katit

Members-

Posts

241 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by katit

-

Difference between using a Larger Pulley vs. Speed reducer?

katit replied to tofu's topic in Leather Sewing Machines

Your reducer looks approximately ~ 1:6. To do same with 2 pulleys (top and bottom) you roughly need: a. Bottom pulley 75 -> 45mm so it's about .8 reduction b. In order to achieve same reduction as you have with a box you need to reduce by additional x5.2 on top. So, it means from about 6in pulley to 30in in diameter. This is what would it take to achieve same reduction/torque which is not possible because you don't have 15 inches from top shaft to your table. -

Browsing various online stores, eBay, etc. I didn't find any cross-references. I think they put 3/8 thickness for 206RB and 11mm for PFAFF (which is slightly bigger). Just by holding them they look almost identical. Also, 206RB bobbins always have holes (or it's very common). PFAFF bobbins almost always solid.

-

On iPhone emailing pics with "Medium" size works best for this forum. This is very annoying though. And sometimes you want to post larger image with more details, size "Large" works but only 1 or 2 pics can be attached.

-

1. Cleaned with compressed air. There was only dust, no crud.. 2. Replaced lube in gearboxes with synthetic grease on top and bottom. 3. Oiled everything throughout, soaked it literally. I have pan, so it's no big deal. All wicks were dry. Took needle plate off, started to see what is hitting. Hook was hitting needle. Ok, took out needle and it was wrong needle! Seller said needle were broken, so maybe it was an attempt to "fix" broken needle. I can tell because tiny bolt which holds thread guard on needle bar was missing.. Anyway, after inserting new titanium needle all started to look normal, at least to my eye. I did not go through any adjustments, it just looked like hook arriving to needle just right. So I threaded it and it just works!!! Question. Bobbins I just received for 206RB (with holes) look pretty much identical as my PFAFF 1245 bobbins. Are they the same by chance? And Now I really have hard time deciding if PFAFF is better. To me they both very smooth but this Consew is like brand new.. And I kind of like side load bobbin, it is first time I work with it and it was really easy to load bobbin. Should I still hold onto 2 threads when starting? I've seen some videos when guys use 206rb without paying any attention where thread is...

-

Is there standard for twin needle machines?

katit replied to katit's topic in Leather Sewing Machines

I think adjustment can be made from a top, see picture. But no "user" adjustment. It should be (by manual) on a pulley but it's not. Needle system on sticker also doesn't match what's in a book. I will remove needle and see if it's 135x17 as I got those. Would be nice if it's in fact 135x17. I want to make seams like on a picture. 3D for car upholstery. Those are decorative without any tape usually. And need to be less than 3/8.. -

Is there standard for twin needle machines?

katit replied to katit's topic in Leather Sewing Machines

Picked up machine. Well, it's not exactly as in manual, guess this is where "SV" is? First of all sticker says 135x17-20 needle, so it's "regular" one.. Stitch size adjustment not on pulley as in manual. Also see custom needle plate customization - like a ramp brazed on. And a walking (vibrating feet) look unusual. And it's 1/2 gauge Too much for me, will be looking for 3/8 or smaller one. And it's VERY VERY heavy... -

Difference between using a Larger Pulley vs. Speed reducer?

katit replied to tofu's topic in Leather Sewing Machines

Reason is that they do lot more reduction in compact package. Yes, it doesn't seem so because "box and pulleys" but it's under table out of sight. To achieve the same reduction very big pulley needed and convenience for operator reduced (turning large wheel by hand) It's easy math to calculate reduction, but box used for compactness, nothing else. Also, keep in mind, those reducers were sold long ago(?) along with clutch motors. Today I don't think you need to buy expensive reducer box, I'd rather spend money on good servo motor. How slow do you need to go? Motor I got from @Gregg From Keystone Sewing starts very slow and I can do 1 stitch with light tap on pedal (with needle positioner) -

Difference between using a Larger Pulley vs. Speed reducer?

katit replied to tofu's topic in Leather Sewing Machines

There is no difference if you can achieve needed ratio using smaller pulley at motor and larger on machine. -

Is there standard for twin needle machines?

katit replied to katit's topic in Leather Sewing Machines

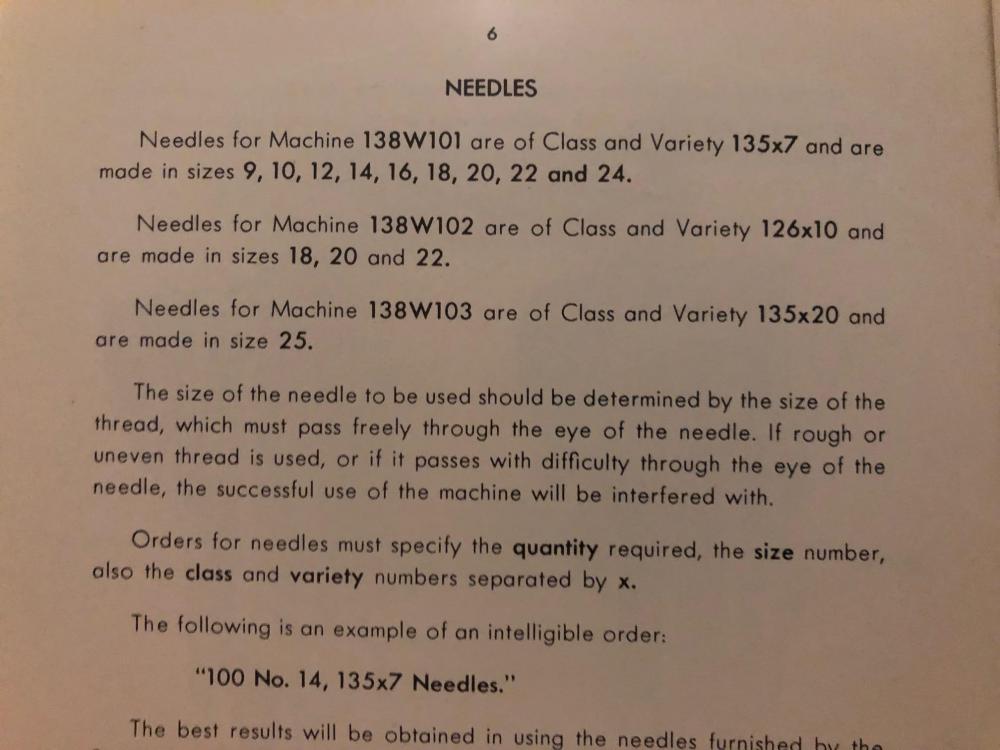

I got my answer. 103 is definitely heavy duty and not what I need. Judging by needle size 102 is just perfect for upholstery. Need to figure out where to get 126x10 needles.. -

Is there standard for twin needle machines?

katit replied to katit's topic in Leather Sewing Machines

Purchased manual before machine. Anyway, not sure what it means. 102 is not for heavy thread? What is heavy in w103 would mean? I don’t need more than 138 on top... -

$3-4 shipped from China. Just ordered one yesterday. But I guess it's part of fun to DIY I do lot's of things that don't make any financial sense..

-

I think I'm good now. I ordered 1 part I was missing..

-

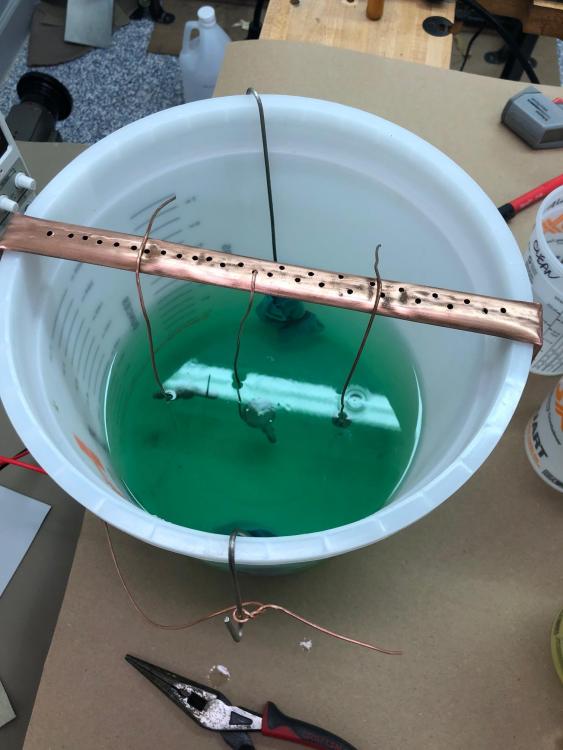

Nickel plating is a failure so far. I don't get even plating on parts. Corners/etc get plated and then it burns. And it's very slow. If someone got experience/knowledge please chime in. My current understanding is that I need to copper-plate first in order for nickel plating to "stick". Metal used for parts is not very friendly.

-

I will do some cleaning and lube first, then I’m going to go through all adjustments per book/video. Won’t even try to make a quick fix.

-

Yes, I first asked what model but then I just told the guy to tell me where to go to pick it up, worst case my guess would be wrong and I wouldn't take it... Had to work on his schedule.. He said there was 8 more people interested..

-

Yep. 91. But manual I found dates back to 78. So it's not even 30 year old yet Got needles, bobbins and motor on order. I think for the price machine deserves all of it. Yes, I'm going to replace grease and oil everything, will go over whole machine.. Sounds like machine wasn't used for business, just for hobby.

-

I just know they make 206RB-5 now. So, this one got to be pretty old. Maybe someone chimes in with more details on when they started to make those? Looks like new, but I would think at least 30+ years old?

-

I need to remove CraigsList search for "walking foot" from my phone. I just got down to one machine and this one came up without model number. But pictures revealed it looks like 206RB and price was $250. I couldn't resist and sure it was 206RB. Now I think that might be my main machine. Its basically new stored in perfect conditions. All original paint, no rust no scratches, no bolts touched. Needle hits shuttle but I'm sure that is a simple adjustment. Seller's grandma used it for quilts and such. No heavy vinyl or leather from what I understand.. They said the only thing it wouldn't sew is "thick leather". Table is in perfect condition as well, but of course got clutch motor (easy fix)

-

Thread stuck to bobbin when pull out the work

katit replied to Orrrmygod's topic in Leather Sewing Machines

-

Is there standard for twin needle machines?

katit replied to katit's topic in Leather Sewing Machines

Glenn, Thanks for feedback! It does look like 3/8 spacing but I didn't see it better. Also I measured spacing in car(s) seats that I like and it's 7-8mm which is slightly less. I'm pretty sure machine works, but there will be no way to test it. It turns, it's even threaded. But years and years of grime. No rust though from what I can tell. From what I know it was taken off the factory all working. So, SV (special version) can mean anything I guess? I only see top of the post rounded and I guess this part is special. What kind of other "special" stuff they did? I am guessing I can get it for 100-200 as is. Wanted to make sure I can get little more after it's cleaned/adjusted and working if I decide to get rid of it. Adding larger pic of the post.. -

Some progress. All parts to be painted already stripped/cleaned and mostly primed. I use rustoleum bare metal primer, I think it's got acid for etching and my experience with it great so far. All rusty parts is actually acid cleaned, next I will do final degrease/acid and nickel plating. Overall it's a progress. Worst/hardest part is over. Inside of a main body was a PITA to clean. Piecing back clean/new parts should be easy/fun. The only thing is that from a factory it was painted after partial assembly. I may need to do the same because assembly happens metal to metal. I am going to prime top parts of a skiver lightly to prevent rust and then do partial assembly. Final paint will be with Valspar paint mixed with hardener and sprayed. This color should be pretty good match. I used this paint before and it dries very hard, has good gloss and very hardy. I may need to do some bondo on top/front of machine. There was about 1/16-1/32 from a factory to make it smooth/flat. https://www.amazon.com/gp/product/B000LNV5UU/ref=ppx_yo_dt_b_asin_title_o02_s00?ie=UTF8&psc=1

-

Is there standard for twin needle machines?

katit replied to katit's topic in Leather Sewing Machines

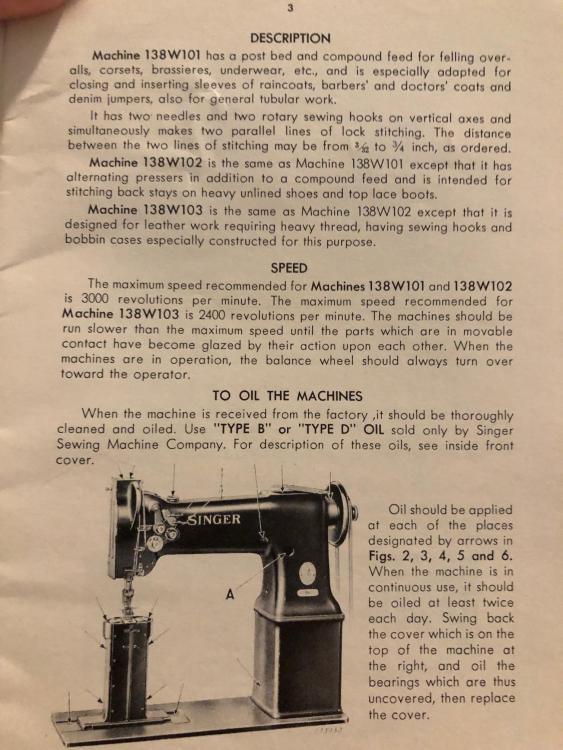

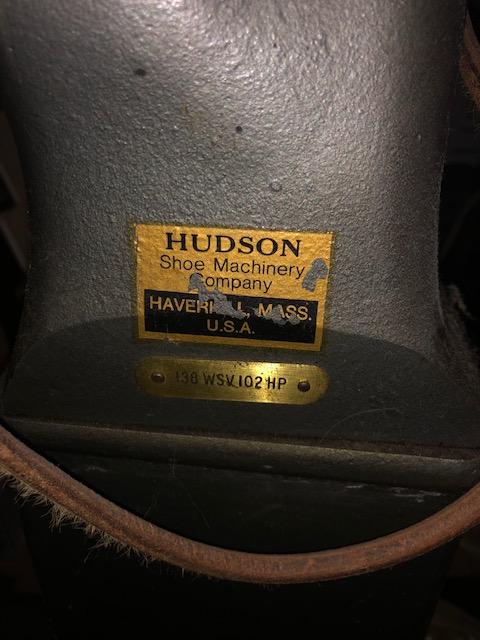

I think machine #1 is walking foot, second picture shows it.. and it’s correct gauge. Do you know what WSV in a middle means? HP at the end looks like “high post” Do you have any idea what is a good price for such machine will be? thanks a lot for all the info!! I really appreciate it -

Is there standard for twin needle machines?

katit replied to katit's topic in Leather Sewing Machines

Stopped by and checked those machines in person. My bad, they looked like walking foot but they are not? 1. Machine with laaarge post is 138WSV102HP. Seem to be complete and gauge looks right at ~1/3. This one also does look like walking foot. 2. Machine with smaller post is 138W101 3. Machine with single needle all complete/working 17-30 #1-2 is of interest to sew French seams in out of shape places, etc. Seems like machines of the same breed, however feet's look different and they are not walking foot. #3 is interesting because I can really get into any places I want with it. What is stich size and thickness capabilities? Is that a great machine? Guy used to be shoemaker and he really likes machine. Question is: What are those machines capabilities? I need to do about 6-8oz at most (2-3 layers of upholstery leather). Will they do it without walking foot? They look heavy duty but without walking foot, strange? Another question: Will I be able to get parts for those machines? Like gauge sets? Seconds machine does not have bobbin cover and hook, but those are standard.. Last question: Pretending they all were working when taken out of production and just covered in old dust/grime, what is fair/cheap market value? I want to make sure I can sell it quickly after I'm done. -

Is there standard for twin needle machines?

katit replied to katit's topic in Leather Sewing Machines

I barely remember how it looks, but it didn’t seem like posts were separate visually. It was just one wider post I hope someone experienced with those machines can chime in -

Is there standard for twin needle machines?

katit replied to katit's topic in Leather Sewing Machines

I didn’t pick it up yet. It is Singer, black. Looks exactly as 168w101 walking foot post bed but 2 needle. I don’t know model number but I guess it’s from the same time. It’s the same seller who I got 168w101 from