All Activity

- Past hour

-

See the update I wrote in my earlier comments, up the page.

-

Markdown or other programmatic entry

Johanna replied to friquant's topic in Feedback and Suggestions

You're welcome! -

Markdown or other programmatic entry

friquant replied to friquant's topic in Feedback and Suggestions

-

I think they can go 10,000 miles, er stitches between oil changes! ;-)

-

Markdown or other programmatic entry

Johanna replied to friquant's topic in Feedback and Suggestions

Try it now - Today

-

Full STOP! The needle you listed is a "System" 190 profile, and a number (width of the business end) 22. The System 190 is an extra long needle. It is only recommended for higher than standard lift, mainly on walking foot machines. The reason is that the higher capacity of the foot or feet to lift and function properly would be too high for a shorter needle to clear the top of the lifted foot or feet. A standard walking foot machine might be able to sew up to 3/8 inch of compressible material. If you stuff 1/2 inch under the feet and hack them to lift higher up, the bottom of the needle bar will make hard contact with the raised inner or outer foot and something will give or break. So, some machines are already setup to sew thicker than standard and have their needle bar raised up high enough to clear the feet in their highest working position. Many are made to use the longer System 190 needle in the needle bar. Since the distance is longer from top to the eye, these needles can still go down far enough for a loop to form at the eye of the needle and the hook to pick it off. Note, that these longer needles are more fragile in smaller sizes (diameters) and are more likely to get deflected and break that a shorter needle of the same "size." Get the manual for that machine and compare the full model number to whatever is shown in the manual for the factory needle system. The 22 part relates to a business end outside diameter of 0.718 mm. Due to the rib channel one one side and the cutout around the eye side, the actual diameter changes. No matter its geometry, a #22 needle is the minimum size required to sew with #138 (Tex 135) bonded thread on the top and bottom when you sew into soft to medium temper materials, and soft chap or garment leather. The thread itself has an outside diameter of about .414 mm. When you sew on a standard lockstitch machine, the top thread captures the bobbin thread and folds around it as it draws it up into the material. We refer to this lock configuration as a "knot." The knot is about twice the diameter of the individual top and bottom threads. Veg-tan leather is less pliable than chrome-tan chap and garment leather and its extra density means that you'll probably need a needle one number larger for the same thread sizes. Thus, to get the "knots" pulled well into the leather, you'll need a #23 needle with #138 bonded thread. One parameter that hasn't been mentioned is the top mounting diameter of the part that goes up into the needle bar hole. It must be a good fit; not too loose and definitely not wider than the hole. You should be able to insert and remove a needle with finger pressure alone. It should not wobble when all the way up and tightened down with the needle bar set screw. Many modern era walking foot machines take a 2 mm diameter top needle shank. Some ancient machines only took 1.5 or some random number smaller than 2.0 mm.

-

Markdown or other programmatic entry

friquant replied to friquant's topic in Feedback and Suggestions

Promise 😉 -

Markdown or other programmatic entry

Johanna replied to friquant's topic in Feedback and Suggestions

I'd have to enable "can post html" for the member group, which looks like a huge security issue. I have it enabled for the mods and contributing members because they are unlikely to do malicious things with HTML. I can put you in that group if you promise not to break anything. hahahaha -

Markdown or other programmatic entry

Johanna replied to friquant's topic in Feedback and Suggestions

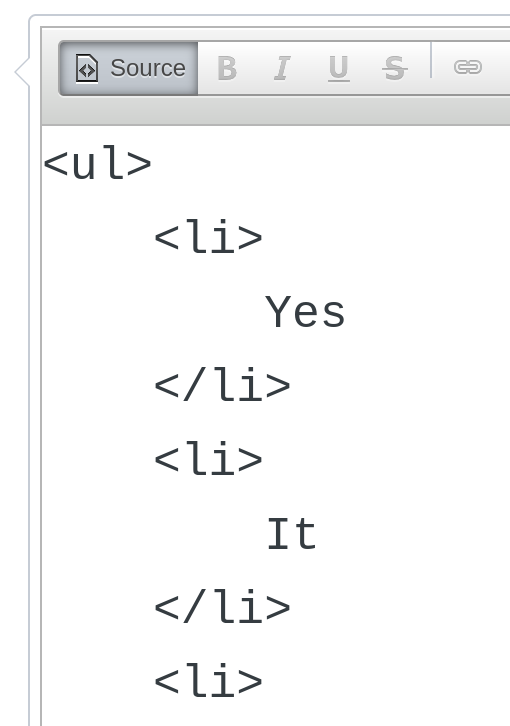

It seems that everyone but "members" has the source button. It looks like I need to do some tweaking. In the admin CP there are ways to customize the toolbars, but no source button to add. Somehow it must have remained in the legacy versions? I'll look into it more tonight. -

Markdown or other programmatic entry

friquant replied to friquant's topic in Feedback and Suggestions

If you are using CKEditor, I see this pull request which alludes to a checkbox that allows non-admins to view the source button: https://github.com/craftcms/ckeditor/pull/87 -

Markdown or other programmatic entry

Johanna replied to friquant's topic in Feedback and Suggestions

I have the "source" button. Checking to see if this is a browser or software issue. I see the source button on my phone and using Chrome. -

FYI: I would not use spent casings to make a bandolier. (Unless you are running them through a resizing die first.). The cases expand when they are fired. The loops will be loose when carrying new ammo, if they were made from spent casings.

- Yesterday

-

As a note some people did converted their machines from 134-35 needle system to the 135 needle system. If the previous owner did the conversion then for leather you would need 135 X 16 X (correct needle size) and for fabric 135 X 17 X (correct needle size). What I have found is using a leather point needle will give a cleaner needle hole in vinyl then a fabric needle. Fabric needles are meant to separate the fibres of the material rather then cut them. Really depends on what size of thread you are planning on using and the needle system it is setup for. Your machine can accept up to V138 thread. The 190-22 if I'm not mistaken is a system 190 needle used on the older PFAFF 145 so what they are suggesting is a #22 needle which is good for V92 thread. kgg

-

Pfaff says 134-35 needle system: https://www.pfaff-industrial.com/en/portfolio/sewing-machines/flat-bed-heavy-duty/pfaff1245 You'll then need to select a size to match your thread: https://tolindsewmach.com/thread-chart.html And then research the many different points available to decide what kind of look you want your stitches to have (scroll down about half way): https://www.techsew.com/us/blog/needle-buying-guide.html

-

Very cool!!

-

A properly made gun-belt should have a curve in it. It might be just exaggerating that curve. I have a/some Tandy Gun Leather pattern(s) which have the belts on it/them. And they are cut on the curve Do you want copies of the patterns?

-

My thoughts, find the fittings you want to use, preferably a brand that has lots of different choices to allow for future needs, then either make adapters or ream/sleeve the tool so they fit. I was given, amongst other things, three Carr Fasteners presses along with an assortment of dies, anvils etc for them, some of which didn't fit (I still don't know what they're for). I had to make up adapters for some of the fittings which is no big deal for someone with a lathe.

-

New Tool Idea - Large Leather Shears - Should I make these for sale?

dikman replied to Stagesmith's topic in Leather Tools

When you talk about making them do you mean making them from scratch or simply modifying existing scissors? It would be a lot of work to make scissors by hand and I doubt it would be cost-effective to sell them. -

That's certainly different, very nicely done - and a lot of hand stitching there!

-

Markdown or other programmatic entry

AlZilla replied to friquant's topic in Feedback and Suggestions

Just what you'd expect, a paragraph with the heading tags I copied and another paragraph of me blathering about the tags. It might have to do with post count. Maybe the software doesn't let s user enter raw HTML until a certain threshold. I wonder if @Johanna knows off the top of her head? EDIT:I went through and deleted most of that back and forth, it was just clutter. I left enough that Johanna can see what we're talking about. It's ok here in Feedback and Suggestions. -

Working through some vintage pattern and project books-

dikman replied to MAKleather's topic in Show Off!!

Very nice carving, it looks good. -

It's that curve that has to be thought about. Shouldn't take much to work it out, just wondered if there was a "standard". I used to reload including reforming 22 Hornet cases sometimes. Still got the presses and dies somewhere so if I can find the heads it should be easy to set em.

-

Markdown or other programmatic entry

friquant replied to friquant's topic in Feedback and Suggestions

Titles are good! What does it show in the "Source" tab when you have a title? -

Markdown or other programmatic entry

AlZilla replied to friquant's topic in Feedback and Suggestions

Maybe there's a setting deep in your settings to choose a different editor. I'm out of ideas ...