katit

Members-

Posts

241 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by katit

-

Seiko STW-8B - question on servo with needle positioner

katit replied to katit's topic in Leather Sewing Machines

This becomes a "restoration" thread. I am not sure if I should start separate thread for this. I got piece of butcher block from my friend, he had 16ft board just laying in garage Got edges routes, glued pieces of wood. Today spent some time with router, all ready but will do cutout for belt and finishing after all pieces together and I can see it working. Routing wasn't bad, got it all done in less than hour. First I used forstner bits on corners and then just used clamped board as a guide. Tomorrow taking legs/parts for sand-blasting and going to order servo motor. I'm thinking this is going to be MY table and I will sell another machine. Not sure which one, but either this Seiko or my PFAFF 1245 will go. -

Yep. Thats what I did with my 9x20 HF lathe. VFD and motor. There is DYI out there how to do it and I got all controls for speed, on/off and reverse right on front of the lathe

-

Seiko STW-8B - question on servo with needle positioner

katit replied to katit's topic in Leather Sewing Machines

Looks like I will be getting this motor, but first things first - need to take care of table (get it restored). I asked buddy for some hardwood remnants but he actually had some maple butcher block and I got a nice 50x25 piece of a 1.5 inch thick block! Now I have question about hardware. Bottom part is easy, just some nuts. Are those correct?? 3/8: https://www.amazon.com/LQ-Industrial-Furniture-Connector-Assortment/dp/B076WKTGMV/ref=sr_1_2_sspa?ie=UTF8&qid=1545091511&sr=8-2-spons&keywords=wood+nuts+3%2F8+25mm&psc=1 Next - top hardware. Table I got had those round hinges, which seems like "old style" hinges. On my other machine I got new "Euro" hinges. Are those interchangeable? When I put Seiko into my new table it was sitting little high it seems? Ideally I'd like to get kit like attached adn have it all nice and new. -

Now that I think about it.. I just want working nice looking machine with durable finish. Not exact restoration. I need machine and table repainted/refinished. I have about quart of black and yellow John Deere paint with hardener. Those are tough paints and just sitting in my basement. Maybe paint all black and just some cover's/pedals/reverse with yellow. Will be cheap (free) and it will work.. All I need is to take it all apart, take parts to local sand blast place, pay $50-60 and then respray everything. Will not be labor-intensive and result should be good. No mess with sanding/grinding at home. Oh yes, I may need to spend $40 for DTM epoxy primer.

-

Ffloyd, primer is OK, I personally like epoxy. But what about paint? Something that matches factory? What did they use? I guess it’s urethane without clear coat. How do you achieve this “hammered” finish?

-

I did search. But didn't come up with any exact/solid info. Question is: What is good match for consew gray hammered finish? (or Seiko)? The only paint I found is this: https://www.ebay.com/itm/Beige-hammer-tone-paint-can-for-Juki-Pfaff/202530350416?_trksid=p2485497.m4902.l9144 But I'm sceptical about spray cans. Will it hold? What primer would you use? So, let's pretend machine is stripped to bare metal. What materials would be used for max protection/durability? Doesn't have to be spray cans. Is automotive paint strong enough? Or something else need to be used for this application? Clear coat?

-

Seiko STW-8B - question on servo with needle positioner

katit replied to katit's topic in Leather Sewing Machines

I kind of think that it's one of the things every man should do in life Rebuild sewing machine. -

Seiko STW-8B - question on servo with needle positioner

katit replied to katit's topic in Leather Sewing Machines

Never mind this! I think I know enough to be dangerous now. Uwe's videos on 111 machines have everything I need. If I find something that doesn't look the same I will post additional questions. I'm really tempted to take it apart completely and do sandblasting/repaint. -

Seiko STW-8B - question on servo with needle positioner

katit replied to katit's topic in Leather Sewing Machines

Yes, looks like this machine as far as main timing goes - 100% or really close to match. What about reverse? Can reverse be adjusted after everything else? I just wanted to make sure if I go through all the process I won't have to redo it for setting reverse correctly. Currently reverse lever knocking on machine body during sewing and reverse is pretty much sewing on one spot, definitely not "walking back" -

Seiko STW-8B - question on servo with needle positioner

katit replied to katit's topic in Leather Sewing Machines

Thanks! I got it (file is not working here but I found link): http://keysew.com/Webpages/DemoImages/USNavySinger111WConsew225REPAIR.pdf -

Seiko STW-8B - question on servo with needle positioner

katit replied to katit's topic in Leather Sewing Machines

I found videos. But can't find any service manuals. Any help? I know machine is the same as Consew 226R and Consew 226R user manual is all I have. -

Seiko STW-8B - question on servo with needle positioner

katit replied to katit's topic in Leather Sewing Machines

Don, I don't see any other damage so far. Machine was workhorse for sure, but it wasn't dry. I now see it as a project. I got it to sew without fraying thread but it still skips. I didn't do any adjustments yet and needle is some really oversized one for the threads. And bottom thread is mismatch. Anyway, I'm thinking I will replace feed dog and plate too, they look very worn and hole maybe another reason for fraying thread. So, at the end it may be $500-600 but with bunch of accessories, servo/positioner, some new parts and lot's of labor. I am kind of pleased to see that prices on stuff is like 1/3 of prices on my PFAFF parts/accessories. P.S. Any hints on winding bobbins without winder? I wonder if my PFAFF winder will work, but those bobbins don't have cutoffs.. -

Seiko STW-8B - question on servo with needle positioner

katit replied to katit's topic in Leather Sewing Machines

I got bobbins and needles ordered. I tried again after oiling, cleaning hook/shuttle, properly threading. Needle is too big, bottom thread is whatever I got from seller, but anyways. It's not working, I get 3-4 stitches and then thread get's frayed. Would you say I need to order new bottom plate and dog? Those look really worn. And what are those smooth feet should be good for? I'm thinking if I should get some extra feet's. All takes time, mine as well order all at the same time.. -

Seiko STW-8B - question on servo with needle positioner

katit replied to katit's topic in Leather Sewing Machines

Took stand apart. I think I will give it a shot. Like I thought an hour with grinder, some spray cans with paint, some new hardware and it will be good to go. So far 3 thing I'm potentially going to like about machine if I make it work: a. Pedal lift (seller said he got rear linkage parts hopefully will get them this week) should be better than knee lift and rear lever to raise feet much easier to operate, b. Reverse lever seem to be easier to use than one I got in PFAFF, c. Head is not as bulky as in PFAFF, looks easier to move work around it (like headrests) Matt, I got it all oiled. Ordered #19 needles Organ titanium 135x17. Going to order some bobbins. I do have bobbin cover, it's off on pictures but I got it. Front cover I have it too, I just need to get knurled bolt and drill out broken stud. What do you mean when you say PFAFF cannot do reverse? My plan A clean and make it sew, then plan B get it nicely restored (painted). Didn't find any parts lists yet. I will see how it works out and if all well I will be considering selling one machine. I don't and don't plan on doing any #69 sewing. 90% will be #92 and maybe sometimes 138 for topstitching. -

Seiko STW-8B - question on servo with needle positioner

katit replied to katit's topic in Leather Sewing Machines

@dikman I found manual, but there is not much beyond basic threading/oiling Here is table. First of all, should I bother with it? Steel looks very good comparing to newer table, thicker. How much new tables going for? I will definitely need new top as current one warped. And second, what is this other pedal with chain? I assume it's a foot lift, but where do I hook it up on machine??? If that's what it is - I already love it for the simple fact that I hate knee lift I got with my other machine (my knee is not really where it needs to be and no adjustments help) Basically, should I salvage anything here? I can see myself spending couple hours on disassembly, grinding and respraying. Not sure about top, probably going to buy ready one. -

Seiko STW-8B - question on servo with needle positioner

katit replied to katit's topic in Leather Sewing Machines

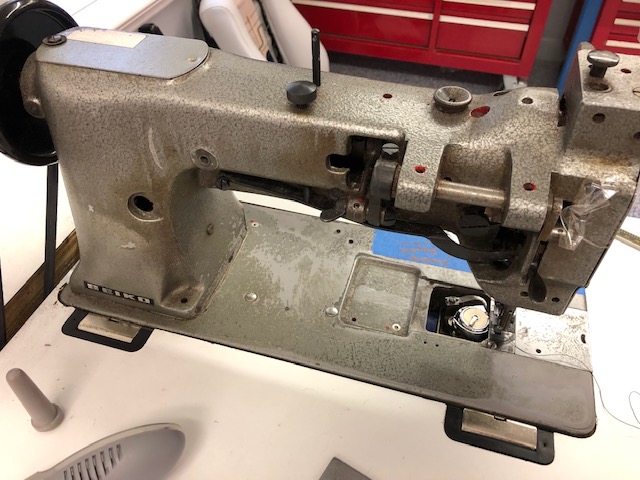

Looks like "positioner" debate should be left for later time. Not sure what I got myself into. I brought machine home. Bought it for $200 from retired upholstered. We met on a parking lot (was a far drive). I asked to show that it sews and we did couple of stitches by turning wheel. Everything moves smoothly. Now I brought it home and realized couple things: 1. I should have left table with a seller. It's rusty on a bottom, top is bent, clutch motor. AND my table from PFAFF 1245 perfectly fits this machine (I wish I knew). But U-shaped legs look very sturdy (OLD). Maybe it's worth restoring? Basic grind/respray? 2. Machine is filthy. NO rust which is great, not dried up, but just filthy everywhere, needs a good cleaning. Good part of paint remains, stickers, etc all there. 3. Everything seem to move smoothly, there is no play in needle bar or anywhere. Seller claims new rotary hook was installed. It does look new. However, seller also says "cleaned, serviced" and it doesn't look that way. I tried to sew on it - does not work. Skips stitches. Now to the questions. 1. Does anybody have good links to manuals, videos? What type needle? I found good video from Uwe on timing the hook. 2. See picture with timing belt gear. There is epoxy on it? What was fixed? 3. Front cover bolt broken (cover was taped in). What thread size there? 4. When machine sews reverse lever knocks on a body. Issue? 5. I tried adjusting stitch length but reverse always seem to be 0 or so. Almost no move in reverse. 6. Something missing on a back? I see hole and I see threaded hole. 7. How does it look to you overall? Did I get myself $200 door stop? It seems that I need to start from basics. Get some #19 needles, metal bobbins. Then clean everything top to bottom. Lube/Grease and do all adjustments from A to Z. Right now I noticed hook touches needle. -

Thanks! Just one more question. I though Size 19 is smallest for 92 thread? Why you said 18?

-

Seiko STW-8B - question on servo with needle positioner

katit replied to katit's topic in Leather Sewing Machines

With my Pfaff 1245 I have servo and smaller 45mm pulley. It is slow but I have to manually crank up or down every single time it seems. And I can go faster in general in what I do (car upholstery) so it feels like this is very good frature. But I do need a way to easily control if it’s going to be needle up or down. Is there a name for this specific feature? -

Seems like there is some kind of virus, after you get one machine you need another So, machine in question came up for sale locally (finally). It's the same as 226R (thanks to this forum). For the price I think it's great even though smaller bobbin which is not a big deal for me as I see it now. But it has reverse which IS a good feature to have. It will have clutch and I am immediately thinking about slowing down and going servo. I started to check ebay and they have motors with positioner at about $150. I think this needle positioner is a bomb for what I do. I always deal with this when sewing. Either raise needle to take work off or keep it lowered to make turns. If it works as I think it does - I'm not even going to be concerned about speed per se. If I can jerk pedal and cause one full stitch that is all I really need. Or something close to that. And then there is a button to control either it works with needle up or needle down for 2 modes. Does it work just like I described? Do all of them work for up or down (with button switch)? Any specific issues/problems with equipping this machine with positioner? P.S. Machine needs some TLC but it works and I got some experience with machines now

-

Glenn, Not sure if that's what you mean, but when I try to lift that spring up with a finger I feel like there is a notch. Almost like slight "click" at beginning of movement. Does it have to lift up smoothly and if so, what should I do? I don't want to just take it out because there seem to be another adjustment? OTOH - I got smaller (120/19) needles today and tried some seams. I think they look good. Most right is LR and others LL. Most left is when I got tension dialed in correctly. They look good to me. Bottom awful of course. What would you use one vs another (LL vs LR)? In my mind (for upholstery) I would use LL for plain seams and maybe use LR for top(visible) seams.

-

Glenn, How do I adjust take up spring? Is that know next to top tension? Should I make it tighter?

-

Too late I mean too late I placed order yesterday with threadsexchange. Ordered LL and LR needlses in size 120 (this one on pic is 125 LR) I have 130R - not much difference. I'm blaming thread too, gray and black way too different. Main thing you guys see a problem too, so it's not normal.

-

Now, this gray is different thread. #92 from thread exchange. Seems like it lays better, but holes even bigger? Black thread almost feels "stiff" when I pull it through tensioner it's like "grinding" comparing to gray one. Do you think it's OK and I should just leave it as is? I want to achieve this "puff" effect. Not sure how it called, like thread jams into the leather with stitches going in more radiused. Or maybe this leather I got too dry? This is automotive leather.

-

Back with the same problem. I don't like thread appearance. Does it look OK or I'm thinking too much? In this particular case it's Organ 125/20 LR. Smallest I have. Thread is #92 black from Tandy's. I don't like how leather get's cut on a bottom and it's too much of a cut on a top, no? Left piece -4 layers, right piece - 2 layers. On 2 layers knot sometimes on top, sometimes on bottom. No consistency.

-

Thanks! Seems like this problem fixed also I'm not sure what it was. I use polyester thread from thread exchange (gray one) #92. It leaves some kind of white "wax" on parts. Between tension disks there was some of this wax, but nothing else. Not thread, etc. Pretty clean. I left machine threaded as is and it started to sew properly without an issue. Weird if it was this piece of wax.. P.S. Now I'm back to my problem with stitch appearance, will post in topic I created before..