All Activity

- Past hour

-

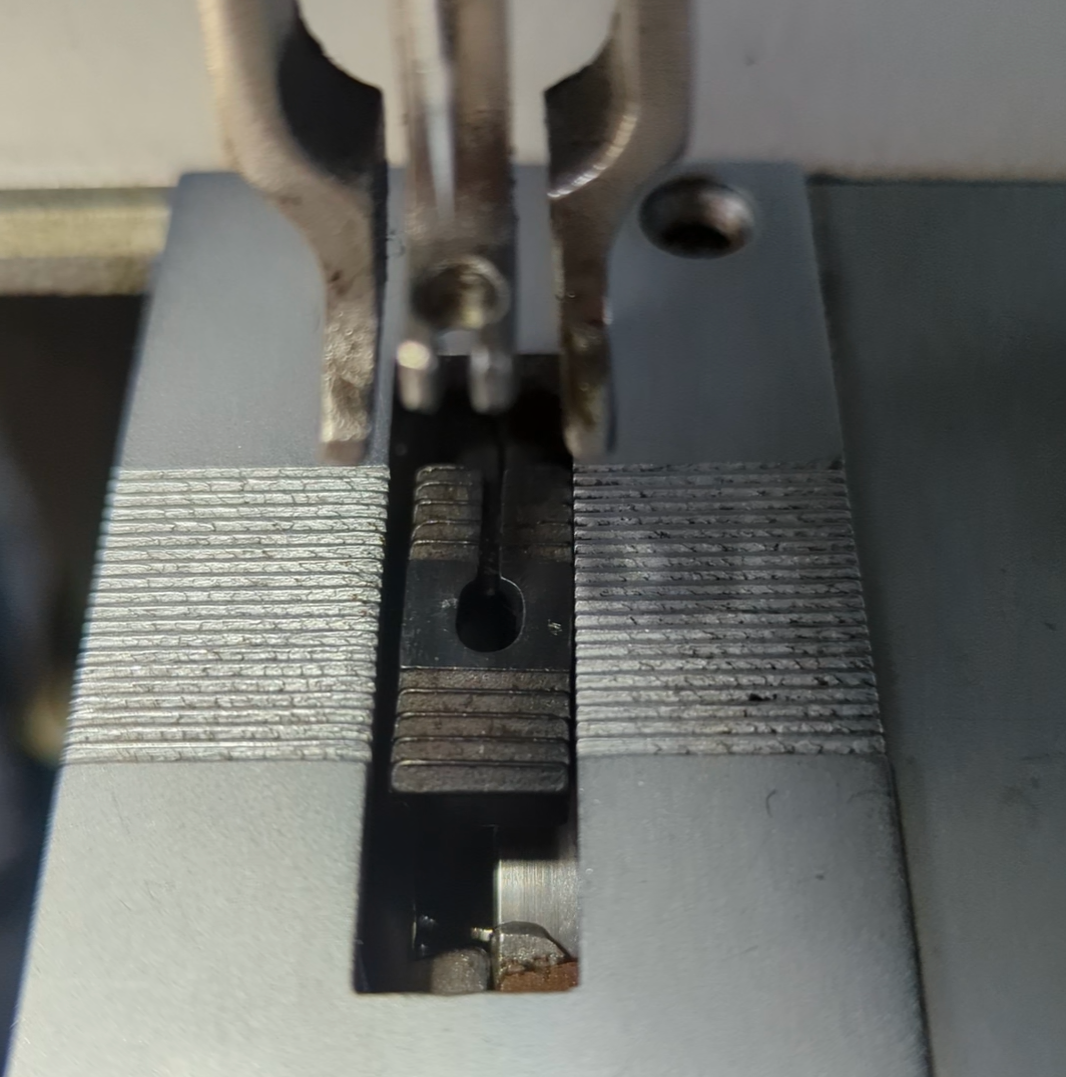

You can move the feed dog holder a bit sideways.The feed dog holder is attached to the feeding rod with 2 pointed screws (one on either side). When I look at this picture I think the feed dog seems to be misaligned. What I would do first is loosen the 2 feed dog screws and try to align the feed dog. Then I would try to move the feed dog holder to the left. It should be the same as on Singer or 45K Adler 104 flat bed machines. I´ll take picture tomorrow

-

lol thanks yes, it's a tool above all made for a purpose, keeping the blade clean and dry and keeping my body parts in order. On that note, and to those making outdoor gear that may read this. One coat of whatever you use for conditioning or waterproofing may not be enough. Give it a day or two to soak in well, then, if it has gotten stiff and dry again, give it some more. This thing was bone dry again this morning, so I gave it another coat.

-

Pardon my ignorant behavior; I've not commented on the leatherwork Tis a nice bit of functional leather work.

-

In the UK; illegal to carry openly without a good reason, concealed is generally alright, but it needs to be secured

- Today

-

Next they'll be outlawing chain saws. Lol

-

Is it illegal to carry a hatchet or ax? Curious minds want to know… But Chuck, both pieces look really nice! —AZR

-

Chuck, returning to your question, I use warm water and dawn dish soap beforehand. I figure if it’ll get crude oil off of a duck, then it’ll get whatever oils that come to the surface without damaging the hide, then rinsed as many times with warm water as needed, and once more for good measure. Because it’s usually fully-saturated by then, I let it air dry for several hours (AZ, it’s a dry heat, etc.) And I do have logic regarding dawn, albeit it may be flawed logic… It pulls the oils out, leaving it thirsty, which then will pull the oils from the dye deeper into the hide (almost exclusively use Fiebing’s Pro). But again, my logic could very well be flawed. With finished leather, then I use saddle soap. Only exception I can think of is my couch. Then I use dawn if I absolutely have to, followed by saddle soap. So far, it’s worked well for me, but if you have a different process, then I’m all ears. — AZR

-

I'll bet those gangsters will just go down and turn 'em right in when you do.

-

-

Not totally banned in UK yet. In the UK its the weapon of choice for gangs. To be killing other gangs or often innocents (yes, real innocent people). We don't have any real wild areas where a machete is needed but a few groundsmen and gardeners have them in their tool boxes

-

I'll do that tomorrow, the day is over on this side of the Atlantic and I am no longer at the workshop

-

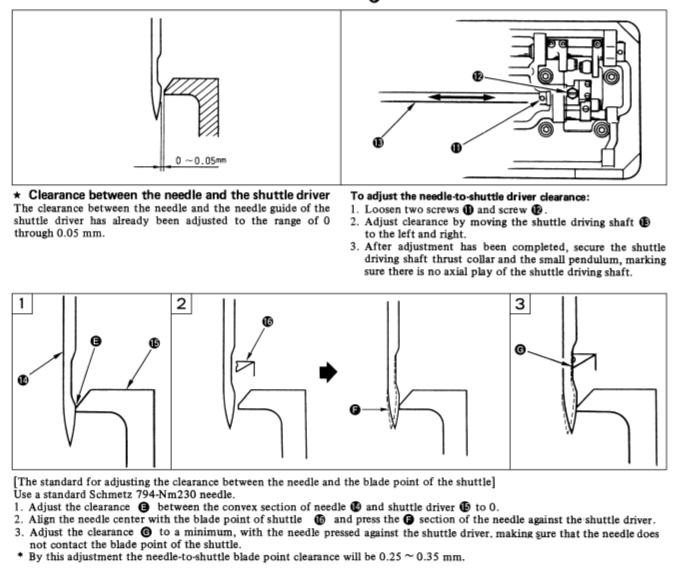

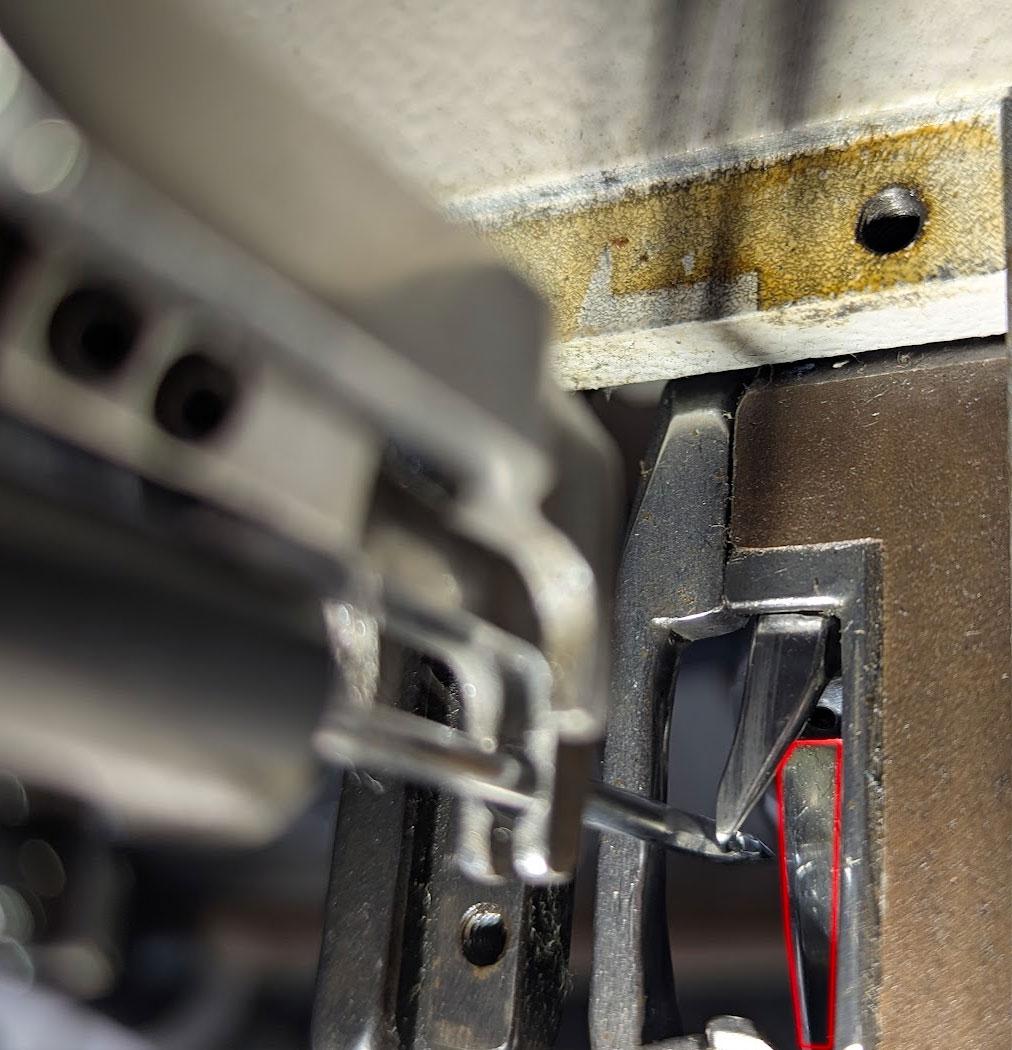

@AlZilla It's in the post below the one you mention that I am wondering if it's bent or not (post is still visible on previous page). I cheched it and can not decide if it's bent or not... It's hard to tell when you have nothing to compare to so I ordered a new one but won't get it before two weeks Meanwhile, I put a 230/26 needle in the machine (I normally use 160/23), as asked in engineer's manual and needle was rubbing on the shuttle point so I set "needle to shuttle clearance" accordingly, it's not rubbing anymore I am now trying to set up "needle to shuttle driver clearance" but I am confused trying to understand what I have to look at. Is it the part of the shuttle circled in red in my pic ?

-

I use a contact adhesive all the time For small areas or seams I use a tube glue called UHU. For larger areas I use a brand none of youse would have heard of. I work straight from the 1 litre tin. Sometimes I pour in a wee bit of Evostick adhesive cleaner which acts as a thinner too and it stops the glue going 'off' I rarely wait for the glue to go tacky. One generous coat of glue on one of the item parts then I stick the items together and clamp up. After a couple of hours I remove the clamps and tap down with a small rubber-head mallet Never had a problem doing it this way and 99.9999% of the time I get a good glue bond

-

Choosing durable dog collar thread... linen, Nylex etc...?

TomE replied to LakeOtter's topic in Sewing Leather

Tapering the end of the thread works for heavy linen thread, but not for synthetics. For linen I wax the thread, ends and all, after making the tapered ends. The wax will help keep the thread from slipping through the eye of the needle. However, most of my hand sewing is done with bonded nylon thread from my sewing machine. For hand sewing I wax the nylon thread and rub the wax with heavy wrapping paper to smooth it out. I use waxed polyester thread (0.04" = 1 mm) from the Maine Thread Co for some heavier jobs like sewing billets on a saddle. For that task I double the thread, tie a knot in the end, and use a single needle backstitch instead of a saddle stitch. -

I refill a Barge quart can from a gallon can, adding Barge thinner as needed. Made a funnel from a 16 oz plastic bottle. What is everyone's favorite glue pot?

-

yea, i have a smaller glass weldwood bottle with a brush that I transfer to. You can also replenish the acetone as needed if it starts drying up. i usually put a bit in the can after opening it or transferring.

-

I replace the lid after I finish gluing an item. I also tap the lid around the edges with a mallet. Used to do a lot of plastic laminate work. Bought the contact cement in five gallon buckets. Also: I used latex contact cement on laminate, only use solvent based on leather.

-

OK? So are you guys popping the lid on wildwood glue each time you use it or are you transferring the glue to a different container and using a different type of applicator? I've been using barge quart cans with the applicator and a pair of channel lock pliers to get it open every time I need it. Is their a different more convenient method?

-

Your first version of this post said the feed dog was bent. Have you decided it's not? Maybe drop the foot and lower the needle to evaluate the position of all 3 (foot , feed dog and needle) to get a better idea what's going on.

-

My general impression is that a single blade and a basic Craftool knife eventually trade hands for around $50. That is perfect with no chips. Sometimes you will find the right buyer who will give $60-$70. It looks like from the pictures one of the straight blades is chipped. If so, that makes it a part of the team but sitting at the end of the bench. Two good blades - I'd think expect $80-$100.

-

Oh so you need to build complete panels from scratch? maybe use fiberboard or whatever it was like antique and vintage vehicles used. Look up some vintage restoration stuff to study the process. Also some newer panel building techniques where they use and shape foam, Ive watched some of those on utube when doing my MGB.

-

Sweeeeeet! Nice work!

-

I don't think Fred meant you to seach for your exact truck. Those metal mounting brackets are pretty generic; I've encountered them before on cars from different makes. Just look for panels with this kind of mount, saw the plastic mounts out of the scrap panels (take at least an inch around the mounts so you have room for screws), glue/screw them to your MDF board in the right positions, and finally upholster the MDF in leather.

-

Railed sig 1911 bbq rig

chuck123wapati replied to Stetson912's topic in Gun Holsters, Rifle Slings and Knife Sheathes

-

I've been using a heat gun to "activate" contact cement - just a brief warming of the glued pieces before assembly. Bonds well with less cement so I have fewer problems with the glue interfering with burnishing edges. For some shaped pieces I case the leather lightly and shape the leather before applying the glue, and the heat gun treatment results in a better bond when the leather is damp. I'm using Barge cement but will probably switch to Weldwood in the future.