R8R

Members-

Posts

363 -

Joined

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by R8R

-

Synco Super-Lube. Only grease I used on all the big machines I maintained when I worked in screen printing. We had zero problems with lubrication failures.

-

It's the slow control that I like, but yeah overkill never hurt either.

-

Speed lock disables the plus/minus buttons from directly changing the top speed.

-

And then Hightex (Cowboy) went and posted this... https://www.youtube.com/watch?v=-hSvDOyIgFQ Hmm.

-

-

I've used everything from a very old clutch motor with clay disks for the clutch surfaces, to some nice modern servos with a bunch of bells and whistles. Hands down the best I've used for the money is this one: https://store.keysew.com/sp-1100-npfl It is unflinchingly strong, has a starting rotation of 100 rpm and has very accurate needle positioning. I'm using it on my Juki 2810 and it's damn near perfect. No speed reducer required. Vote for runner up would be the Reliable Sewquiet or the Sailrite Workhorse (same motor, different packaging). Good slow speed control and decent build quality.

-

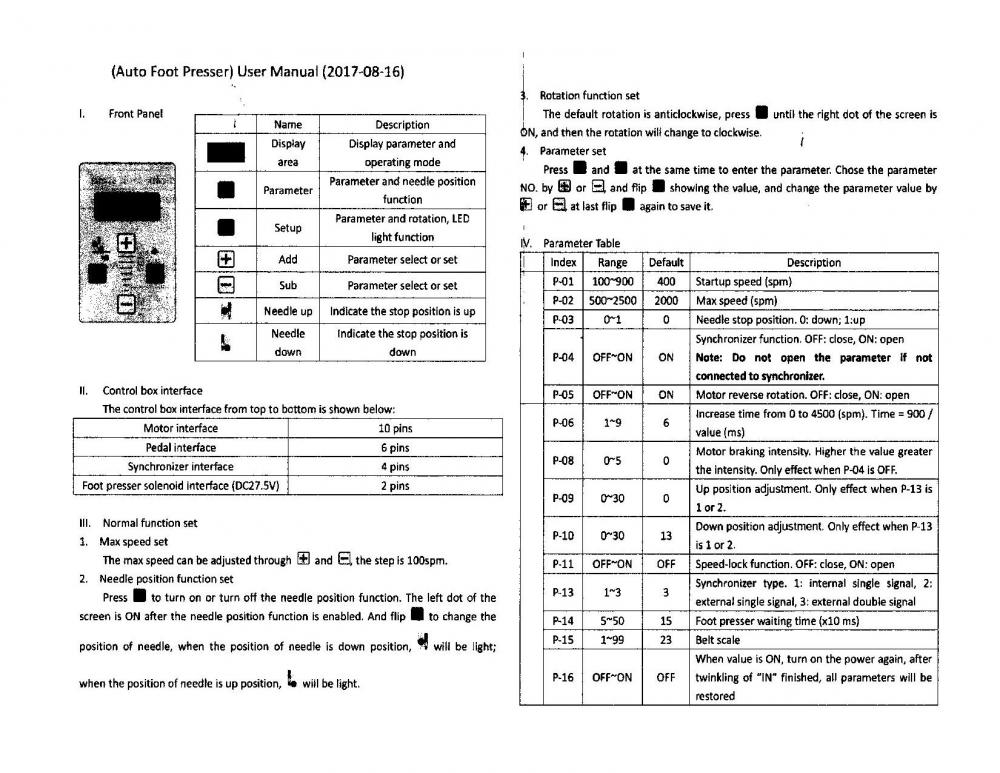

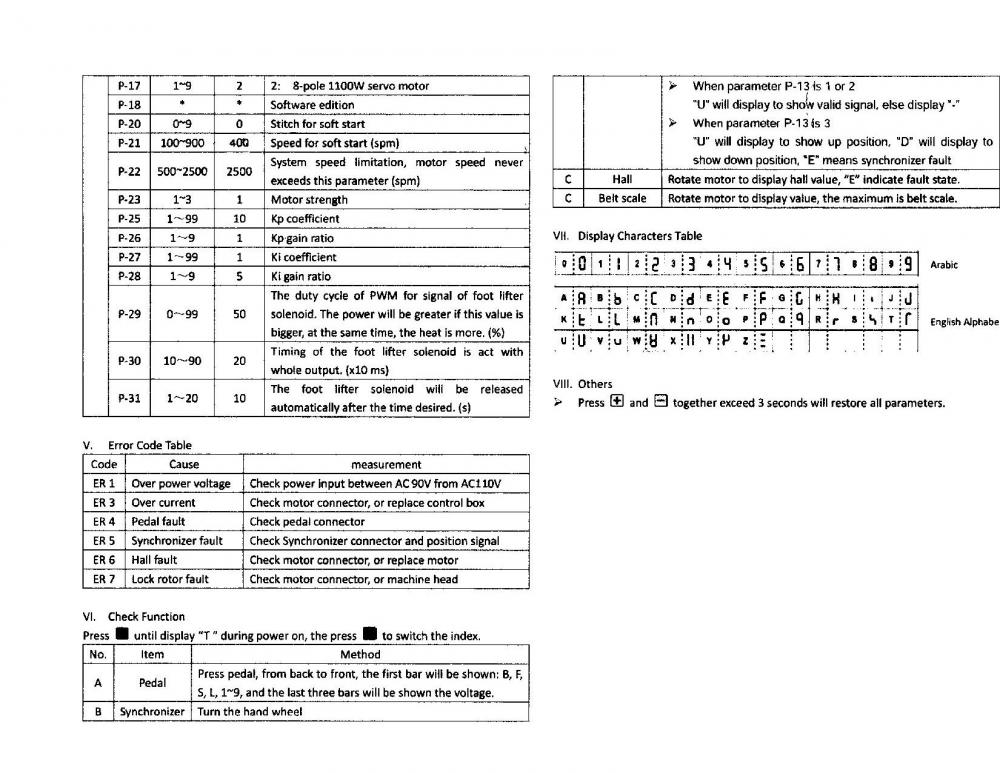

On my servo, the instructions show this in the parameter table: P-06: 1~9, default 6 "Increase time from 0 to 4500 (spm). Time = 900 / value (ms)" This is a soft-start adjustment. Which is to say it adds time to how it ramps up from 0 to max rpm. 900 divided by the entered value = milliseconds? So setting it to 9 equals 100 ms. Setting it to 1 equals 900 ms (almost one full second till it reaches full rpm) I can confirm this is correct. When set at "9" and I floor the pedal, it instantly goes full blast. When set to "1" and I floor it, it ramps up to full blast. Takes slightly less than a second. P-08: 0~5, default 0 "Motor braking intensity. Higher the value greater the intensity. Only effect when P-04 is OFF." I can confirm this is correct. With the positioner turned off, this function clamps down on the machine's rotation when set to "5". I can floor it and it stops immediately when I take my foot off. When set to "0" it drifts ever so slightly to a stop. I can imagine having this would be helpful if a heavy reducer wheel is installed, those things have some momentum. BTW - P-04 on my motor is the positioner function, which can also be toggled directly by the needle up/down button.

-

Keep the Rex. It will be good for binding, zippers, or other things you want to set and forget and not have to swap over on the Consew. It's a good little machine, kind of like a big brother version of the Sailrite mini walker. The Consew will take standard 111W style feet so you have about ..well, ALL the options for feet really. You can buy full sets of cheap feet on Ebay for whatever you want to do. 135x16 (leather) or 135x17 (fabric) needles. Get the best servo you can afford for it and you're golden.

-

Ok and just to make it all more complicated, I am looking at the DA 669 Eco. Dammit.

-

The Techsew 2600 actually sewed what I needed it to sew - thick binding with 92 thread. The synchro binder worked well. Not sure if it would handle 138 well. Maybe, but I didn't get that far with it. I returned it for other reasons, of which I won't speak of here, I am still waiting for this transaction to be resolved. In my experience Juki is conservative with their specs so I bet the genuine 246 would handle 138 with a little tweaking. It's still in my short list of machines if I can find a decent used one. New, it's too close in price to some other nice really machines. For the 1341 - you are looking at a custom solution or ordering their fixed binder attachment. The OEM synchro attachment kit is no longer an option.

-

Might be. The controller is different though I think, and that is where the magic happens. The one from Keystone is $75 cheaper too.

-

It is a large-to-small pulley reduction wheel. Typically made of iron. This is one of the ones I have: https://store.keysew.com/parts/sewing-parts/sr-2 Many (most) industrial sewing vendors sell them. It bolts under the table between the servo motor and the machine. You then have a two belt power transfer - one belt from the small pulley of the motor to the large pulley of the reducer, then one belt from the small pulley of the reducer to the pulley on the machine. This adds torque and slows the machine to a stitch-by-stitch crawl. Trade off is it adds complexity and can be tricky to set up, and can make tilting the head back a chore if you have to undo the belts.

-

Oh and the hook just soak it in sewing oil and scrub with a toothbrush or similar soft brush till clean, then rinse in more oil. Avoid solvents as they can stick around and reduce the effectiveness of any lubrication from the oil.

-

I cleaned up an old Juki with some Lysol hydrogen peroxide cleaner, a small nylon brush and some good microfiber towels. You have to scrub the gunk out of the "pores" of the textured paint. http://www.lysol.com/products/see-all-products/lysol-with-hydrogen-peroxide-multi-purpose-cleaner-citrus-sparkle-zest/ It came from a very, very dirty factory and by the time I was done it looked new. One of those 550w servos with no speed reducer is great for upholstery or garments, but it won't have much low speed torque, and it will need speed and momentum to penetrate anything substantial. A smaller pulley on the motor will help, but a reducer will make all the difference.

-

Hmmm... And I could easily step down to a small swing away on the 2810 if I needed to do any thinner binding with 69 thread or less. It's the bigger/thicker binding that I can't find a solution for. Hmmm... And I'd have a 205 for anything the upper limit of the 2810 could not manage. Hmmm...

-

I considered it. Plenty of umph but what is the lightest a 205 will go to realistically? There may be too wide a gap of what my 2810 can do and what that a 205 can do.

-

One more thing to watch - cheap bobbins. Sometimes they can be just slightly out of round or tweaked and they can bind up a bit in the bobbin case leading to inconsistent lower thread tension. Make sure the bobbin rotates free in the case and the tension on the thread is even.

-

Ok I'm stumped. The Techsew 2600 machine did not work out, it's on it's way back to them. I'm looking machine that can do synchronous binding with a bit more "umph" than an average small cylinder machine that make up most dedicated synchronous binder designs. (335, etc) Juki DSC-246 is a very good candidate but a new one is over $5k (if I can find it) and used ones are seemingly non-existent. There is a auto "-7" version on ebay but I don't really want or need trimmers and auto back-tacking etc. Also the -7 sacrifices some foot lift and a little capacity, and it would need a whole synchro kit added anyway. Juki has discontinued the add-on binder kit for the LS-1341. The binder kit for the LS-1342 might still be available but I can't find one of those machines, except for Penn Sew who have the auto -7 version, which does not accept the kit. (wtf Juki? sigh) I can get the new LS-2342, and they make a binder kit for it, but it would be over $7k delivered and take months. What I'm looking for is a cylinder arm machine that has a foot lift and max capacity somewhere similar to a Juki 1341, or 341, (16mm lift, 3/8" assemblies) that can "maybe" do synchronous binding, as I'll have some tight corners to do with both leather and heavy woven nylon bias tape. I am actually trying to use 1050 ballistic nylon cut on the bias as one binding option, and chrome tanned leather as another, (also marine fabrics as a third option) I've wrestled with this off and on for quite awhile on my flat bed machine and nothing is satisfactory. I've also been out of town most of the year so now I'm home for a bit I was hoping to hit the ground running and make some final prototypes of these bags I'm working on, but the sewing world is being difficult. Thoughts? Should I just go for a used Juki 341 and cobble a fixed binder plate to it with some scrap metal?

-

And if the main shaft got shifted, who knows what else is out of whack? Sounds like it would need to be at least partially disassembled, each connecting part inspected, replacement parts assessed, then reassembled and tuned. If you're not a pro sewing machine mechanic, I'd imagine it's going to cost a good chunk to get it up and running again, but maybe never as good as it was. Part it out on ebay?

-

All of these machines are clones based on the Juki LS-341 machine. (which is a pretty great machine) They can generally handle up to 138 thread, 207 possibly with some tweaking. The foot lift is 16mm (5/8") and they sew up to 3/8". That's it. The needle stroke pretty much maxes out here. If you read specs past that, they are blowing smoke. Aside from all this, pick the vendor you feel most comfortable with and read up on each vendor as much as you can. These are all clone machines produced in China with slightly different paint and table stands. What makes each of these machines good (or bad) is how the vendor assembles and tunes the machine prior to shipment.

-

People who use JB Weld on everything use JB Weld on EVERYTHING.

-

Artisan makes a "portable" 335 machine: I am going to stop by there soon, they moved to a new location in San Bruno south of SF, which is a little closer to me now. I'll take some pics. The 1100w positioner motor Keystone is selling would work great on many different versions of this kind of setup. With a big enough pulley on the machine, no reducer required.