dans79

Members-

Posts

149 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by dans79

-

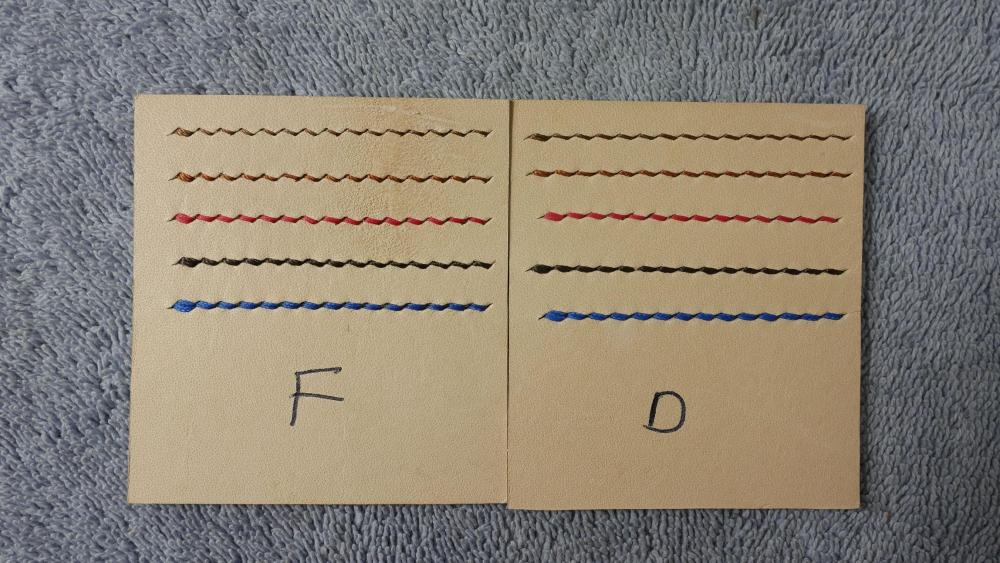

I have the 3.85 mm set, and used them to make the test sample on the left side of this photo. The right test sample was done with the the 4.0 mm diamond set. The thread from top to bottom is : 0.4 to 0.45mm Vinymo MBT #8 0.6mm Vinymo MBT #5 0.6mm tiger thread 0.75mm Vinymo MBT #1 0.8mm tiger thread Please note I'm a complete newbie!

-

keep in mind JJ needles are fairly cheap and made in china! In the past I've wondered if sizes #1 through #3 aren't just quality control binning, because you need meteorology equipment or a good loop to tell the difference. Not to mention i have some #3s that look bigger than #2s. I've thought about picking up some System S+U needles that are made in Germany, as they have a more diverse size range. However they are 2.5 to 3 times more expensive than JJ needles, and seem much harder to find in the states. Here is a photo I found showing the size range of System S+U needles.

-

The eyelet inner and outer sizes are different. That effects how easy it is to get the needle and the thread immediate next to the needle through the leather.

-

Your using a larger needle than you need to, and that's making your life a little harder than it needs to be. 0.8mm will work fine with a #3 needle, and with a little finagling you can even get it to work with a #4. with regards to the Sinabroks, they are wider at the tip than other french style irons if memory serves. French irons should by nature require a little more force as they are flat at the tip while diamonds form a point.

-

It can be worth it, but it needs to be like a 40+ year old hammer, preferably even older if you can find it. My brother has one of my grandfathers hammers from the 1920' or 30's, that is a real jem. Hard enough that it won't mar, but soft enough that it won't chip.

-

Personally I wouldn't risk it, unless you can get your hands on a hammer that you know is 30 to 40+ years old. If you have the tools for forging, you would probably be better off starting with a piece of bar stock of a known grade of steel. God knows what random cheap steel they use to make hammers now.

-

It's a lot easier and faster to do on a hammer, as you don't have to worry about screwing up the edge like you do on a knife or chisel!

-

This is why I haven't purchased anything from Osborne. They charge top tier prices, but what they sell has bottom tier fit and finish. I modified a ball pein to use as a cobblers hammer, maybe the info will help you make the Osborne usable.

-

Yea, manufacturers and retailers have made a real mess by using an inconsistent naming convention.

-

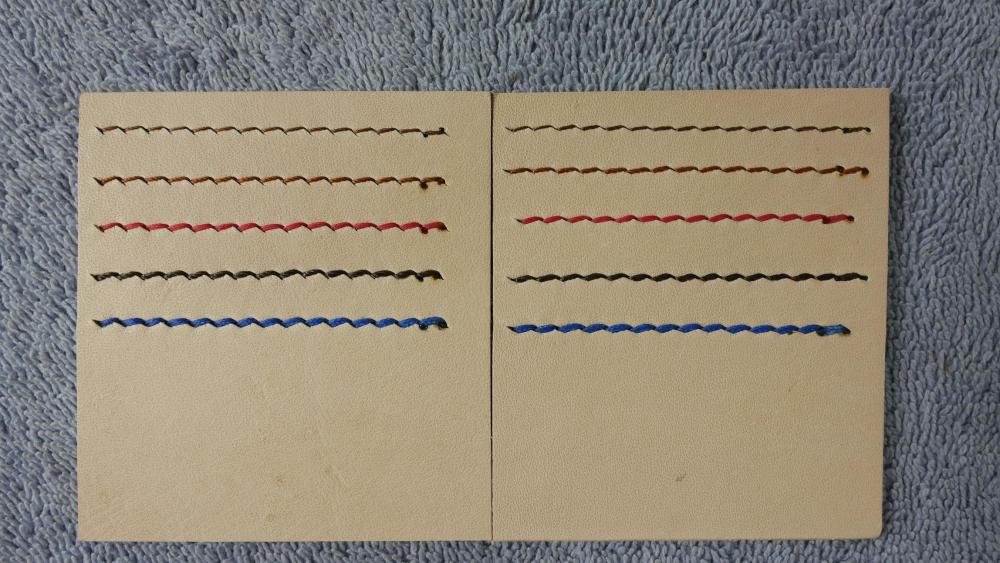

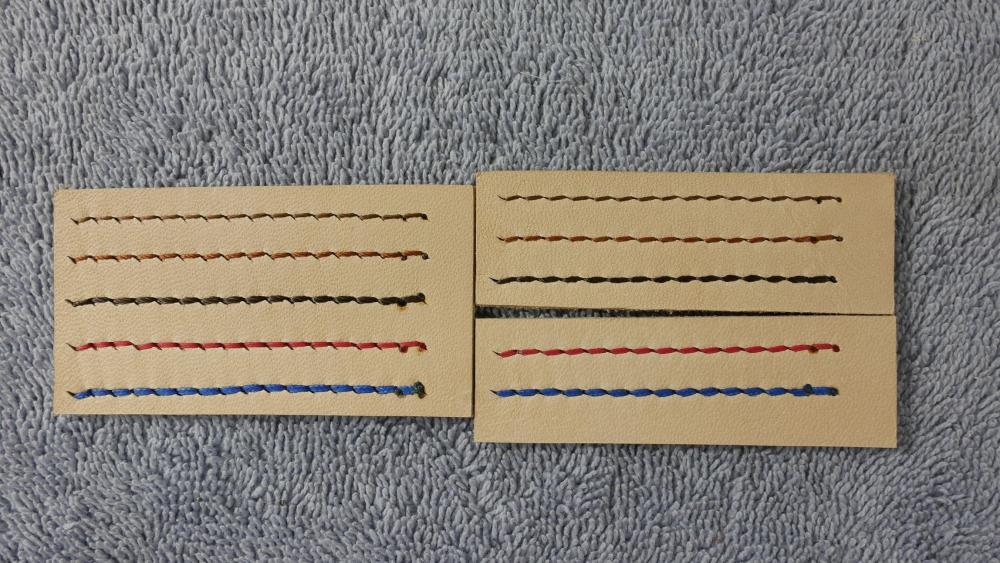

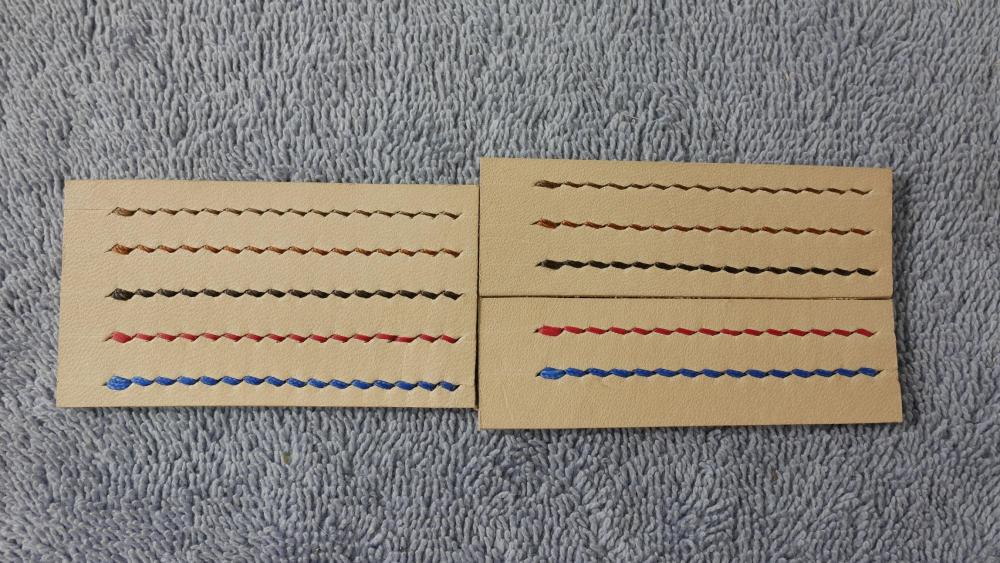

Here you can see a comparison now that I'm doing the cast correctly, thought i still need to get a better handle on the appropriate amount of tension for both types of irons so the stitches look more consistent, but I'm much happier with the results. 2 layers of 2.5oz glued together. The thread from top to bottom is : 0.4 to 0.45mm Vinymo MBT #8 0.6mm Vinymo MBT #5 0.6mm tiger thread 0.75mm Vinymo MBT #1 0.8mm tiger thread Personally I think the french irons look better on the front side up to Vinymo #1. For the diamonds i wouldn't go larger than the 0.6mm tiger thread or Vinymo #5. On the back side the french are much better than what they where yesterday. Are there any tricks to make the back side of the french look better (more centered vertically)? Or maybe a book with good information in it? As an aside, one thing I've noticed is that the tiger thread is a little easier to work with imo. Every now and then the Vinymo will twist itself tighter for a stitch or two and throw of the look of the stich. Front Back

-

Yea I'm doing that, i picked that part up from the Leodis Leather video on saddle stitching. I'm working on some practice pieces right now, and i think I have my issue corrected. However the French irons definitely seem more sensitive than the diamonds to the angle and amount of force you use when tensioning the thread.

-

Take a look at the full resolution photo of the back (right click open in a new window), and you will see that the thread is shifted up on all the french lines, but is centered on the diamond lines. The fronts look the same way to me, just not as extreme. I was casting, but since I posted the photos, I think i might have had one step wrong, and the diamonds are just doing a better job of covering it up. I need to glue up some more practice leather, But i will give it another go this afternoon when I work through what i think i was doing wrong. I think the thing that makes it hard to learn, is that none of the popular personalities showing how to stich, use the same terminology.

-

I started out with round dents, but they are more niche than i originally thought so I ordered a set of diamond and French irons to try out. The irons arrived Wednesday, and today was the first day i really had a chance to try them out. The diamond irons are 4mm spacing, and the French are 3.85mm 2 layers of 2.5oz glued together. The thread from top to bottom is : Vinymo MBT #8 Vinymo MBT #5 Vinymo MBT #1 0.6mm tiger thread 0.8mm tiger thread French on the left, diamonds on the right I stitched ever line using the exact same technique (minus the one mistake), and for some reason the french lines seem off to me. All the thread except the 0.8mm tiger thread doesn't seem to fill the holes right on the front. On the back side all the french lines look bad. Am i doing something wrong, do I need use a special technique with french irons? Front Back The holes before stitching.

-

Why are so few small/mid sized items lined?

dans79 replied to dans79's topic in Leatherwork Conversation

Here you guys go, this is a simple and I would assume very profitable way of disposing of scraps/off-cuts. The fact that someone is paying $35 dollars for this is mind boggling. https://www.tannergoods.com/products/single-wristband-cognac-stainless -

Why are so few small/mid sized items lined?

dans79 replied to dans79's topic in Leatherwork Conversation

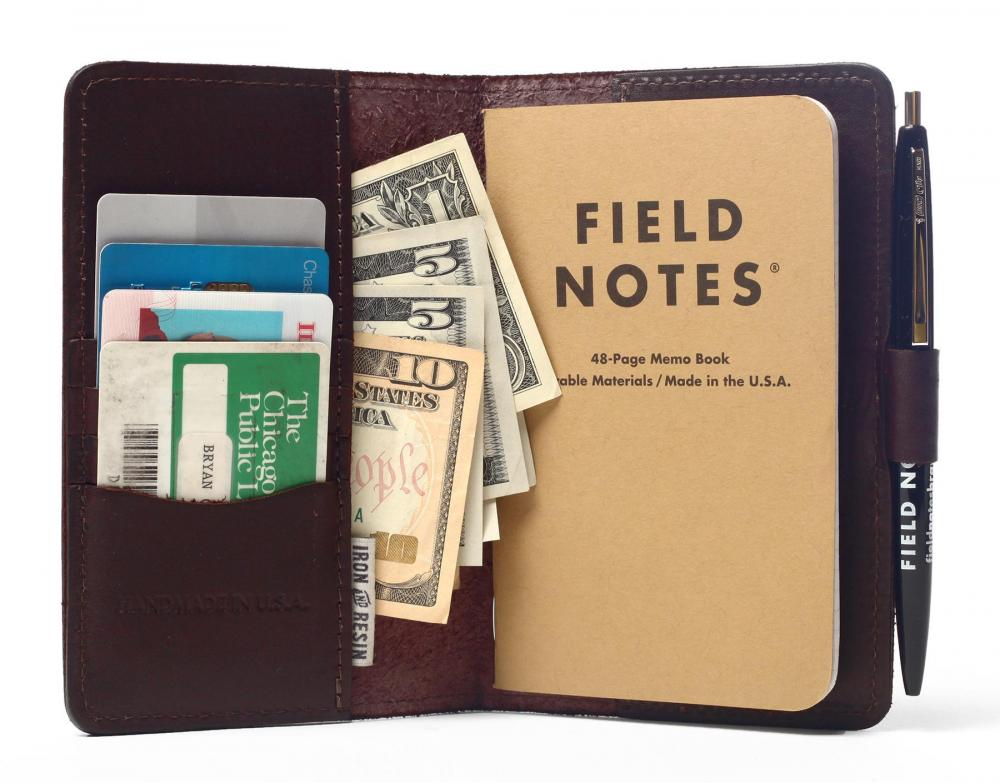

I got into leathercraft just so I could make a folio (i guess is the best word for it), because i couldn't find anything of the quality or style I wanted even up to the $1k range. -

Why are so few small/mid sized items lined?

dans79 replied to dans79's topic in Leatherwork Conversation

I was trained as a physicist who specialized in software, and I have worked most of my professional career as a developer, And I love what I do. Imo, the number one issue with most of the people who get disillusioned with tech/IT, is that they shouldn't have been here in the first place. Some of them got sucked in by the allure of a well paying job. A lot of others I have known thought, it would be cool, because it's an office job with lots of down time, and a flexible schedule. However, Almost every single one of them had the same underlying issue, they don't want to learn new things, and they don't want to solve new problems every day. IMO, the out of hand social media stuff, and general lack of caring about anything, is a sign of poor parenting. I was raised to take pride in my work, whatever it is, and I Generally don't care what most people think one way or the other, as i was raised to know my worth and have self respect. I'm the type of guy who generally says we are either going to do it right, or we aren't going to do it at all. One of my other hobbies is woodworking, and knowing your worth is a topic that's routinely brought up in the community. Doesn't matter if you're a hobbyist who does a commission piece every year or two or a self employed bushiness owner. If you're cheap people who know you will always expect you to be on the cheaper side, and you will never get out from underneath the stigma. I've seen videos, and they usually offer a seminar or who at woodworking shows to go over the details, as they are talking about more than your time and the cost of the materials. Imo, The internet is a benefit or a hindrance depending on who you are. Back in the day if you wanted to sell something, you had to do it locally unless you where a large company who could afford regional or national level advertising. Thus, if you were in a saturated market you where going to have a real hard time staying in business. Today anyone can set up an Instagram account to promote themselves, and an etsy or shopify account to sell their products to anyone anywhere in the world. The down side is that you need to be able to stand out from the crowed. You need to be able to promote yourself via social media with quality videos and photos, and you need the same for your website/store. Sadly I see a lot of people fall flat on their face in this regard, as they think having a website is all they need. Barry Kings website for example is atrocious. If you go looking for a Maul you will find tiny images and no details other then the diameter of the head and the weight. If you want to know how long the handle is, what it or the head are made out of you need to start googling. People reselling his products aren't any better either. Imo, leather craft is also an industry where the customer needs to be educated to an extent, but very few people are doing it. If I started a leather goods company tomorrow I'd probably have some products that have multiple versions. Hand stitched and machine stitched, lined and unlined, normal and premium leather etc. But i would also have a place where potential customers could learn what those terms mean and what the benefits of one vs the other are. I saw a very nice portfolio the other day on etsy, but the marketing was terrible. It had a few small pictures, and the description was something like hand made from full grain vegetable tanned shoulder leather. The first thing that came to mind, was your average person has no idea what any of that means, and they aren't going to spend the time to look it up. -

Why are so few small/mid sized items lined?

dans79 replied to dans79's topic in Leatherwork Conversation

That part I get, as I've been experimenting with it my self. As Tugadude said though you can get leather really thin now. For example I have a 1 oz. sample of Badalassi Carlo Waxy. Imo it would require being lined with something equally as thick as it is, just to be usable. It's so thin and soft to start with, I don't know what you could use it for on it's own. -

Maybe its just me, but it seems like most wallets, notebook covers, folios etc aren't lined. I'm not talking about about the inside of a card pocket or something that never gets seen. I'm talking about features that you are going to see every time you use use the product. I've thought about it for a while, and the only thing that comes to mind, are cost and aesthetics. For a hobbyist on a budget, or someone just starting out, I can understand not wanting to buy multiple weights of leather so you can line a project, or spending the time to do so. However, I even see a lot of professionals and small mom and pop companies making stuff like this, where cost should be less of a concern. Take this $90 filed notebook cover for example. This is a "premium" item produced/sold by a good sized company with a good reputation. Imo, this is a rather extreme example, as the flesh side is nasty/hairy, not to mention the stings around the front card slot opening. https://fieldnotesbrand.com/products/daily-carry-leather-notebook-cover Am, I missing something? other than costs and aesthetics why are so few items lined?

-

Armitage Leather did a 19 min on Vinymo MBT Thread. I'm just getting into leather craft, and since I'm more interested in small items like wallets and follios, I went with Vinymo #5 and John James Size 4 (004) needles. I 100% agree with this, The guide is a must have do the sheer number of color options (82).

-

I found this while poking around Springfield Leathers site. It's far from perfect, but at $2.59 a square foot it's perfect for a beginner like me to practice with. https://www.springfieldleather.com/Side-SP-Veg-Tan-D-Grade This 20 sq ft. Hide plus taxes and shipping, was only $61.29. Queen sized bed for reference. q ftsqsq ft. ft

-

No matter what, make sure the spot where you plan to do your chisel/pricking/punch work is heavily reinforced. Ideally you want one or more legs in close proximity if possible. It doesn't matter if its woodworking, metalworking, leatherworking etc, if the pounding area isn't rigid, it will be loud, and a lot of the power you put into strikes will be wasted as the top flexes under the load. For example a very popular style woodworking bench is one that's fitted with a leg vise, and a wagon wheel vise. The benefit of both of these vises, is that when you are going to town with a mallet and chisel you are usually doing it right over, or right next to a leg.

-

The cold blue didn't come out well (I expected thats would be the case before I started), and since I didn't want to trash a perfectly good handle just so I could rust blue the head, I begrudgingly , broke out some flat black industrial spray paint! The pictures didn't come out the great, as I was playing dodge the toddler at the same time!