katit

Members-

Posts

241 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Everything posted by katit

-

Thanks! When you say "need some back pressure". How do I achieve that? I can see that the way it's threaded now - 3 holes missed. You see right there on a picture it's only in one hole. And above there is a rod on top with 4 holes, only 2 used. I used instructions I found to thread machine. Maybe for leather I need to put thread through all of those?

-

Need some advice on what to look for. I was practicing with vinyl (automotive) and machine didn't give me any single issue. 10 layers? No problem. fast, slow - no problem. I finally decided to start practicing with real stuff, leather. Got 2 hides of eBay ($50 shipped!!!) - strictly for practicing, cheap enough but real stuff. Anyway. Started doing some seams and I hear "pop" sound and bottom thread goes in loops (see pic below). Then I realized that thread coming off the tensioner (see picture). It should stay between 2 plates but it just pops out for some reason. I should say that I did increase tension about 1 turn on top when switched to leather. However, just to check - I took some vinyl and did bunch of sewing - not problem. Switched to 2 layers of this leather - within 5 inches I hear "pop" and thread comes off. Any pointers on what I should look for?

-

I thought it's just me. If I go slow - all is good. If I want to go faster - my eyes focus on a needle and I stop seeing whole thing :0

-

Steve, I have same motor on my Pfaff 1245. With original 75mm pulley it was little too fast for me. With 45mm pulley it is much better. Keep in mind I'm learning too, so it may not be a problem to someone with experience. To me - this one change is good enough, but I'm working on upholstery stuff. For small items like you mentioned I would probably think about reducer, but again, I think this is 95% experience and 5% motor reducer

-

Tom, Thanks a lot for explanations! #1 - I did practice but need to work on it. Not always getting through the same hole result. #2 - Didn't practice yet, but I didn't realize that reverese lever can be used for that, all videos I've seen involved pressure release and material movement. #3 - I will practice more. Yesterday I tried to increase tension on both top/bottom and started to get a lot of tangles on a bottom. Took me awhile to figure out. What happened was that top thread got out of tensioner and was on a tensioner spool but not between plates. And even with releaved pressure it wasn't getting in. Good expirience I guess! #4 - See picture. I think it makes less dust now. It is straight, it does deflect about 1 inch. Completely inside pulley on bottom pulley, top pulley see pic, about even.

-

I wish we had those choices here in St Louis NONE since July.

-

Got it! Makes sense, then my theory not good and I need to setup tension whenever I deal with different materials...

-

Got it. Another question about needle I just thought about.. What is signs of "dull" needle? When you change needle, do you keep it or get rid of it? I read somewhere to get rid of old needles and not mix with new. Especially that sizes is almost impossible to read.. I'm most likely going to change from 19/20 to 22 when doing french seams and vice versa Q2: Does tension work the same for all materials? For example, I did 2 layers of vinyl, looks good. I did 3 layers of leather and had to make adjustment to top tension. To me it looks like vinyl looked good because it's thin/soft and I didn't notice difference. With thicker leather thread tension misadjustment became more visible. It almost seems like I need to adjust thread tension on thicker/tougher material and then it will be good for thinner stuff. Am I correct or it's wrong?

-

Understood. Then I just do what I did? Eyeball position? I was thinking there is some trick on installing needle "precisely". Or maybe turning it right/left slightly will affect something.

-

Forgot to ask simple question. Maybe I'm missing something. In my machine needle shank is just round. I can install it pretty much any way I want. What I was doing is using needle threader to get it where hole is inline with main shaft. But obviously it's not 100%. I would expect needles to be ground on left side for the screw but they aren't. How do you install them?

-

Finally installed 45mm pulley on a bottom (smaller belt needed, OReilly didn't have right size, had to get online). So, for less that $20 I got machine slow the way I need. For material thickness I will use it's enough to penetrate, motor setting is about 950RPM, this gives me good control and can go decently fast when pushed. Also tried guide foot. nice even seam, not bad for newbie Have couple more questions: 1. When locking seam with reverse, what is the correct procedure? Specifically items I'm curious about: - Should I start sewing and then reverse? Which means I will get 3 stiches through the hole. Or should I start backwards and then go in? - When I reverse a lot of time I don't get holes aligned, sometimes I have missed stitch. I think it' because of the timing. When should I back-stitch? Needle up? Down? 2. When I need to make shorter stitch, how should I do it? For example, I need 1/2 stitch, what is correct steps to do it? 3. When sewing french seam (like on picture), what needs to be done so there is no visible thread inside? You see on start/end some vinyl, this is where backstitching was done 4. I see some belt black "dust" on sewing table. Is that normal for new belt or my tension might be little too tight?

-

I tried #20 LR and #19R. No visible difference on top stitch, with LR I get straight stitch on a bottom. Top definitely tighter, smaller hole.

-

What makes leather good automotive upholstery leather?

katit replied to katit's topic in All About Leather

Yes, St Louis, MO. Places I found that sell original german BMW leather sent me samples - very soft I would say. Leather I pulled from seats very hard but from age, don't know what it was back then. -

What makes leather good automotive upholstery leather?

katit replied to katit's topic in All About Leather

It's for 94 BMW 5 series. And it's St Louis. Get's pretty hot. Car tinted now, should have less UV impact. -

What makes leather good automotive upholstery leather?

katit replied to katit's topic in All About Leather

Well, I do have exact task: Reupholster car seats. In reality I don't think I will drive more than 50k miles in this car. But I do want leather to last 10 years even if parked in sun. I also want leather to feel and look nice. I did see nice upholstery hides at Tandys, but not sure if "upholstery" is the same as "automotive". -

So, for what I have it's normal? I am new to this, don't even know what "proper" look should be. When you say "tighter" - isn't it a function of tightening bottom (and, in turn, top) ? Right now bottom have some resistance and top is close to maxing out on loosening. I ordered Schmetz #19 standard (R) and Organ #20 LR

-

After posting pictures I noticed that it looks like not enough tension on top (judging by blue vinyl bottom) So, I did another run inside after adjusting little (tighten top). Still little loose. I did yet another adjustment and did inner most run. Now it looks like vinyl is perfect. But leather looks horrible on a bottom.

-

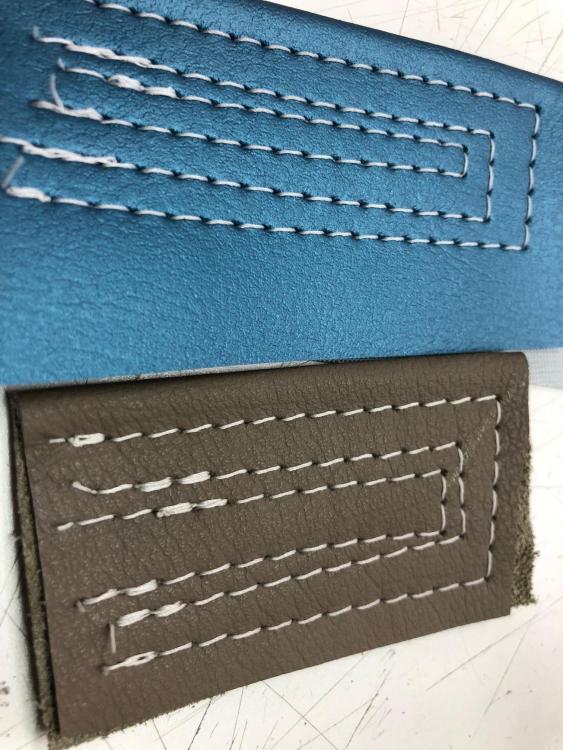

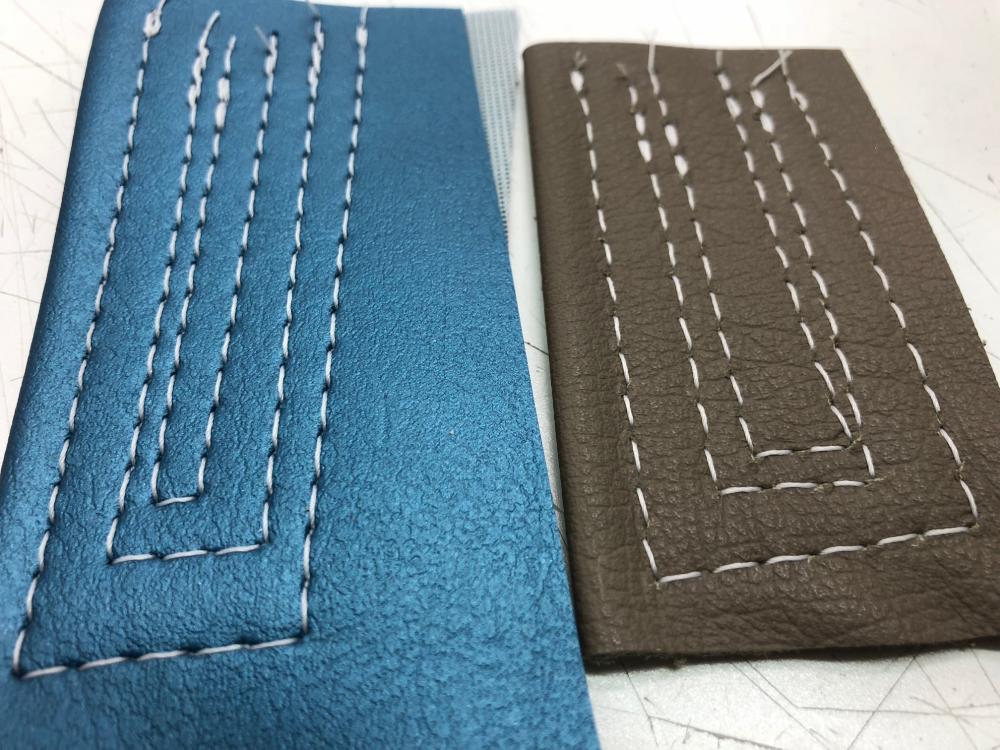

That makes sense, thank you! I ordered some Schmetz #19 and Organ #20 needles, will see how it works. But for now the best I was able to do is here... See top image - both vinyl and leather look decent. However, bottoms on vinyl look OK and leather look ugly. Is that a problem with oversized needle or something else? Also, in theory doesn't matter what material thickness if you setup tension correctly for thread/needle - it should work, right? I'm asking because now I'm setting it with 2 layers of vinyl/leather. But my actual sewing will involve layers of sew foam in-between.

-

Interesting. This is how I was shown in a store to thread (not around a pin). Then I found video and "fixed" it. Another mistake I found is bobbin direction. I put it on with thread "clock-wise" which seemed natural to me how thread will exit. Changed that now too. Hm. I read a lot of different auto-upholster forums and that's what people use. 92 with 22 needle. Or 138 with same needle if decorative seam needed.. That's what I was given with machine..

-

Need some advice/guidance on thread tension setup in my machine. Here is what happening now. I use 92 thread with 22 needle, works great. I used following video to thread machine: https://www.youtube.com/watch?v=35zxtSRFXwQ Next I try to set bottom tension to be not so tight. I didn't know how it should be but I thought it should be just little tight. Just like this video shows https://www.youtube.com/watch?v=41R2Og1AELE Well, it doesn't work. If I do this - then bottom thread get's pulled up and I run out of adjustment on top thread (nut come off). I had to barely put top adjustment on and then tighten bottom until I got good seam. Now bottom thread is not as easy to pull as on a video. When I finish a seam, raise needle and need to pull work - there is considerable resistance. Is that normal or I should do something about? Or it's OK because I'm approaching thread size limit of machine? Seam itself seem to be good, no wrinkling, tight. P.S. I think it's important to know that thread is "Tandy" brand polyester. I'm still waiting on my package from thread exchange

-

Thanks! I eventually got machine from Nick. He brought this Pfaff to local store and the deal was pretty good. All this time (since July) I monitored local CL and nothing showed up... STL is like a "black hole" So. 1. Extra part removed, much easier to deal with machine now! 2. Hook cleaned up. Took it out as per instructions, used brake clean then immediate oil everything and then wipe. Now I know where to put oil when changing bobbing (little hole and wick between tiny bolts). It seems like it's sewing better now (placebo most likely ) 3. Guide foot ordered. Looking forward to nice French seams.

-

Yep. It is brake. Sligtly pressing on pedal removes tension. did my first project- machine cover. Almost got used to speed control. Thinking that 45mm pulley might solve issue Will try soaking wiyh rubbing alcohol. Tried simple green - no luck

-

Yep. I can do that. Problem with missing belt cover will be solved automatically as I will have to take other one out as well

-

Ok, I see. And it’s pretty expensive. I will see what 75->45mm pulley will do. Maybe practice and exchange will fix it for me

-

Can you point me to speed reducer? Can’t find what it is thank you!