All Activity

- Today

-

It has been crazy on the farm, haven't spent much time on the computer. Had some fun tonight making an EDC sleeve for my Buck 301, Kaweco Fountain Pen, and a spot for cash and cards. It was fun having to split leather with a skiving knife, it isn't even totally but it works. Going to be fun seeing it age.

-

Thank you for the kind words. I enjoy teaching at Tandy, they are all skill levels. I am learning also. Appreciate it, ths has been an adventure for me also. Can't wait to bring my setup down. Nice

-

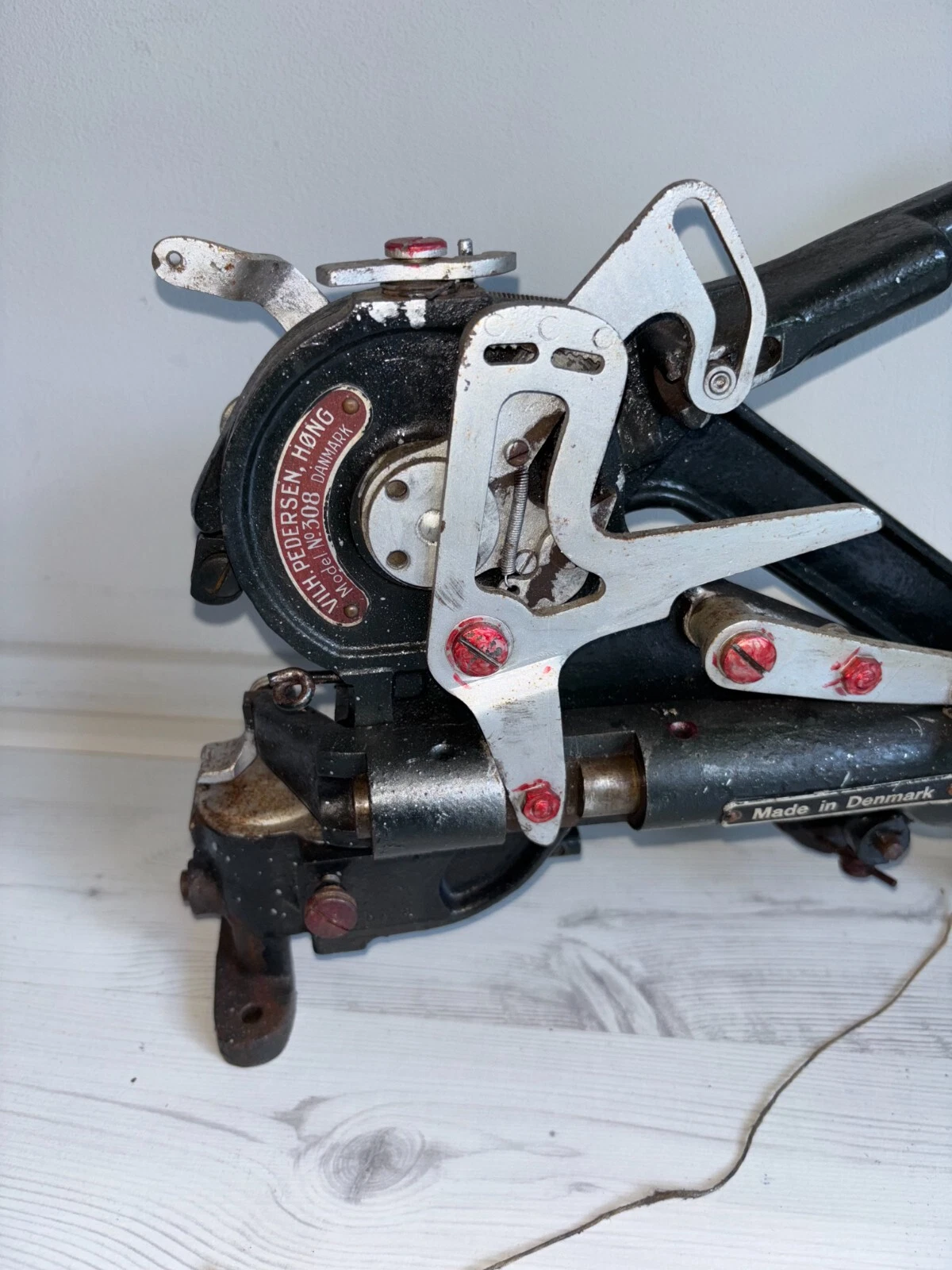

@Calidora There is a German classified page that usually has some spare parts on it: https://www.kleinanzeigen.de/s-junker-ruh-sd/k0 I just searched for "Junker Ruh SD" at the moment there are two parts for sale. But there have a seller that had a bunch of parts. I know that shipping will be a bit expensive,but I hope that you'll be able to find the parts. Brgds Jonas

-

Rather than start a new thread I've tacked this on here. My daughter has a gym and some time ago when she moved locations she had a heap of rubber mats, the ones they use on the floor of gyms, left over so I grabbed a couple (I didn't have a use for them but....). Anyhow I've been using them to stand on in my shed when it suddenly occurred to me maybe they would be good as a punching mat? They're very dense rubber, so very heavy, and 15mm thick (3/4" for any heathens out there). Tried punching some leather, nope, just lots of rebound! Hmmm, a cutting mat maybe? Yep, that seems to work, has some "give" so hopefully won't blunt knives too easily and the leather doesn't slip on it. I guess time will tell.

-

help choosing first leather sewing machine

RockyAussie replied to TakashiOkada's topic in Leather Sewing Machines

That would be my choice and is the same as mine which can do about 90% of the work I do at Wild Harry. Note that the feet available on this machine have the same as the old Singer 111W machines which covers about anything you could ever want. Also note that this is for the head only and you may want to get a table and servo motor from them as well perhaps. Do not get the U shaped table as they get in the way too much as shown in the following video which is a different machine but shows the same problem - -

While the bodice of this Letterman Jacket was made from wool and lined with quilted satin, this piece was a transformation of sorts into the leather realm for me. In addition to the hair-on leather stacked letter B, I made the sleeves with some of the softest deerskin I have ever come across. I am also ever-searching for a supplier that can match this quality hide as it is my favorite skin due to its resiliency in relation to its softness. In fact, it was when I was out shopping and first came across this deerskin that I was the inspiration for this jacket. I wanted something that could represent the brand and this is what I came up with. Some other details are the hand cut leather back lettering, the Ursa Major (Great Bear) embroidery, and leather BCN lettering on the front. If you look closely, there is some errors in the stitching. I was till getting used to stitching several layer of leather together. Comments and/or questions are welcome.

-

Development of best servo motor for leather sewing machine

dikman replied to CowBoyOUTLAW's topic in Leather Sewing Machines

Al, I understand what you're saying, I've spent $1000's since getting into shooting (primers and powder are ridiculously expensive now ) and once I got interested in leatherworking I sort of lost track of the expenditure BUT I also do my homework and there's nothing I've read to indicate replacing my existing motor/reducer setup with this "supermotor" is economically viable, nor do I think it will do anything better. Goods in Australia are more expensive than in the US so unfortunately I tend to get "wrapped up" in pricing (particularly since that Chinese Cough has stuffed up shipping costs!). I'm just genuinely confused about this motor and this thread, I think Cumberland Highpower probably picked it, the motor is already made, with the features in the first post, and this is essentially a publicity blitz. -

Development of best servo motor for leather sewing machine

AlZilla replied to CowBoyOUTLAW's topic in Leather Sewing Machines

I wouldn't get too wrapped up about price. Lots of people splurge on expensive stuff for their hobbies. Lots of people here drop thousands on a machine anyway, what's a couple hundred more for a cool motor? And bragging rights? I've never found easy availability of the HM-750 in the couple of years I've known about it. I don't even know what they retail for, so will we even be able to point and click the new wonder motor you guys are designing? -

Development of best servo motor for leather sewing machine

dikman replied to CowBoyOUTLAW's topic in Leather Sewing Machines

A google search for Kinedyne was interesting, the company specialises in manufacturing cargo handling/securing products. They do not make motors they source them from Hightex, who I believe manufacture Cowboy sewing machines. So, who is Cowboy Outlaw working for? The posting makes it sound like Kinedyne, but that can't be the case because they don't manufacture motors but the OP is talking about seeking information for the next motor they're making. If it's Hightex then I doubt they would be very interested in what we say because by his own admission they make motors for large manufacturers who want features we don't. And you didn't answer my question - does it have a built-in gearbox, which you said it does in reply to GerryR? This is becoming confusing. -

The minimum speed is 50 RPM only, and the torque of motor is enough to drive any extra heavy duty sewing machine, why with gear reducer? For the high price, easy to explain: other 800W and 1000W servo motor in today market cannot drive CB4500 withour speed reducer, but our 750W motor can; Other motor use Hall Effect sensor, we use optical sensor; If you tight the machine belt, other motor frame maybe bend, our motor frame will not.... For the NPS, I might be wrong, in China we mainly sell to manufacturers who need high speed, all motors to them must be with needle positioner. Jog dials, needle position and 1/2 stitch adjustment, they are optional for people who need it. "For a decent servo to run a 441 sewing heavy leather you only need to keep it simple" -- thank you, really appreciate it!

-

Tr3vor joined the community

-

Development of best servo motor for leather sewing machine

dikman replied to CowBoyOUTLAW's topic in Leather Sewing Machines

So your motor has an internal 5:1 gear reducer? That's what you just said, and if so that would explain the high cost. You say that an NPS is "necessary". Who says it's necessary, it's the considered opinion of some of the more experienced on this forum that it is not necessary. I think we need to clarify exactly what your intended market is, on the one hand you're emphasizing extreme slow speed control (without needing a speed reducer) for the likes of a 441-class machine and then you're talking about the necessity for NPS, jog dials, needle up/down position and 1/2 stitch adjustment (?). For a decent servo to run a 441 sewing heavy leather you only need to keep it simple, as has been pointed out - slow speed and easily adjusted variable speed, nothing more is needed. All the other "extras" are more suited to higher speed sewing. -

It may be a cultural difference. We need the hand-on experience from leather workers to improve the quality of the motor, so we carefully analyze and explain these suggestions. Is there anything wrong? We tested ISM SV-71 650w servo motor, it can't directly drive extra heavy duty leather sewing machine like CB4500, if without speed reducer

-

We have been looking for over 6 months, we have contacted all motor supplier include HO HSING and ISM.... Even ingnore durbility and perfomance, no servo motor can directly drive CowBoy CB4500 if without speed reducer. Kinedyne HM-750T and HM-750L Energy-saving Motor use Hall Effect sensors, HM-750SL and HM-750S servo motor use optical sensors

- Yesterday

-

Development of best servo motor for leather sewing machine

GerryR replied to CowBoyOUTLAW's topic in Leather Sewing Machines

My opinion, from a mechanical standpoint, is to start with a servo that has an integral 5:1 gear reducer. This automatically increases torque and allows the servo to start at a higher speed. This is easier on the motor and the drive electronics. Also, a dual pot foot pedal, one pot sets the max speed and is hand adjustable, the other is the foot-operated pot so you always have the full range of the foot pedal for whatever your max speed is set to. I have this on my system which utilizes a variable frequency drive (VFD).) You might even consider offering an AC-servo system (VFD controlled) instead of a DC system. The electronics are inexpensive, especially for 1 HP and less, however, they require a 3 ph motor to operate, but they can be had with integral gear boxes. As you are designing from scratch, you can spec your own motor. I have had two systems with AC servos and two with DC servos and personally prefer the AC units. Also, a needle position sensor can be implemented with a proximity sensor and metel "flags" put at appropriate locations and you can have multiple flags to stop at various needle positions. If this is implemented along with a jog button or heel pedal switch, you can control all your stop positions quite easily. Just some food for thought. -

Development of best servo motor for leather sewing machine

dikman replied to CowBoyOUTLAW's topic in Leather Sewing Machines

That's commendable that you make your own motor, although if you had so much trouble with the original motors you supplied why not just change supplier? It would be interesting to know the failure rate of the motors used by other sellers - Cowboy, Techsew etc. In general modern electronics are pretty reliable but ANY circuit board can fail at ANY time, often for no discernible reason, although surges/spikes are often the main culprit. Wiz, interesting thought but I'd be surprised if they use optical sensors, everyone seems to have gone to Hall Effect sensors now. -

Looks like someone moved the hook saddle over, trying to disengage the left hook. You can see the extra gap between the needle plate and bobbin case. That lets the tab on the bobbin case hang up on the stops under the needle plate. Might be an easy fix. Whoever had it before was sewing single needle. Another tinker while I await the motor ...

-

Thank you. I'll just buy one I should learn how to disassemble this machine anyway.

-

Don Acott joined the community

-

Yeah, I have a few needles. I looked through Ebay and they currently don't have the parts I need. I'm sure I can make the tensioner and the plate thing myself but the screw for the stitch length is another story. If I knew the thread pitch and size, I might be able to make one on the lathe but I'm not sure. never made a screw before. I do have a machine shop near by maybe I'll go to them if I can find the info I need. thanks for the help.

-

@Calidora I think the only place to find spare parts are on Ebay or similar sites. But just as a "warning" before you spend too much time and money hunting parts: The needles are really hard to find, and not readily available. I once checked Gross Beckert, and they'll make a production run if I ordered something like 500 needles. But if you have a couple of needles, then all is good :-) I have a machine like it at home, but I have been too busy tinkering with it. But I am pretty sure that it dodn't come with any spare parts (I am at sea right now, so I can't go check it) Brgds Jonas

.webp.4d7785cc054b1306bd20880d2db0a74f.webp)

.webp.b95d0633375da6bddcfbcefd1ad1da3c.webp)

.webp.051589581b2f950c1958c87c114f2d5a.webp)

.webp.caea44d68c216fef4dbdf65561598be6.webp)

.webp.3431bbd6928190ddec16d972e97c1063.webp)

.webp.f27d31de04a1c4f15e8ac13939d0925d.webp)

.webp.75e6e77fe7a48e5f9253494467eee692.webp)

.webp.8b5cc0c9d6bd30ad96cb8fb1f927cc7f.webp)

.webp.81b187ea43bf315bb46c21f53360c48e.webp)

.webp.d299762019f966b0d27f98f80bd131e8.webp)

.webp.1ff2138da00e7c11b81bc98baca9863b.webp)

.webp.590d295836f0a25741f01fd8df1f5b9e.webp)