All Activity

- Past hour

- Yesterday

-

Development of best servo motor for leather sewing machine

GerryR replied to CowBoyOUTLAW's topic in Leather Sewing Machines

My opinion, from a mechanical standpoint, is to start with a servo that has an integral 5:1 gear reducer. This automatically increases torque and allows the servo to start at a higher speed. This is easier on the motor and the drive electronics. Also, a dual pot foot pedal, one pot sets the max speed and is hand adjustable, the other is the foot-operated pot so you always have the full range of the foot pedal for whatever your max speed is set to. I have this on my system which utilizes a variable frequency drive (VFD).) You might even consider offering an AC-servo system (VFD controlled) instead of a DC system. The electronics are inexpensive, especially for 1 HP and less, however, they require a 3 ph motor to operate, but they can be had with integral gear boxes. As you are designing from scratch, you can spec your own motor. I have had two systems with AC servos and two with DC servos and personally prefer the AC units. Also, a needle position sensor can be implemented with a proximity sensor and metel "flags" put at appropriate locations and you can have multiple flags to stop at various needle positions. If this is implemented along with a jog button or heel pedal switch, you can control all your stop positions quite easily. Just some food for thought. -

Development of best servo motor for leather sewing machine

dikman replied to CowBoyOUTLAW's topic in Leather Sewing Machines

That's commendable that you make your own motor, although if you had so much trouble with the original motors you supplied why not just change supplier? It would be interesting to know the failure rate of the motors used by other sellers - Cowboy, Techsew etc. In general modern electronics are pretty reliable but ANY circuit board can fail at ANY time, often for no discernible reason, although surges/spikes are often the main culprit. Wiz, interesting thought but I'd be surprised if they use optical sensors, everyone seems to have gone to Hall Effect sensors now. -

Looks like someone moved the hook saddle over, trying to disengage the left hook. You can see the extra gap between the needle plate and bobbin case. That lets the tab on the bobbin case hang up on the stops under the needle plate. Might be an easy fix. Whoever had it before was sewing single needle. Another tinker while I await the motor ...

-

Thank you. I'll just buy one I should learn how to disassemble this machine anyway.

-

Yeah, I have a few needles. I looked through Ebay and they currently don't have the parts I need. I'm sure I can make the tensioner and the plate thing myself but the screw for the stitch length is another story. If I knew the thread pitch and size, I might be able to make one on the lathe but I'm not sure. never made a screw before. I do have a machine shop near by maybe I'll go to them if I can find the info I need. thanks for the help.

-

@Calidora I think the only place to find spare parts are on Ebay or similar sites. But just as a "warning" before you spend too much time and money hunting parts: The needles are really hard to find, and not readily available. I once checked Gross Beckert, and they'll make a production run if I ordered something like 500 needles. But if you have a couple of needles, then all is good :-) I have a machine like it at home, but I have been too busy tinkering with it. But I am pretty sure that it dodn't come with any spare parts (I am at sea right now, so I can't go check it) Brgds Jonas

-

I want to get into leather holster making

kgg replied to Angrywrench's topic in Gun Holsters, Rifle Slings and Knife Sheathes

How true. If a machine was ever built someone on the forum probably has it. kgg -

Some follow up would be nice just to see how it actually worked out. But in the end if someone asks about XYZ sewing machine for a particular use and gets good advice, then it's here for the next person who comes along wondering the same thing. This place is pretty much Encyclopedia Britannica for leather sewing machines.

-

I want to get into leather holster making

kgg replied to Angrywrench's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Maybe new members should have to post a couple of times before asking a question like on some other forums I'm on. Nothing surprises me anymore particularly since the China Cough. What I have found is people seem to be more noticeably thinking they are entitled somehow with no manners and demanding as all get go then before the Cough. Basically a** holes. Then again it could be just me being me. kgg -

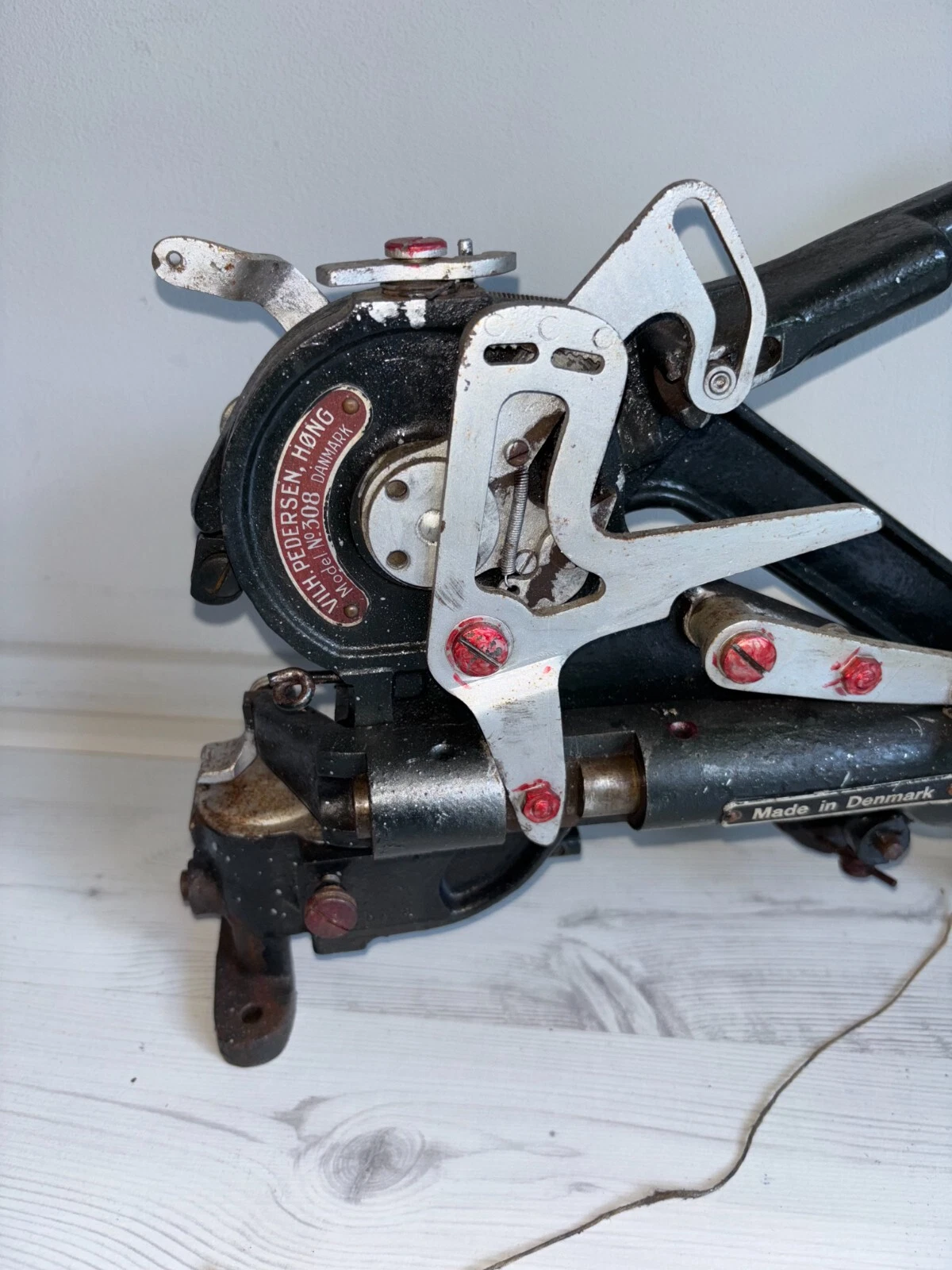

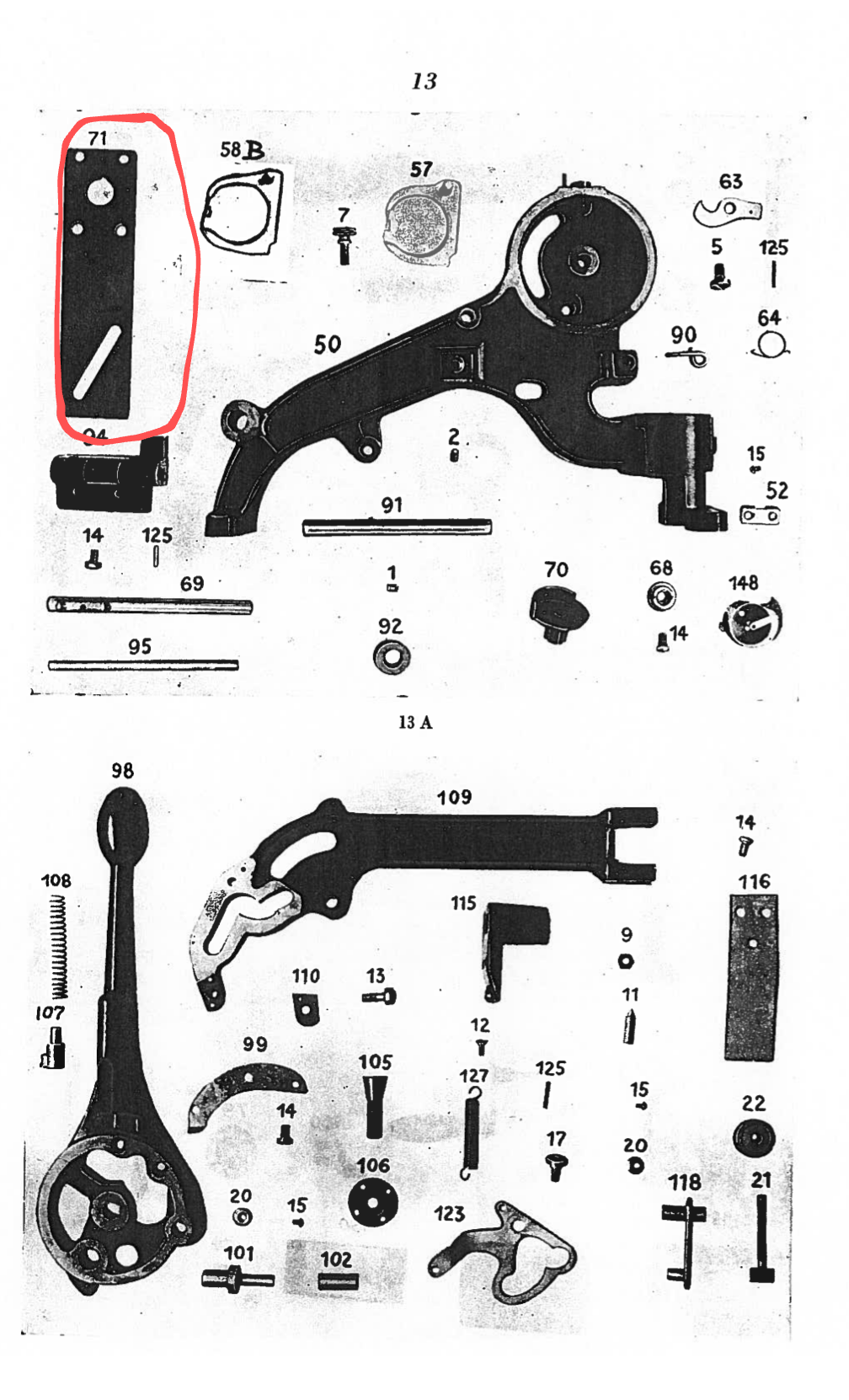

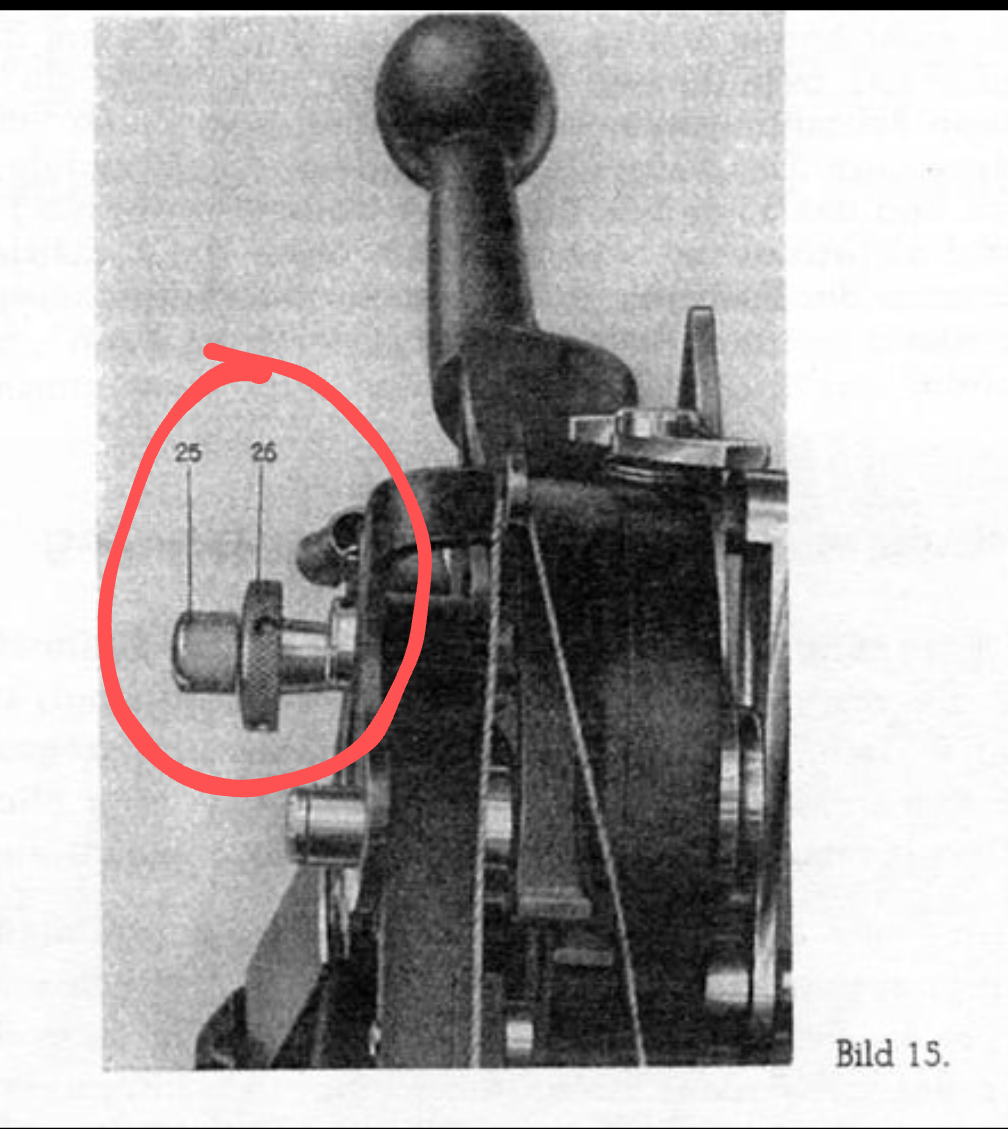

I recently purchased a Pederson model 308 and noticed that it needs some parts. It's missing the entire tensioning unit and the parts circled in the images. I believe they are interchangeable with the Junker and Ruh SD28. Is there somewhere that I might find these parts or am I out of luck and will have to make them myself. Thank you for your time

-

Is this motor optically controlled? If so, there were people printing variable density optical filters that users could install inside their digital motors. These filters smoothed out to speed variations so the motor started at zero rpm and steadily increased as the operator pushed down on the speed pedal. Stopping the foot motion left the motor at that speed until one backed it off or pushed down further. I had this modification on a motor that came with my Cowboy cb4500, in 2011 or 2012. I would compare the action to the analog motors that replaced it.

-

help choosing first leather sewing machine

Cumberland Highpower replied to TakashiOkada's topic in Leather Sewing Machines

I'd probably just buy this machine. I like the Singer/Seiko clones and this one has a reverse that's maybe easier to use (opinion). Don't know what size bobbin that "Typical" uses....So I'm guessing it's the "Typical" bobbin? Wonder if you have a little ability to negotiate with the merchant on price? When you ask for advice everyone has a different idea of what a machine should be used for. It's also pretty easy to spend someone else's money.... You can sew allot of various things on this machine. You can sew handbags and wallets on this machine no problem. watch bands also. A smaller diameter cylinder arm would be a plus on maybe an infrequent occasion, but this might be all you need? Heavy saddle work? No, but sounds like that's not your thing anyway. The 341 clones are a good choice but not necessary if it is more expensive. It's kinda like asking a farmer what tractor you should get to move hay? One would say a Ford, one a Deere and another a Kubota. The Deere and Kubota may have wet brakes and better hydraulics, but the Ford will move the hay bales around just the same-And for less money. -

It does appear to have been used in a few different machines, lucky for me. I think this machine is the ancestor of the W&W D12, except the couple of pictures I can find of the D12 show a single bobbin serving both needles. This is by no means definitive, just me searching the net.

-

Thanks for taking the time to send this along. It's quite close, a good clear copy and has an Adjusters section, which I don't have. Very helpful!

-

The manual for this machine is very close to yours. 72w19.pdf

-

It looks to me that you've just drummed up a thread on this forum to make sales of what you already market, Right? You're asking for input on "designing" a new servo, yet debate every time someone mentions a point or suggestion contrary to what you're already marketing/selling. For example when a member suggests options for supply voltages, you just jump to market your "Kenedyne" motor as it's available in both. You should have said, that's a great idea, we'll incorporate that into the worlds best heavy servo motor that we're working on, maybe we'll make it a dual voltage, plug and play unit! If you're looking to design a servo for leatherworkers to use on heavy stitchers, follow our collective advice and be open minded. If you want to add all these features including a ridiculous "jog dial" you're not really going to get anywhere. ISM in the Republic of China already has the best servo going with all those "other" features we don't really need. The ISM SV-71 650w servo is around $300. I bought mine from College Sewing machine for 189GBP ($258). Those units are light years ahead of any of the lower cost PRC made units and not all that inferior to a Ho Hsing unit. Maybe I'm a little too skeptical, I don't know. It could be something innocent like a mistake in translation from English to Chinese, or maybe a cultural communication mismatch? The members here buy Servos for 2 reasons. 1) Better low speed control 2) Needle Positioning Those are the only major advantages they have over a clutch motor and yes, clutch motors are very much still a thing. They're nearly indestructible, basic, easy to adjust, and power machines along all day, every day. I actually like the faint hum they make, you know the machine is on. Yes, they do consume a little more power, but unless you have a shop floor with 100-+ machines running, it's not an issue. If you factor in maintenance/repair/replacement of burned units as well as electricity consumption over a 10 year span, servos could and probably do, carry a higher cost. I have 21 clutch motors operating on my shop floor, the oldest date on one is 1967, the newest is dated 1993. (Most all are made in Taiwan/ROC back when that wasn't really a great thing quality wise). I seriously doubt any brushless servo would last 30-50 years?

-

Development of best servo motor for leather sewing machine

kgg replied to CowBoyOUTLAW's topic in Leather Sewing Machines

Like @dikman I did a similar search for servo motors and I find that I can get a Brushless for about $150 CAD or a Brushed for about $200 CAD. As I don't need or want a Brushless servo motor or any of the additional features the documentation needed for a Brushed servo motor is so basic. 5 easy steps: 1. how to install the servo motor and mechanical linkages, 2. install belt to the machine or belts if you have a speed reducer, 3. set speed by turning the speed dial, 4. plug it in to a wall outlet, 5. turn power switch on and hit the "go" pedal. If at some point a Brushed servo motor fails you typically have to replace the servo motors fuse and brushes. If a Brushless servo motor fails chances are you replace the complete servo motor setup. kgg -

The part # you are looking for is B1525-053-0A0. An original Juki part will have the needle guard while a lot of after market ones will just be the presser foot. If you contact a Juki dealer and ask for the complete presser foot assembly you will get it with the needle guard. Another alternative is to buy a Needle Finger Guard off places like Amazon. Example: ( https://www.amazon.ca/YICBOR-Sewing-Machine-Brother-Machines/dp/B08ZCF899N/ref=sr_1_17?crid=UO5IAKRG7BVO&dib=eyJ2IjoiMSJ9.2fLw6Era9Ry_EQb4ctlNR0XMnKd9cxPTyATq6kljrRUsFAsAY60K0rL24TCK1bhBM71KGBRj_bN5NkMMVaN4cKrL0Ttl1dPFMzVojOWsPo7wY9ruXUERvP51UQ9Z6Ws0-PC59GirIwKvznJSxcsbXhB2D9FV30xEjQtKF_ez23X6JfLEHT1L_DGHy5IyTM5Gud5gVQ5sQeej1YO1MFbOCaz30Vq3Omf80-yk9hkngzDM7Zv7Kht2CXjrZ-tNUZxKCzXU_reMtpUjrD4o9CfPCmsvX480rlFWypy8fpcw3Lw.v6_DjuKOKwrz96P_yooYKPm6sQqqEQ2RE5efMMrS0UU&dib_tag=se&keywords=needle+guard+for+Juki+presser+foot+for+juki+ls-341&qid=1751713038&sprefix=needle+guard+for+juki+presser+foot+for+juki+ls-341%2Caps%2C317&sr=8-17 ) kgg

-

I learnt sewing with modern servo motor with needle positioner. I am buying them in Europe from a big reseller, Strima, they are around 300 euros. They start at 100 rpm minimumspeed I think, 750 we. Thanks to needle positioner I don't miss lower speeds. I do needle up, needle down and I can go step by step when I want. And the needle is always in the right position (locked stitch or open tensioner etc) so working is easy and precise. I don't need and don't want a speed reducer under the table. A jog dial would be useful to limit upper speed which I need to do on the controller. I also miss more robust needle positioner with better and easier fixing to different types of machines. For me a middle priced servos with good documentation and support would be interesting. Efkas prices are too steep, the cheapest Chinese imports are undocumented and have often strange quirks that are difficult to solve

.webp.4d7785cc054b1306bd20880d2db0a74f.webp)

.webp.b95d0633375da6bddcfbcefd1ad1da3c.webp)

.webp.051589581b2f950c1958c87c114f2d5a.webp)

.webp.caea44d68c216fef4dbdf65561598be6.webp)

.webp.3431bbd6928190ddec16d972e97c1063.webp)

.webp.f27d31de04a1c4f15e8ac13939d0925d.webp)

.webp.75e6e77fe7a48e5f9253494467eee692.webp)

.webp.8b5cc0c9d6bd30ad96cb8fb1f927cc7f.webp)

.webp.81b187ea43bf315bb46c21f53360c48e.webp)

.webp.d299762019f966b0d27f98f80bd131e8.webp)

.webp.1ff2138da00e7c11b81bc98baca9863b.webp)

.webp.590d295836f0a25741f01fd8df1f5b9e.webp)