R8R

Members-

Posts

363 -

Joined

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by R8R

-

servo motor Servo motor with syncro and speed reducer

R8R replied to Reacher10's topic in Leather Sewing Machines

One solution - although you're already down this path - a motor with a synchro input and better low speed torque. I have a Sailrite Fabricator with their "Workhorse" motor and I have to say it's got an insane amount of low speed torque and control for a supposed 550w motor. It totally crawls and I have not found anything it won't punch through (I get needle breakage first and the motor doesn't flinch) It's essentially the exact same 12-coil motor as the Reliable Sewquiet 6000, which is available with a synchro. The Workhorse has the positioner functions in the menu and a receptacle on the back for a synchro, (exactly like the Sewquiet) but they don't sell a synchro for it, as there is no way to attach it with their Posi-pin system. At least not one they've made available yet. I just bought a new Juki 2810 and the dealer had a 750w motor with a synchro in stock, so I picked that one up and installed it. I should have went with the Workhorse or Reliable, the speed control is much better and the torque is comparable or better. I might get the Sewquiet later or swap out this Workhorse if I sell the Fabricator. (or I'll bite the bullet and get an Efka or something similar) Here's the Sailrite vid with their Ultrafeed and the Workhorse in a retrofit table they sell. (skip tot he end to see it working): https://youtu.be/p0tSylFVJlc -

NICE. Casters are essential in any shop, especially if you like to keep things clean.

- 16 replies

-

- sewingmachine

- juki 1541s

-

(and 3 more)

Tagged with:

-

leather sewing machines Thor sewing machines

R8R replied to shoepatcher's topic in Leather Sewing Machines

You posted the same question multiple times on separate threads. People are answering this on another thread you started, no need to keep posting the same question over and over. -

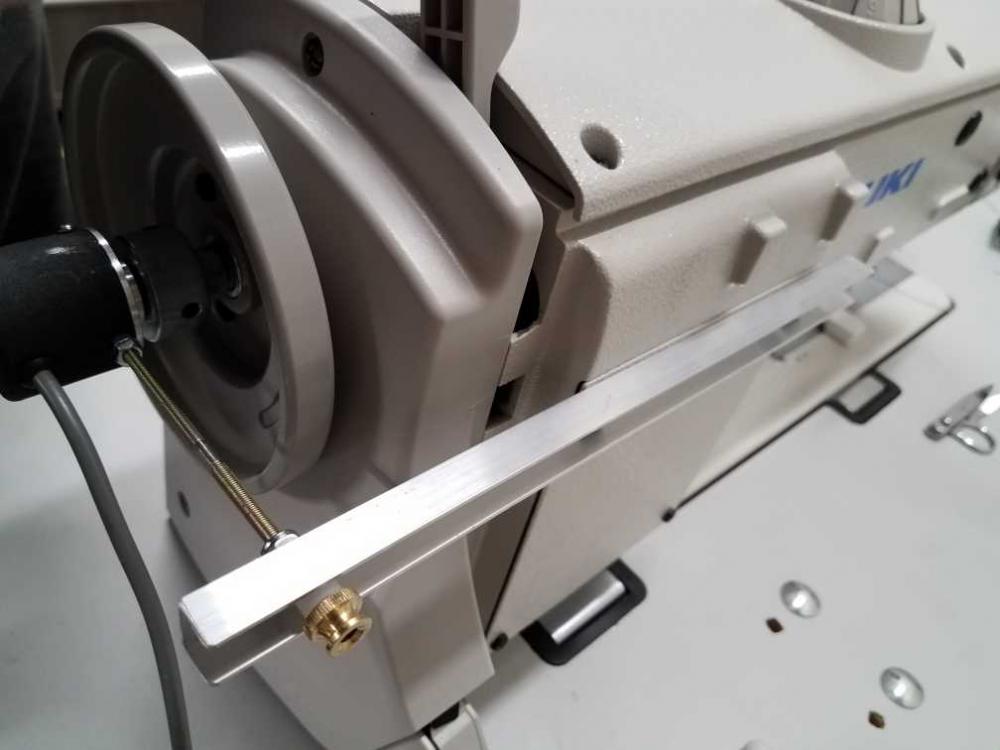

Here is a little DIY trick I did for the synchronizer. On the 2810 basic model there is no holes or bushings for a synchro mount, so I took a small piece of aluminum U-angle and drilled it to fit under the screws on the back cover. Works perfectly and no additional holes needed to be drilled in the machine or the table. Thought this pic was funny... scale reference next to my Ultrafeed clone...

-

2810-7 street price is closer to $4600. The super full loaded 2828A-7 is about $5500 (extra big bobbin, short thread trimmer, etc.) I looked at the Adler stuff and it's super nice but not 50% nicer, which was typically how much more it costs. Juki parts and accessories are easier to get in this neck of the woods too. So far this machine is everything I hoped it would be. I swapped the stock Family servo it came with for a 750w servo with a synchro and it's working great.

-

I suppose it's missing the "S" and "R"? 144 A 305 is a Singer for sure.

-

Could not find a $15 one. But who's counting? https://www.ebay.com/itm/282660057433

-

That is a machine with all the bells and whistles and the correct motor contoller to operate the backtack, trimmer etc. I think we are talking about just the needle positioner device and slightly better than basic motor that has this option, nothing more. I would think most any machine that can accept the bushing screwed into the main shaft could accept the positioner, (as long as there is room to mount it solidly) then it's a matter of how good is your motor and what speeds are you running.

-

I'm not recalling what the backside of the casing looks like on those machines. Perhaps drilling and tapping some mounting holes might be in order. KH has a ton of options.

-

1400w? That's a big clutch motor! KH might have a pull down guide that can be fitted. http://www.khsew.com/index.php?route=product/category&path=273

-

Also the Reliable 4200 is a 1541 clone, so if the distributor is correct, you can't put a positioner on that one either. I don't think that is right though. The 4400 is a Mitsubishi clone btw.

-

Did they give any particular arguments against attaching a positioner to a 1541? I don't see why a Reliable machine would be a more likely candidate. With the right setup and the right motor you can probably attach a positioner to just about any machine. On larger machines you might not be able to go full throttle, as they simply have more inertia and the positioning will not be accurate. At the lower speeds you'd be running for leather it's probably not a big deal.

-

Is a bowl of cereal with milk in it a soup or a salad? Oh and nice first piece!

-

Well... let's start by asking if a 1508 is the best machine to do the binding you're planning to do. Also, describe the binding you're planning to do. Also, describe the 1-1/4 binding material, the thread, the type of material it will be attached to, the thickness, etc etc. The 1508 might be the best thing ever for this application, or it might be a nightmare. Information will help to determine the outcome - until then your solution remains in a quantum state.

-

On some Juki models "S" denotes "safety", as in it has a safety clutch. (ex: DNU-1541 does not have a safety clutch, DNU-1541S does) On others (often the second or third letter behind the model number) like in the 1500 series, it denotes "standard" gauge, as in it uses the "standard" Singer style presser feet and throat plates, etc. "A" typically denotes it is "Euro" gauge (Adler style feet, etc) "H" means "heavy". All the specs for every current machine are on the Juki site, and for older models a web search will turn up manuals and spec sheets for just about anything.

-

Thanks! Was going to order from you but a local shop made me a deal I could not refuse. We might talk motors in the near future though.

-

I had checked out a 1508N, a 1508NH, a 1541s, and a 1508NH clone. I also breifly owned a 1560N. (sold it cause I didn't need a double needle) I'm going to say initial impressions of the 2810 is that it's better than all of those. Like ... way better. In my limited testing so far, it climbs over assemblies easily, no flinching or stalling and just seems to sew smoother than the other Juki's in this range. Most people seem to say the Japanese made machines are inherently better, and I think in the near past that was true, but I see little to no difference so far in build quality with this Chinese made machine. Fit and finish is very nice. Time will tell how it holds up. If you are not familiar with the newer Juki flat beds, the overall design is super cool - no shafts or bearings exposed, everything is housed under a full length top cover, including all the feed mechanisms. It's "semi-dry", all the auto lubrication is from a tank and tubes to the lower feed parts and hook. Seemingly, all the upper drive components are sealed bearings or grease. Not much manual oiling to speak of. The one I got is the "A" Euro gauge variety, shares common feet with Adler 467, etc. Auto-feed feature on the bobbin winder is super cool. There is a thread knife/thread clip on it, and when you trim the thread the clip holds it in place. Stick a bobbin on it, throw the release lever and the thread spools onto the bobbin automatically - no need to pass the thread through the bobbin hole and hold it while it starts, or trim the excess. Super quick and brainless. My hand is in the pic for scale. This is a monster flat bed. I'm 6'4" with large hands. This makes a Singer 111w look like a Singer 221. More pics and impressions once I get more treadle time on it.

-

Cool! Hey everyone else that was asking... these are getting picked up, so me not having to crate and ship wins out! Thanks for all the inquiries.

-

They didn't get burned, just smoked. And yes they are mostly complete as far as I can tell but may need parts replaced.

-

Ok I am straight up out of time to deal with these, and out of space, as I have another machine on the way. Free Singer 111W153 and a 111W155 heads to a good home! You pay actual shipping via Paypal. 111W153 has been fully de-greased and de-rusted and re-oiled. (nothing is frozen or obviously worn loose) but will need further cleaning and tuning and possible new parts. 111W155 works and it sews but it's a little rough (nothing is frozen or obviously worn loose) but will need a thorough cleaning and tuning and possible new parts. NO WARRANTY EXPRESSED OR IMPLIED.

-

Using Single Needle on a Double Needle Machine?

R8R replied to LloydChristmas's topic in Leather Sewing Machines

I had a double need Juki 1560 and was strongly warned by a reputable shop against running it single needle. The explanation was they are designed to handle the stresses balanced across both needles and running it single loads the stresses laterally to one side and can lead to uneven wear on the needle bar, bushings, etc. Aside from that the presser feet are crazy wide and a pain in the ass to sew assemblies with narrow allowances. -

Of all those, I would pick the 1508. Made in Japan, square feed locus, big vertical bobbin, smooth sewing and easy to get original or a myriad of cloned parts for. I was at a toss up between that and the 2810, I went 2810 for the longer and taller arm.

-

I just paid for a 2810 at a local shop, picking it up next week. I'll post a review of it up in here once I get some time on the treadle. I was gonna go for the 2810-7 but I decided I'd see how I like the basic machine first before I shelled out for thread cutter, direct drive, etc. Also the basic belt drive machine uses whatever motor I want, (as apposed to the fixed power on the direct drive models) so I can add a 1 hp servo and a speed reducer, etc.