-

Posts

289 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Mocivnik

-

So you recommend to buy natural, black and brown color? (I only work with these colors for now, but I'm into bordeux red also, but I really don't intend to use red dye for edges). I got few more questions about (fiebings) edge kote: How long can bottle be opened? Does it last a year or so? How long does last one 4 oz. (118ml) bottle?

-

@alpha2 Thank You for your great comment, it really helps me a lot. I'm not new, but still at the very beggining in the leatherwork, because I don't do as much as I'd want to. I've used gum trag on quite a few leather edges (mostly leather belts), but I always came to the that kind of finish, where it looks like it's cracked, you could se cracks all over. I thought it was bad gum trag (I got it from China for few $), but someone told me it doesn't matter, what trag you're using. That's why I'm confused now. And what color it should be? Same as leather is dyed or some sort of a contrast should be applied? I use black, brown and red dyes so far.

-

About edge kote (fiebings, to be more accurate): Why was I told, that edge kote looks completely amateur? I'm having difficulties with finishing edges only with dye and gum trag, as the edge isn't looking great.

-

What is the normal price for a) full hide and b ) shoulders and back if we're talking about 6/7 oz. thickness? I'm without the supplier currently and I'm searching for one..

-

Well, that changed just recently, before I could make a first buy. The store stopped selling hides, only equipment and rivets from now on. Unfortunatelly. But they got quality and cheap dyes for leather, they keep brand called Nero d'Inferno. 1dl costs about 6$ and as far as I've used it, it's looking great. But for further leather, what's the actual price that is reasonable for non-dyed veg tan, thickness about 5/6 or 6/7 oz. veg tan? ps: on the thickness you've recommended: I think that 6/7 would be just perfect for knife sheats as such: or while for axe sheats I'd use 6/7 or 7/8 veg tan, maybe different for different parts. PS2: Thanks for your next comment. And what thickness do you use for it? And what is so wrong with the belly? I really don't get it. Is it that, that the back is the thinnest, while the belly is the thickest or something? I know for those vids, they are really good ones Yup, I know that I'm not expecting to have zero waste, don't worry I've done it few times already, I know that

-

Thank you so much the answer! Okay, how about Leather dye, PRO dye and an Acrylic dye? What's the actual difference between them, which suits for what purpose? And LOW - VOC dye? Yes, about the prices: But for those 2 sq feet you get the BEST leather, without any marks - a perfect sheet, while the other one is for..well, you have to cut away much. 5/6 oz. veg tan is fine? Sure? Isn't it too light or anything? (Sorry, just wanna be sure) And a question, I'm a bit confused at: What part of a cowhide is used for what? I know, that back is thinner than belly, but which part is best suited for what products? Jup, I'm reading forum over and over and I've already eliminated a lot of questions, I'd post here otherwise

-

Hey everyone! I'm very fresh to the leatherwork, although my desire to work with leather is in me for a long time. I'm really into knife sheats (also sheats for hatchets, axes and machetes) so I'd really like to find out some better advices about the leather itself. I know there's been a lot written, but I....I'm a lazy person, please forgive me for that. So, first things first: Thickness of leather? I'm currently having 5/6 oz. veg tan, that I'm dealing with, but someone (not so long ago, but I still managed to forgot, sorry :/ ) told me, that it's a little bit thin for the knife sheat and that I should use 7/8 oz. veg tan for all the work. How is with this thickness all about with knife sheats? I'm thinking of such sheats (and simmilar): Ok, next question: Which part of the cowhide is the best and which the worst, to sew stuff like this? My supplier demands 80-120€ for the whole cow (95$-140$) and I really don't know, if it's worth it, or should I just rather buy leather from ebay (China), where the 12x24" of 5/6 veg tan costs about 30$ including shipping. DYEs: I'm using Fiebings for now, Fiebings PRO dye. What's the difference between PRO and OIL dye? Afterwards I'm using resolene and gum trag (for edges only). When the product is finished, I "wax" it with seal's fat (the whole product, except for the leather belt, on the inner side). Thanks for all the questions! And PS: Don't be afraid, I've got tons more questions

-

Yup, that's what I was hoping for. Hmm..I hope I can find any. And yes, it's true. I don't need a new one ps: for everyone, that ever used the leather sewing machine, driven by foot: how difficult is to operate with that kind of machine?

-

Nope, not anything as such. Knife sheats mostly and things such as pouches/bags etc. That's what I'd like to do in future. Yup, that's what I'm planning to do, but before all, I need to know first, what I need. Like the type of feed and decide whether should I use flatbed or cylinder one..

-

Jup, got it right That's how I imagined the whole thing. Well, i'd really be glad if I could ever get anything under 300$ (or 250€) that's working. Doesn't have to be new, doesn't have to be nice..just that i will be able to sew with it. Unfortunatelly, I live in a country, where's not much of an offer and I can only buy from other countries in EU, but then the shipping comes expensive...ah well, I'm not in that rush with the machine.

-

Hmm. Why is then on any kinds the flatbed machine better than cylinder? Yeah, it's already getting expensive for me, I've spend some money on tools and leather already, now I really want a machine..but I'm afraid, I wont get it really soon. I'm not into machines to collect them, they present "a tool" for me, not something to collect. I have other things to stuff them in leather and collect (as it's a reason, I'm buying the machine :D )

-

Therefore, there's not a chance for doing holsters at any point. I won't be doing them much, but as much as I will, I will sew them by hand, I guess. And for one machine (unfortunatelly, I have a 8h/day job and this is only a hobby for me. I'd like to have a full time store for leather products or even work by order, but I don't think this will ever happen), I think that the flatbed will do it for me for now. I know for the cylinder arm would come much much more in handy in case of holstery or bags, but I think (because I don't know much) that it cannot produce so straight stitches (in case I would like to sew a leather belt) on longer distance.

-

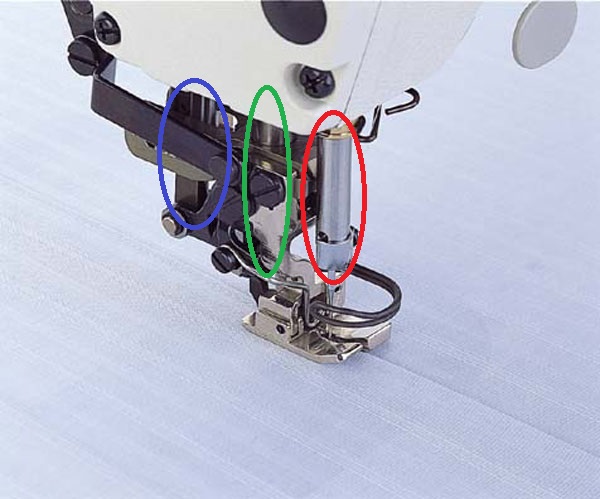

If I got this right, this is a photo of a Juki machine with walking foot. The RED is the needle, the GREEN is the foot and the BLUE is the feed for the foot, am I right? And if I got it right, it's the best thing if I could get a "compound feed" one, any other is quite innapropriate for me? And when I'm looking for the machine, I should be checking for those 3 bars down? :D And if I find the machine, with lifting a foot up to only 10mm, it will be more than enough for me (while sewing mostly just 2 layers of 2.5mm veg tan together)? (Please forgive me for asking stupid and repeating questions here, but I'm having slightly difficulties understanding english in some phrases)

-

@mikesc: thank you very much for a comment! So, first thing first: a domestic machine is out of the question. Good, this cleans off 1/3 of all machines out there (vs. electric and vs. Tippman hand machine). Great. Next, what should I be looking for is a walking foot (3 bars from the top; needle and 2 on the walking feet. If the foot could be lifted up to 10mm above the table, it's proper for sewing whatever you can feed under it? Is that correct, is that something I should be looking for at the machines? (if I want, as I said in first post; sew 2-3 layers of 2.5mm thick veg tan leather together, but that's maximum. I will mostly just sew 1-2 layers of 2.5mm veg tan).

-

Exactly, what I did! I got a few offers for about 800$, but that's the price they want it for old, used machines. I am very unsure in three things now: 1. How do I know, if the machine is proper for leather sewing, based on look? (and how thick leather can it sew) 2. So, what I'm looking for is bottom AND top feed, which means with walking foot, right? 3. Flat vs. cylinder bed: If I got this right, it's cylinder bed ment for shoemaking and holsters, while the flat bed is for knife sheats, bags, etc.? What you can get in my country for under 150$ right now: price for below: 120$ price for below: 10$ for below: 50$ for below: 60$ for below: 100$

-

Hmm...I didn't realise, they are SO expensive. But for a begginner, is there even any chance of getting anything under 300$ (used, ofcourse)?

-

Thanks everyone for answers! @Uwe: Sorry for changing question every time, but I don't know nothing about sewing machines and therefore I'm just asking tons of questions..like I will do now: How about sewing machines by hand (or how they are even called?!)? Are they worth of buying? Like that one on the picture below:

-

@woodysworkshop: Thank you. A friend of mine 3D printed it for me, for a price of a beer. The thing is, it was printed from ABS plastic, which unfortunatelly held me only for 2 stampings. But I just got a VERY cheap logo stamp, made from brass, diameter up to 30mm is done for ~18$/ea. Feel free to comment in this topic, where I opened a discussion about brass stamps:

-

I've updated the whole thing, things changed a bit. Here are new designs, but still cannot decide about the "produced in country", whether it's difference between "handmade" and "handcrafted"? Oppinion? I still cannot decide, which one to use as template to provide a stamp, although I've decided to make a LOGO stamp without any kind of text. And the final version of logo:

-

Yes indeed! Mine is quite simmilar to the one in the first post and these below are the stamps, that I've taken. The leather is 5/6 oz. veg tan, upper is raw color and the lower is already dyed and burnished with resolene. The LOGO was 3D printed and is 1"x1" (25x25mm).

-

I've made a 3d printed stamp for leather for the testing, which resulted into more than excellent for me. But because the material was ABS and was too soft for serial stamping onto 5-6 oz. veg tan, it crushed after few stampings only. Unfortunatelly. (That's showing on 1st picture). But now I came to the idea, that I should make myself a brass stamp for leather, which would present me with a logo and a sign, that says it was made by hand in my homecountry. Now I've came to dilemma, whether I should put the text: 1. Handmade or handcrafted? Which suits more, if I'm buying only leather, rivets, buckles and thread, rest is done by my hands? (I would like to stamp leather belts (mostly), but also knife/axe/gun sheats/holsters and maybe one day even messenger bags, etc. 2. Should the text be around the logo or should I have two stamps? I saw many both options applied onto leather products, but never had a conversation about it. I'm a bit more tending to 2 stamps because I don't want to stamp on everything, that was made by my hands in my homecountry. (picture 2) 3. I've set 4 slightly different logos on top of the 2nd picture (above red line). Which is more suitable/better/worse/appropriate...etc. for leatherwork? Or there are completely no limits?

-

Are brass still available? How much is the shipping to Slovenia for 25pcs?

-

Since I live in an ultrasmall country, where you can barely find a leatherstore (which has only 5 products), I'm searching over the web and couldn't find anything proper. For now, I'm searching for some veg tan leather, thick from 2.8/3.2mm and 3.5/4.0 mm (for US: 7/8 oz and 9/10 oz.), where 9/10 oz must be proper for belts, long at least 120cm (48 inch). The 7/8 veg tan would be best the whole hide, need for various knife/axe sheats. I also need belt buckles, all 40mm wide (if you have 30mm, let me know via PM), must be in color of antique brass, possibility of 1 or 2 needles, such as shown below. Right now I'm buying about 10-20 belt buckles. or .

-

@Uwe: Hmm...and unwaxed with same dimensions? The wax I'd say is optional here and just offers as much as gliding while sewing and "sticking" just a bit while it's done. But I don't find it decisive (I hope I'm not wrong). Yep, but that's the only thing I've had for an option, until I started to think "outside the...country". Yes, I know that a Germany is very good for used items and even proper to find things as such there. I will try to search german ebay also, I just might find anything there. What type of machines should I be looking for or "how will I know, that the machine will stitch 3 layers of 7/8 oz. veg. tan. leather"? What's the crucial information for me here? Also, what about foot-drived sewing machines? I found used in my country EXTREMELY (~200$) cheap and for a good start, I'd reconsider about using one? Most of them are Pfaff or even Singer, but you can get them in mixed conditions, some even on tables, that came along. @Yetibelle: Yes, certainly I want to practice with different sewing machines!

-

Hmm..yes. The budget is quite holding me back at most of my work lately, but I always try to get as much as possible for the limited budget. Also there's the thing, that I probably will never sell my leatherwork (or at least as much to pay off the sewing machine), so I will just try to buy something from middle-class. I don't want the cheapest, as I want to work good and for a long time with the machine, and also not the very top, because I'm new to leatherworks. I guess I should also list down things I want to work (one day..), so...the leather machine should be suitable for knife/axe sheats, leather belts (6/7 oz. veg tan), maybe messenger bags/pencases, gun holsters, belt holsters for various things (such as cameras, phones, etc.). As from amateur's view point, I think that there should be a single sewing machine, that would handle all listed things I'd like to make. I'd also like to point out the fact, I'm using the 150D Leather Sewing Waxed thread (link to the thread). And what prices are we talking about for example something from middlerange from Durkopp Adler or Golden wheel? The seller in my country hasn't listed any prices and demands to give prices only for single offer. List below shows the sewing machines, that dealer in my country currently offers, is there any of them suitable for me? Durkopp Adler: Durkopp Adler 888-160122 Durkopp Adler 888-260122 Durkopp Adler 888-460522M Durkopp Adler 523i Durkopp Adler 524i Durkopp Adler 525i Durkopp Adler 887-160122 Durkopp Adler 669-180010 Golden wheel: Golden Wheel CS-8881 (Pfaff 1591BL) Golden Wheel CS-8883-MBFT Golden Wheel CSR-8891D-LBFT (Pfaff 591) Golden Wheel CSR-8892D-LBFT (Pfaff 592) Golden Wheel CS-8830 (Pfaf 574) Golden Wheel CS-8850DN-MBFT/L (Durkopp 888) Golden Wheel CS-4060 (Strobel) Golden Wheel CST-4060 (Strobel) Golden Wheel CS-8910SC Golden Wheel CS-8911C Golden Wheel CS-8911M Golden Wheel CS-335L-PH Golden Wheel CS-8369