Search the Community

Showing results for tags 'consew 226'.

-

I bought a Consew 226R clone last year and it came with one bobbin that measures about 31/32mm in diameter and 14mm in height. I would really like to buy some more bobbins for different colours but I can't find this style of bobbin anywhere. I'm based in Europe and would like to buy them online. Is this a particularly unusual size or am I just looking in the wrong places? Thanks in advance for your help!

-

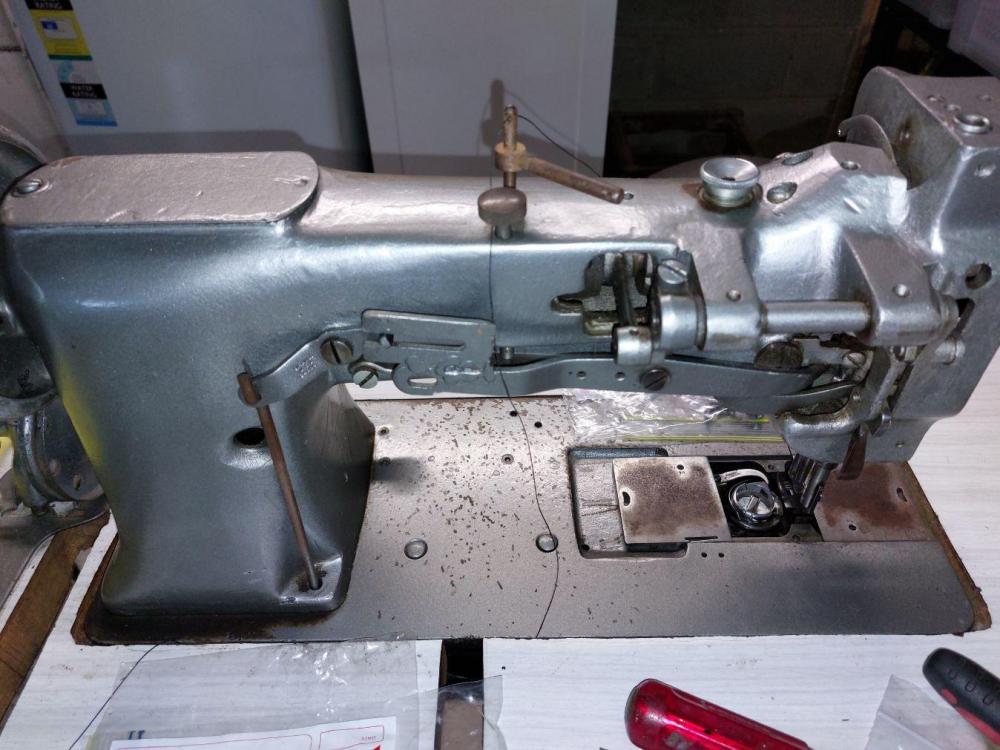

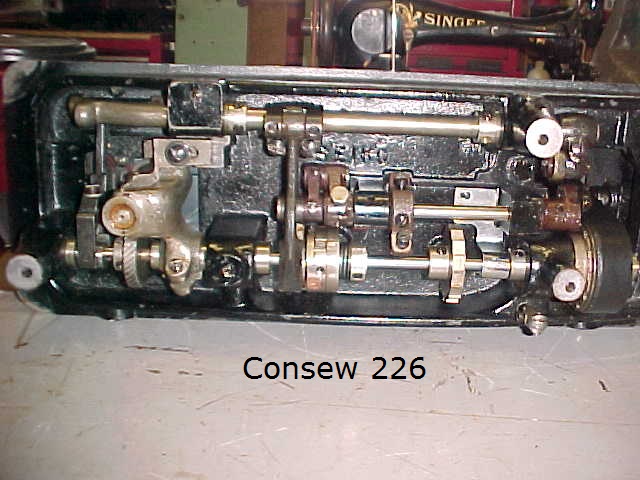

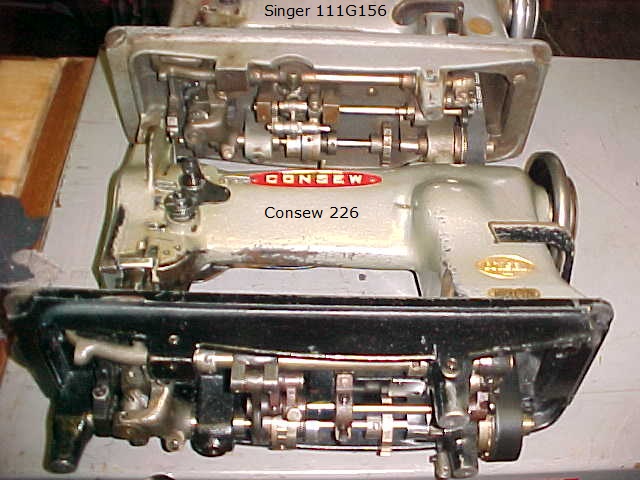

I bought a machine over here in Australia for my better half. I figured these machines are built well and parts are available, so just took the plunge. The timing belt had broken and the previous owners had sourced a new one they were supplying with the machine. The machine was looked over by a mechanic late last year so figured it was a safe buy. I removed the arm bushing (banged it up pretty bad removing it) and installed the new timing belt. I timed it with the take up lever and the arrows and then timed the hook, so she is capable of creating a stitch but there are a few things not right. The presser foot doesn't lift as part of the mechanism just sort of sits on the leather with constant pressure and the feed is out of time. I get the feeling a few things have been moved by the previous owner and trying to figure it all out leaves me feeling a few things are missing. From my studying, mostly from looking at the Consew 226 exploded parts list and the Singer 211 drawings and cross referencing with the 111G156 parts list, I think I am missing at least: 240500 - Tension release slide 240142 - Tension release slide spring 240185 - Vibrating presser bar extension 240188 - Vibrating presser bar spring 350299C - Vibrating presser bar thumb screw (pressure regulating) 200996C - Lifting bell crank cap screw Could the experts here and those with the same machine have a look over these photos and advise if these are required and any other missing parts I may not have picked up. Thanks Clive

-

I’ve got my Consew 226 about ready to put into use, except that I can’t figure out how to balance the forward and reverse stitch lengths. This is the older version of the 226, but I’m not sure which one. It’s not an “R” machine. The reverse stitch length is a much shorter length than the forward. Did I miss a thread where this was discussed? The Consew 226 is built differently than the Singer 111G156, so I can’t use the Singer guide. Thanks for any help. CD in Oklahoma

- 7 replies

-

- consew

- stitch length

-

(and 1 more)

Tagged with:

-

Urghhhhhh!!!!! I've been cruising, with my new to me machine.. but my bobbin ran out.. I wound another one, and put it in, and now for some reason I have absolutely no bobbin tension.. I didn't touch anything!!! I swear.. I did re-thread the needle side too, but that seems fine.. On the bobbin I can literally just spin the thread out, and I put it in, and it spins counter clockwise like the instructions say.. Here are the instructions.. www.consew.com/Files/112347/InstructionManuals/225.pdf I'm not sure what to do??? Any thoughts? Thanks

- 11 replies

-

- consew 226

- bobbin

-

(and 1 more)

Tagged with:

-

I'm having an issue with a Consew 226. When turning the handwheel there are two sticking points in the rotation. I wanted to determine weather it was friction in the upper shaft or lower shaft, so I slid the timing belt off and found the two sticking points were related to the lower shaft. So I reinstalled the timing belt, making sure to align the arrows under the machine (they were aligned before as well). I had to replace the hook anyway, so I went ahead and swapped that out. I chased the old hook out with a 3/8" dowel to prevent the gear from moving. Machine now sews well, but still has two points where there's more friction somewhere in the lower shaft. - Adjusted for symmetrical foot lift - Adjusted feed dog fore/aft position -Adjusted feed dog height - Made sure rocker bar spacing was 8.5mm @ zero stitch length All of these settings were very close to correct, and didn't seem to improve the friction issue I was having. I can remove the drive belt, thread, needle, and throat plates and feet and still have the two sticking points. Decreasing the foot pressure springs to zero makes a very subtle improvement. I have obviously oiled each point tenaciously, but still have two "sticking points" that occur when the take up lever is approaching top position, and approaching bottom position. Any thoughts?

- 6 replies

-

- friction

- resistance

-

(and 2 more)

Tagged with:

-

Hi all, I've been a fan of this forum for a while. Thought my video on converting a Consew 226r to a large bobbin (Juki-lu563) might be of interest. https://youtu.be/LE87ukxP2mw Hope this helps others out. BRE

- 2 replies

-

- consew

- consew 226

-

(and 3 more)

Tagged with:

-

I Have an older Consew 226 with reverse (name plate just says 226) that has been used, maybe well used. It sews fairly well as far as stitching goes but I can't seems to make it run quite straight as the needlebar rock frame moves on the stud. I also need to get this last bit of backfeed taken care of. I have gone through all of the upper end adjustments/eccentrics and this is as close as I can get. The feet and feed dog are worn and I will be replacing those soon, hopefully straightening out the stitch and relieving the rock. What do I try next? Adjusting feed dogs on the rockbar?

- 3 replies

-

- consew 226

- singer 111

-

(and 3 more)

Tagged with:

-

Just wondering why my Consew 226 needs so much upper tension to sew a balanced stitch? I just finished dialing in my other walking foot, a Consew 206 RB-1, and it needs very little upper tension to sew well. The 226 on the other hand, must be cranked down pretty good to sew well. The adjustment knob on the upper tension mechanism is nearly maxed out by the time the bottom side of the leather looks good. The threaded, split rod on the tension mechanism was splayed a little. I noticed that the nut would jump a thread on the split rod occasionally. In other words when I tighten the tension knob, sometimes the nut will strip on the threaded rod. So I ordered a new tension assembly and installed it today. The spring on this Chinese made tension assembly seemed very weak. I gradually increased tension and checked the stitch quality, but no dice. The tension was maxed out and the bottom stitches were still showing a bit of the upper thread. Not big loops or anything like that, just not a pretty and balanced stitch. With the tension maxed out on the new assembly, the tension discs were still pretty easy to move. So I put the original tension assembly back on, and it works, but the tension is really cranked up. Here are some additional details... 1. Bobbin thread pulls freely, with no significant tension. 2. I'm using #138 nylon thread. 3. #22 Schmetz leather point needle. 4. Sewing samples are two layers of 2oz. goat leather. It is soft and supple leather. 5. Tension releases normally with either presser foot lift or knee lift. So... any ideas why my 226 needs so much upper tension? Should I buy a quality Japanese made tension assembly or? Thanks

- 11 replies

-

- consew 226

- upper tension

-

(and 1 more)

Tagged with:

-

Ok, I have a Consew 226r-2. Had great even thread tension when I first got it, had it set up in my garage. It had been used mainly for Upholstery jobs prior to my getting it. Then when I moved it into my house ( sewing in an unheated garage when the temps are 50F and under, wasn't going to happen, and now we've been -38F a few mornings i'm glad i brought it in) but i digress.. since i brought it in i've been having tension issues. thought i had it sorted out, but was wrong. When i stitch 95% of the time the bottom threads loop is showing on the topside. once in a rare while it will be just right and the knot won't show top or bottom, but as i said that is rare! I've read the manual multiple times, gone through all the adjustments for tension for both top and bobbin.. and still no love. I can pull the bobbin thread and there is almost no resistance at all... I'm just at a loss at what to do to figure it out. I attached a couple pictures. the one on the dark leather is how the stitch looks most of the time, the spur straps show it doing it's sometimes nice, sometimes off stitch, and then the other pale leather is the one time it seemed to be stitching just right...

- 10 replies

-

- thread tension

- consew 226

-

(and 1 more)

Tagged with:

-

Hey everyone, I just got this new to me Consew 226. super psyched about having this hoss.. I had to take it apart a bit to get it back to my shop, and now I'm hooking the presser foot lift back up and running into an issue. Check out the attached pic where I tried to point everything out. But basically its not hooking in right. That vertical bar coming up from the bottom is what is attached to my foot pedal. It somehow attaches to the lever that lifts the walking foot and that's my issue. I'm not 100% sure how it should attach. I think it should somehow attach to that piece on the body, but its on the wrong side. What would be really great is if someone out there with a 226 would just take a pic of theirs and I could go from there.. Thanks! Todd

- 9 replies

-

- consew 226

- walking foot

-

(and 1 more)

Tagged with:

-

G'day all. I recently bought a nice Seiko STW-8B which as far as i can see is al a Consew 226r and there is a brother and singer variant. The machine came from a known dealer with a new table and new servo. Man i love that thing. Being able to sew slow, even 1/2 cycle at a time. Even without an enps, i can jab and get the needle up or down. Anyway, where I need advice. The machine,only came with one set of feet, and that was a 1/4 inch piping set. What feet variations should I buy? I have order a standard set, but are there others that would be useful . I have considered a top stitch set. As i am making bags, and pouches i also need to sew fabric lining on occasion. Cheers, Tony