All Activity

- Past hour

-

Thank you, @Tove09Tilda for your kind words. Welcome to the forum. Hope to see your work here. For the dee rings, these are a bit heavier than needed and I welcome ideas about different designs to pad them. I have seen a crank using a small ring with a tab that was buried between the end of the strap and the padding. It appeared that the tab had a slot and the stitching was placed into the slot to secure the ring. The underlying padding extended past the ring, similar to what you described, but it was a short overhang that looked tidy. I haven't found this type of ring/tab/slot at my usual hardware suppliers.

-

I'll definitely get some pictures. I'm not relying on memory to reassemble, although I've grouped related parts together in containers as I go. I've got a copy of a US Army technical manual with some nice exploded diagrams of all the parts, plus a US Navy guide with pretty detailed disassembly/reassembly instructions.

-

Hi all it’s been a while, I bought a front hub ,shaft , gear from a place in England . The gear hole is .003 smaller than shaft , is it a shrink fit ?, there is no set screw on gear . Any advice on installing this and the front balance wheel would be appreciated thanks

-

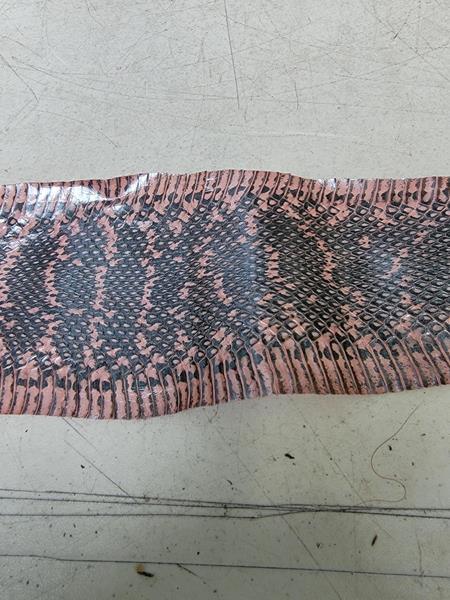

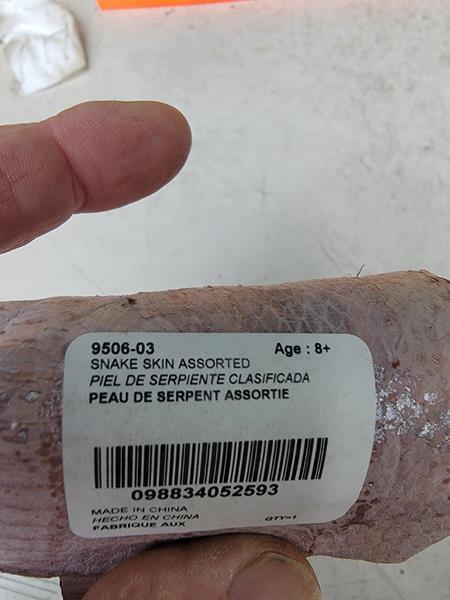

I bought these many years ago and never got around to using them. The large one is Back Cut Python and is 8 feet long and approximately 9.5 inches wide at my hand span. The smaller Tandy skin is probably 2 feet or so. The product number is no longer listed in Tandy's ever-changing catalog. But a fellow user ID'd it as probably Whip Snake, or similar. $180 for both, (+shipping) Shipping will be at my actual cost.

- Today

-

These look nice! And welcome from SE Wyoming!

-

Hello from Germany - New Member Introduction

FrankHester replied to Tove09Tilda's topic in Member Gallery

And welcome from SE Wyoming, USA! -

Would enjoy seeing pictures of the machine in its disassembled state, as well as how you've got the parts laid out for remembering how they go back together. The most I've removed on the singer 144 is removing the needle bar rock frame so I could grind a passage into it for a screwdriver to access the needle bar pinch screws. Everything else I fixed in-place.

-

Nice work! Inspiring me to start my tooled belt project! Beautiful work!

-

Nobody is sitting waiting for you to post a question and able to immediately answer you. You need to be patient. I have merged your 2 posts into one to reduce clutter.

-

Less is more and reapply as needed. Think of leather like that dry stiff kitchen sponge. Like a sponge, there are little gaps between the fibers. A dry sponge is stiff. Add a little moisture and it absorbs - some swelling of fibers and some remaining in those gaps. The sponge is now soft and flexible. This is the place with oiling leather to usually stop. Yes you can add more and it will take it - just like the sponge. And just like the sponge - add too much and it drips back out. The sponge actually loses a little "body" and gets floppy - just like over-oiled leather. Oil is not a waterproofer. If you are worried about weather effects then you need something else. One brand is SnowSeal. My granddad and uncle fought over grandma's goose grease, Mink Oil paste, there's a bunch.

-

Moved your post to Leather Sewing Machines

-

It looks to me like the two circles the leather goes through are grommets that were painted. If you look at the edge of the patch there is a spot where the leather is thicker. I believe that's where the loop leather is anchored, much like you make a purse handle. it's tubular in the center and flat on the ends. It just passes through two grommets. It's a neat concept but I would worry if it can take the weight of the jacket for long. I guess if it's large enough it can be ok.

-

First off it really depends on what you want to sew. Which is ??? Keep in mind i) the machine could date back to the mid 1930's and with all PFAFF machines parts can be expensive if available. ii) Chances are it has a clutch motor which really needs to be replace with a servo motor and that will cost about an additional $200 USD. Personally I would not consider paying a $1000 USD plus $200 for a motor for a machine that old. If you tell us what items you want to sew there are better options available. kgg

-

This is a great setup! Yes a laser cutter did the cutting but YOU told the laser where to put everything, YOU did the stitching, YOU put in the hardware, YOU worked the leather, and most importantly YOU came up with a great design.

-

Thanks for the reply. I kinda figured as much. I've got some time before I need to worry about what to replace it with, I've disassembled the entire upper arm to clean up some rust on the timing belt pulley and feed lift eccentric (that had a broken set screw which was fun to remove). While it's disassembled I'm gonna give it a new coat of paint, then I'll see how easily it all goes back together.

-

Just want to say hello to everyone. I don't actually do any leather work (so far, not that I need another hobby), but the information on industrial machines available here is some of the best I've found on the internet. I've been doing some work repurposing old horse blankets and my domestic machine wasn't up to the job. I recently acquired an old Singer 111W155 that I'm in the process of refurbishing. It's in good shape overall but the timing belt was in multiple pieces and the safety clutch and upper pulley it rides on were both a rusty mess. Here's a set I made my daughter for Christmas using my Bernette B79. It got it done, but sewing threw all that blanket/canvas/lining/webbing was a struggle.

-

Welcome to the forum! On my singer 144 I replaced all the wicks I've found with small pieces of polyester felt. I suspect any kind of yarn or absorbent fabric would work. It just needs to hold the oil as a reservoir so the oil can slowly feed the shaft.

-

Thanks for kind words, but the laser cutter does the difficult stuff.....

-

Can anyone advise me on the value of this machine? According to the fellow who is selling it it works, however he doesn’t know how to run it. He’s selling it for his wife’s deceased grandfather. I can go to his place and try it, however the distance is a trek for me to go without having more info about it. Would it be reasonable to ask him to have it serviced/evaluated before going? Is a machine this old worth $1000? Many thanks for any advice.

-

With the background that is in it yes

- 2 replies

-

- bsa

- order of the arrow

-

(and 2 more)

Tagged with:

-

Yvon joined the community

-

Hi, I have a Pfaff 145, that I’m trying to reduce the clearance between the hook and the needle. Timing is ok, but the hook is too far away from the needle. when I move the shuttle block towards the needle, it hits the hook washer, while the clearance is about .005”. has anyone encountered this situation before, and what is the solution? Thank you

-

Hello from Germany - New Member Introduction

PastorBob replied to Tove09Tilda's topic in Member Gallery

Welcome from SW Missouri, USA. Lots of folks from around the world here. Glad to have you and happy crafting!!

.thumb.jpg.6e903dd66163ad5672f00f144058c571.jpg)