All Activity

- Past hour

-

I'd wear it proudly if I were a lady May God bless, Dwight

-

Leather Weight for Lined Holsters.

dikman replied to Latigo Smith's topic in Gun Holsters, Rifle Slings and Knife Sheathes

All my holsters were made glued flat and then folded, it's inevitable that wrinkling will occur although sometimes it's possible to minimise them. The last holster I made was a SlimJim style and I wanted to carve it so used thicker leather for the outside but this time I tried pre-curving it while glueing to the inner (as Dwight suggested). It did make a neater finish although it was a bit more messing around getting it right. -

That would be made by me using two molds. Both are 2 piece molds . . . one big enough for the pen body . . . the other one big enough to hold the total pen body. You might try making one big enough to put both pieces in there . . . that would alleviate any match-up problems later on. I'd then find out the dimensions of his pens . . . taking a decent picture of them . . . you can fairly accurately predict the size for each hole . . . and I would add a 1/16 to 1/8 inch to each hold just to make sure. Wooden dowels can be substituted for the real thing. And don't worry about the expense . . . if you do that right . . . I'm betting for more orders based on word of mouth . May God bless, Dwight

-

Leather Weight for Lined Holsters.

Dwight replied to Latigo Smith's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Yes . . . I totally pre bend my holsters that are lined. AND . . . you isolated the big reason . . . wrinkles. If you glue them flat . . . you have a 999 out of 1000 chance that the inside will wrinkle like the 98 yr old witch living down the road. I moisten and wet mold the inside piece . . . as it touches the weapon . . . so it needs it's positioning settled up front and wet molding it does that trick. I then let it dry . . . completely . . . At the same time . . . I will also wet mold the outer layer so that the sight track portion knows it is not laying flat the rest of it's life. It's only a so-so molding . . . just enough to set the curve for the final bonding. I do the same for the back flap of the holster . . . bending the inside piece before bonding with the outer piece. It makes for a much better curve for the flap. Concerning the weight . . . generally speaking the thicker the leather . . . the stiffer the final product. But that can also be achieved by cheating. Putting the two pieces together . . . and either slipping it thru the Mexican loops or adding the front buckle loop . . . you then wet the whole thing . . . and hang it in a 140 degree farenhite "hot box" . . . take it out after a couple hours . . . if it was made out of 5/6 or 7/8 . . . the holster itself is a weapon . . . you could knock someone out . . . banging them on the head with that holster. May God bless, Dwight -

Hi everyone! I’m planning to make a 12-pen fountain pen case similar to the one in the attached photo, and I’m trying to figure out the best way to create the inner wooden form. For those of you who have made fountain pen cases before: Did you make your own or buy a wooden form somewhere? If you made it yourself, how did you determine the dimensions for the pen slots? I only have one fountain pen on hand (this is a commission), so I don’t have multiple pens to measure for variation in size. I’d really appreciate any advice on how you handled sizing when you didn’t have access to the client’s full collection. Thanks in advance!

- Today

-

Bringing a neglected machine back to life (Juki LU-563)

AlZilla replied to MikeG's topic in Leather Sewing Machines

Well, the good news is that you probably don't have to take it all apart. and you might just be able to oil it and go. Some pictures would help us to to evaluate it. Maybe a video walk around. Do you have the whole machine, table,motor and all? Or just a head unit? For starters, I'd oil it everywhere metal moves against metal. All the oiling points on top, everyplace underneath that a bushing, bearing or anything else moves metal on metal. Turn it over by hand and let it sit for a day. If you have the whole setup, motor and all try running it and give it a listen. When I got my first industrial, it turned over a lot harder than any domestic i had worked with. I had no idea how tight it should have been so I erred way on the side of caution and flushed PB Blaster through everything followed by sewing machine oil. Turned it endlessly by hand trying to decide if it was too tight. I removed the internal belt so I could evaluate the top and bottom separately. After a week or so of this activity, turned out it was fine to begin with. -

Leather Weight for Lined Holsters.

Thadrick replied to Latigo Smith's topic in Gun Holsters, Rifle Slings and Knife Sheathes

After doing several holsters with different techniques I've settled on using a heavy weight for the outside layer for one reason only. I like to carve as deep as possible. For me, lighter weight leather doesn't give me the depth I like when carving and doesn't hold the carving as well after final forming and bending. My most recent holster was 8/9 outside and 3/4 inside. Forms great and is very stiff when dry. If your not carving the leather, any combination equaling 12oz is perfect. -

Chris Andre does his with 2 layers of equal weight. I do this when I want a lined holster and I can say it is very stiff. My method is different than Dwight. I just glue 2 layers together and treat it as I would normally. I haven't read the article but I do know bianchi was a fan of using suede linings, in which case would be lighter in weight and adhered to the heavier holster body. I'd recommend 2 layers if 4/5 oz for owb and 3/4 for iwb.

-

Got a great deal on a Juki LU-563. Essentially a one-owner machine that has spent the last 10-15 years in storage. It is tight and free, but it will obviously need to be oiled and checked out before being put into use. Most of the discussions on this forum seem to deal with damaged or broken machines. This one appears to be in remarkably good condition. My question is: Does the machine need to be completely disassembled? I have not yet found a service manual, and I'm hoping not to have to take it apart using a parts diagram. Thanks in advance for thoughts on how to proceed.

-

Custom Tooled & Painted Saddle Bag

ChesterHasAProblem replied to ChesterHasAProblem's topic in Show Off!!

Sorry, I unintendedly posted a duplicate post. The original has the pictures, but here they are again. -

Thank you very much for the replies, everybody. Chuck, I agree that experimenting with different weights to find what works best is the way to go. I'll probably try to find a decent source for smaller panel-type cuts of Hermann Oak for trial holster purposes. Since I use leather around 4/5oz for shoulder holster straps, and the 8/9 or 9/10oz stuff for unlined holsters, about the only use I'll have for the medium weight stuff would be for the lined holsters, so I'd certainly like to find the ideal weight for it before I invest in multiple sides for lined holsters. ALZilla, I'm sure Mr. Nichols does recommend horsehide, for the reason that he's been fascinated by Seventrees holsters since roughly 1970, and Seventrees used horsehide nearly exclusively for their holsters. I've heard very interesting things about using horsehide for holsters, namely that the flesh side is nearly as smooth as the hair side, and that once a horsehide holster has been wet molded and dried it becomes about as rigid as kydex. I'd be interested to try it out if I could find a source for it. Mr. Tragacanth, I've never considered whether the mineral content of the water used for wet molding could have an effect on the rigidity of the leather, but it very well could. That'd be an interesting test, trying pieces from the same cut of leather using distilled, spring and tap water. Dwight, I was sure this was the case, but I'm very glad to get your opinion on the matter. I'm not really sure what happened there when Mr. Nichols wrote that passage, as he really is quite knowledgeable. That's why I wondered if there was some variable or combination of variables that caused this to be Mr. Nichols firsthand experience making lined holsters, but I'm not sure what that could be. In any case, I do have a few more questions for you about your process for making lined holsters. Do you find that pre-bending the outer layer before glue up as you describe gives you better results than gluing the layers flat and folding the holster afterwards? I had figured on gluing the layers flat and setting one of my granite tooling slabs on it while the contact cement cures, as I thought that weighing it down real good would help to create a stronger bond. But I know that a number of people pre-bend their lined holsters to prevent the liner layer from wrinkling when the holster is folded. Have you found wrinkling to be a problem when cementing the layers flat and bending the holster after the cement is cured? Also, regarding the weight of leather used, in reading some of your various older posts on this subject, I've read that you've used two layers of 4/5oz, 5/6 oz and 6/7 oz. Which of these weights do you find produces the best balance of stiffness and moldability for you?

-

ObstacleOnion joined the community

-

- Yesterday

-

Awesome! Thank you, let me know what you find 😊 Thank you!!

-

Ah we need some pictures?

-

Hi, If you give me your e-mail address via personal message, I will send you a pdf of the original user manual for the Adler 4 and 5 machines. It is in German language - so you should be able to understand the text without an AI translator. Another thing : are you sure that you have the needle positioned the right way ? Industrial needles as used in the Adler 4 and 5 units have to be in such a position, that the thread enters from the left side of the needle when facing your machine and exits to the right side - not like home sewing machines where you are facing the thread hole of the needle when sitting in front of the machine. Latter is just to make sure that your needle is in the correct position - else your thread will break as soon as it tries to tie a knot with the hook. Are you also sure that the needle size used is the correct one analog to the thread used ? - A heavy thread will require a thicker needle in order to ensure proper pass through the fabric/leather. Last but not least - what type of needle are you using - the Adler type 4 and 5 use needle type 328 - get the ones made by Schmetz and avoid copies made in Chinesistan or India - they are mostly junk with inferior dimensions and quality. Also : try to pull on the thread before it is engaged to the eye of the needle - if you can not pull it a centimeter before it breaks, your top thread tension settings are way to stiff/strong. Greetings Hans

-

This is my first tooled bag and one of the first tooling designs that I have made by myself. The wheat and wild roses were included to reflect the Albertan prairies where the client lives. Solid brass hardware; the bag is finished with mink oil; and the tooled piece also finished with resolene to try to preserve the painted parts. The leather is bought from an old style Mennonite community in Belize, where I suspect is was made. The pattern was modified from Retro Leather Goods' leather saddle bag pattern. This project has taught me to use antiquing gel! Tooling takes too long to not use the proper product. Any thoughts, recommendations, or critiques? I would like to know how I can improve. Thank you.

-

spring flowers and good food

Darren8306 replied to chuck123wapati's topic in All About Us and Off Topic

I have a bunch of hair-on sealhide, and a ready source of caribou (all I can tan, pretty much) but haven't found a way, that I like, to include it in leatherwork. Be cool to see how you do with it. -

-

Leather Weight for Lined Holsters.

dikman replied to Latigo Smith's topic in Gun Holsters, Rifle Slings and Knife Sheathes

I've only made a few Western-style holsters so I have limited experience but I would have to question that article, it seems to me he is making a blanket statement that he considers fact when in reality there are lots of variables when dealing with leather. My first couple of holsters were made using fairly light leather (I can't remember the weight) with two layers glued back-to-back. By the time I'd finished they were rigid, and still are. I progressed to using the same weight for the liner but a slightly heavier weight for the outside, only because I thought it looked better. I noticed he mentioned using a suede liner, that is going to be softer than a "normal" hide so won't add much to the overall stiffness. Also, leather that is wet-formed tends to gain stiffness. The best thing you can do is try different combinations to work out what style you like and whether lined or unlined works best for you, but at the end of the day the customer will determine which style you make. -

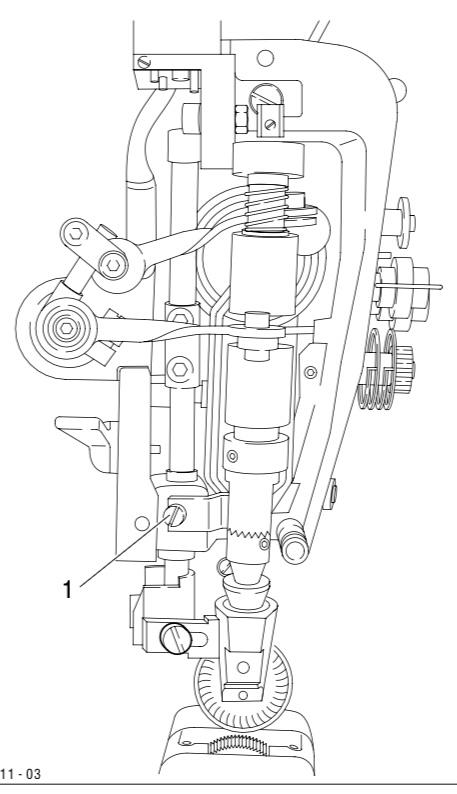

Meanwhile i did some searching and reading and found this drawing. That gives me a kind of answer. That the teeth from the upper and lower part should lock in to each other.

-

Yes . That are the parts. Thank you.

-

This is my first tooled bag and one of the first tooling designs that I have made by myself. The wheat and wild roses were included to reflect the Albertan prairies where the client lives. Solid brass hardware; the bag is finished with mink oil; and the tooled piece also finished with resolene to try to preserve the painted parts. The leather is bought from an old style Mennonite community in Belize, where I suspect is was made. The pattern was modified from Retro Leather Goods' leather saddle bag pattern. This project has taught me to use antiquing gel! Tooling takes too long to not use the proper product. Any thoughts, recommendations, or critiques? I would like to know how I can improve. Thank you.

-

I'm never sure which one does what! I'll try one after the other until it gets the job done. I'll always try the thinners first, the toluene usually does it. This is the one I use to thin the contact stuff. I don't use it often so I'll usually pour a little if this on top of the glue before I put it away. It is an animal though, The other day I found a small plastic glass that I had left a glue brush in with some thinners was just a puddle. The white spirit is best for removing the white leather marker lines. Acetone is last.

.jpeg.b20cd81de291a858492aace2ec79d53a.jpeg)

.jpeg.62620c426b89a8c64cd902da0eb1500f.jpeg)

.jpeg.dd6f97eac322b0737e3659b34749c600.jpeg)

.jpeg.6ce8d3708faae3893053e290d6fd4d0f.jpeg)