-

Posts

146 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Newfman

-

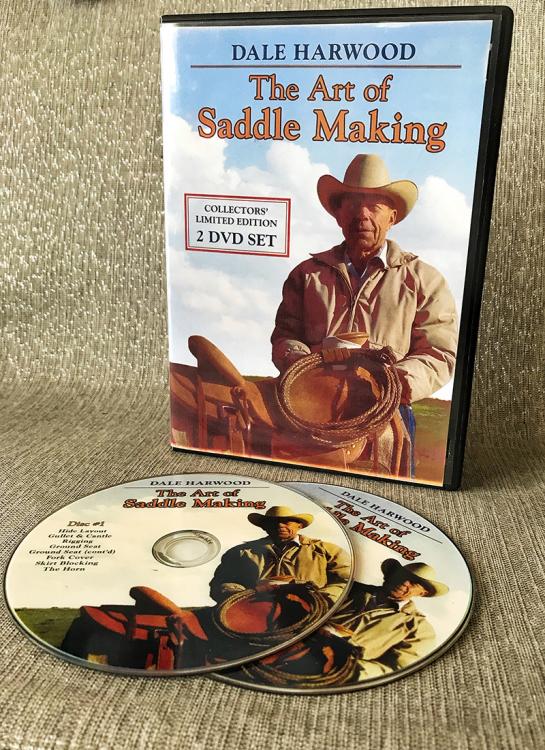

THese aren't so easy to come by these days, so I thought I'd give a last minute heads up. https://www.ebay.com/itm/Dale-Harwood-Saddle-Making-DVD-2-Disc-set/183204673767?hash=item2aa7d978e7:g:A8EAAOSwQ~ha6KTy

-

Hello Bob! Thank you for the warm welcome back. I completely understand the sentiment about 'pics not doing justice'. There is so much hard work, craftsmanship, and artistry that goes into making these cowboy trappings that it is a shame that everyone doesn't have the resources to show their works in the best 'light' possible. I hope that I can at least help some of the craftsmen in my new home region. Saddles may be a bit unwieldy to ship for images for most makers, but smaller items can ship without a problem. It adds to the overall cost, but if you are just wanting a handful of examples for your website, it may ultimately be cost effective. If you have a good commercial product photographer in your area, it could be a good business move to work something out with them for your images. Rambles to the community.... There is a big trend to shoot everything on black, or clip the product and drop it on a black background. There is a richness to leather and black when you put them together, but they also tend to look very flat because the product is sucked into the blackness of negative space. Beautiful saddles look like they have been sliced from horn through the jockey laces like they are some sort of weird half-saddle. Most saddles come with two stirrup leathers and stirrups, but in those images, you see just one. I realize the off side stirrup isn't pretty on the backside, but it is still part of the saddle. Good lighting will downplay the lack of tooling, but will still give your saddle a more three-dimensional look. The other thing I have noticed is the image files are so small that, as a prospective buyer, you can't get a close-up view of the detail. I have to wonder just how many times people have felt compelled to run their fingertips across the toolings of fine leather when they see it in person. Like, pretty much everyone. With photos, you can't do that of course, but people still want to really get a sense of the workmanship. The potential buyers that get an emotional reaction to viewing your work are the ones that will buy from you more readily. No matter who is photographing your work, you should put files up that are at least 1500 pixels across on the long edge, so that people can bring it up full screen on their monitors and really feel like they are as close to being in the room with your leather work as possible. Hig quality close-ups of detail with good lighting is also important because they get to see the fine nuances of your workmanship, which they are not normally privy to if you live far away. On my website, I upload as large an image as I can, limited by the website software. Am I afraid someone will steal my images? Yes, to some extent. Hey, if you love Cannolis so much that you want to steal the image from my website and use it as a background on your computer, knock yourself out! I'd be honored. Even more so if you appreciated me with the photo credits. Of course, should you try to sell it as your own, to a company for advertising, it is going to cost you a lot of money in back licensing fees and attorney's But, there is nothing worse to me when I think I am interested in a product to purchase and I click on it to make it bigger and it moves to a new page, but is the same darn tiny size it originally was! Makes me wonder what they are hiding. So, there are some rambling thoughts for ya! Now if I can figure out how to get notices of comments to threads...

- 2 replies

-

- photso

- photography

-

(and 2 more)

Tagged with:

-

Hey Folks, Been a very long time since I have posted anything. Years ago I was very interested in making saddles and learning the trade. I ended up getting very busy in the career field I left years ago, and found myself back in. Commercial Photography. I had my business in Maine and just shut my studio down and have since moved to Denton Texas, just nort of Dallas and Fort Worth. My goal is to expand my business to include equine photography for ads and promos. (not a show photographer) But, I still do studio work. SO, if any of you saddle, tack or makers of other fine cowboy trappings need professional images of your products for web or catalog, give me a shout and lets see if we can put something together for you. Feel free to look at some of my various projects at my website wwwDManske.com I am sure there are craftsmen and women in the area that could use some good images for their business. My contact info is on my website. Glad to See Leatherworker is still going strong! Best regards, Dennis Manske

- 2 replies

-

- photso

- photography

-

(and 2 more)

Tagged with:

-

That's an interesting point George. People that know me, often comment that what little I have is usually of the highest quality. I will go years without, before buying something cheap. It isn't always avoidable, but it is more the case than not by far. The down side is that my high quality things make me look like a snob or I have a lot of money. I don't and I am not. It just takes a lot of restraint to wait and save to buy the best or high quality. It takes even longer if you are spending money on cheap crap in the mean time.

-

I hope the horse fared better than the saddle. Of course you felt an obligation to repair the saddle in that situation. I get it. That being said, that looked like a pretty durn nice repair job. No doubt you are right, stronger than the original. I wouldn't ride in it, but that is a good looking repair. I hope that comes out on your computer, the way it sounds in my head. More simply. . . nice job. Dennis

-

Weird, I was thinking the same thing and then I read Terry's post and it was like, whoa, i already said that, only. . .I didn't. Weird. Just havin' a moment. Really though, Flashy is nice but sometimes simple and clean is just right. Really nice. Plus, you made it. how cool is that?!?! Dennis

-

Who Is Selling Night Latches?

Newfman replied to Bo Hemian's topic in Saddle and Tack Accessory Items

I use a dog collar. I guess I should upgrade. -

That's um. . .geez. . .um. . .Nope, still speechless.

-

I'll have to get back to you. Presently. . .I'm gobsmacked.

-

StandardBred racers have Pacers and Trotters. The off track Pacers usually have to be retrained to trot to find homes for them. The raceorse owner/trainers isn't going to bother. They just dump them. Go figure. You can cover a lot of ground, real fast on a pacer, and he isn't likely to break gate. Pretty smooth as Sylvia posts. Now there is a horse that needs to be fitted for a saddle. They have Lonnngggg backs, tend a little towards mutton withers and broader backs. Really nice horses to rescue off the track if you want a good, but inexpensive horse. You'll also have to get his feet back under him. Many track farriers seem to have forgotten anatomy.

-

Both posted the same thing at 11:10. Pretty funny. What are the odds on that?!

-

I found this: http://www.saddlemakersshopmanual.info/Order_Now.html Hope it helps. Dennis

-

For a better evaluation of your situation, you may want to post pictures of your own saddle. An over-all photo, and then set your camera to close-up (macro or the 'flower' symbol if so equipped) and get some good close-ups of the stain. Like from a few inches away. Blurry out of focus photos won't help, so keep shooting as close as you can until you get good, clean, sharp photos and then post them here. Confuseus say, A bird in the hand is easier to identify, than the one hiding in the bush. Thats's not really how that goes. . .is it?!?!?

-

What about the Appendix Quarterhorses? (Yes, I know they are not gaited.) I see very few of them up heah in uppah New England, but I do see hundreds of Warmbloods and quite a few Thoroughbreds. I noticed they have been breeding horses with more and more prominent withers. That leads me to believe that the new "Type" hot blood is getting bred back to the quarter horse. So is anybody noticing an increase in wither prominence in the Appendix QH breeds, and are you having to get modified trees to allow for it? My warmblood has very prominent withers, and my Wade allows for just enough clearance. It fits well on the rest of his back. If he were to develop more muscling in his back it would provide even more clearance for the wither, but then the bars may no longer fit well. ( Not that it matters with him, since he is somewhat of a maniac, and the trainers say he should be canned.) Anyhow, it just got me thinking about the Warmed-up quarter horse and what difference, if any, saddle makers have seen in tree design modifications. Dennis

-

ADAM, That is an incredible indoor arena. I've always had this image in my head of an indoor using Glu-Lam trusses for a high ceiling and broad clearspan. I just never thought somebody would do it! Is that a private arena or a riding club? Now that I have seen one, I know my vision was a good one. Not that it is actually fulfillable. Nice video too. Thanks for adding that to the topic.

-

Hey, he is looking great! I just came back from riding an OTTB. Yup, an Off track Thoroughbred. Not only that, I rode in a D-r-e-s-s-a-g-e- saddle! Just a bit different. It went well with my boots, blue jeans and Cinch shirt. talk about being out of shape! My legs feel like fat hams! It was interesting. I'm going to do it some more. I think it will do a lot for my balance in a western working saddle. Should be interesting to see how it all works out. Cris Cox got me thinking about crossing to the dark side for awhile to become a more rounded rider. A blend of both worlds. Just imagine me at a branding. . .Wrangler Jeans, Cowboy boots, Cinch shirt, Wade saddle, top hat and tails! Duke is looking great. glad he is enjoying his new arena! Cheers, and thanks for the update. GO Duke! D

-

Thanks Frank Funny about your signature. . .that is what mine says (said) in another forum I belonged to. Good words to live by. That certainly makes sense, if production is really up and on the move. Starting out, I won't have that problem. Maybe, I will be fortunate enough to have that be a problem. Like you, I am all about the right tool for the job, and no silly monkey buisness. If I can afford it. I heard from Tippman on the Aerostitcher. Seems I arrived on scene long after the show was over. They felt that that stitcher served a part of the market that was too small to support it. I guess it would be that transition between being an advanced amatuer and turning Pro. Too much machine for a beginner, and by the time you were ready for one, you suck it up and buy a big machine. Too bad, because the AeroStitcher looked pretty good. Simple and functional.

-

Wax On-Wax Off- Stitching Question.

Newfman replied to Newfman's topic in General Saddlery Discussion

See, now I did not pick that info up in anything I have read. Man oh man there is so much to learn. Thanks for the info Syl and Keith. Cheers -

Sorry that this may seem like a dumb question, but I couldn't find the dumb question forum. I figured it is generally dumb, so why not put it here in the general topics?!?! I have been reading and absorbing all I can on hand stitching and machine stitching. Then it dawned on me. Machine stitching uses unwaxed thread (for obvious reasons), and you use waxed for hand stitching for reasons not so obvious. I understand that the waxed thread provides protection from the elements, but many saddle makers, I understand, do both kinds of stitching on the same saddle. You may do hand stitched cantles, machine sewn in other places, billets, straps, skirts etc. So, why is it acceptable to use waxed thread for part of the saddle and not the others, or isn't it? Also, isn't there a color shift in the threads, waxed-v- unwaxed? How do you treat the thread in the machine stitched areas, after the stitching is complete? Am I over thinking things just a bit? Dennis

-

Woah! That is really nice! Looks like I am going to have to expand my video wish list.

-

Cool. thanks for your advice. Dennis

-

Very interesting conversation. One of the things that interest me about considering old tools, as in really old tools, is the quality of the steel, not just the name or 'looks' of it. The type and quality of hand made tools of the late 1800's and very early 1900's seems to be lost forever. I think the part that got lost is the process, and effectively, the recipe for the tool makers steel. I might be jumping to conclusions here, but, even in a family owned and operated company, modern ovens, forges, power forges, alloys etc., have changed the character of the products, though they may carry the same stamp. I, amongst other things, am a Timberframer. I am very particular about the framing chisles I buy. Good ones cut across the grain of a timber like butter. There will be no tearing or separating of the grain fibers, and getting a perfect 90 degree cut is a breeze, hand held and well eyeballed. A framing chisle made at a modern factory, doesn't stand a chance. Doesn't hold an edge, and can't take a good edge to begin with. There was a chisle maker in the late 1800's and early 1900's named James Swan. To find a Swan Chisle today is really a treat. Many of his chisles were made from Crucible Steel. The old ways are lost, as well as the formulas. That being said, not all old framing chisles were good. There were tons of makers, but many were pretty utilitarian, and the steel was a bit lacking. I have had an opportunity to use a 1.5" Swan framing chisle, and it was better than my Barr Quarton hand hand forged chisle, and Barr is the best available today. . .bar none. (Sorry Barr). I think the amount of carbon in todays products is lacking. Shiny and pretty, as well as light seems to be the way. Yep, the higher carbon, hand forged, tools of yesteryear rust and or get that (wonderful) patina, but they take an edge like nothing else. Even better than the the best made modern tools. That is how I found it to be in the Timberframing world, I would be surprised to find it that much different in Leather tools. Somebody may be making tools "like" the past, but they won't be the same. Not unless they do it how their forefathers did, and that isn't very likely. Just an opinon, for what it's worth. $.02 Dennis

-

Having worked for UPS and their oversize and international division (Cartage), I can tell you, they try to cram as much as possible into the shipping pods. I have watched a few of my fellow emplyees just cram something in and not care that the item they put on top will crush the item below. Not their 'personal' problem. Heed the advice of getting your container reinforced. You will never really get satisfaction from them, after the damage is done. Luan, ie., wood door skin is available at home depot. It is a Very strong, and very light plywood. We used it for making flats (walls) for the movie industry a lot. You could make inner linings out of that and some cheap one by. Bill it to the customer. Twenty five dollars in materials to get their wonderful, hand made saddle there, has got to be worth the price. Maybe that is excessive, but you should talk to the people that make shipping containers for this very purpose. They have seen it all. I also have watched some of the drivers and dock workers at ABF, throw things into the trucks as well. It will never come back to the individual that did it, so there is no reason to change their ways.