All Activity

- Past hour

-

Help! Singer 111w155 stripped / stuck screw

friquant replied to matthew123's topic in Leather Sewing Machines

Depends on how hard you hit it I suppose. -

Tips/advice for 1st craft market tent?

fredk replied to ThisIsMyFirstRodeo's topic in Marketing and Advertising

Whatever you use as a show table use a cloth covering it. I/we found dark red or brown best with leatherwork. There are websites which tell you which colours are welcoming or 'cold' et cetera -

33" That is a long billet! The lengths that I can get from Laederiet (my supplier) are 13", 18" or 26" So far I mainly get the 18 and 26" ones. My only gripe is that the holes are a bit elongated on the 18" ones, and not one the 26". It is only a visual problem, when I need to use a long one on the front part of a saddle and a shorter one near the middle (on Kieffer dressage saddles for example). I have only heard of Hermes saddles, never seen one in real life :-) I agree on the maltreatment of the cobblers hammer. It should not be used as a regular hammer, I have a ball peen hammer with a polished ball end, I only use that one for peening copper rivets. The sad thing is that despite her shortcomings in tool treatment and repair knowledge/execution, she seems to have a large audience. Maybe it is because people are more likely to watch someone telling them that "this is just a simple job that anyone can do" compared to someone who knows what he/she is doing and telling people that "this part is better left to someone who has a basic understanding of saddle repair". I guess it is just rare that a good craftsman also makes good videos, I know that there are some out there capable of both, Lisa Sorrel is a prime example. Her boot making videos are top notch, and she really seems to know what she is talking about. Once in a while you manage to come across a video made by such a person, and it is almost reinvigorating to watch it. Sadly this saddle repair video was the complete opposite Brgds Jonas

- Today

-

So you can focus on buying a class of machine that does what you want, since you can fix it up. Most "fixing" is actually adjusting, with some cleaning and oiling along the way. I have bought a new hook for a machine where I broke the hook trying to get it out. But there were aftermarket parts available.

-

Tips/advice for 1st craft market tent?

ThisIsMyFirstRodeo replied to ThisIsMyFirstRodeo's topic in Marketing and Advertising

Bruce — Wow, thank you. Your experience, especially being much closer (3hrs or so) to me helps a lot. Most definitely individual wrapped candy, and SF definitely. But more importantly, the ideas for what we called an “elevator pitch” in school (I barely passed speech class…), and communication with the promoters/managers. The general ideas I’m gathering from everyone are how to successfully invite people into my stall, and create a connection, however brief. Definitely stepping out of my comfort zone, but necessary for the potential of success. Returning to ideas for setup, what are people’s thoughts regarding a couple cable spools stacked to create a rounder, with my concept being to bring people in to see what else is out of sight? I’m wavering though, as I don’t want something too big to see around or take up half of my tent. I haven’t bothered yet to flesh out how to keep the design clean. But, if it winds up looking a little too redneck, it won’t be leaving my garage. At face value, I like the concept of a rounder, but what are other’s thoughts? — AZR -

I haven't seen much good about the portable consews. https://leatherworker.net/forum/topic/111864-consew-cp206rl/#findComment-731591

-

Most of them are clutch motors, but I already have a servo I can swap in.

-

I like that singers have documentation. If you buy a clone, you end up finding the documentation for whatever it was cloned from. The 211G is shown on this page: https://ismacs.net/singer_sewing_machine_company/model-list/classes-200-299.html Do any of the machines you're looking at come with a variable speed motor? That would bring the overall cost down.

-

Thank you so much for that response. Your work looks really great, wow, I have so much to learn, thank you for explaining and showing your work process.

-

I haven't read any comments about her tool use. (Or, maybe I missed it.) When replacing billets, I punch my holes in the leather first, before attaching them to the webbing, and gluing them doesn't help much in my opinion. But, what bothered me the most was her use of tools. Using a cobblers hammer on stitching irons, or hole punches, to set the holes irks the hell out of me. I know it's "anal" of me, but I even polish the face of my cobbler hammers so not to leave marks on my leather. I agree with Mulesaw, trying to glue a patch on to this saddle probably won't hold. Ron

-

I did manage to find a Consew CP206RL locally, and it's owned by a person in acquaintances with. She let me try it out, but I had problems getting the stitch length longer and had issues with the needle thread breaking no matter how I set the tension. I assume that if I could fix these issues that it would be a good enough machine, especially since it's local and only $500. She might even give me a discount for the issues we had with it.

-

Pretty clever! I love seeing creative ideas to solve a problem. Looks like this solved yours.

-

https://springfieldleather.com/products/money-clip-redneck-np?_pos=1&_psq=mone&_ss=e&_v=1.0

-

They have a video on the listing of it starting up (some noise that goes away happens) and running without fabric or thread. So it does at least function in those ways. And I do love fixing things, which is why I'm kinda drawn to these older all metal machines. If I could find one with good documentation and parts availability, I'd be happy as a clam.

-

velmatmartinez joined the community

-

The cutline looks interesting. Anybody know if a manual is available for those? I put in Asheville, NC and started searching. How about some of these: Tacsew gc6-6: https://www.facebook.com/marketplace/item/1217068313162876 Adler: https://www.facebook.com/marketplace/item/1256624485648626/ Unknown walking foot: https://www.facebook.com/marketplace/item/1411826190265789/ Nakajima: https://www.facebook.com/marketplace/item/1685486795446778

-

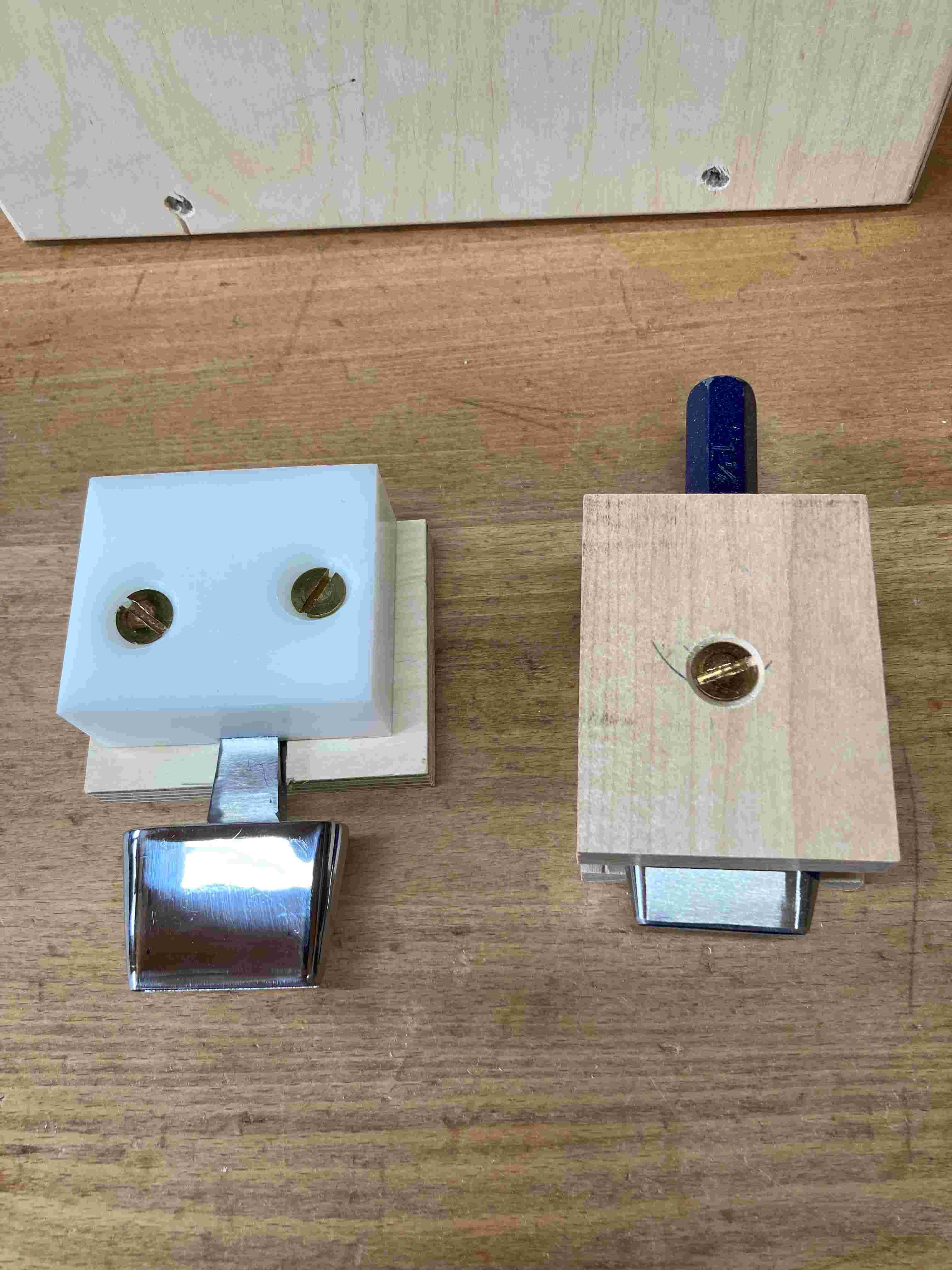

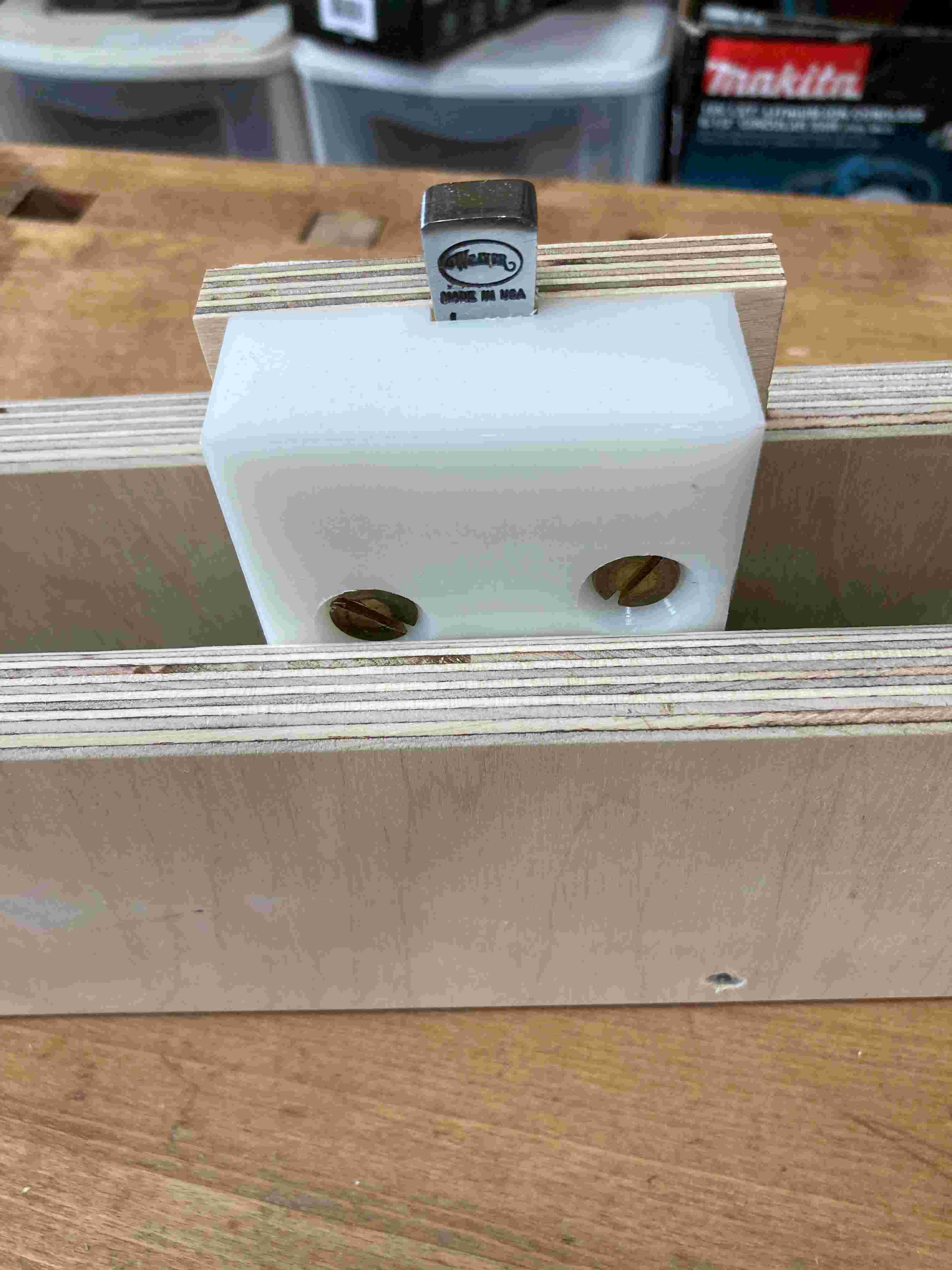

I wanted to precisely punch centered oblong holes in 1 1/2" belt blanks for attaching the buckle. This jig allows me to it easily. The punches are sandwiched between blocks and screwed together. The blocks were sized to snuggly fit into the 1 1/2" wide box that the belt blank slides into. They were also cut to allow the punch to be centered in the jig. The blocks are easily removed whenever I need to use the punch without the jig. They are held together with flathead screws and Tee nuts.

-

Post some photos of the machine.

-

Cheap! Has it sewn recently, or has it been stored in a barn? (affects how much cleaning it needs). You could ask sellers of any of these to demo sewing five layers of vinyl. Another option is to post your own ad. By the way, do you enjoy fixing things?

-

Help! Singer 111w155 stripped / stuck screw

friquant replied to matthew123's topic in Leather Sewing Machines

Do you have any parallel sided screwdrivers? (Hollow ground) My first set of hollow ground was just whatever I could collect from all the stray screwdriver bit sets. Eventually had a variety of sizes. -

I moved your post to leather sewing machines. I think you'll get more response here.

-

I do like that style of clip, but didn't see it on offer anywhere. Have you got a source for this kind of hardware? As to the evenness, I could use some more attention there. The visibly irregular one (with the Cdn flag) suffered a bit from my being very new with the drum sander. I should probably make a table for it. Tool-rest kind of thing.

-

That's some good work there. Agreed...practice, practice, practice.

- 7 replies

-

- portrait carving

- figure carving

-

(and 1 more)

Tagged with:

-

Thanks for sharing your work. I agree, that style of clip can be kind of boring. I really like the type that attaches to the outside of the wallet. A suggestion i would make is for those pieces you sew together, cut one of the pieces a little larger, then after stitching, trim them down so they are even.

-

Thanks for gently keeping me from the edge. This certainly is making me crazy. I'm really only steering towards flatbed because of budget reasons. That one Singer came up because it's in the range I'm able to spend right now. And for my most pressing concern being the boat seats, the cylinder arm isn't really necessary. I think I'm trying to just maximize my spend since both space and money are restrictive for getting endless machines. It also seems that to get any machine at all, I'm going to need to drive an hour and a hall or more in almost any direction. I'm getting worn down by the idea of so much travel to see machines that maybe need work or won't actually do my boat seats. Additionally, there is no one nearby that works on industrial machines. I did find a guy that's willing to travel to me, but I don't know anything of his reputation. All that is to say that if something on the list looks more reliable than the next, I'd like to just go that direction. I looked for the other models recommended, but came up short (presumably I live in a machine void, which is odd since there are so many creative people here) and time is running out to finish my project. I think I'm just afraid to make the wrong choice. If anything happens with whichever machine I choose, I'm likely going to have to learn to repair it myself, so good documentation and parts availability would be helpful. And you can bet I'll come back here for advice on that. Thanks to everyone for your help!

.thumb.jpg.6e903dd66163ad5672f00f144058c571.jpg)