-

Posts

2,274 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Ferg

-

One of the finest individuals I never met in leather work. I think I may have spoken to him on the phone once but most likely e-mails. He never declined to answer any of my many questions. I wish him and family the best. Hard when losing your mate.

-

That's funny. I needed your response to that post after a not too great past week!

-

-

Did you ever bite the bullet and get a CO2 Laser? Or are you cutting these with a Diode? Nice work anyway. Ferg

-

-

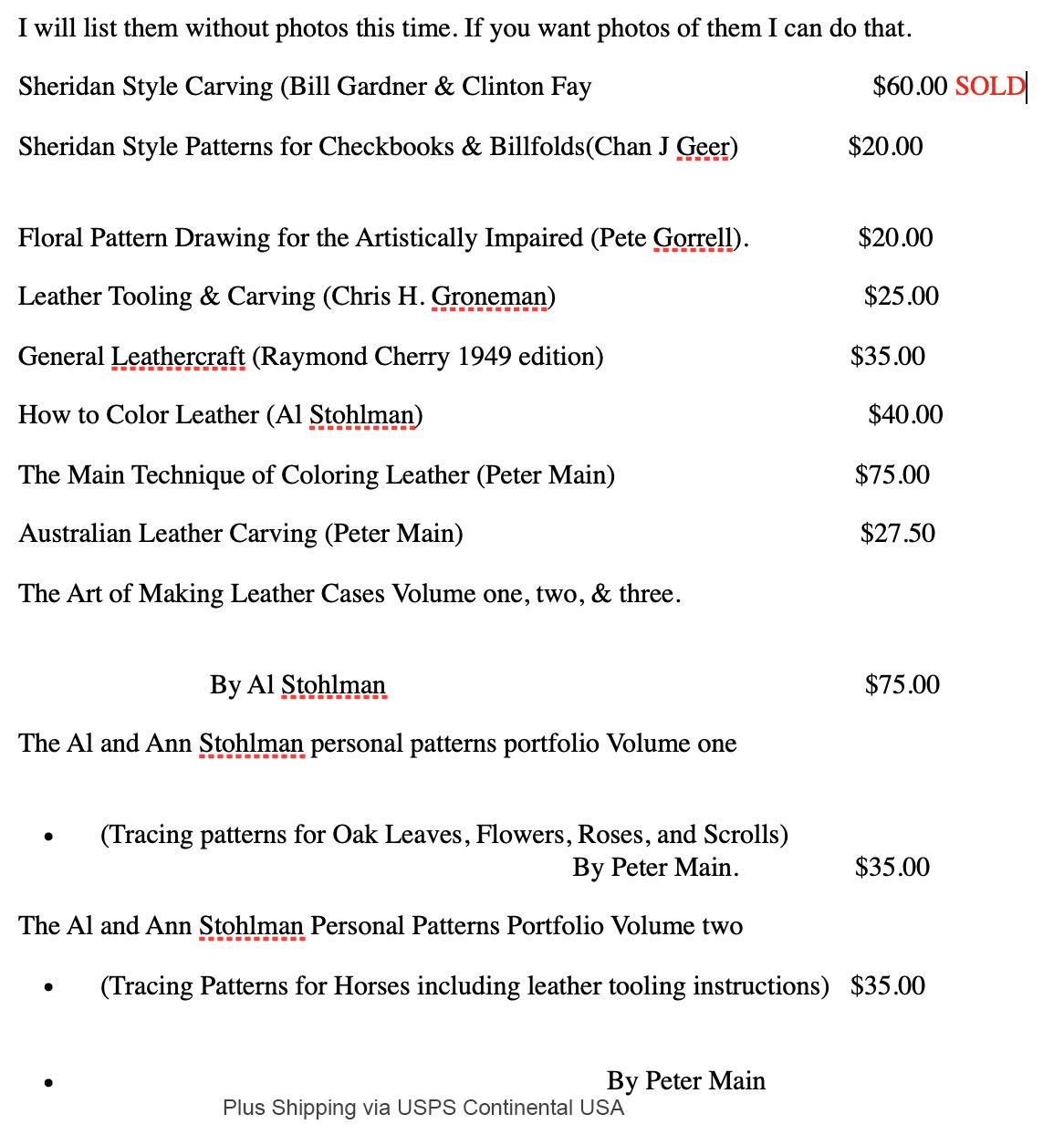

As I have said many times, "I have been at this a long time." There are probably as many ways to do this as there are folks trying. That said: I run the tap water so it is moderately warm. I hold the leather under the faucet until there are no bubbles emitting from leather, turn it over to opposite side and do the same. Use an old terry cloth towel or old clean T-shirt laying it flat on table, lay the dampened leather on top of the cloth and roll the towel and leather together. Leave overnight. When you unroll it next day it will be damp and a little darker in color than when dry plus very pliable. Lay the leather out on your stone you use to engrave and stamp. Allow the leather to dry enough you can see it begin to change back to original color. It is ready to work. Naturally it will dry out as you work your stamping. Use a large cellulose sponge that is wet, not dripping, to go over the leather piece. This will replace some or most of the moisture you started with. Continue your carving or stamping. When I am finished with the engrave I make sure the piece is laying flat and place the towel over it overnight. You can do what ever finish you wish at this time plus the leather will take an impression with a personalized stamp with ample pressure. Hope this helps. Remember one very important thing. Take your time with casing the leather. Do it correctly and you will never regret your results. Photo is of a piece I carved over 40 years ago after using above tempering method. Ferg

-

Awww! Woman Repurposes Mom's Singer in Her Memory

Ferg replied to Sheilajeanne's topic in All About Us and Off Topic

What a delightful story and fantastic woodwork. Have often wished I had saved my mom's old Singer -

Machine Man looking to become a better Leatherworker

Ferg replied to mbnaegle's topic in Member Gallery

You have had a very interesting life. I have worked with leather for over 70 years, not a lot recently with too many physical limitations. Most of my life's work has been in residential and light commercial building plus over 40 years of manufacturing wooden commercial cabinetry and decorative items for the home and children's wooden puzzles. I have always felt woodworking and leather go hand-in-hand. Stick around. We all learn new things every day. -

I have an unrelated/related question for the OP. Why on earth are you soaking your leather overnight or longer? Do you know how to "Temper" leather?

-

I forget where I got those punches. I placed colored leather on the backs of the leather I filigreed. I have been at this a long time and learn something I missed every day.

-

I have a set of 39 filigree punches I will sell for $125 plus shipping. A little difficult photographing them unless I done them one at a time.

-

Have fun with your endeavor. You will find that building your first shoe will at the least, be exasperating. Hang in there. I had to stop on my shoemaking venture because of extreme arthritis in my wrists and some fingers.

-

I found that actual measurements of your feet hold true. Did you consider the sock you may be wearing? Not accounting for it can make a vey uncomfortable shoe

-

According to USPS you should have your book today.

- 18 replies

-

- bob park

- western floral designs

-

(and 1 more)

Tagged with:

-

I think so far you have done a great job BUT! I assume the boots will be for you? Measure your foot at least ten or fifteen times in all directions and fine tune last to those measurements. I haven't built any from scratch but I did build a set for myself using a close set of commercial available. I don't remember how many times I measured different spots on my feet and the last. I used leather strips glued on to original last to conform to my feet after I essentially crushed my right ankle. Note: If you remove too much wood in a spot use leather strips glued on the last then sand the leather to exact fit.

-

From my experience I think you are barking up the wrong tree. lol If the leather is wax impregnated I do not know of any adhesive I have ever used that will adhere to the wax surface you speak of. Not knowing what your project looks like my only suggestion would be to make a rolled edge and stitch. If you keep the leather tight on both sides it may work for you. If the adhesive you are using holds for several hours you could stitch with rolled edge while it is "stuck". Think I would try it anyway.

-

Your USPS Tracking #:hidden by Johanna Thank you, If any other specific books or tools etc. you are interested in I may have them. I began my Leather Business seventy two years ago and have more "stuff" than anyone should ever think about having.

- 18 replies

-

- bob park

- western floral designs

-

(and 1 more)

Tagged with:

-

I have your address. What name for address? Use my e-mail: XX@donet.com to access me in PayPal (email hidden by Johanna) Total including shipping of $9.90 $59.90 Just give me a whistle if you need anything else. It will ship tomorrow. Will send you the tracking number tomorrow . Ferg

- 18 replies

-

- bob park

- western floral designs

-

(and 1 more)

Tagged with:

-

Still have the book. I will need your shipping address. I take PayPal at my e-mail. I will need to get the shipping cost before informing you of total amount for the book. Thanks, Ferg

- 18 replies

-

- bob park

- western floral designs

-

(and 1 more)

Tagged with:

-

I have a like new copy of Bob Parks book "Western Floral Designs"I will sell for $50.00 plus shipping.

- 18 replies

-

- bob park

- western floral designs

-

(and 1 more)

Tagged with:

-

Not with all the legal entanglements.

-

I have a pristine copy of this book. The cover isn't even creased. Would sell for $150 plus shipping If I was to make a PDF copy of this book it would cost you a lot more than I am asking for an original. lol

-

Made in USA