All Activity

- Past hour

-

New pistol, new holster

AlZilla replied to Thadrick's topic in Gun Holsters, Rifle Slings and Knife Sheathes

I love it. I use those conchos every chance I get. Good Choice! -

You posted in a very old thread. Different machine even. Split your post off to a new thread. Have you looked through the leather sewing machine forum, especially the pinned topics?

-

Hi Toxo, moved your post to leather sewing machines. I think you might get the attention of the right members here.

- Yesterday

-

New pistol, new holster

dikman replied to Thadrick's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Those conchos look much better, more subtle. The others stood out too much, being solid metal. -

paffaf sewing machine with 240 V motor & air compressor

dikman replied to Haitham's topic in Leather Sewing Machines

More info always helps, along with photos. Pfaff makes a lot of machines. -

That was doing my head in trying to figure it out until it suddenly clicked into place. Simple but very effective.

-

I've been looking for a sewing machine to sew leather belts, bags and wallets this is a consew 227r i tried searching the internet and youtube but I cannot find any with the black nameplate to compare it to. I assume this doesn't have a reducer if not can one be added? About the only thing I've found is "R" means it has reverse. What are the pros and cons to this machine? Any help would be greatly appreciated. A techsew 2750 or Cobra 26 would be great but this is 1/2 the price of not more.

-

I figured the more ambitious the project, the better excuse I'd have when I failed 😅 Just got lucky that it turned out better than I expected.

-

That's a pretty solid looking belt you've got there, should be good for a few years!

-

For a first effort that's pretty impressive - and ambitious. One of the problems with being the maker is that you notice all the little flaws, things which others won't see. Which also means you can see where improvements need to be made. I'd call it a success.

-

So near and yet so far. Epic fail. How do I get the tape to come out of the folder the same on both sides of the leather? Is it a question of what type of tape is used?

-

Thank you, the few people I've shown didn't notice the stitching issues. So you're probably right that I should just not point it out. But since I made it it seems so obvious. So far it does carry a 45 1911 pretty well, even with my extra weight. So I think the height does help a bit.

-

That looks easier than I expected! I should be able to make that. Maybe a dog collar itself for my Poochie as I learn how to lace like that. Thanks @TomE

-

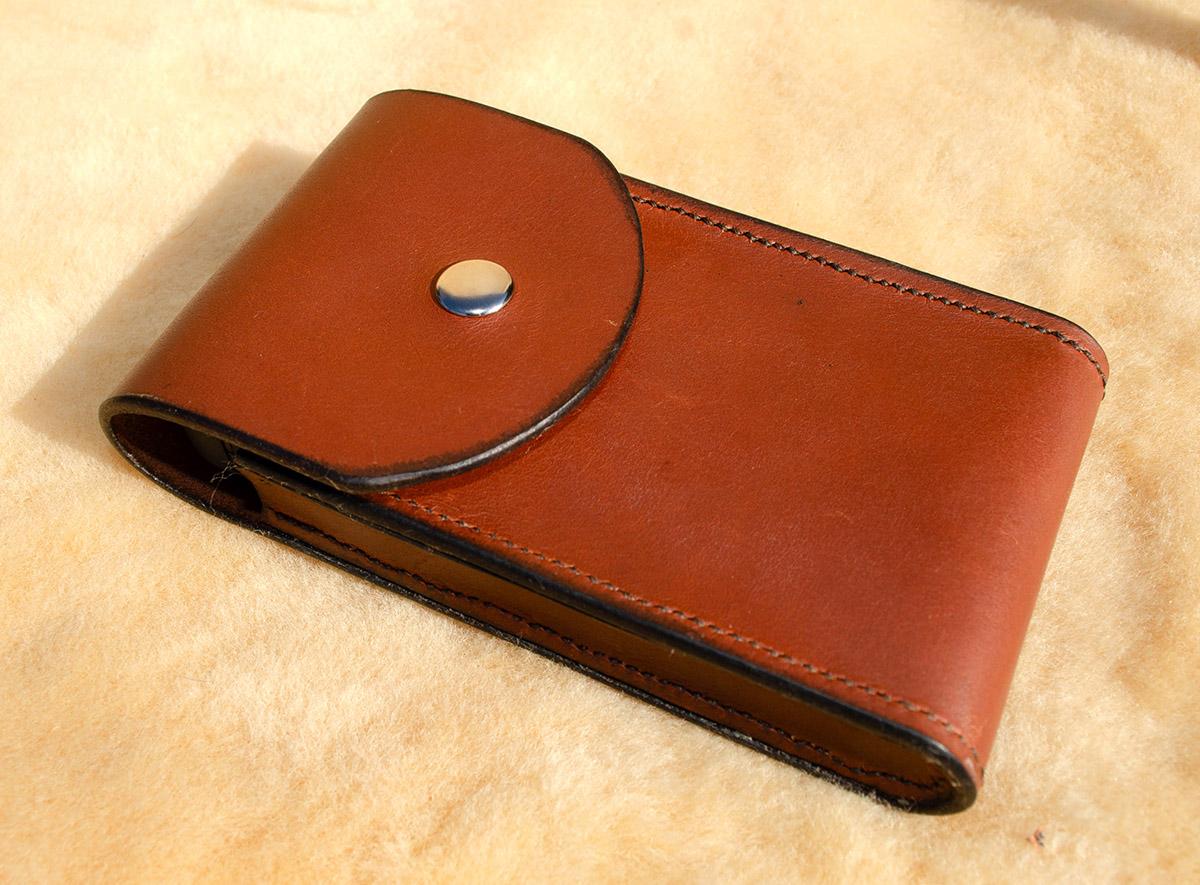

I got tired of my stretchy work belt and phone clips that break, so I made a couple of accessories for my day job as assistant mucker at Maefield Farm. The belt is made from 10 oz Hermann Oak chocolate harness leather with a liner. The phone case is made from 5-6 oz "oil tanned" leather from the SB Foot Tanning Co. The case was constructed around a block of closed cell foam, glued and sewn at 10 stitches per inch. The edges of the belt and case are sealed with beeswax.

-

sadimari joined the community

-

Just pick up a singer 281-141 I hope this will work for leather no idea where to start hope I can get advice on where to start thank you .Dale

-

paffaf sewing machine with 240 V motor & air compressor

AlZilla replied to Haitham's topic in Leather Sewing Machines

Slipped this over to leather sewing machines. It might make a difference which Pfaff you got. If it's a standard industrial with the motor under the table, swapping the motor out might solve part of it. If it doesn't care about the source of it's compressed air, a small contractor compressor might be the rest of the solution. -

This post contains @Wizcrafts recent dissertation on all things Check Spring.

-

That's a great holster, first one or not. I think I see where you're talking about on the stitching but it's no big issue. Julia Child said don't tell your guests what's wrong with your food and they'll never figure it out. The height of the belt loop slots might keep the top of the firearm from torquing out. I suspect this is more a fat guy problem

-

bankovskoe joined the community

-

While working a commission for a company, one of the employees asked if I could do holsters. I had never made one so I did my best to find out if I could. I see many mistakes in my part, especially messing up the last bit of stitching of the entire piece. But for a first try im pretty pleased with myself. I'll have to use it for awhile before I'd be comfortable trusting one I made enough to sell though.

-

A #23 needle is the right size for #138 thread on the top and bottom. Look closely at the leather under the needle to see if it is lifting with the needle as it ascends. This almost always causes skipped stitches. If it is lifting, add more foot pressure. Inserting the needle backwards has the same effect. Make sure the rib side is on the left and the scarf side faces due-right. If the check spring is set wrong for the work, it can cause skipped stitches. The bottom stopper should halt the downward motion of the check spring as or just after the tip of the needle enters the top of the work. The longest it should allow downward motion would be as the eye shows just under the bottom layer. The other settings are spring tension and slack adjustment, via a set screw inside a curved slot. Try changing the position of that screw.

-

Very nice and very interesting. Looks easy enuff to replicate. I might try it on a sword/axe hangar

-

Ryan Neel and Neel Saddlery- a review you need to read

jrdunn replied to HideDesigns's topic in Leatherwork Conversation

Agreed! It is heartening to find this level of service and commitment. JM2C, Jim -

I think you could adapt the method for laced reins to make this pattern. Would decrease the spacing between holes and perhaps use a lacing chisel (or a sharpened screwdriver), instead of a round hole punch, on the outer holes of the pattern. This would help to keep the lace lying flat. I'd make lace out of the leather of your choice, about 1/8" wide of 5 oz thickness. I would use bridle leather for some stiffness and tap it with a polished hammer to set the shape. Here's how laced reins are laced:

-

ASKING $2800 Located in Cedar Park, Texas in the buttercup creek neighborhood (North Austin, Texas) Industrial Cowboy hydraulic clicker press is in great working condition. Outside of the HDPE boards its as good as new. It's runs on standard 220v. Here are the specs... - 10 Tons of Cutting Pressure - Cutting Bed is 17" x 36" - Cutting Bed is 36" from the ground - Swing Arm Pressure Foot is 13" x 18" It Is still on the pallet It was shipped on to make It easy to move with a forklift or pallet jack. A pallet jack and box truck WITH LIFT GATE need to be utilized as it Is too heavy to be moved by hand. It weight approximately 900 pound including the pallet. Reach out if you have any questions.

-

Shauna860 joined the community

-

Hi, I’m looking to sell this leather stamp kit. I’ve never used it. I bought it from an estate sale many years ago it’s a lovely set. It’s just not something I use and I don’t know anyone who would marketplace just tends to send me a lot of messages about the stamp set I don’t know much about it. Maybe some experts could help me figure out what it’s worth and maybe you could go to someone who would really enjoy it.

.thumb.jpg.6e903dd66163ad5672f00f144058c571.jpg)