-

Posts

101 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Everything posted by BillinOK

-

How To Ruin A Day

BillinOK replied to BillinOK's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Years ago I took a plastic tub, cut a hole on the side bottom, and put an old hair dryer minus the heat at the hole. I had a rack inside. that's how I air dried the holsters. I don't think I got the rigidness of the heat dried ones. I may try building the box heater and try that. Does there need to be "air flow" around the holster/box? I just checked at Walmart and they have a Black and Decker convection oven for $40.00. -

Thank goodness this was just a trial holster. I have been wanting to try out Lobo's avenger style holster. Got a side of Wicket and Craig saddle skirting skived down to 7-8oz. Drawed out my pattern to my Ruger P90 and finally ended up with a pattern I liked. Cut everything out, grooved a stitch line, and dyed everything saddle tan. Got everything sewed together....with a couple mistakes, but as I said this was a trial run. Dunked in water for 2-3 seconds, then worked the gun into the holster. It was a tight fit. Got out my brand new in the box heat gun and started drying the holster. Holy mackrel........the leather wilted like your fingers do when you've had them in water a long time. Lesson learned, keep heat gun in box! But............I like the fit and style of the holster. There are several mistakes, besides the wilted part, that I will correct. The gun fit tight, but loose enough for fast draw. The holster was snug against my side and the gun did not bow out. The fast heat dry hardened the holster to a nice degree. Got the back side belt loop to close to the stitch line, so there are several corrections to be made. The leather I got from Wicket and Craig was excellent. Nice and smooth flesh side. They have me sold on these. Thanks Ray for helping me with this. Hopefully the next one will be better.

-

I went to Harbor Freight yesterday and bought a airbrush/compressor kit. It was $99.00, on sale for $79, and I got an additional 20% off that with a coupon. Ended up paying $64.00. Now I've got to learn to use it. Can someone point me to some of the threads that would be good for learning? I have got to figure out a booth to use it in. My shop is a little cramped 8" X 16'. Also, while at harbor freight, I bought the vacuum that Denster was talking about in another thread on molding holsters. It was on sale for $59.

-

Johanna, made the donation by paypal and sent a PM with my details....Thanks

-

Johanna....I would like to get the DVD by mail. Can you PM me and get me the details. Thanks.....Bill

-

The ticket books that I have been making lately are made from light skirting. Yes it's a little heavy, but the officers love them. They have their names and their badge (thanks to Jeff at Grey Ghost Graphics) on them. I have a set price and anything extra, costs extra (such as tooling and designs). The badge is a little hard to see. I have a 4 ton press that I have to use to get a good impression of the badge, but due to the size and detail of the badge stamp, it doesn't show real good. The books have an inside pocket on each side of the book. Inside the pockets is a 1/8" board (cut up notebook from the dollar store). This gives the firmness that I and the others needed for the citation book. As far as writing the citation, they have to use the cardboard that came with the citation book itself or some of them get a very thin piece of aluminum or plexiglass. Haven't heard any complaints on that yet. I only have pics of the ticket book closed. If you need to see the inside, let me know and I will post a pic. Sorry the pics aren't the greatest.

-

Thankyou so much! I have looked everywhere (I thought) for these. Those are the ones.

-

I am trying to find a supplier for the spring notebook clips. I make alot of law enforcement citation (ticket) books. I have been buying the clip boards from a dollar store. They are cheap made. These clips need to be about 5 inches wide and open wide enough to hold a ticket book. I have looked everywhere online and cannot find just the clip by itself. Anyone know of a supplier that has these?

-

I'm using 207 mostly. I'm getting ready to order some more. The stitching looks good. I may go ahead and try the once around and see how that does. Who are you getting your thread from? I was thinking about trying Springfield Leather. I got the last from Tandy but it's considerably higher. Also, I'm still planning on getting the vacuum. Been watching for it to go on sale. It's been holding at $90. I'll be in touch with you when I get everything ready.

-

I bought my aerostitch several years ago and I believe it was a rebuilt one. The book that came with it was for an aerostitch that had reverse and several differnet things on it than mine. This book instructed to run the thread around the primary tensioner twice. I have been using this method for a long time and it seems to work ok. I recently discovered I have the version 2 aerostitch. In this manual it shows the thread only wound once around the primary tensioner. I have not tried this yet. Has anyone experienced this?

-

I'm with Kevin on this. The female snap is counter sunk once put together. This also helps in the female snap being out of the way of drawing the gun. I've done this on may holsters and works well.

-

I have been recouping from back surgery and haven't used my sewing machine (aerostitch) in several months. Here's what happens when you get out of practice. I "was" making myself a ranger style belt. Got everything ready to sew. Started the main belt and going pretty good, and noticed I got out of the stitch grove. Not too bad, but noticeable. Then I noticed the areostitch slowing down, due to the air compressor had stopped. Finally got the air compressor going and finished. Not impressed. So I started the ranger portion (tongue) of the belt. Overstitched on the end of it and missed the stitch grove coming back, and then repeated the same thing on the other end. Took belt and razor and cut the tongue off the belt. Put up all tools and went to the house. Will try again tomorrow after practicing some with the sewing machine.

-

Law Enforcement Ticket Book

BillinOK posted a topic in Gun Holsters, Rifle Slings and Knife Sheathes

After spending 1/2 hour trying to figure out why the aerostitch would not tension right, I got it going. Haven't used it in a while and I didn't notice the thread had slipped on one of the tension wheels. I did this one a little different: Done all stamping after casing. The badge is not too visible. I had Jeff at Gray Ghost Graphics make this. It takes about 3 tons of pressure to get it this way. I then put a coat of neats foot oil on and let it dry, then dyed with medium brown. Done the stitching, and yes I need to practice more, then a coat of Aussie for the final coat and buffed. I was pleased with the color and so was the customer. -

Great looking holster Bruce. I too would stitch around the belt loops. I like decorative stitching, where feasible, around the entire holster......such as across the top and bottom. A picture is hardly ever as good as plain sight of the holster. I am curious as how the gun/holster rides. Is the gun snug against your side? I carry a P90 and the smaller holsters are just not ump enough, depending on location of belt loops. Anyway, very nice looking.

-

Starting A Master List Of Craftaids

BillinOK replied to BillinOK's topic in Leatherwork Conversation

Hi Joe, Well I posted on IILG and that was where I got the response from Max at. Maybe I better dig a little before going much further. No, you didn't mislead me. I am just amazed that Tandy didn't have a list. They suggested obtaining some of their old catologs and start from there. That would have taken a while, let alone trying to track down old catologs. I would just like to see a completed list and like Bill said, pictures with the list. I know this will take a while. I'll do some digging at IILG and make sure. I may send Cathy a line and see if there is anything we have missed. -

Starting A Master List Of Craftaids

BillinOK replied to BillinOK's topic in Leatherwork Conversation

Hi Bill I have thought about adding the pics to the list. Right now I'm just interested in getting a list started. My ideal list would also include the date along with the pic. Thanks for your thoughts because that gets me thinking about it. Bill -

New Holster Challenge

BillinOK replied to mattsh's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Try a search on IWB holsters. Here is a thread of one: http://leatherworker.net/forum/index.php?showtopic=22595 -

I made the outside first then the inside. The outside had a lot of tooling, then a name stamped on it. I then made the inside with my maker's stamp on it. Dyed the outside, then the inside and then stitched them.

-

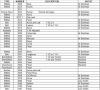

I didn't know where to post this, so I'll start here. I have started a sort of master list of craftaids, thanks in part to Max in New York. This list is in Microsoft works spreadsheet format. So far there are 460+ craftaids on the list ( 9 pages). The list contains the craftaid #, type of craftaid (billfold, belt, etc), a short description (floral, horse, etc.), and the artist. I know there are many, many more that are not on the list. I would like to have your help in building this list. If you would be interested in the list, or helping build it, PM me and I will send what I have, or send me a list of what you have and I will add it. My goal is to have a complete master list of these. I talked to Tandy Leather in Ft. Worth, and they didn't think a list existed. I have attached a .jpg of one page to show you what it looks like. There are blanks and numbers skipped. Let me know what you think.

-

Another Holster And Belt

BillinOK replied to doubleh's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Wow that is really beautiful work. I really like the border, and every thing else. You should post the pic with tool #'s for beginners and others to see the way it is done. That is really nice work. -

Sent you a PM. Thanks so much!

-

Looking to buy Craftaid #4040 Hummingbirds by Al Stohlman with pictorial. Would consider craftaid without pictorial. Bill

-

I have two questions; First does anyone have a craftaid of a hummingbird? I have been using a drawing on paper, then transfer it over to leather. Second, does anyone have a complete list of all craftaids? I like collecting these, and using some of them. Thanks.........Bill

-

Most Unusual Holster Requests?

BillinOK replied to Lobo's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Here's one that I remember. A guy called me and wanted to know if I "refinished" leather things. I told him it depends on what it is. He told me he had an old, old bible and cover that was in his family for over 100 years. I told him that I really didn't want to attempt that, but he insisted on it. He brought the bible to me and I just set there in awe looking. This cover was brittle and coming to pieces. I told him again I was too scared of making it worse, but he wanted me to try no matter what. It took better than a week to do this. I used 2-3 oz, stitched around this new piece of leather, dressing it up, then carefully glued to the old leather. I had to do a little at a time. I was really worried about the outcome, but he was happy as a lark with it. But for me, never again!