-

Posts

4,408 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by bruce johnson

-

I made a hard seat smooth-out saddle with just some basket stamped corners several years ago. Took me about four hours more time being careful to not make marks and then rubbing out the ones I did with antler tines and bones. The guy picks it up and carried it out. He threw it on its side on the diamond plate flatbed of his ranch pickup and bounced down the road. I was thinking then what a waste of my time being careful. Here's a picture of it a couple years later. Smile says it all. Yeah, don't sweat it, it will be fine!

-

Best source for clicker dies?

bruce johnson replied to wizard of tragacanth's topic in Leather Tools

Personal experience - Texas Custom Dies - some years ago - quite fast, reasonable cost compared to other die makers that were on the leather worker radar screen at the time, and they followed up to make sure I was happy. Those were the only new dies I have ordered that I can think of. Realistically there are several more die makers that have been in business for a while, but now marketing more to leatherworkers. Milwaukee Steel Rule Dies, Ohio Clicker Dies, and others. I'd think between these and the ones mentioned, you'll find somebody you are happy with. I get a fair bit of used dies and really can't say anyone consistently makes a "bad die". Some that come from the industrial or production companies are pretty beat up but that is understandable. 4 ton press - Weaver Mighty Wonder is good. I have had a few through here. I have used a 20 ton shop press with plates, bench top 12 ton shop press with plates (Weaver) with the hydraulic jack replaced with an air over hydraulic jack, Weaver 4 ton Mighty Wonder, Weaver 8 ton Mighty Wonder that was parked here for a few days, Lucris M3, Import 2 post table top, WUTA 4 post table top. That is what I can think of off the top of my head. Least expensive and realistically good for non-production work is a shop press with plates. Right now we have the benchtop shop press for heavy leather and larger dies and a WUTA 4 post for smaller work. My wife really likes them both and between them she can do everything she needs. -

My thoughts and experience. 1 - You can’t change the overall blade angle much with stropping compounds even if you use black emery. If You can do that, you have my respect for perserverence. 2. You can however round over a blade edge very easily using mild compound on a strop and either a) - not keeping a constant angle or rolling that angle b) keeping the angle too high or c) using a soft strop 3. Use a mild compound on a firm surface like card stock, file folder, or hard roll horsebutt for stropping a swivel knife. And don’t do it a ton. A few strokes to clean but much more than will violate point #2 above. I like purple compound but green or white is OK. Whatever you’ve got that isn’t black or red. Round and cutting knives can use a “softer” strop like vegan leather because a little convexing of the edge can make a “Moran edge” that is durable. On the other hand Swivel knives I feel need a flat edge all the way out for easier and cleaner cutting. That means a harder strop and less aggressive compound. I’ve had a bunch of swivel knife blades through here in all tiers of quality and use. I probably have 75 blades right now. When I sharpen one I set the blade up in a jig and mark the facets with fluid. . I can guarantee that more than 95% of them will not scratch the marking fluid off the very edge intially because the edges have been rounded from in inconsistent angle on an abrasive maybe but mostly due to over stropping. I go back up the grits to something coarser to flatten the facets and bring back the angle and then run through my grits to 5000. Then I strop with the jig at 1 to 1.5 degrees higher with purple compound to take off the burr edge. It’s literally almost just a touch on each side for the bur. By hand, there are a few jigs I like and the Big Red you mentioned is sure one of them. I think hitting a blade on 2000 if needed and then 5000 wet/dry with a jig and a light strop as above to maintain is better to maintain than stropping the crap out of them like has been recommended by a lot of people the last 50 years. My thoughts for what it’s worth.

-

Problem using a TandyPro Deluxe Leather Splitter

bruce johnson replied to Coloradoguy's topic in How Do I Do That?

Thanks Tom, I do sharpen splitter blades. I am currently in Ohio at a leather and tool auction. I will be back in the shop middle of next week -

Something else that makes edging the flesh side easier is slicking your leather. I know, I'm old school. Basically for vegtan you case or at least dampen the surface then run a glass or wooden slicker over it a few times. I slicked flesh and grain side. On a cosmetic note slicking makes the bottom side appearance smoother and more pleasing. Functionally - slicking will compress the fibers, smooth the grain a bit, take some stretch out. it helps to prevent paired straps from stretching unevenly. It will also make your bottom edging feel almost like grain side edging. For chrome tan leathers like latigo, you can use something like saddles soap, BlackRock, gum trag or Tokonole on the flesh side and then slick to lay down fibers and allow some compression. Slicking will also let you use some of that leather you all are throwing or giving away. Cut the flanks out of the bellies and save the bellies. Case them and slick the snot of them. They will compress and make a nice piece for things like card cases or leather that molds easier for sheaths depending on thickness. You can work at it and slick a belly up to almost resemble shell cordovan.

-

I have seen that advice a couple times with no reason given to back it up. The flesh side can be a little harder to bevel sometimes because of the stringier fibers, but that shouldn't matter in what order you do it as long as your edger is sharp.

-

I deal in refurbished and selected new leather tools. People cut leather with a $350 round knife down to a $10 Olfa rotary cutter, $7 utility knife, or maybe the $6 HF scissors that cut pennies. The range of leather workers and their cutting tools is pretty vast. I get some leather scissors or shears in some of the old sets once in a while . Overall, I don't think they have been marketed the best as a cutting option in the last 20 years. The best thing you can do is put some out there and see how they sell. Price them at what is fair to you, not what you think the market is. In my case what I personally think rarely happens close to expectations. Many things I think won't sell fast due to price (high or low) ends up reordered the next week. Stuff that I think is a dead-on great value gets reordered in 6 months.

-

I think a call to Osborne to see what the hole size is will be your best bet. I decided several years ago to put new rawhide heads on several wore out mauls. What I found was that every maker had their own better (and different idea) of what the round stock should be even among the same general sizes. I gave up at that point and used them for ballast in the trash can. Dan Preston from then ShopTalk magazine did some refurbishing on mauls and made up rawhide heads. I think he had an article or two about it. I bought out his stuff twice and those mauls were not the shiniest. They ended up ballast as well.

-

If Barbara at Y-Knot doesn’t have 2.7 mm she or I have tools available to cut down lace to any width.

-

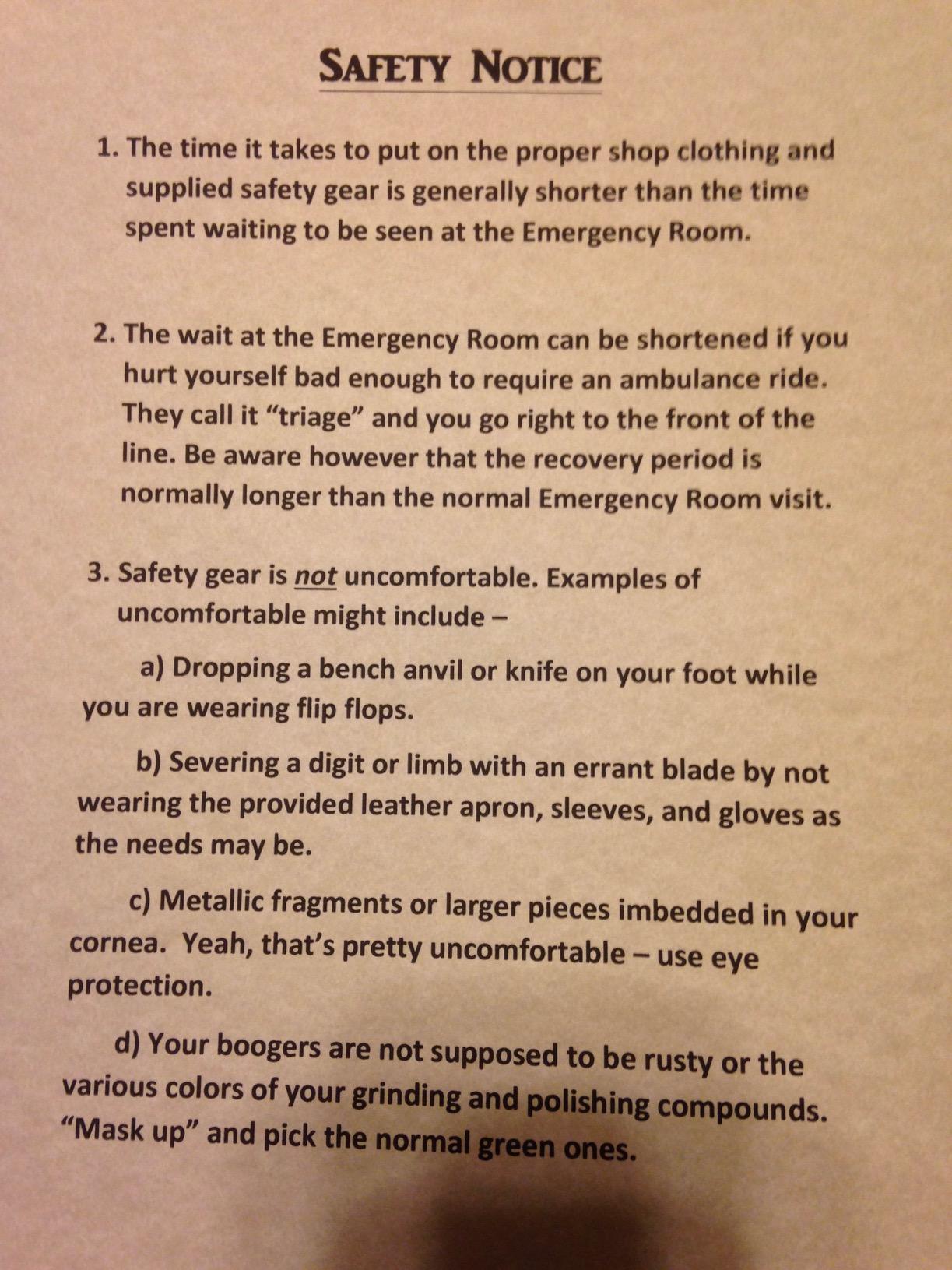

When I first got my business license I had a county inspection - some work place guy and a fire dept inspector. Not pain in the a** guys, they just wanted to know what they’d up against in a fire or industrial accident. I’m a one man shop so mostly formality probably. Really pretty cool guys. The work-place guy noticed I didn’t have a workplace safety poster in place. He said to just send him a picture when I got it and he’d sign me off. I came up with this. He said it was official enough for him and one of the best he’d seen.

-

How to sell or donate Mom's old leather tools

bruce johnson replied to Michelle M's topic in Member Gallery

I'll see if I can dig up his name, He just shows up at the show and I recognize him. -

How to sell or donate Mom's old leather tools

bruce johnson replied to Michelle M's topic in Member Gallery

Leather trade shows - we set up as venders at Prescott Az, Sheridan WY, Pendleton OR, and new show in Las Vegas next January. We are going to miss Waco this year but on the radar for next year. -

How to sell or donate Mom's old leather tools

bruce johnson replied to Michelle M's topic in Member Gallery

Michelle, I deal in leather tools and come across this situation more often than not. You can sell them through the market place here. Ebay is another option, some people have good luck on FaceBook marketplace too. There are also FaceBook groups dedicated to just selling leather tools. If you want to get them moved as a group and sell them, these are all viable options. Problem with all this is taking pictures, dealing with the selling process and collecting payment, then shipment. Oh yeah and figuring a price first. Pricing - There is a lot of smoke and advice from people who have never done this. I tried Craftool stamps early on with my website. There was too much time in pictures and descriptions for singles to make it worth the time. Put them in small groups by type and you get five questions about "I just want that one, not the other 4". We evolved to just selling them on a bargain table at the shows. In about the last 5 years I have all but stopped intentionally buying just Craftools for resale. Still with estate sets I end up with 500-700 Craftool stamps a year, plus the hand tools and patterns. Contrary to popular belief, older Craftools do not necessarily sell better than newer ones to most people. Maybe a single stamp or small group here and there, but overall - no. For the shows, I used to price the preletter Craftool stamps at $7 and letter prefix stamps at $5. I spent a lot of time at the shows explaining the difference to people who in the end just didn't care. They either liked the stamp or they didn't and tried to deal down on the $7 price anyway. Now all stamps are $5 each and Ms Rundi will deal them at 5 for $20. The hand tools are usually on the bottom end too - lot of $5 tools and they are still piling up here. Patterns and books depend. Some are pretty much outdated styles and projects. Some are good like the Baird books, some are fire-starters like bowling ball bag patterns. Likewise with Craft-Aids - a few good ones, more though that we bundle and hope. What do we do now? We take them to the shows and reliably the Prescott AZ show is our better one for them. We found they sell decently at Prescott, barely sell at Sheridan, do just Ok at the Pendleton show. Overall we end up and sell maybe half the stamps at best. Now Maker's Leather Supply is set up across from us at the Prescott show. They are great about having kid's project kits they give away. The kids get a free kit and then Janie Sue sends them across the way to us. They get to pick out up to 5 stamps for free. Mallets are free too if we have any. The cool thing about Prescott also is there is a guy who has a leather craft program at the VA facility. He gets whatever he asks for and more. There are a few kids whose parents take classes or are venders at the shows. I have a loosely structured informal program with free roaming kids. They help empty my candy dish, I give them a deal on a few tools for part of their pocket cash. Later on they trade up to something they like better, or sell stuff back (at a profit for them). It keeps them occupied throughout the show and learning cowboy bartering skills. My experience anyway -

Agree on the planer for thickness reduction as the best option. but those places with the capacity for 2 feet wide seem to be getting fewer all the time in some areas. I have successfully resurfaced mine by hand. I did light pressure with a fairly coarse paper on a palm sander to take down the high spots. I think I started in the low 100s for grit. You want to almost float it over the surface. The paper cleans easy enough with a crepe belt cleaner every so often, no different than wood as long as it doesn't melt.. Then follow up with a couple progression of finer grits until you are satisfied. The key is keep moving with light pressure. Excess pressure or staying in one spot can melt the plastic and that gums up the paper and makes a divot. You don't have to take out the cut lines as much as just take down the high ridges next to those cut lines. A belt sander is probably going to run too fast and "hot".

-

The most popular weight depends on the job at hand. The right size makes the job easier and more enjoyable. Otherwise you can wear yourself out trying to hold up a heavy maul for easy stuff or wear yourself out beating a light maul repeatedly on heavy stuff. Stamping Tools - everyone needs a 1# maul. With most stamps that weight gives a good deadfall effect. For larger face stamps like 1/2 inch or more geometrics - 1.5# or 2# depending on how intricate the design is. For tiny faced or sharper stamps like seeders and bargrounders, consider stepping down to a 12 ounce maul. Hardware setting, smaller round punches, and most strap end punches - 1#. If you fall to the side of "I don't want to my punches to be really sharp" then 2# for the strap ends and rounds. I don't follow that theory but some do. Large round (2 inches and up) and Rosette punches - 2.5# or 3#. I sell 4.5# mauls for the heavy hitters on big punches. I don't mean to dissuade you from rawhide, but a few things to consider. The industrial handle rawhide mauls new are about twice the cost of a good leather handle maul ike the Wayne Jueschke mauls I sell or Barry King mauls. Rawhide can wear a little faster and can flake off onto your work. There are definite fans of rawhide and I do like them, just not as affordable new and the good used ones are few and far between.

-

Vintage Champion Shoe sewing or stitching machine?

bruce johnson replied to aml311's topic in Leather Sewing Machines

There are a few Champions that got traded around this area for years. The old deal with Champions and American straight needles was that most shops had two. One to sew and another to scavenge parts off when they wore totally out on the main machine. The problem was that those same parts were likely worn on the scavenge machine as well. The parts availability is not necessarily what they are for the Landis, Campbell, and Randall machines. The last Champion I know of around here that sewed pretty well sold for $1200. A friend had a Champion deep throat that sort of sewed and he stored it here when he was between places. Once in a while he'd come over and we'd BS for the afternoon, get it going somewhat, and then have some Crown Royal and a steak. When we finally got through the bucket of scavenged parts and it wasn't much better, we called it some quality buddy time and scrapped it. On the stand it weighed around 600#. -

That tool is for setting "bar snaps". Bar snaps are used on the edge of wide flaps like on the coin pocket in a wallet. It was a wide piece of brass with the snap stead molded in. This tool was used to crimp the bar on the edge of the flap.

-

If you want to go natural, one of the best wood surfaces I cut on was a 20 year old plank of clear sugar pine. occasionally resurfaced with a sander. What do I have in my shop and recommend for a cutting surface? Hint - it isn't wood. - https://brucejohnsonleather.com/links-resources/tool-talk/cutting-surfaces-knives-and-blades

-

Randall leather sewing machine needs a shuttle

bruce johnson replied to Vicki Vallencourt's topic in Leather Sewing Machines

There is zero reason for you to stay neutral, you are in Conroe and not Switzerland. I was happy to see your name pop up here when you first joined. There is a real lack of understanding about these big old machines and parts sourcing. The guys that knew them inside and out (like my late friends Sam Huey and Keith Pommer) are thinning out. Please feel free to promote away and any information threads or history you want to post will be welcome. I have had nothing but positive experiences with Campbell-Randall. If I was still a maker and not a tool seller, you can bet my supplies would still come from C-R. When I transitioned to refurbishing tools and bench machines I appreciated the support and referrals from Dan early on a lot! -

Randall leather sewing machine needs a shuttle

bruce johnson replied to Vicki Vallencourt's topic in Leather Sewing Machines

Campbell-randall.com @mbnaegle -

The heaviest rawhide comes from slaughter bulls. Percentage-wise, packer bulls are a very small number versus the total number of cattle slaughtered everyday, and not done by a lot of major packing plants. The hides are big and heavy from English breed bulls and especially northern cattle. Commercially, you may run across sourcing those in a smaller plant. Denise and Rod Nikkell used to build saddle trees. They drove to a small processor when they got a call there would be bulls. They picked up the wet hides and fleshed and dehaired themselves. I'm not going to say impossible to find processed bull rawhide but harder than straight run rawhide.

-

Screws ripped out of saddle tree

bruce johnson replied to Mendosa's topic in Saddle Identification, Restoration & Repair

Call your saddle maker and tell them what happened. My guess is that at a minimum you will be told to move the screws and not use the same holes. -

No dog in the fight either but here's my experience. Tippmann originally made the Boss with a cast iron frame. I am not sure exactly when Dwight bought his but I bought mine in early to mid 2000 and it was cast iron. Cost was around $1600 then. Everybody and their uncle was a Tippmann dealer and I'm sure that the profit margin dealer pricing agreements made them $1600 list. Anything else that sewed leather then was $5000 or more. No Artisans, Cobras, or clones then so it was the first somewhat affordable option. I think the aluminum frame Boss came a few years later but not sure on that. I don't recall a lifetime warranty, only one year. I know that a few parts were upgraded and sent out at no charge. I got a few replacement parts that broke later on - rack and cable over time. I don't think they were free but can't say 100%. The lifetime deal on mine was that you send the machine in to them, they'd go through it for something like $100 0r $150 and they would rewarranty it again then. Obviously living close and driving it over, they might do repairs or adjustments as a favor in that business relationship. When I sold mine, I sent it to them, they went through it for the fee and sent it on to the buyer with the warranty. In use, I sewed some 415 but mostly 277 or 346 on top, one size smaller in bobbin. The short throat was really limiting for some of my work. Still for belt and edge sewing it was good. My late wife and a 14 year old son could sew on it. My current wife sewed a bunch of production belts on it when we were dating. The Boss likely ran $200,000 or more through it. If I was buying today - Outlaw if I was to buy a hand crank. You may not think you need more throat space but its enough of a plus that the cost would have been worth it for me. If you want to add another $1000 then the Cobra 26 is a solid choice unless you are sewing saddle skirts. Reach for Rundi Johnson's #26 and you will pull back a bloody stump.

-

Help Needed:About wiping the glue and edge paint

bruce johnson replied to kellyswanson's topic in How Do I Do That?

All glues are not the same and all edge paints aren't either. As said, most contact cements on the surface can be removed with a crepe block or eraser. Realize that the solvent in them makes them penetrate the leather a bit and that won't wipe off. It will block stains and dyes depending on how deep it goes. If you have to rub much to remove cements then the surface of leather will abrade. From there on will not take dyes and finishes the same as the leather around it. Edge paints - not all the same - I used the Fiebings a fair amount on smaller stuff. It was OK, kind of the standard then. Most of my larger projects had a dyed and burnished edge. My wife is now making a lot of smaller projects from chrome tan leathers. You would be hard pressed to make her switch from the Giardini edge coat system. Jerry Van Amburg spent about an hour with her at Pendleton last fall showing her the steps and tips/tricks for Giardini. Those edges are nice! She orders it from Buckleguy and they have a YouTube on it.

-1.jpg.4306740b0a4f65f359664a7aecdfb916.jpg)