R8R

Members-

Posts

363 -

Joined

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by R8R

-

Is this a CSM1001 or a CS1001? Here is a pdf I found for the CS1001: https://www.docdroid.net/BzWcujK/consew-cs-1001.pdf Looks like there is no off/on toggle for positioner.

-

So the table is a TSS. Height and tilt adjustable (up to standing height) with a channel in back to route cables and daisy chain multiple machines together. Pretty sweet.

-

E6 is a positioner error. The motor is spinning and not getting a stop signal from a synchronizer. If you aren't running a synchronizer with it, turn off the needle positioning function.

-

What ZIGZAG machine would compliment my Consew 206RB-2 for leather?

R8R replied to myjtp's topic in Leather Sewing Machines

I would call them "utility" machines. They are definitely stronger than most any home machine, but nobody should pretend they are regular professional use machines. I keep em around for the occasional zig zag, which is rare. -

What ZIGZAG machine would compliment my Consew 206RB-2 for leather?

R8R replied to myjtp's topic in Leather Sewing Machines

Yep. As of the other day, 2 of them. Picked up one on CL with a neat little butcher block table someone made for it. -

Well I held off buying an Adler 669 and then a Mauser 335 fell in my lap. And then this machine fell in my lap too. I have a lap full of machines. I will prob have questions. LK-1900A-HS. Set up for a 22 needle. Works perfectly so far. Damn these things are fast. I don't know what brand the table is, but it's the nicest sewing table I've ever seen.

-

What ZIGZAG machine would compliment my Consew 206RB-2 for leather?

R8R replied to myjtp's topic in Leather Sewing Machines

The little zig zag walking foot machine I have was in a bin at the Goodwill receiving depot. I payed less than 10 bucks for it. Sews great. I see them on Craig's List occasionally, always cheap. -

Well so far I really like it, and it's smooth and pretty quiet. It's not the strongest climber but it will get me by for now. Still cleaning it and tweaking it a bit. I will say that the 669 is in my future still. I can tell already that some projects will require a heavier machine. FWIW the 335 has been around forever. This is essentially a Chinese built modern Pfaff 335, with many actual Pfaff parts. Generic parts are easy to find and cheap.

-

Checkout Sailrite on Youtube. The Sailrite Fabricator is essentially identical to that machine (except for the flywheel) and they have a wealth of nicely produced vids on that machine and walking foot sewing in general. Then, read as much as you can here. There is literally hundreds of years of sewing expertise on this forum.

-

Consew 206RB-2 back stitch tangles? Tension or what?

R8R replied to myjtp's topic in Leather Sewing Machines

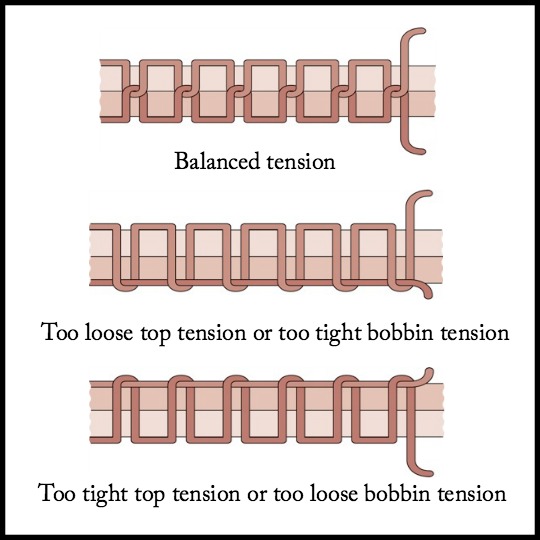

Not enough top tension or Too much bobbin tension or Machine is timed for a much smaller needle/thread combo or ?? 206RB owners will be along soon to make further assessment. In the meantime, your top thread tension is weak. The joining lock of each stitch should meet in the middle of the material. Your bottom tension is higher than the top so it is pulling the knots to the backside of the material (run a fingernail along a stitch and you will feel the nubs of each knot. Crank up your top tension till it starts to pull those knots up top, then back off till it sets them in the middle. This will give you a sense of the range of tension you need to work with for this material. The very best thing is to find the correct tension with 2 layers of similar materials first. Get the knot in the middle of those layers. -

My god... it's beautiful. Every sewing machine service manual should have color renderings. It makes it all so clear.

-

YOU RULE.

-

Maybe a standard throat plate and a feed dog for binding or other purposes and the two are mismatched. The feed dog might be the correct height for a throat plate that is machined to be thinner profile. Kwok Hing KH69R regular size plate/dog set is about $35, and they ship quick. Only grinding you might have to do is to smooth the teeth a bit.

-

Ok to simplify my life (or complicate it?) I just scored locally a Mauser 335 with a full binding kit that will handle much of my binding tasks except the heaviest stuff. Machine is in beautiful shape, was impossible to say no!

-

What ZIGZAG machine would compliment my Consew 206RB-2 for leather?

R8R replied to myjtp's topic in Leather Sewing Machines

Sailrite Ultrafeed LSZ-1 Reliable Barracuda Rex 607Z TuffSew Super ZigZag Family Sew Super ZigZag Etc These are all machines based on the Thomson mini walking foot machine. They are small, portable and can handle light leather work, and they are cheap, especially if found used. They can (mostly) swap out with Sailrite parts which are slightly upgraded and refined from most of the clones. Sailrite has HOURS of how-to and maintenance video about the Ultrafeed, enough to make anyone a certified mechanic on them. If you need a simple machine for zigzag on light leather, I can think of none better. Full size walking foot zigzag machines are NOT cheap. -

What ZIGZAG machine would compliment my Consew 206RB-2 for leather?

R8R replied to myjtp's topic in Leather Sewing Machines

20U is an apparel machine, FYI. -

Nope. I am looking hard at the Adler 669 now, mainly because (except for the price) it has everything you described. It's actually not terrible in price compared to say a brand new Juki, and there are levels to the 669 - Eco, Classic, etc that give some cheaper options. The Eco versions are basic belt-driven and the Classics are automatic with direct drive options, etc. A new Juki 2342 is only direct drive with auto functions - there are no cheap options to that machine and you pay for a bunch of bells and whistles you may not need. I mainly want a cylinder arm machine that can match the capacity of mu Juki 2810 that doesn't have a bunch of extras that tag on a few thousand bucks. 69 - 138 or maybe 92 - 207 with some tweaks. High foot lift Synchro binder option Longer arm with a narrow arm if possible Adjustable vertical lift knob Adler 669 has all that.

-

What ZIGZAG machine would compliment my Consew 206RB-2 for leather?

R8R replied to myjtp's topic in Leather Sewing Machines

If not crazy thick stuff, the Sailrite Ultrafeed or any of the multitude clones of those mini walking foot machines. (Family Sew, Morse, Tuffsew, etc) They are surprisingly capable but have a definite "stop" limit. In other words, a full tabled industrial machine will struggle at it's top end of capacity, while the mini walking foot machines just say "nope" when they hit their limit. But for the price they can't be beat. -

Yeah this is not threaded correctly, please watch the vid and go through each step, it's pretty clear. The thread needs to go under the check spring wire. Also yes that first disc is a pre-tensioner and it needs a spring to operate correctly, although you can compensate for it in the meantime by threading it through all the holes of the thread post on top of the machine. (each loop through adds a little tension)

-

Nope. That machines has been off and on Craigslist for months. It's a little over priced considering it does not have a servo motor. How thick of canvas are we talking here?

-

I would thoroughly comb these forums there is a huge wealth of information here. You will need a heavy stitching machine for saddles. It may be too heavy for canvas work. Industrial machines generally have a narrow range of capability, light medium and heavy. There is no single do-all machine. The materials and thickness of a specific assembly dictate the specific machine. Check out all the vendor links above, they generally offer machines for heavy saddlery and some lighter stuff.

-

Unfortunately if you need to repair saddles AND canvas, you will likely need more than one machine. Where in CA are you? From the link you posted somewhere between the bay area and Sac?

-

When you say "top right tension spring" which part do you mean exactly? Close up pics help. Threading vid: https://www.youtube.com/watch?v=_J1b57wIdIQ

-

Juki 145 is a top/bottom feed (walking foot presser foot), not a compound feed feed (no needle feed). Similar to how a Juki DU-1181 or Sailrite Ultrafeed work. The 246 is a compound feed machine with a higher foot lift and a bit more heavy duty. The 277R is ..."kinda" comparable to the 669 in thread size capability but that's about it. 669 has a longer arm, higher foot lift, adjustable climbing, etc. It's about mid way between a Juki 246 and 2342. I'm taking a long look at it, seems to be the perfect machine for what I need right now.

-

Check your threading, looks like you are bypassing the check spring.