-

Posts

972 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Everything posted by gtwister09

-

Bruce, Balance is a HUGE deal for me as well. The handle design contributes to this as well as the head materials and head weights. Ed and I have had some long conversations about maul designs, balance and materials. How people use the maul as well impact this as well. Regards, Ben

-

Bob makes an excellent point about the acquisition of tools and making do with your first purchase if you only can purchase one. Everyone is different in making a decision based on what type of tooling you do most or you can meet in the middle like Bob said. Regards, Ben

-

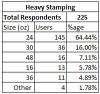

I have compiled some information from many different users on weight of maul/mallet that they use (238 respondents) on regular tooling and basketweave/geometric stamping (225 respondents - not as many as the regular tooling). As you can see the 16 oz is the most common one for regular tooling and 24 oz is the most common one for basketweave/geometric stamping. Of course there are others listed as well. See Below Regards, Ben

-

Well Bruce has pretty much hit the nail on the head about a single purpose saddle. He likewise has done a good synopsis of their concerns and design requirements about seat length, width, stirrups, rigging and styles. It is spot on with what I have been gathering from ropers and saddlemakers over the years. Other ropers have different requirements as well including different styles such as team roping or the WRCA (as JW mentioned about working cowboys). In talking with some family members and other guys, they have tried a bunch of different custom makers and semi-production models. Some of the custom ones that they have used and liked are Faith, Hogg, Slone, Council, Wharton, Kaspersky, Hamil, Tieking/Lewis and Martin (before Equibrand). Some of the tree styles that they like are as follows: Dee Pickett Bowman/SF Bowman Toots Mansfield/Low Toots Mansfield Olin Young Chuck Shepherd Betty Gayle Cooper WIll James I know Lewis Saddle Tree and Oxbow both produce a Hogg tree. I know that Tieking/Lewis have a great reputation among the team ropers and I don't know much about Oxbow. Hopefully this information can fill in some more gaps. Regards, Ben

-

Bobcat, Great work, design and execution! Regards, Ben

-

There are other manufacturers of the "pressurized brush cans" out there. Many years ago (30 or so) when we were doing some custom combine services, a farmer in Kansas used these for his chains to keep them lubricated in that dusty environment and to reduce the oil waste with squirt cans. We used these later in a manufacturing environment that required some foam laminated between various composites. We didn't want to use sprays because of the overspray issue on the assembly benches. One of the things to remember about the high cost of the Kabi's is that they are almost solid brass internally and the pressurized pump is also calibrated as well. If I remember correctly they have 3 or 4 brushes from about 3/8" to 1" as well as a small tip (maybe a couple of sizes of tips also but I don't remember). Regards, Ben

-

Bruce, Will Rundi be able to find you now that she can't listen to the mallet ring? Enjoy your new bench. Regards, Ben

-

JW, Congratulations and best wishes to them. We did the same with our oldest daughter last December. Regards, Ben

-

Troy, As always... A great job! Everyone else has already commented on balance, beauty and style so there's not a lot more to add except to join in the concert of accolades. I have always liked the uniqueness of the open diamond patterns that many of your saddle carry. Regards, Ben

-

Steve, As others have said a great saddle with clean lines. Regards, Ben

-

Ok I Want To Build A Saddle. What Tools Do I Need?

gtwister09 replied to GrampaJoel's topic in Saddle Supplies, Tools & Trees

Joel, Here's a couple of older threads that should answer your question. Hope these help. Tools #1 Tools #2 Regards, Ben P.S. Looks like I was too slow [Denise beat me to the punch.....edited] -

Ed, WOW... Never seen one with the green sales label. Learned something new today. Regards, Ben

-

Ed, The setup looks almost like a stack of saddlemaker rolls.... What's the green on the Beard maul? Regards, Ben

-

Jeff, Stohlman's design is good but has a flaw. The front end is too high. Unfortunately this allows the tree to sit higher in the front on the stand than with a horse. This will foul up your design for saddle. Troy West had an post on this as well. Stohlman Drawdown Review Regards, Ben

-

Covering Swell Problem! Need An Answer Fast!

gtwister09 replied to pete's topic in Saddle Construction

Pete, Somehow I missed this one. Here's the link CW was talking about. Welts & Swell Covers Regards, Ben -

Who's Going To The Wichita Falls Show?

gtwister09 replied to Rod and Denise Nikkel's topic in Leatherwork Conversation

Denise, Well I guess that I will have to make it this year since you two are heading south of the border. Regards, Ben -

The closest thing that I have seen to a stock blade similar to a round knife would be the Ulu blades. They are not round knifes by any stretch of the imagination but as I said before they are the closest "stock" precut blade out there. There are a few variations of them. I know Jantz carries them. Jantz FYI. Here's some thickness data. I miked several hand saws, circular saw blades, round and half round knives. See Below. Hand Saw / Thickness Stanley New Rip / 0.05 Stanley Old Crosscut / 0.04 Stanley Old Rip / 0.04 Stanley Old Crosscut / 0.05 Stanley New Crosscut / 0.05 Stanley FatMax / 0.06 Blade / Thickness Milwaukee Endurance / 0.05 Oldham Combo/Finish / 0.10 B & D Combo Rip/CC / 0.05 Dewalt Hardi-Plank / 0.06 Vermont Amer Smooth / 0.06 Dewalt Plywood Panel / 0.04 Amana Plywood Panel / 0.04 Dewalt Combo Rip/CC / 0.05 Amana CC / 0.05 Several of these circular saw blades had no carbide and no relief lines cut in them. The relief cuts are there to prevent warping as the blades heats and cools (expands and contracts). I also miked some round and half round blades that I could easily get to. Round Knife / Thickness Rose / 0.08 Rose / 0.08 Marlin / 0.06 Marlin / 0.06 Osborne / 0.06 Half Round Knife / Thickness Marlin / 0.06 Osborne / 0.07 All of these blades were measured at the top of the blade to show the actual thickness w/o the profiles. Most of them are profiled from the tip to the top of the blade. That gives you some data points to chew upon. Oh yes.... The thickest ones on the list are the ones I consider to be some of the best blades out there...the Roses. I know others consider them to be great steel as well regardless of their thickness. Regards, Ben

-

Steve, Great looking saddle .... as always. Regards, Ben

-

Phil, Somehow this one got past me. Just a couple of things to add to Clay's notes. Clay gave you lots of great tips and techniques on leather selection and so forth. I have made lots of handles and more than a few pens with leather. It has been a while since I made them (over 10 years now). Somewhere I have a special tap-off that marks the outline of the holes centered on the piece. A clicker die would have been a GREAT thing to have that would cut both holes. Here's some things I do differently for speed purposes for handles. I punch mine with an arch punch so they start off round. Like I said a clicker die would be great rather than two whacks with punches. I use a piece of all-thread to compress the layers of leather(A LOT) - All-thread size is same as handle base or pen (7mm/5mm). Compressing the layers seemed to have a very positive impact in turning them. I hit both sides (flesh/grain) with a belt sander with 30 grit to rough it up. This is LOTS faster than a leather rougher. I dip the leather circles in wood glue like Titebond II and use waxed paper for easy clean-up on the bench. On leather maul handles and such I use the all-thread to turn the handle after in conjunction with a template/follower. There are lots of followers available for turning pens as well. For the handles they had to be made specifically for each size. Regards, Ben

-

Bruce, You've been busy. When you said a skeleton a while back a dancing one wasn't what I was thinking . They should like them. Regards, Ben

-

Ed, Looks great! Can't wait to see the finished case for carving tools. Regards, Ben

-

Ditto on the nice saddle Andy. Regards, Ben

-

Clay, Vivian said that you were the proud owner of Billy's tool making gear. Good luck with your new tools. Clay B. said in his blog that he appreciated your tools for his project. Regards, Ben

-

Relining Skirts

gtwister09 replied to bruce johnson's topic in Saddle Identification, Restoration & Repair

bdt46, I have used Listerine as well for a mold inhibitor in dextrine as well. Regards, Ben -

Relining Skirts

gtwister09 replied to bruce johnson's topic in Saddle Identification, Restoration & Repair

Bruce, For some odd reason this one made it past me. In reviewing some of the responses in the older saddlemaker's interviewing/project, I have run across several that are using dextrin and a couple that had changed to wallpaper paste. Most of the comments that I got concerning the dextrin were either that was the way they were taught or it was already on hand. Most of them used it for the undercut swells even if they didn't use it for the woolskins. Several of these guys really didn't pay attention to how well the dextrin held up because they were more concerned with getting them loose to replace them. A couple of them thought that the dextrin held it for a while and then broke loose which made it easy to replace woolskins. In fact the majority of them said most of theirs were "mostly" loose when they came in to be relined. To them it made the relining job easier by not having to work to remove the woolskins. However the wallpaper paste ones said that they were sticking pretty well after many years and some steam would loosen them right up. They were pretty happy with the results and yes they liked the fact that it wouldn't mold (both commented on that fact). Regards, Ben