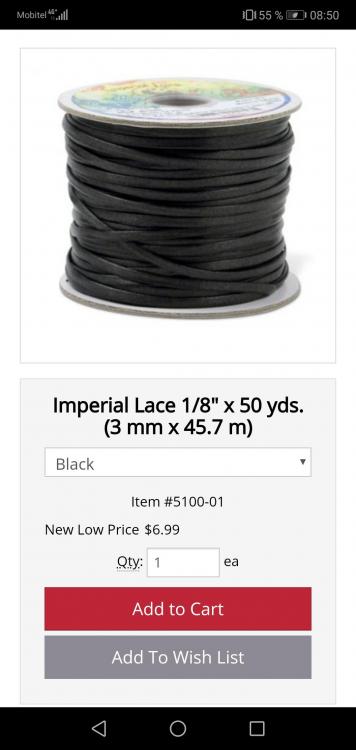

What's so wrong with them? PS: What's Tandy's shipping time to arrive within US? (Miami, Florida) PS2: I instead put this lace into cart - this is genuine leather, as previous from the link was faux. Took black and brown, can't wait to start working with them (I hope I choose the right leather lace for lacing tho ) https://www.tandyleather.com/en/product/craftsman-lace-1-8-x-25-yd-3-mm-x-22-9-m-black

-

I took 1 spool of this Craftsman Lace 1/8" x 25 yd. (3 mm x 22.9 m) while I took 3 types of needles: 1193-01 - Perma Lok Needle Lok-Eye Needle (Hook-n-Eye) 10/pk 2-Prong Lacing Needle 10/pk I hope this will be OK.

-

@JLSleather but 936 and 701 looks same to me?

-

-

@JLSleather and @Sheilajeanne Heres the list ive put in cart: A104(background filler) , B701 and B60(beveler) , C431 and P217 (camoflage shader), V407(veiner) , S706(seeder) , U851(mules foot) . That should do it?

-

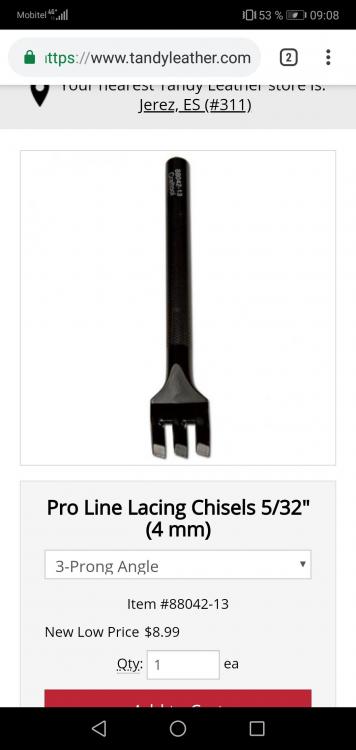

Find this one. This one is angled. Is 3 prong good for use? For less than 3 I can just use the 1-prong I already have and angle it?

-

If i got this right, i just need flat front chisels (black from the photo) and this lace and these needles?

-

So I am looking for 1/8" lace and what needles do i need? Tand link perhaps?

-

I've bought these from China. Should they work fine?

-

I've bought all chisels from (China) photo below, sized 4mm apart. None of them is working as should. Are any of them from Tandy better than Chinese ones?

-

1. I tried to polish them yesterday, but unfortunatelly - no better feeling. Going out same as before :/ 2. Will try with beeswax aswell, but I doubt it will make much more difference. Yeah, I want to avoid that. I tried, but the holes I poked on the other side were uneven and sideways, when I piked holes with ice pick from one side. But I could try making holes like that..will do in future as test for sure! @wizard of tragacanth: Will try to do this aswell, but already now it takes me eternity, then it will take even longer for me :/ @fredk: But is it easier to pull them out? @chuck123wapati: Yeah, metric standard is TIP-TO-TIP while imperial is stitches per inches.

-

Neither am I But the answer is NO. I haven't polished them, because I thought that punches are hardened. (hardened + sandpaper = NO GO). But will give it a go! Will give it a go! Probably from all 4 sides each spike, right? I know for beeswax but it's taking hell of a long time if I stick it into wax between each punch..I know I'm already super-slow, but this would expand time x10 :/ Twisting the chisel you mean probably from one side to another? Yes, but I got friend going to US for couple of weeks and he said he can bring me 3-4kg pack of items from US :D therefore I decided to spend all the weight on Tandy :D

-

I got highly upset and just about to do some carvings as such (let's forget that I have 0 experience of carving, but i'm really interested about it), so therefore I decided to give it a go. If I want to do something as below (except the letters), which stamps would be good to start with (beside swivel knife, ofc. :D )? Thanks for all replies in advance!

-

Does Tandy have some proper stitching chisels to use? I'm talking about 2-4-6 prongs, buying as set from the photo below. I've got the diamond shaped ones from China, they're pretty useless, I think. They're impossible to pull out from nearly just 1 layer of leather, but really impossible to use them at 2 or even 3 layers of 7-8 veg tan at once (or is it that I'm doing something wrong?!).

-

I got interested in lacing for holsters and knife sheaths so I decided to buy the tools needed for lacing. (I will learn techniques later ) I want to lace holsters like holster below. What exactly tools and materials I need so I can lace like the one from the photo? (a tandy's list would be perfection )

-

I was buying from LePrevo until recently, when they raised shipping charges. I was paying 12-14 GBP so far, while this week they wanted to charge me suddenly 44 GBP. Since this is unacceptable for me, I'm searching for someone else in EU, who's shipping for more normal rates. I know for Tandy that their shipping is 30 $ (which is almost half of what LePrevo wants to charge me), but I don't think they ship from EU. I need someone to deliver proper quality tools, and even better would be, with option to buy leather from aswell. I know it's better to buy leather with personal visit of the store, but since it's only 1 store in my country (FFS) I can't really afford to go and buy leather to other coutnries everytime. I'm located in Slovenia, Europe, EU.

-

Im interested. Where are you located?

-

Just found this gem. I'd say it wouldn't be very unusual to actually see something as such on Balkan nowadays..

-

To fix or start over

Mocivnik replied to chiefjason's topic in Gun Holsters, Rifle Slings and Knife Sheathes

If i were you, i would just cut 2 needles off about 1/2inch from the loop in it. Thats how you get very small meedle and for those 10 holes it should work just fine. Its cheaper to buy 2 mew needles than leather for new holster. And you can just make it perfect from now on. -

is it possible to use tippmann boss with waxed thread?

-

To add or not to add? (the wooden board to the back)

Mocivnik replied to Mocivnik's topic in Leatherwork Conversation

I will use (most likely) 15mm plywood. @zuludog: Yep, I saw his vids. But he attached his boards to the wall, I think. @hwinbermuda: Yup! That's a great idea! I had an idea of only text already @hasbeencowboy: it's not a door blank, but solid 30mm plywood. I will most likely tried as hwinbermuda recomended. I might not fasten it down to the legs of the desk, but will just use 3cm (1 1/4") of the board to screw it through. Will use brackets on side. While the shelf..isn't a bad idea at all Will consider that aswell Thanks! I just have to wait till my carpenter comes back to work (wrinkled ankle) to give him an order PS2: Should I cut this board for behind into 2 or 3 pieces? Or should be solid one?