R8R

Members-

Posts

363 -

Joined

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by R8R

-

I was using an Artisan ACF-652C with a standard reducer wheel. Worked really well as long as you kept the top speed somewhat controlled. It didn't like trying to brake from over 2500 rpm - it might add a stitch or two before burying the needle but it was consistent if you kept the speed realistic. Never had a positioner error though. This one btw - http://artisansew.com/pdf/ACF-625cInstructionManual10_2017.pdf

-

Beginner sewing machine for wallets,watch straps,light stufd

R8R replied to KennethM's topic in Leather Sewing Machines

Keep reading this forum. There is a wealth of info on pretty much every leather capable machine made in the last 100 years here. Not sure where you are in Mississippi but a drive up to Nick O Sew in TN might be worth it to you. -

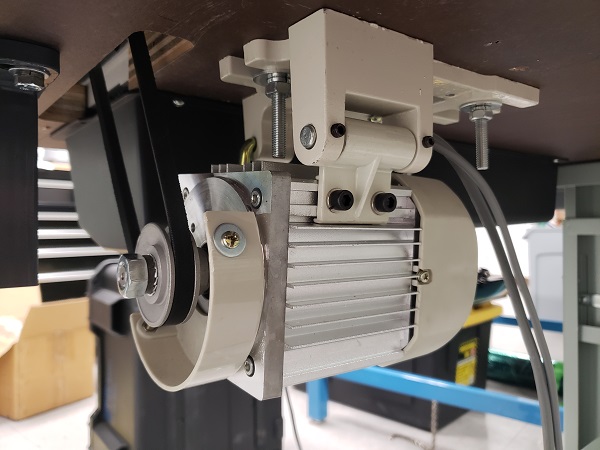

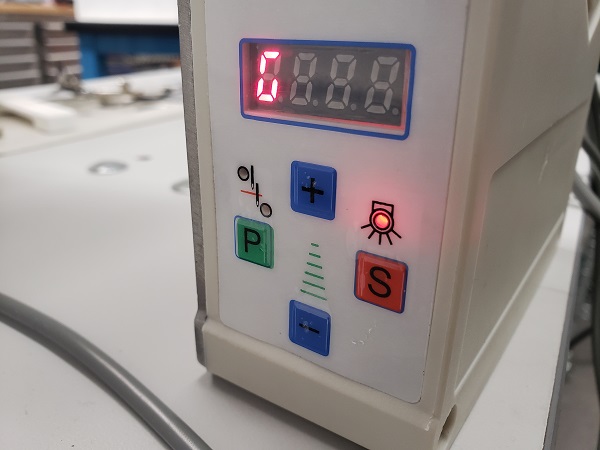

Btw I tried out a reducer on that SP-1100 motor I posted and it worked great, positioner worked fine with it. I ended up removing it though as the 100 rpm start was fine and I will prob put the reducer on another machine. Of all the motors I've looked at or used, this one is a winner. Great balance of power and utility vs cost. Other motors with similar power and low speed control have extra features I didn't need and it drives the cost up (auto back-tack, trimmer, etc)

-

Depends on who makes the motor. Often the claimed watts on a servo motor is almost meaningless in my experience. I've used a 550w motor that had cranking amounts of torque and great low speed control, whereas I recently installed a claimed 1400 watt motor that had lousy control and struggled with needle penetration on slow stuff. I'm trusting trial and error more than listed specs these days. The 1100 watt motor I posted, while maybe not even a true 1100 watts, definitely has "umph". Much more so than a motor with even higher wattage stamped on it. Maybe contact Keystone and see if they have a lead on a 220v version?

-

Your other option, and I end up doing this all the time with electronics (cameras etc) is buy the Ho Hsing and if it doesn't work out for you, ebay it. If you end up losing a little money consider it a rental. Right now I have 2 motors that I'm probably going to sell after finding this new one, its that good. Sometimes you have to eat a bit of cash to find exactly the right equipment. That one is 650 watts. You might be disappointed in the torque unless you're using a reducer.

-

I just received today a motor from Keystone sewing that fits the bill. At least so far I think so. https://store.keysew.com/sp-1100-npfl A nice amount of torque, 100 rpm start, dual position synchronizer (you can adjust both the high and low needle stops), a fairly simple menu and bonus points for a simple +/- speed control buttons on the front. (100-2500 rpm) Also has one outlet for LED light and one for 24v foot lift solenoid. The menu has dozens of adjustable parameters - even braking strength. I did a preliminary mounting on my Juki 2810 and with the included 50mm pulley it buried the needle in anything I could fit under the foot and it has a nice modulation in speed. Slow ramp up and no sudden drastic steps in velocity. Very impressive so far! I might throw the reducer back on but I'm not even sure it needs it now, at least not for torque. It's slow but maybe not slow enough. I might just need to get used to it. Haven't installed the synchro yet but it's a nice unit, much better than the one I've been running. Chinese import, so maybe it's avail in your neck of the woods?

-

I bet Uwe's vid can get you close it's for a Juki 563 style machine which are all basically 111's anyway. https://www.youtube.com/watch?v=iiaaT1npYrQ It shows how to readjust the stitch length indicator if it is not showing the correct stitches per inch. It's possible yours bottoms out at "5" but it might be closer "0". That vid is really easy to understand.

-

If it sews it sews but when things go wrong that you can't tune out of the machine at least you will know the culprit. Maybe pull the shaft out and take it to a local welder to see if the broken piece can be brazed back on. (or tig welded). Should not be an expensive fix.

-

Cheap tools are expensive.

-

These vids are specific to the Sailrite machine but much (most?) of it applies to all industrial table/machine setups, including setting up the bobbin winder, etc. https://www.youtube.com/watch?v=nfWLB5fGkLI https://www.youtube.com/watch?v=o70w1dUHyuo

- 9 replies

-

- 206rb5

- sewing machine

-

(and 3 more)

Tagged with:

-

Sewing Machines Question and Recommendation

R8R replied to pepeunidos's topic in Leather Sewing Machines

1541S with free delivery... https://austin.craigslist.org/app/d/juki-dnu-1541s-walking-foot/6691001136.html Honestly that Cowboy with the flatbed might be everything you'd need to sew thin leather all the way up to the max you'd want to go. Priced right too. -

Sewing Machines Question and Recommendation

R8R replied to pepeunidos's topic in Leather Sewing Machines

Spanky new CB3200 in Austin.... https://austin.craigslist.org/tls/d/leather-sewing-machine/6706710684.html -

Sewing Machines Question and Recommendation

R8R replied to pepeunidos's topic in Leather Sewing Machines

If I were to pick one flatbed machine of all of those it would be the Artisan. It's based on the Juki 1508N*H* and is a "heavy" version of the 1508N with a little more capacity and longer needle stroke. Also square feed locus which really does improve feed ability. (the feed dogs move squarely up and back, not in an ellipse) Good machines, I've seen em in person in SF and test drove a few. (Artisan is next door to the place I bought my Juki) The rest of the machines you listed can go up to 138 thread, (give or take) the 1508-10H can in theory go up to 277 although 207 is prob more reasonable. Of all the clones out there, the ones based off of later model Juki square feed machines are my favorite. Keep your eyes peeled on Craigs List though! These made-in-Japan Juki's crop up on there from time to time for decent prices. -

Sewing Machines Question and Recommendation

R8R replied to pepeunidos's topic in Leather Sewing Machines

My first foray into "heavy duty" machines was a generic portable zig-zag walking foot (clone of a Sailrite Ultrafeed/Thomson) I found at the Goodwill depot for $3.00 (yes THREE dollars) I think it's a Family Sew or similar brand. No actual brand name, made in Taiwan though. Sews great! Keep your eyes peeled! -

Looks all like scrap metal? That table stand with the bent tube legs is awesome though.

-

I think I meant it's finally getting ubiquitous, with touch panels right on the machines, NFC features, etc. You know, "smart" stuff. Example the old guard in screen printing is M&R. Amazing machines, rock solid company. A few digitally controlled presses some years ago, but mostly for very high end shops. Other equipment manufacturers came in with automated features and touch panels, programmable temperature controls, job recall, production data downloads, etc. The whole industry stepped it up and now that kind of digital control is standard in many new machines. But like sewing you can still buy a basic metal machine that will get the job done for years.

-

I worked at a shop that was 50/50 embroidery/screenprinting. That place was a cacophony.

-

TLC? Maybe a little 3-in-1 oil, adjust the timing...

-

This machine if spec'd same as the orig Juki will take up to a 24 needle, (standard size for it is 23). That, with proper tuning should handle up to 138 thread in the needle. Can speak to the bobbin as I've never ran one of these.

-

Yeah my understanding is Singer used a lot of thread specs that were very specific to Singer only. Someone else can chime in here about it but careful re-tapping anything to "standard" as you know it. For future reference, B'laster PB penetrating oil is the best I've used for freeing stuck threads where permanent Loctite is not involved. Often no hammering needed. Spray it, go have a sandwich, come back and things are freed up. When red Loctite is used, a heat gun and cranking it to about 400 degrees Fahrenheit or more does the trick.

-

Yep. I went full analog - ordered a Techsew 2600 yesterday.

-

I agree! https://youtu.be/qryBuUxURvQ Sewing is just now getting some true digital automation function that other industries have had for years. Even screen printing went through this about a decade ago. We had automation but digital automation took it to the next level. Being able to digitally set parameters and save them for repeat jobs is HUGE if your machine is there to make you money, and this kind of thing trickles down into lower priced machines later on.

-

Yeah... they are thinking the new machine with this option will set a customer back about $7k delivered. And that is for the BASE model, not the fancy "-7" version. I do love my LU-2810 but WOW, add a cylinder to it and it blows up the price by 250%.

.jpg.d60258221c476480a6e073a8805645bb.jpg)