All Activity

- Past hour

-

Domestic sewing machines

Curious Observer replied to Curious Observer's topic in Leather Sewing Machines

-

I've got a scad of these old domestics, but no Pfaffs I'll agree with Friquant that the old Pfaff really should start slow and smooth and ramp up evenly. Foot controllers are often a culprit, The motor itself can be a factor. Most of them can be disassembled, cleaned, the commutator surface refreshed and new brushes installed. Plenty of youtube videos. Find one shows how to test the windings for opens and shorts. A multimeter can test the foot controller. I don't have any exact values to give you but the resistance should start off high and drop to zero or close enough with the pedal fully engaged and do it smoothly. Let us know how its going.

- Today

-

Can you post some photos/videos of your Pfaff 130? Foot Pedal Does your foot pedal give linear response? That is, proportionally more torque based on how far your press the pedal? If not, buy a new pedal. Here's one I bought recently which gives good response: https://www.amazon.com/dp/B08D8WPWTY Slow Downers As for slowing it down (and increasing available torque) there are many ways to slow down a machine. Adding an oversize handwheel is just one: https://leatherworker.net/forum/topic/132445-domestic-motor-with-plywood-pulley/ Other ways include going to a smaller motor pulley, or adding a speed reducer between the motor and the machine. Or finding a motor that is slower in the first place. Here is a link to the Used Sewing Machines: https://leatherworker.net/forum/forum/84-used/

-

FEIT DCL-8500N : Stump for Tilting Machine Head

friquant replied to friquant's topic in Leather Sewing Machines

No lock screws on this one. I've got the head unit on my workbench, and I've been experimenting with different support points using a test support. Some positions are quite stable, other cause it to lift at the hinge line. I think I'll 3D print a new support (shorter than the original so the head unit pivots exactly 90 degrees) and use either a screw or double-sided sticky tape to hold it down in one of the stabler locations. The other idea that popped in would be to screw the support to the back of the machine head. But then I'd have to source screws that match the threads that the rear cover plate is already using. -

I moved your post to stamping

-

For sale items should go in the marketplace. This is unusual to be posting for someone else. I'm moving it to the marketplace. See the marketplace rules here https://leatherworker.net/forum/forum/70-announcements/

-

.thumb.jpg.6e903dd66163ad5672f00f144058c571.jpg)

FEIT DCL-8500N : Stump for Tilting Machine Head

Northmount replied to friquant's topic in Leather Sewing Machines

Some machines have a screw that locks the hinge to the machine base. Stops the machine from sliding around when tilted. Have a closer look at your machine and the type of hinge it uses. Maybe you will have an easy fix. -

I'm interested in one of them - I live pretty close

-

Here is a knife sheath I cut out and scored the pattern with my S1 40w, then tooled it. Not the prettiest but it was my first shot at using the laser to score the pattern instead of using a pattern and transferring with a stylus. Also used the shape tool to make the belt loops - not the final shape, but again, for an experiment it didnt turn out too bad.

-

RenTin joined the community

-

I moved your post to Leather Sewing Machines since you want to learn how sewing machines work. This is the place!

-

Dang, to far away. Been looking for a used Cobra 26 for a while with not a lot of luck.

- Yesterday

-

Greetings and Happy Holidays to all I am trying to learn how to machine sew, in that effort I bought an old domestic machine. A true leather sewing machine is too expensive for me to experiment and find out if I’m able to machine sew at all. I probably overpaid for a Pfaff 332 but don’t regret it. I did fall for the vintage machine thing as I later fell for a 130 of the same brand which was in shambles, but was able to bring back to life. This latter one actually sews while the 332 I have yet to bring to full operational status. I’ll admit it, I then grabbed a 260 which is also in very sad shape and awaits in the shed for a spring makeover. This 260 I feel was a good deal as was the 130, though admittedly I’m no expert. I would like to know if someone can tell me if there might be a way to reign in and better control the speed on my old yet spirited 130. I’m trying to design a specialized bag which she might be able to sew. Other than that, at this time I make coin and card holders which is what, like many others I suppose, I’ve started my leather making/playing with. I hope to eventually buy a used leather capable machine which is my other question. Where in your site may I find used leather sewing machines for sale? TIA for your help and time. Mario

-

I've read about this drop test but it never occurred to me that the bobbin must be different to be able to do it. I always go with a try first. Because my hobby uses different types and thicknesses of leather I'll always test on a bit of scrap first to check tension and needle size. I'll always use the 45 degree slide test as a starting point for needle size and adjust if necessary.

-

Beautiful job! Mine is still in its battered old grey paint - having restored a machine once I'm in no hurry to do it again!! Mine had the cutter assembly which I removed.

-

FEIT DCL-8500N : Stump for Tilting Machine Head

dikman replied to friquant's topic in Leather Sewing Machines

With "older" machines the rest (which is what it is) is made of wood and just pushes into the hole in the table, I've made my own from a broomstick handle. If you think it's too high you could cut it down or once you get it out try making a couple of replacements at different heights to see which works best. -

You can disconnect the belt while you diagnose.

-

made a leather card holder for a friend for christmas, different to what was going to do. leather did not want to allow me to transfer image, even when I tried cutting into leather was hard to see the lines with the fuzz part so just make outline stincel traced out before adding all the detailing in by hand.

-

these original manuals pop up every now and then. i just recently bought two from a guy in France he still has some: https://www.ebay.de/sch/i.html?ssPageName=&_ssn=zougoulouba

-

Do u have the same skiver?

-

FEIT DCL-8500N : Stump for Tilting Machine Head

friquant replied to friquant's topic in Leather Sewing Machines

Anybody care to measure the distance from the hinge line to the tilt stump on their machine? My working hypothesis is that a tilt stump too close the the hinge axis will lift the machine off its hinges. For reference, this is the hinge type on the table. I have not personally owned this style of hinge. It appears that even with the machine head tilted back, the hinge can still be pulled straight out of the table. But I suspect that is true of this other style as well: -

Well if anyone needs a scanned copy, or the actual books, they can message me details.

-

Cowboy 3500 Running when Powered On

Constabulary replied to KYCat's topic in Leather Sewing Machines

Guessing - most likely a motor problem. I guess the machine has a servo motor so I would guess the lever of the accelerator unit or the hall sensor is loose / has moved and is probably stuck in the "run" position. Please post some pictures of your motor and the accelerator unit and lever where the it man rod is attached and maybe a video showing the issue (please not just 5 second video or so" upload it to YT and post a link here. -

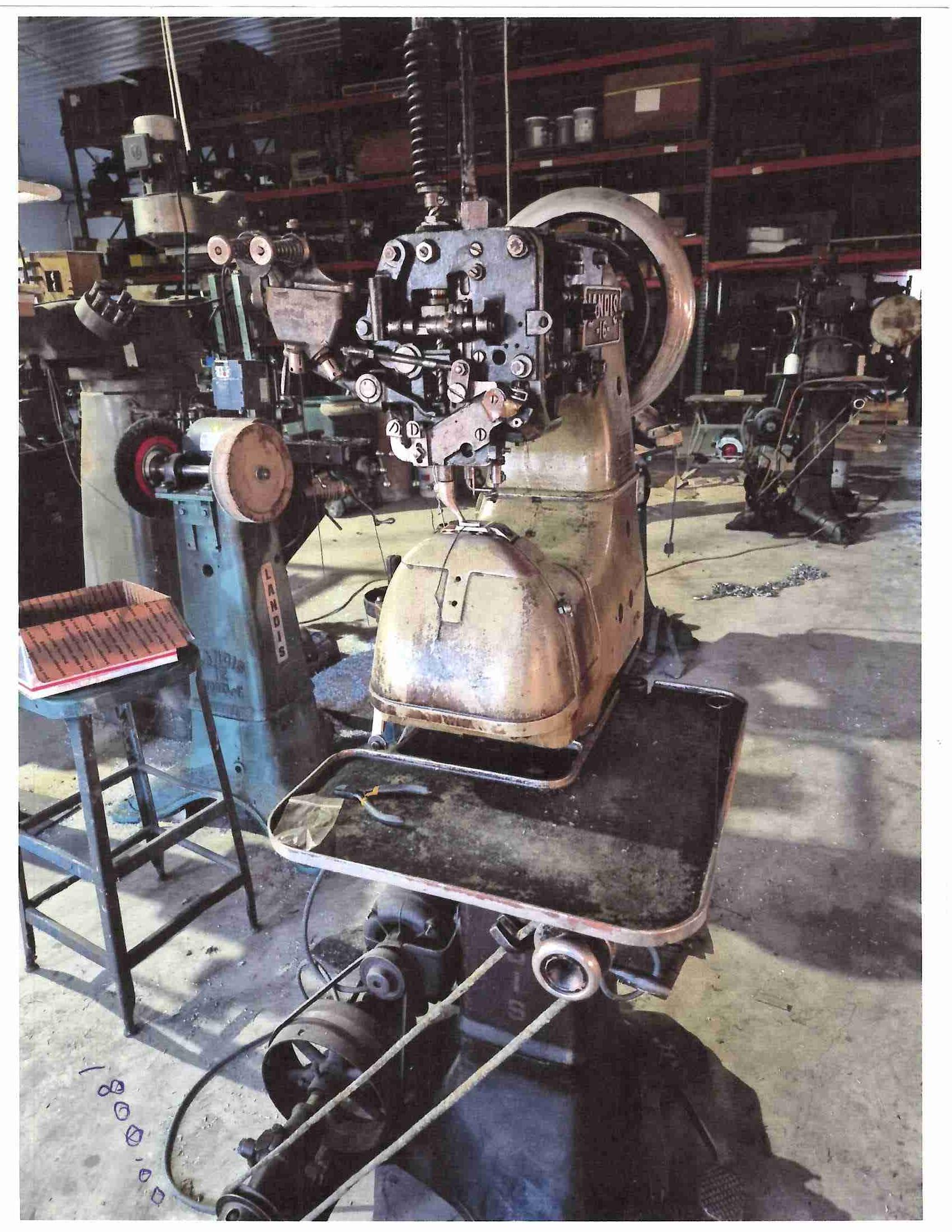

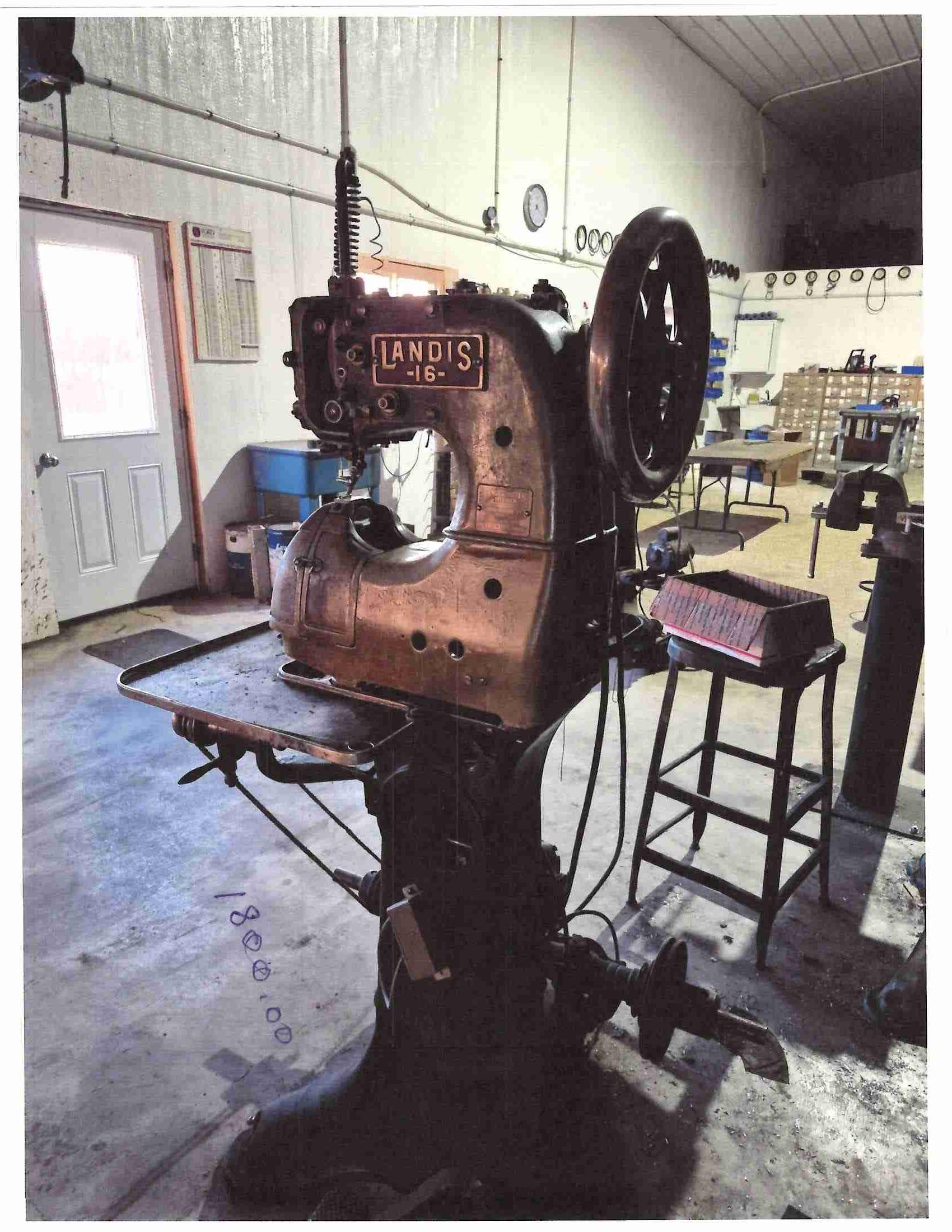

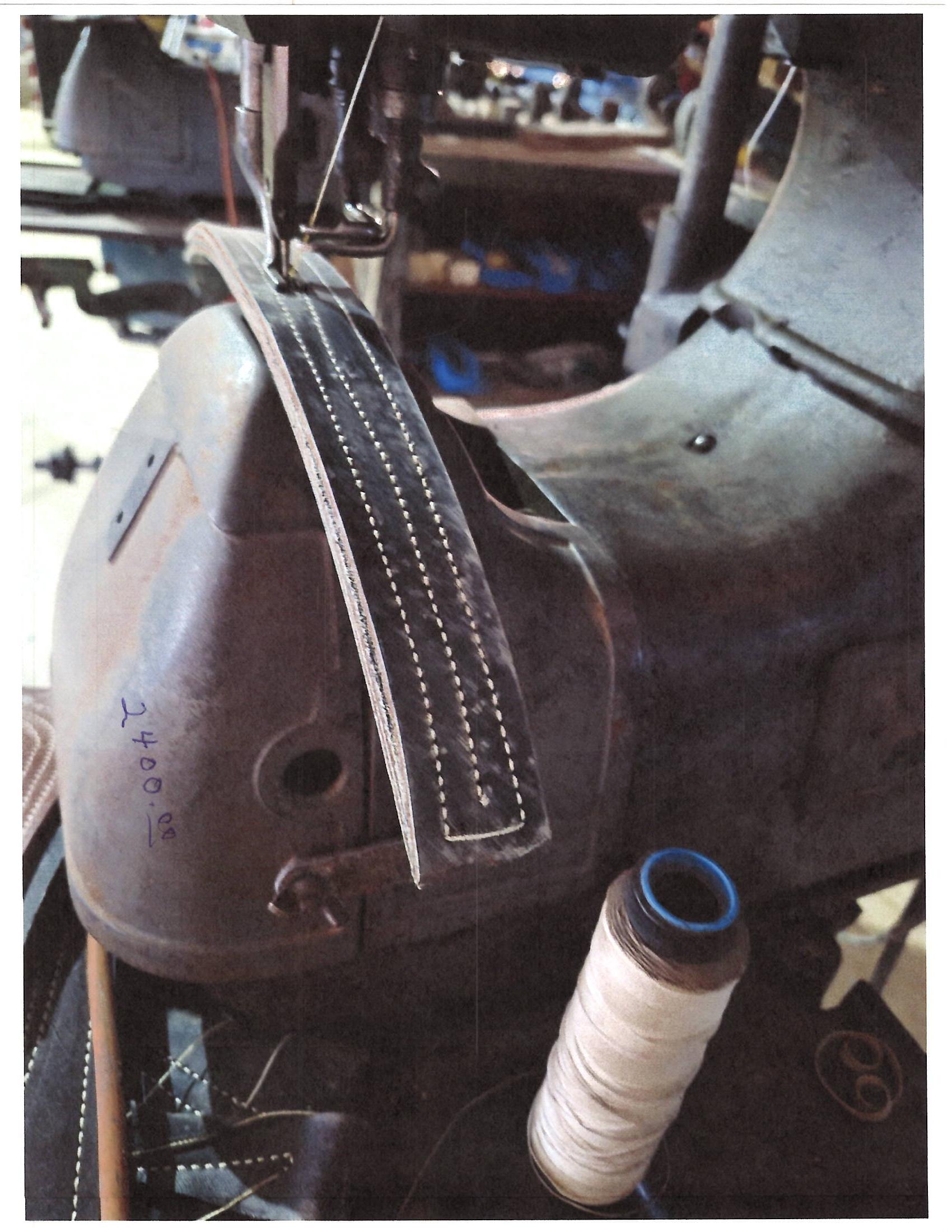

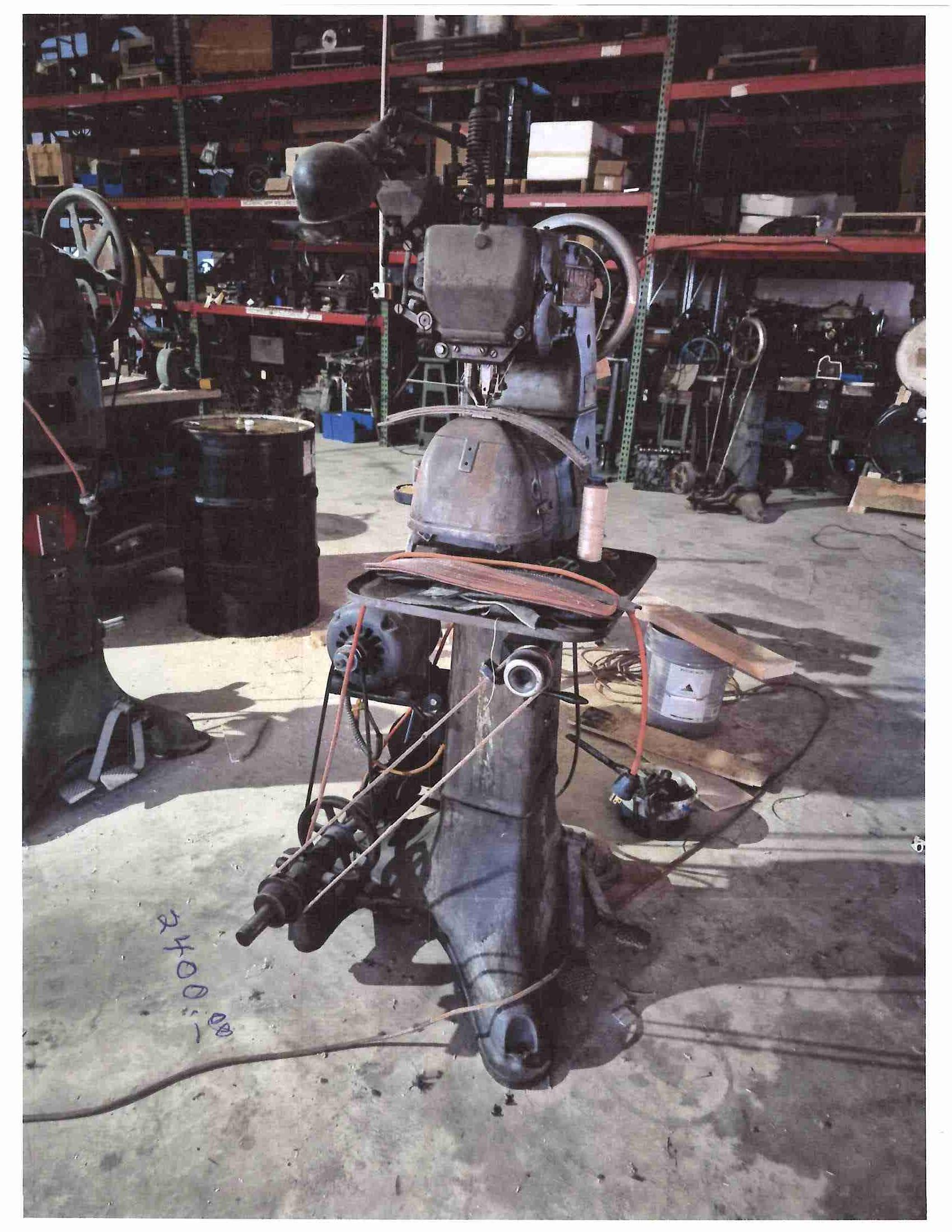

Hi I talked to Eli today over at Landis Machine Co was making sure he received a check that I sent him for a part for my Landis 16. I am posting this on here for Eli. He said he has two Landis 16 for sale he went through these machines and they are ready to sew and he is selling them for one of his customers. I told him to send me the photos and I would post them on here for him. Eli is a really good guy and one of the only people that has parts and can fix these old Landis 16. I sent him my Landis 16 and she is sewing a beautiful stitch. Give him a call if you are interested. The one machine is $1,800.00 and the other is $2,400.00. Here is Eli contact info. I was not sure where to post this one. Landis Machine Co 6373 Country Road 400 N. McLeansboro IL 62859 for pickup. Phone # 217-543-3464

-

yeah - keep that old cast iron alive - I seldom went wrong with that! 😉 I love my 51w but the 2nd type as yours would be even more preferred but I love mine too. Singer crazy me is. 😁

.jpg.f58aae0a5a412488c859062e96d83d65.jpg)