-

Posts

361 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Garyak

-

I’ll have to look. I use two different types. The needles that came with it were ball point so I swapped needles. No doing anything to the machines I use 23 in the 16 and 17 system for my 29k. The others fit my Union Special 61300 and I’ll have to look. Crazy thing, neither will work in the other, but the both work in the patcher. Go finger.

-

No complaints, makes nothing but money, and people look better. Only used for 207. My TAKING 29k is maxed at 138, but it’s brown. Doesn’t matter what rig is chosen, it matters who’s driving. Whatever the operator is using it for is still gonna look like the last thing made by that operator. 15000$ machine, or a goodwill freebee. You still gotta add skill.

-

There’s one that gives me the blues now and again, but I get over it. My grandpa worked there in the 40’s and 50’s. If he hadn’t started loosing his mind I’d take him in so he could speak to the manager… Ha! Wanting to know why they won’t honor my free ………… coupon from 44…. I really have some . A lot, back to 33. Man I got lost on this one. Blues, I know my local Big T store has piles of full hides in all kinds of blues in what looks pebble grain. Looks like your pic.

-

Help! My cat peed on $300 worth of unused veg tan leather!!!

Garyak replied to SlickWilly's topic in Leatherwork Conversation

Urine has used in the tanning of leather since the very very start. It was actually used for the heavy metals being pissed out in human urine. I still get sides that smell like piss, although piss is not used anymore, supposedly. Use as usual. Carry on. -

Keep each bobbin with the correct machine. Other than that don’t put exacto knives in your back pocket. Hope for the best. Live on the edge. I have no idea where anything is.

-

Thanks fellas, and I totally agree with everything said. I’d love to spend a year or so playing with one, maybe someday, but not this day!

-

I’ve been looking at the Durkopp Adler 969. From what I’ve found online it looks to be a very capable machine. I’m positive it’s built with the same quality that is Adler, my question is, or my fear is, all the ‘Lectric functions that I’ve spent a lifetime doing manually. Push button tension? Push button everything. Is it worth almost 10 grand in the long run? Anybody had one since they came around in 2013? Opinions? Thanks.

-

There is a method to this madness. I don’t know what it is, but I know where it’s at. Maybe. Thanks man!

-

Choosing a sewing machine for upholstery up to $ 1200

Garyak replied to Miroslaw's topic in Leather Sewing Machines

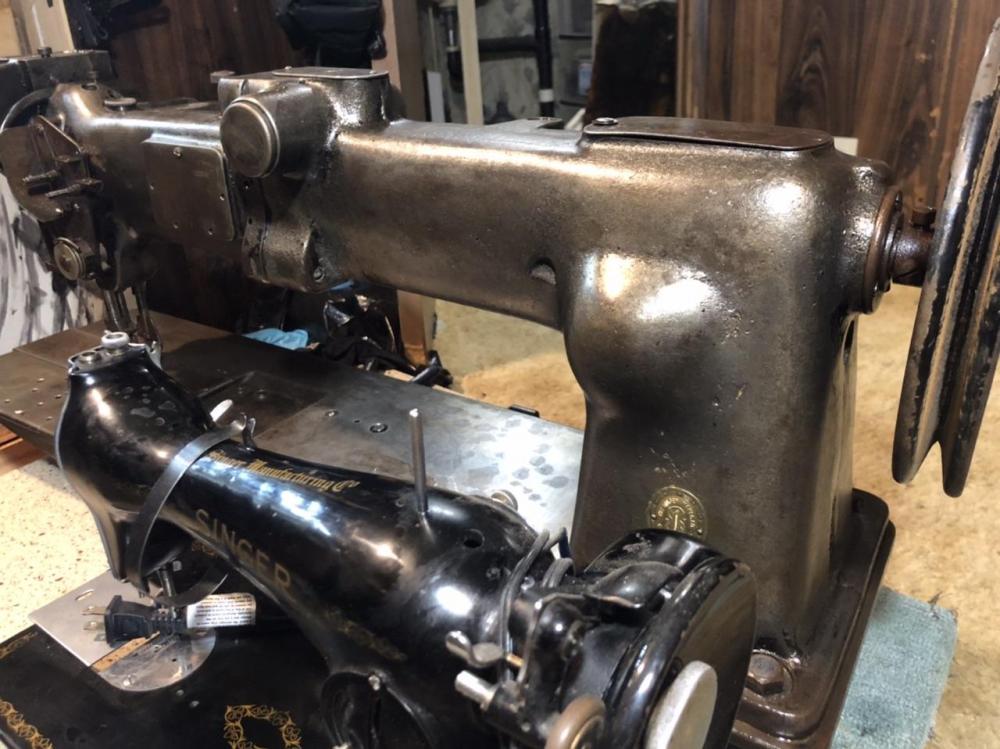

I picked up this 145w204 at a once in a lifetime deal. Supposed to be a great rig for upholstery. 7/8 lift compound walker. Sparkly clean inside and out. It had never been cleaned. I might sell, prefer trade -

That’s pretty slick Man. I dig it.

- 11 replies

-

- 145 w 204

- adler 220-50-273

-

(and 1 more)

Tagged with:

-

Man. Thanks a lot. You laid that out perfectly. I see exactly what your saying. I appreciate it. Now if I could find parts.

- 11 replies

-

- 145 w 204

- adler 220-50-273

-

(and 1 more)

Tagged with:

-

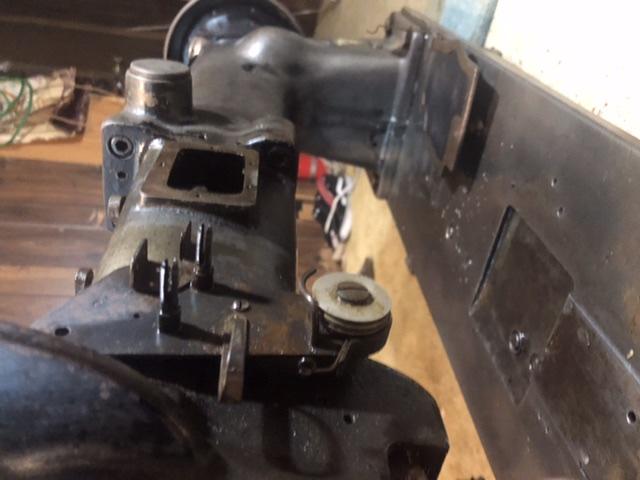

Picked this up for super cheap. It’s set up for double needle. I know you can convert a single needle to double, I’m assuming it can be reversed. Anyone ever done this? Thanks

- 11 replies

-

- 145 w 204

- adler 220-50-273

-

(and 1 more)

Tagged with:

-

Paper patterns? Or blue Guns? How many, how much? Thanks man.

-

Sorry, it took a Minute to get back with some pics. It was challenging to say the least. That’s a thick welt. It wanted to slide when gluing under pressure. Holes were made already. It wanted to roll under the presser foot when sewing. Just had to go slow.

-

-

Yeah, it’s slow, slower than needle and awl. Horribly slow. I don’t know why I’d even try to share such an awfully slow process on such a piece of crap machine. Sorry i wasted your precious time. It’s called a stitch marking wheel. They’ve been available now for a day or two. You have about an 1/8 of an inch on most sewing machines. 1/8th= 2-32nds=4-64ths . How much time would it take, and how hard do you think it would be to get your needle to match up if you were (pre punching) holes? You got a whole 1/8 to work with? I don’t care how you stitch, if it works for you, do it. There are literally 100’s of these machines purchased everyday, with 100’s of people that don’t know how to use them. It’s my job to teach the ones wanting to learn. Most of them folks, it’s all they can afford. They work with what they have, and not worry what the next man thinks. The ones that really get it move on to bigger and better machines if it fits their need, but I can guarantee you the Clsp stays in rotation. Unless you got a Claes/Pfaff you ain’t patching with 207. Clsp laughs at 207. My cobra gets scared at the mention of 207. Any problems with using the CLSP successfully are not with the machine. Any questions I can reached in person thru Singer sewing center Corpus Christi Texas. Ask for the industrial service mechanic, on Saturday’s at Tandys instructing a class, or on Facebook. Questions only. I don’t care if I’m not doing it right according to Paul.

-

Who’s making top notch work with them? There’s a few hundred of us over at Patcher Solutions (Proven DIY) FB group. Shoe makers, sheath makers, patchers, etc… if it’s patchers, or patcher related, it’s there. Need help, tips, it’s there. You’re invited. P.S. A pair of custom Air Jordan’s made on the CLSP will set you back a grand.

-

-

They are completely different. I have both a cobra and China patcher. My patcher sews with the best out there. It excels in the fact that it can sew 207 on both ends, unlike the rest of the patchers (except Claes/pfaff) that top out at 138. A sewing machine is nothing but a tool. It’s only going to do what the operator makes it do. It’s only going to do what it was designed to do, and the China patcher does exactly what it was designed to do. Lots of folks are producing top notch leather work with it, ive never had a complaint. 4-3/4 stars when used as intended, without physical changes to the rig. Singer 29-1 thru the latest clone (cobra,techsew,Consew,etc) are all singer 29s. The China patchers next of kin is the Bradbury.two completely different set ups.

-

Thanks man.

- 11 replies

-

- woundedwarriors

- 1911

-

(and 2 more)

Tagged with:

-

Will my sewing machine work well with leather?

Garyak replied to Warhauk's topic in Leatherwork Conversation

eBay, again, here goes the 30$ 220v motor on eBay. I’m running 5 of them now. They run 220 and 110. Running them daily for a couple years now. eBay enduro pro 220v is the search. That’s the motor in the picture. Everything I used to make that set up I got out of trash at work…. I got 0 dollars in it. Can’t beat that price. -

Not the one you want, but the drawer that came on my machine was useless. Thrift store and 10$ later, looks like it was planned. There were several different treadles in one shop.just gotta deal with the grumpy fella that owns it.