Search the Community

Showing results for tags 'threading'.

-

HI, I am hoping to get some help with my Consew 226R. I have had it for a few weeks, purchased from an ex upholsterer. It was very dirty and some parts were not attached, so i have been cleaning it up, putting it back together and ordering the odd screw, spring etc online to replace things. I now have it sewing and operational, however I just can't get the thread tension right. I thread it up according to the manual (and according to the amazingly helpful youtube videos that I've found). But what happens it that the thread seems to be too loose when the needle comes up and then the thread jumps off the thread controller disc, out of the spring and then wraps itself around the back of the thread controller nut, or sometimes the back of the thread controller itself. I have tried various settings by turning the thread controller more to the left or more to the right, I have tightened the spring, moved the spring stop up or down - and I just can't crack it. I pulled to whole tension bracket set up apart and checked each component, and everything 'seems' to be working as it should. I have read posts on this forum referring to worn pins behind the bracket, but it's difficult to tell if this is worn, with nothing to compare to it too. Also, even on the few occasions where the thread does stay inside the thread controller for a while, the thread ends up breaking because it seems to get stuck up inside the tension discs and then it just breaks down at the needle. I got this machine quite cheap and I'm now feeling very frustrated that it won't even sew for 10cm without something going wrong. I'm really hoping there is something simple I've missed. Really appreciate any help offered that will save me going to a sewing machine mechanic just yet (will be my last resort due to finances) - and I can see that there are many experience users on this site. Carrie.

- 27 replies

-

Hi! I'm totally new to this machine- I usually sew for a sheepskin tannery on the isle of Skye in Scotland using a one thread overlocker, and at home using domestic machines. My workplace is shut indefinitely due to bleedin covid19, but they've given me loan of a Seiko Stw 8b to see if I can make use of it if and when I go back. I've looked at several grainy manuals online for it, and I think I've neeeaarrly got it going... Its been sitting untouched in an office for ages so I've oiled it, changed the needle- I'm worried I've made a mistake somewhere threading it, and also worried the timing might be out maybe- if it was one of my machines at home I would change the needle and rethread.. any advice would be amazing! I've attached pictures of the wonky stitching and my probably wonky threading. Cheers!

-

I just recently received this machine and don't have an owners manual or know anything about it. It was given to me and the previous owner did not have it threaded or anything and no manual and i am new to trying to sew so any help is very much appreciated. Thank you in advance.

-

Hello, I have extensively reviewed the manual for the Pfaff 138-6/01 (my personal current machine). I am wondering if anyone has found a way so the needle will not move, when winding the bobbin. (I know usually one is able to adjust this on the hand wheel.) Can keep this forum open for all questions regarding Pfaff 138!! I really like this machine, and am trying to become an expert at it and solve the few issues I have. For anyone reading, here is the only pertinent manual I have been able to find online: Thank you anyone + everyone for your help + input!!

- 5 replies

-

- pfaff 138

- bobbin threading

-

(and 1 more)

Tagged with:

-

I have a new job working with a juki 1541 leather machine. I work with size 69 1/2lb nylon thread and size 22 needles to see through quite thick leather. The thread consistently gets caught in the tension disk and snaps while sewing. Online wisdom is this is caused by threading the machine with the foot down, but when I thread it with the foot up it actually makes the issue worse- the thread feels stuck as soon as I put the foot back down. If I loosen the top thread tension spring I get loops on the bottom of my seams so it's not too tight. Any insights?

- 4 replies

-

- tension problem

- leather sewing machines

- (and 2 more)

-

I recently bought a Singer 16-188. It was very dirty and I have replaced some parts, but it was a steal at $25.00. I am an experienced seamstress, so threading a machine isn't new to me, however, I am not sure I have this correct. I have searched and searched the internet for a diagram of how to thread this machine and I am still empty handed. When I try to sew with the machine after I have it threaded (at least my guess at threading), it won't stitch. It is connecting around the bobbin, so I don't really know what the issue is. If anyone has a diagram of how to properly thread this machine or has any idea of why it isn't stitching, I would really appreciate the input. Thank you!

-

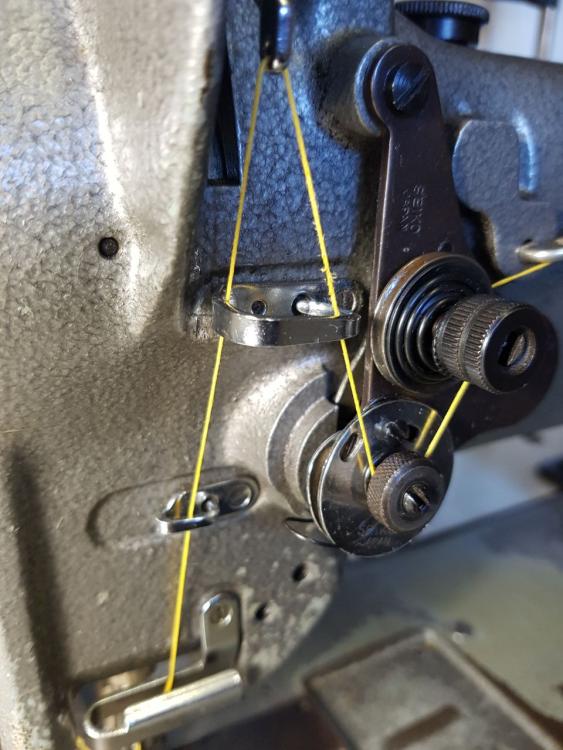

I'm having a little trouble with this new/old machine. It is a Mercury m-380b and is basically a nakajima 380 (from what I understand). I have it sewing, but it's definitely not right yet. I understand most of how to thread it, but the tensioner on top is a bit of a mystery to me, and I haven't been able to find a manual or identical enough system. Does anyone have any insights on the correct way to run it? And might it change depending on thread size? Lastly, I have run it several ways, not just how it is in the picture.

- 1 reply

-

- threading

- mercury m-380b

-

(and 3 more)

Tagged with:

-

This machine works and is complete. I need help figuring out how to adjust the thread feeding system. does anyone out there have one of these machines in working condition that I could talk to in order to get mine adjusted properly? The take-up arm in the second picture moves probably 4 inches left to right...I think it is responsible for pulling the thread back tight after the stitch passes around the shuttle. The third picture is further down the thread delivery chain, but has the same thread carrier as the take-up lever...the outer shell has 3 slots while the inner part has a thread groove. When threading you could put the thread into a slot...go round the inner groove and exit the same slot......or any other combination of in and out. How is this intended to work?? Thanks, brent

-

Hi, I have had a 2000 Juki for many years and although I have it sewing very well I saw a video of a Cobra machine that looks exactly the same as the 2000 but it is threaded differently. The manual that came with the machine was copied and isn't very clear regarding the threading procedure. If there is someone that would take a photo of the correct threading I would appreciate it.

-

Hello Everyone, Jus thought I would share this simple video I made on threading a leather sewing machine. I know when I got the machine - the directions had me searching youtube to find a quick answer. Only after watching several videos did I finally understand how to do it. Now this video makes it short and sweet and easy to see. Check it out... http://www.mrlentz.com/2013/03/how-to-thread-a-leather-sewing-machine/ Cheers! Mr. Lentz