R8R

Members-

Posts

363 -

Joined

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by R8R

-

Artisan 3200 BT Bench top Leather sewing machine

R8R replied to Deryk's topic in Leather Sewing Machines

I've been to the Artisan showroom and seen this one first hand. "Movable" is more the word. Not portable. That bench-top configuration is for people that have limited shop space and workbenches, etc already in place that they don't want to sacrifice for a sewing machine footprint. Nice machine though. -

Oh and for those of you who wince at sewing machine prices, there are screen printing presses with absolute eye watering prices. Many north of $150k, and you can double that with all the required ancillary equipment.

-

I worked and managed a garment screen printing shop for years. The best presses are the ones that have come out in recent years with digital control of variables and job recall. In a production environment this DRASTICALLY reduces setup time and operator error. No reason sewing machines should not have the same. For a hobbyist or small shop it makes little sense but if you are considering volume production and operators are being paid to sew, then the machine only makes money when it's running product. Every time saving step adds up quick. On the other hand the gear nerd side of my just LOVES the stuff.

-

THIS IS CRAZY "Multi-layered part detection function Multi-layered parts of material which occur in the case two or more plies of material are sewn or different kinds of material are sewn can be detected by the multi-layered part detection function to change over the stitch length, thread tension, presser foot presser and amount of alternate vertical movement to those that have been predetermined for sewing those parts of material."

-

WOAH http://www.juki.co.jp/industrial_e/download_e/catalog_e/lu2800v7.pdf I am reading the literature and I can't see where they missed even one bell or whistle, aside from maybe it doesn't make coffee. Digitally controlled tension, programmable foot lift, you name it.

-

And I must say, if I were budgeting $1k - $2k that would be for a basic upholstery flat bed machine. You really should put about $1700 as your low end and go up from there if you want a machine that is good quality with decent support.

- 17 replies

-

This right here is the crux and I think it should be answered as "how are your items constructed, and at what point do the stitches need to happen in the assembly?" and not just "how thick?" Obviously if there are points in the construction method where a rivet tool is the only tool that will reach into a bag and make a connection, then a flatbed won't help much here, and maybe not even a small diameter cylinder bed! Then again if the patterns and construction sequence lend to making flat stitches then a flat bed is no problem. So to look for a machine you need to balance the considerations of your budget, your mechanical aptitude (which is actually part of your budget!) your patterns, overall construction technique and sequence, material type and thickness, etc etc. Problem with industrial machines is you are talking about one machine that does one thing well with a narrow range of adjustment. (typically several thread thicknesses and that's it) If you can construct a bag in that range, you're all good. The wider the range of products, the more tools you will need, often with some overlap it capability. Something like that 4500 with a flat bed is a sweet setup, but ultimately it's up to you to determine if that kind of machine is too heavy, not heavy enough, or just right, and if your work will even fit around the arm. Oh and I must say, the rivet construction is really sharp. Nice work.

- 17 replies

-

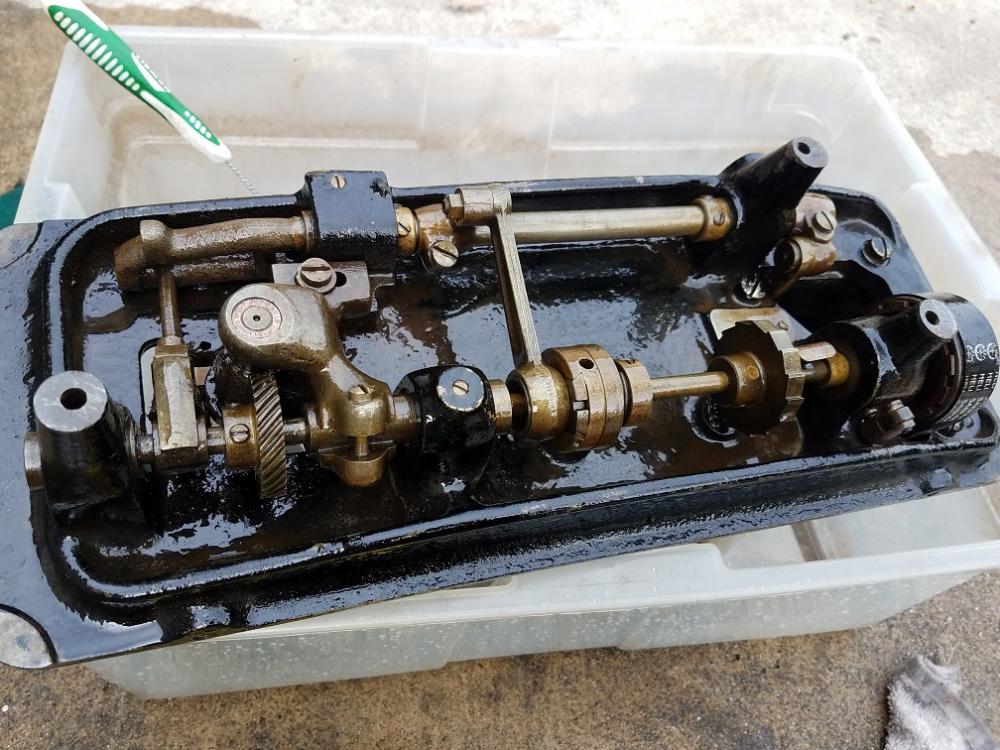

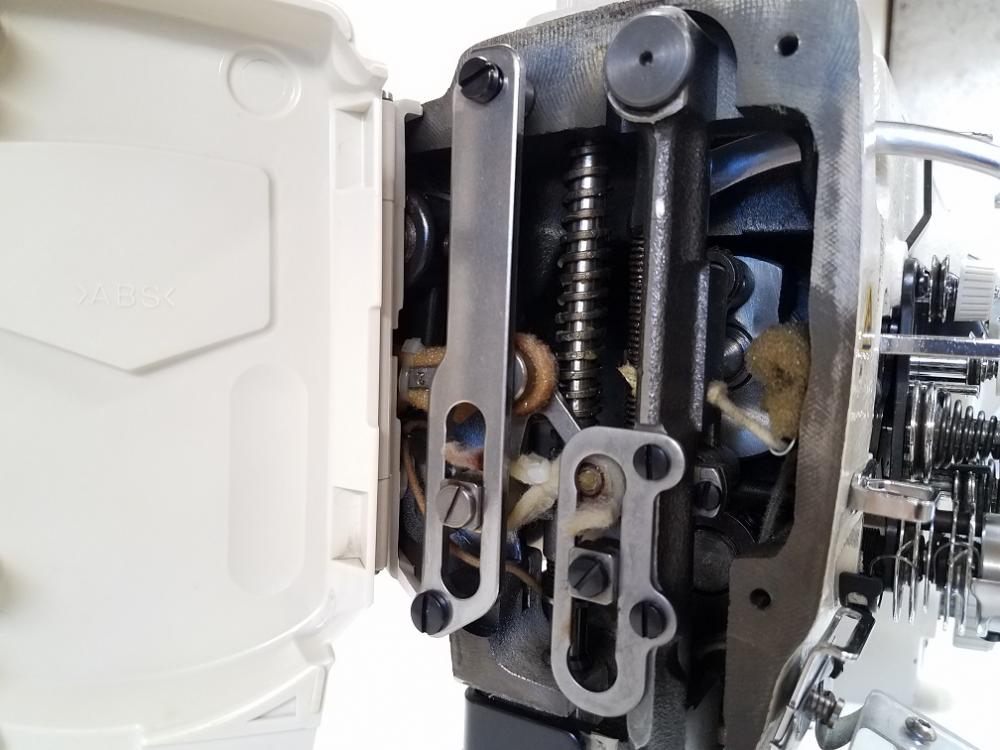

Gotta say the vinegar bath worked great. Quick water rinse and then a WD-40 soak and scrub with a light wire brush and a scotch brite pad, and it's looking like night and day here. (before pic here also...) This thing was JET black on the underside, and before the soak the many of the parts were frozen in place. Just touching this thing would blacken your hands. Once it drains out completely I'll be dousing it in lily white oil, then on to polishing out the hook parts.

-

Picked up an old pair of Singer machines - a 111W153 and a 111W155. They both were apparently in a building that burned down. Covered in soot, oil, general gunk and a little surface rust. I've actually got the 155 sewing (kinda) but I've decided to guinea pig the 153. Here it is immersed in white vinegar do de-rust it after degreasing it with brake cleaner. (bags of water for ballast to keep it immersed) This is an experiment to see what these machines will go through and still come out the other side sewing.

-

Hi - I was a professional screen printer for years. These kind of vendors have been around for decades and they all sell complete garbage equipment. I would not even recommend their screen printing offerings to hobbyists. This same company pushes stuff on Craig's List. It's all overpriced for what it is: garbage.

-

Ok where is the popcorn, this story is getting good.

-

Awesome, thanks Gregg!

-

Cool... so basically any 24v or 30v power source might work.... hmm. Any idea what kind of amperage it might require? I've looked at a bunch of motor controllers but none of them list the amperage supplied in the specs. I found a similar solenoid and knee switch online. I think with a proper power adapter and the knee switch I could make it work.

-

So I bought a used machine recently that had an electric foot lifter solenoid attached underneath the table. Thing is, it was not plugged into anything and did nothing to lift the foot. The motor had no input plugs for it (basic servo). I've since sold the machine but I kept the solenoid. I'd like to apply it to the next flatbed machine I buy. Is there a way to add a 24v (or 30v?) power supply and a knee switch to this thing, with running just a basic motor for the machine? (or a motor with positioner) Or would I need a high end motor setup that has all the various control inputs? The solenoid looks just like the one in the attached file.

-

SOLD

-

Ahh! I just saw this the other day and was going to pull the trigger. Let me know when or if you reconsider.

-

Well, with industrial machines that is the opposite of what you will find. 4 figures will get you a machine that does *one* thing, and it will do it very well. The machines that propose to "do everything" are home machines for light materials. Sewing machines are tools. The more specific, demanding and exacting the task, the more specific, demanding and exacting the tool should be. Price follows accordingly.

-

Btw in my former occupation I was an equipment and facilities manager at a print shop, and a shipping manager. This thing will get royal treatment in shipping.

-

Best offer. If it gets above what I'm being offered for trade-in at the local shop, it's yours. Will ship anywhere in the lower 48 for actual shipping cost. I will palletize for free.

-

$2000 or best offer that is....

-

Nice machine for a nice price! 1) Yes the center foot should make contact with the feed dogs, this is the unison feed feature (needle + foot + feed dog) all feed the materials together. The outer foot holds the materials in place for a brief moment. If there is a great deal of resistance, the timing may be off. There should be some resistance you will feel with the handwheel though. 2) On just about any/all industrial machines, if auto-oiled there would be a pan mounted underneath with a removable drain plug and some indication of low and high oil level markings. If manually oiled, maybe a simple catch pan underneath and many oil port holes on top and around the machine surfaces. When in doubt, add at least several drops to each port, and open up the machine and add oil to any and all moving parts that make contact with each other. Pivots, bushings, bearings, connectors, etc, oil them all. Use a little extra when first oiling and wipe away any excess. Use ONLY clear sewing oil, made for sewing machines. Any other oil will gunk it up. TIP - and this applies to all machines, everywhere - keep it very clean. Dust, dirt, lint etc on the outside all make it into moving parts eventually, and sewing oil can quicken that process. Keep things clean and well oiled and it will last a lifetime. 3) Maybe you mean the tension adjuster knob for the bobbin winder? The thread should wrap though this tension disk assembly first before going to the bobbin. The machine will run without it, but properly winding bobbins will be difficult. See this vid - the top center knob adjusts the foot pressure. The small knob is on the bobbin winder tensioner (with the red thread running through it to the bobbin winder)

-

For sale: One Juki LU-1560n double needle, compound feed walking foot machine with table and 600w servo motor. I recently obtained this in a factory sale but I am quickly realizing I don't have the space for a dedicated two-needle machine. This machine is in excellent clean condition, (doesn't seem like it was in service very long) with only the basic signs of use (some typical scratches here and there on the machine bed, belt guard, etc). I've tested it with 69, 92 and 138 bonded nylon and it sews great and climbs over most anything that will squeeze under the foot. 16 layers of ballistic nylon and it didn't flinch. Only issue with the machine I noticed - the thread tensioner disc for winding the bobbins is missing. I imagine they used pre-wounds in the factory and this was a non-issue. I've ordered a new assembly (genuine Juki part) Specs: http://www.juki.co.jp/industrial_e/download_e/catalog_e/lu1500n.pdf 2- needle, currently 1/4" gauge 0-9mm stitch length 16mm foot lift 135x17/16 needle system up to #24 6.5mm climb Rectangular feed locus Big "U" size bobbins Built-in bobbin winder Auto lubrication with filtration (flows great!) Safety clutch Will come with: Table in "decent" condition. The table seems older than the machine. Has all the expected production environment scratches, etc. There was a electric foot lifter solenoid attached, but no switch or power plug for it available on the basic motor, but I'll include it anyway. 600w basic brush-less servo motor with 50mm pulley Brand new belt Brand new oil filter pad Brand new bottle 700ml Juki Defrix #2 Brand new 4-spool thread stand Brand new magnet LED light Brand new waste oil bottle Spare waste oil bottle Pack of brand new misc needles #16 - #24 Basically add thread and materials and sew. Asking $2000. Would prefer pickup or I can arrange drop off somewhere near the SF bay area. Shipping via LTL freight possible too - I can strap it to a pallet, buyer to pay for freight and extra for lift gate as required.

-

Not an issue IMHO. All in the feet. The Juki's take common Singer 111w feet so your choices are endless.

-

6-20p plugs are generally used for 110v applications where you want to plug it into a dedicated 20 amp circuit, not a 15 amp which is standard household current. Single phase 220v plugs are typically larger dryer plugs, etc. You will need a dedicated 220v circuit receptacle and a dedicated plug for it. Now, if it has blue, brown or orange it might actually be wired for 3 phase input. I would get an electrician to look at it for you.