-

Posts

7,378 -

Joined

Content Type

Profiles

Forums

Events

Blogs

Gallery

Everything posted by JLSleather

-

The only time you would measure from the fold is if they are replacing their belt and using teh same (or a very similar) buckle. The buckle HAS TO be part of the size. Here's why ... Three belts, all teh same length "to the fold". Changing the buckle changes the size BY THE LENGTH OF THE (inside of the) BUCKLE. In fact, when I make belts for kids, I use a buckle no more than 1" long. That way, when the little boogers grow, you can just swap out a longer buckle. Changing to a 2" long buckle adds 1" to the SAME belt, and lets the little goobers wear them a bit longer instead of outgrowing them SO fast.

-

Need help picking a compressor and airbrush

JLSleather replied to AwenMade's topic in Leatherwork Conversation

I've used those Paasche airbrushes for years. Both have been popular with leather people for a long time (like 40 years that I know of) since they are easy to use, easy to clean, and maintenance and parts are simple and inexpensive, and available almost everywhere. The single action has produced some STUNNING artwork, and I would recommend the extra couple dollars for teh double action ONLY because it's often faster to do some things. I have several of the VL brushes myself. Compressor ... I've tried the Paasche D500 (don't remember which version) but didn't care for it. I found it didn't keep up to speed nearly as well as it claimed to. Instead, I use a simple pancake model from Stanley tools. It IS loud, but it only kicks on a minute or so every so often (depending on how much air you're using). And it blows 20-30 psi smoothly with a regulator, without running constantly. The stuff I spray is sprayed with this set up. FWIW. Also the roses in the DIY section of my site (those roses are airbrushed ONLY -- NOT tooled first). http://www.jlsleather.com/diy/ -

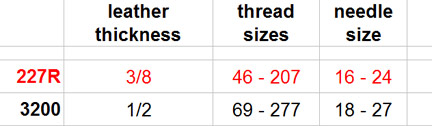

While I should say that I don't have one of these, honestly I've heard nothing but good 'stuff' about the Cowboy 3200. You might call Bob the sewing guy and ask him if he'd recommend the 3200 or the 227R. As a rule, one of the first questions you'll want to answer,.. what weight of thread do you want to use? I've sewn carved and lined belts with thread sizes 138, 207, and 277. Any of these will hold up on a belt, just a different look. From the following pic, the 3200 is just a tad "heavier" use, and it comes standard with a flatbed you might prefer. Again, I'm just gabbin'.. Bob is the guy!

-

I been trying to get some of the questions I get asked put down where's a fella could git at it. Aint gotta stop what yer doin ta find a video, and such.. or even get to a web site to read that 'thing' again. So, on my site are some basic principles for makin basic holsters. Aint' gotta the fancy stuff as yet... wont' stop rainin' up this way. Still, a guycould download a pdf in about a minute that would walk a fella right through layin out his own holster. Check it out, download one for later, one for your Ma, all free http://www.jlsleather.com/diy/pattern-making/leather-pattern-holsters/

-

Avenger version of a holster for that same pistol now up and working. Starting a kinda 'index' page at http://www.jlsleather.com/diy/pattern-making/ Download all ya want.. we'll make more .

-

Well, I'm not opposed to paying and then waiting, entirely. I mean, if you order something from Hermann Oak (for example) you pay, then you wait. Nothing unusual there. But if they had a 3-4 MONTH wait list, ... I'm somewhere else

-

Well, there ya go... it's not "at its widest point"... but rather at EACH point. The offset is NOT the same at the trigger guard as it is at the muzzle end of the slide. Maybe I should put that in there 'Preciate ya looking at this. This is why I asked for pointers... sometimes the way I say what I mean doesn't mean the next guy follows it! After all, I got married back when and I STILL aint sure what i said that caused that!!! Anyway, if your G19 has a slide width of exactly 1" (for example) then the offset at the slide would be 9/16" (half the slide plus half the 8 oz leather). But the trigger guard is more like .600", so half that and half the leather is about 3/8". Where the frame widens, the trigger guard narrows, so in actual practice.. a guy would get it close and then mold in the difference...

-

Still not quite right. Scratchin' the head for a minute.. some short way to say the math ...

-

OH>. now I get ya. Yeah, that should be THICKNESS, not height top to bottom. HOLD ON .. I'm gonna clarify that.. never ocurred to me somebody would see it like that.. which is why I asked

-

Actually, I was just in there myself, in the process of changing that. Durn thing wouldn't let me do it without changing the file name, so DO GO get the update and delete the file you had (different file name was only way it would go through). Thanks for the pointer! Guess I'll go make changes to the "avenger" style before uploading too WAIT>. you got a G19 that's 1/1/2" thick??

-

Next file uploaded... laying out your own pancake holster designs. Somebody gonna proof-read that varmint for me? Staring at it way too long for one day... so do let me know if you think there's something else shoulda got added! http://www.jlsleather.com/sdm_downloads/leather-pattern-making-pancake-holster/

-

Yeah, to be clear -- I wasn't trying to insult anybody. Far as I'm concerned, a grown man sets his own pricing .. no matter to me. In my younger days, I wrote some code for various CNC machines, so I know the routine. Costs something to write the code, then likely costs again for a "set-up fee", price of changing out the toolng and registering offsets, etc. I have a couple of wooden burnishers that seem to do a nice job, so I'm not even actually in the market for one -- just trying to make a helpful suggestion.

-

Seemed like I needed a little room for future expansion, so that file is not moved over one notch, to here... http://www.jlsleather.com/diy/pattern-making/leather-pattern-notebook-layout/

-

Glad I could help somehow, Ron.

-

Yeah, that price seems extreme. Aluminum round stock is about $1 per inch (3/4" or 1" stock) and drill rod is nearly free.. so only cost would be the labor. I've stayed out of that so far since CNC machining would be the way to go -- and I haven't found one of those that is both affordable and worth owning. IF someone knew of a shop who was willing to run some of those after hours (if there is such a thing in manufacturing any more) then I could see $100 for the FIRST one, and more like $30 after the first one - and at $30, a guy could do pretty well. Assuming that a guy already had the drawing decided on, then you'd need to know the type of controller involved to write the code (Haas, Fanuc, etc...) I wonder if that guy I used to know is still working over at the college ... OH>.. and thanks, Trox

-

Leather worked jus fine. Photo upload worked jus fine Clean lines, even tones, solid construction, ... I like it!

-

How many 'lefties' we got around here? NOT for the first time, I got a message from a left-handed feller who couldn't "flip" the pattern (in the computer) because it wouldn't import into Corel software. Honestly, I know nothing about Corel beyond how to spell it I didn't put a "lefty" version in the patterns because I figgered they'd be some confusion over which was which .. folks cutting out the wrong parts (probably ME), etc. Probably better to keep the righty and the lefty separate, doncha think? Commander_P0_L.pdf Okay, maybe try this one out. It just now occurs to me, I don't think I've actually made this one for the Colt commander for a left handed draw! "L" is for Left, so no trouble accidentally overwriting the righy version ...

-

Uh, yeah.. theoretically less cancel when you have their money (that's that loan I was talking about). I have a buddy up the road -- drives a REALLY nice truck. ". According to him, people want to see the contractor pull up in a nice truck, which [he deems] makes him appear "responsible" and "professional". So I said that when I see a contractor in the drive with a really nice truck (no scratches, no "work" marks) I don't see "professional" -- I see a guy who likes driving shiny trucks and wants ME to pay for it Richard's a nice enough guy - just maybe a tad of a small-man complex (?). I mean, I just said "that's a nice lookin' truck", -- never suggested that he should justify anything to me (I mean, it's his show)...

-

I know, Alex (BOY do I know). I once found my 10 year old asking a couple of the boys just how many breaks they felt they would need in ONE day

-

In the course of what I do, I see quite a bit of what people call "lead time". You know, somebody says "hey, look at what I did with your pattern!" or "check out my ...", etc. Granted, there's gonna be a bit of time in anything not straight off the shelf. And I try to keep it 'first come, first served" (though I admit, I've thrown a black holster into the works ahead of a tan one since I was already doing black and had black thread in that machine). But if I can't get to a guy within about 6 weeks, I'm referring them to another leather crafter. And I mean one who can do the work, at a fair price, in the time requested (they do exist!). But lately I see a lot of lead times 12 or 16 or 20 WEEKS. Now, each his own, and what a guy does with his money is rightly none of my business But 16 weeks? You realize that's like... oh... 4 MONTHS. For a simple belt or holster? Not this guy. I'll give a guy 4 weeks... if I know the guy I might even go 6 weeks. Beyond that, no. I use THE best leather available in the states and I have references (I mean, real people, not some who "partner" with me by trading likes n tweets). So I can't think of anything they would be doing that would make it "worth it" to wait months for such simple projects. In fact, beyond 6 weeks, you aren't "reserving a spot", you're giving that guy a no-interest LOAN Now, I understand that some projects involve considerable time. I wouldn't expect a custom saddle by next month, nor would I wait by the window for a large quantity order. But for a belt or holster, or even a belt/holster SET,... seriously, unless it's coming from Elvis -- I aint waiting MONTHS.

-

Just might be time to hike the prices a little

JLSleather replied to Boriqua's topic in Leatherwork Conversation

Yeah, it's good to stick to the price you agreed to. Tell him if it makes him feel better, you'll gouge him extra good on the next one -

Welcome! Did you get the late version? I see about 5 or 6 people got the one with the pics reversed. So, the file you want is called NotebookLayout.pdf The 'wrong' one was deleted, but you folks is QUIK

-

... couple pics reversed in that text. FIXED NOW, but the 5 or 6 who already downloaded should get the latest ....

-

Nothing wrong with using commercially available patterns, but likely much better to make your own. Using a ready-made pattern certainly good for the newcomer, since you can concentrate on learning the LEATHER. But at some point, most of us will find it more convenient to design our own -- whether that's to save the money spent on "so many" patterns, or to let you customize the work to your taste (or that of your customer). That said, here's a quick "thingy" that may help with that. This discussion concerns a folding case for a small notebook. I had in mind the little "field notes" pocket size notebooks when I wrote this, but it can be applied to other projects of various sizes. Once I receive the actual notebook, I'll likely put up a "ready to go" pattern for those who care to use it, but for now .. some of you who already use those books may want to create your own design... http://www.jlsleather.com/diy/pattern-making/ Much like that old saying, 'give a guy a fish, he's good til, dinner. teach a guyta fish, ya never see 'im agin' . or, something like that, right?