-

Posts

7,378 -

Joined

Content Type

Profiles

Forums

Events

Blogs

Gallery

Everything posted by JLSleather

-

Not just from the picture, no - I can't say. That grain does look a bit like sheep, but that's about all that can be said just from this.

-

OOPS... found a couple of straps showing some of the rolls.. almost easier than getting out the rolls! The black on is one rolll (cane weave) and the other is TWO rolls which can be used separately or together.

-

Roll type embosser for sale. Said I'd sell it in a month, but took me 3 months to get around to it! It's only used about a dozen times (ish) so not a BIG discount here. But I WILL throw in 6 or 8 embossing wheels that go to it, and pay the shipping. $400 for the whole package, which includes shipping in teh U.S. I'll get to listing the rolls I have if anyone is interested here. The machine is this one: http://bunkhousetools.com/Embossing_Machine.php

-

Blockades? Worst I get 'round here is the wife takin' my tractor keys

-

Yep. But throw in a "HOLD STILL LADDIE!" and suddenly you have copyright issues in yer face! Brings up a good point though.. IF these people making all the MULTITUDE of videos really are "experts", then HOW did they GET TO BE experts BEFORE the video? And IF they learned watching a video, then what exactly was the purpose of making ANOTHER video regarding the same thing? AND... ah.. nevermind ....

-

See, now there's a thought. I would not ever be in the market to spend $26k on a splitter UNLESS I was hiring it out. If it's just for me, then $26k buys about 130 sides of cowhide already split But I get what you're saying. I don't even stick a project in the sewing machine without first checking stitch lengths and tension settings on a piece FROM THE SAME HIDE.

-

I wouldn't "take the hit" for $80 just because there's no answer. PayPal has a case system for exactly that. Having said that, I would advise you ('you' meaning everyone) not to get 'star-struck' by pretty tools. Always someone wanting to sell us "new" and "improved"... which is fine IF it REALLY IS IMPROVED. So, let me say TWO things here for your consideration. I have one of the pro edge burnishers. I didn't care for the finish they put on it, but once I took that off it works pretty well. No worries. Other hand, think about what you really need. what I do with that 'fancy" burnisher, I could have done with any of a dozen things I already had laying around the garage What do you NEED? Here's a bit of a story, told by a college professor forever ago and used as a teaching tool since... Guy wants his house walls insulated. Google tells him that you can BLOW that in without taking the wall apart. You'll need 1 1/4" holes in teh wall near the ceiling line. So, he checks with the lumber yard, and you can RENT the machine to do that. Off he goes to the hardware store, where the sales guy tells him he'll need a drill. This one here's $19. But this one is reversible - $29. And this one here is variable speed AND reversible -- $39. And this one here is all that PLUS a hammer drill -- $69. And over here, this does all the above, but does it without being plugged in and comes with extra battery - $99... blahblahblah At the end of the story, the professor asks the class.. what should the guy do? What does he need? Most said he really just needs the basic drill... minus all the 'fancy'. Instructor said no... he just needs holes in his walls near the ceiling line (remember, they were told that to begin with) What WE need is something which smooths the edge of the leather, and if takes a bit of the labor out of it that's a plus. For some reason, people seem to think that they can charge leather people MORE for the same items, just give it a new name. Apparently, that's at least sometimes true I have seen a "leather" cutting utility knife priced in the $8-10 range. It's the SAME knife I bought at Menard's (where it's called "utility knife") for under $3.

-

I don't see anybody doing this, at least not here on LW. Is there just not enough demand? People figure that leather is usually bought the thickness desired? I'd buy a splitter, but simply can't find anything reliable. WAY tired of spending money on tools, only to find that I have to sharpen, tune, or adjust it BEFORE I can use it. (Seriously, when did anyone buy a NEW car and get told it will run well once it's tuned up?!@#!!!). I don't have need of this consistently anyway. Just noticing that splitting isn't in the "services" list -- and I might take advantage of that were it available.

-

11 oz (Garland) mallet all I ever use for tooling.

-

Yea, Cuz how kinya have any pudding when ya dont eat yer meat?@#!#!

-

Hi 'n' tight is good... Good to see you fellas gittin' some use outta them!

-

Three guesses at the finish I'm using with this one. No takers?... I'll tell ya anyhow. There is NO finish on this just yet. Water not even thoroughly dry from forming. It's quite black, but the camera is picking up the refection of the graph paper! Just posted to remind the new guys that: regardless of what you hear, it IS possible to make holsters without wrinkles on the back with the good stuff, your leather should buff up to a shine even before applying finish Now, those of us who been at it a bit know that easy 'nough, but the new guy might not. Wrinkles and acrylics are not inevitable

-

http://wickett-craig.com/leathers/

- 7 replies

-

- veg tanned

- color

-

(and 2 more)

Tagged with:

-

We talkin' U.S. currency? Sweeeeet ....

-

Maybe a little clearer without the sketches? Still a very simple project... Due to the addition of photos, I'm increasing the cost 30% (bringing the total to $0). Anyone not comfortable with the absence of video is free to not download if preferred card_hor03.pdf

-

Welcome! More coming soon ....

-

Welcome. And that's 209.5 x 158.75 to you Re-loading with metric measurements. I'm even going to proof read this time before sending

-

I have dealt with Ray and Bunkhouse a number of times and have no complaints whatsoever. Good product, good service, fair price, all from knowledgeable and friendly folks. The molds I bought for the Colt Python and Ruger Blackhawk fit like a glove. And I do like the aluminum molds from Duncan's Outdoor as well. Last I knew, gun molds were $50 and mags were $15 (recently). The mags are (in case Zach is listening) one of the reasons I shop there.... $15 instead of nearly twice that some others charge, but more importantly they are molded on the end as though they are loaded, which is a BIG plus in time savings...

-

The first of several variations of the field notes notebook cover ready for download. I added 1/4" to the height, for those who care to lace the edges instead of stitching. This one uses 4 separate pieces, so you can use up some smaller pieces. Rumor is this will get listed at a small cost on Cutesy, so smart money says download the free one while the sun shines (or something like that). Find it in the "OTHER DIY" section: Field Notes Style A Color added since the pic, but I wanted to show the style and size of it (only). Bob prolly got a tooling design for this one ready to go anyway

-

Let us know if they're on top of it!

-

Welcome. And thanks fer stoppin' ta say 'thanks'. And thanks for not sayin ya git whatya pay fer

-

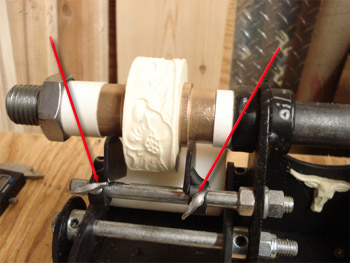

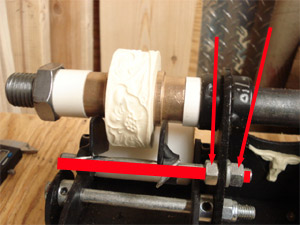

That embosser isn't that difficult. I should maybe drop a line to Ray and friends and ask permission to put that on my site for 'em.... Meanwhile, don't let that a laid back good-ole-boy tone throw you off... I'm guessing Ray hasn't forgotten anything since back in '74 Have we heard of SET SCREWS? Those guides ride on a bolt. Once you set the width to the width of your strap Then a fella what was observin stuff might see that those guides run on a DOUBLE NUTTED BOLT (aka: set screw). And if a guy could tell, looks like that might be about a 16 pitch screw. Meaning 1/16" between each thread peak. Meaning each full turn, the nut moves 1/16". So, really --- if you back off the outside nut ONE FULL TURN, and tighten the inside nut ONE FULL TURN, then you've moved the guides (which are already set the correct width) exactly 1/16" to the left (out). TOO simple.. thanks, Ray T.... Oh, yeah ... keep in mind if you're trying to 'center' a roll on a strap, distance moved should be HALF. If you're side (border) measurements differ by 1/8", move the bolt 1/16". And if you're off by 1/32", run the strap through and don't worry about it

-

Yeah, I been there with the backin' out stitches I'm using a c4 too, but somehow I get a project done ocassionally ANYWAY. I bought it back when I didn't know any better, and while I aint proud of my mistake, I just mention it to let you know taht you CAN run 277 thread with a 24 needle. I do it all the time.. HATE those holes left by teh #25 needle.. always worry I'll fall in one of them gaping holes ... 24 with 277 at about 6spi