-

Posts

4,401 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by bruce johnson

-

I’ve got them in old sets predating Craftools. They were just different diameter rod with the end cut at an angle and then knurled. could go ahead and checker them too

-

When I saw a Tandy announcement for them about 30 years ago I was there every day for a week to see if they came in yet. They really improved my floral and oak carving at the time. Smooth ones are good for inside curves, like the scallops on leaves. mild undercut effect if you tip them. They used to make checkered ones also, somebody still might. Good for cleaning up the slicking effect from smooth undercutters or petal lifters against a checkered background. I like those a lot for inside curves on oakleaves especially. You can just hold them vertically in one spot and turn slowly while tapping. You can do a 180 degree bevel pretty fast and smoothly. It is hard to do that even with really narrow regular bevelers without leaving chatter marks.

-

How do I remove stains caused by sabble soap bubbles?

bruce johnson replied to josephsong's topic in Suppliers

Saddle soap contains oils and conditioners. They wont dry. over time they may migrate and even out some.- 3 replies

-

- question

- question about technique

-

(and 2 more)

Tagged with:

-

Anyone know where to find really short belt rivets?

bruce johnson replied to DanDSilva's topic in Suppliers

You can drive the burr, nip it off slightly more than 1/16”, then peen it to set it. There are tools for this. Economy one piece setters called a “tinner’s rivet setter” - designed for metal but works on leather. You just need to be careful not to mark your leather with then setter. There are three piece sets designed for leather work. A burr driver, peener, and domer for the head. Here is a link that shows the process with the leather set - https://brucejohnsonleather.com/products/rivet-setters -

Looking for part time help In New Hampshire

bruce johnson replied to awharnessshop's topic in Help Wanted

Welcome back my friend! I hope you find the right person. -

This could a chapter in a book. The first thing to consider is thickness and type of leather you are edging. The second thing is to realize that size numbers generally mean nothing between makers. Next factor is your ability to maintain an edger, some styles strop and sharpen up easier than others. Steel types - once you get past the entry level lower priced edgers, I could care less what they they use. The makers have thought it out and and found out what works for them and their manufacturing process. In use, can I tell if an edger was made from D2, 53, or 390? I am not that good and the previous factors are more important to me. Going forward, everyone has a favorite and likely they are going to be different. Once you get past a low price edger that never came sharp and limited instructions to sharpen it then whatever you trade up to is going to be better and your recommendation. Might be Weaver, Barry King, Ron's Tools, WUTA, Palosanto, Owden, older or newer CS Osborne, older Gomph or HF Osborne. Styles might be a round back edger, bisonette edger, fine edger, bent toe or "western" edger, European edge shave, and others. That doesn't make any one of them better than others, just personal experience and we are all different in expectations and budget. You can pay from $30 to $120 for an edger. Everybody's best for the money is going to different.

-

The age old question…how do I get rid of mold!

bruce johnson replied to medievalbard's topic in Stamping

Agree with AlZilla. Metal contamination. You can clear it with an acid treatment. The metal flakes interact with tannins in the leather when it gets wet. Diluted lemon juice wiped on or oxalic acid. Most hardware stores sell oxalic acid as “wood bleach”. Dilute 1 teaspoon into a pint of water and sponge it on. The source of the metal can be anywhere from the tannery to your shop and tools. If you handle a steel tool and then wet leather sometimes that is enough to make specks or smudges. Particles falling off a tool can do it. -

I have not seen that particular version, but see these once in a while. I don't actively seek them out to buy but have a Sutton on the shelf here with a small sack of other heads and anvils for it. I kinda like looking at it for now. These set a lot of different things - eyelets, lace hooks, snaps, etc. These multi-head fly presses seem to be mostly on the back bench in old shoe repair shops next to slopped over glue pots with a cranky 80 year old repairman wearing an apron to match. Those guys normally don't say much but usually open up when I ask if they have an aglet press too. (Press to put the ends on shoelaces). Once I say that they figure I might be worth their time to chat with.

-

Machine Man looking to become a better Leatherworker

bruce johnson replied to mbnaegle's topic in Member Gallery

Welcome to the forum! I don't believe I have talked to you but may have. Dan and I talked quite a bit several years ago when I was still doing active leatherwork and then more when I was getting started in leather tools. I called once and your dad answered. He found out where I lived and we had quite a talk. Knew lots of people in common. When I first moved here to California many of the older horse generation still talked about "ol' Buster Naegle". -

Leather punching with complex shapes?

bruce johnson replied to AEBL's topic in Leatherwork Conversation

It is mostly called filigree work or filigree punching. Used to be pretty common in the 70's and some people referred to it as "hippie style bags and belts". Those shaped punches can be bought in sets and really quite inexpensive. -

Tonight we have added another section of leather tools for sale on our website. At the leather shows my wife, Rundi, has a table she manages of lower priced leather tools. Stamps sorted into cups by type only, trays to contain hand tools, punches, hammers, etc. Set price and U-pick kind of a deal. These are the lower priced more common tools like Craftool, Rampart, Midas, and others. We don't actively seek these tools out but still accumulate them throughout the year from estate and retirement sets. A large share end up donated by us to veteran's and youth programs, and most kids at shows get a few free stamps. They get a free youth project pack from our friends at Makers Leather Supply and come over to us for stamps. At the shows these other tools have been sold in as-found condition in the past. We have decided to start offering them on the website along with our other leather tools now. Here on the website the tools are cleaned up and sharpened to be ready to use. Everything is functional and no junk. I have the initial tools up and going tonight with more additions to come. Please check them out at https://brucejohnsonleather.com/bargain-table Thank you! - Bruce and the ever gracious Ms Rundi

-

I know it is semantics but it makes them adjustable creasers. Creasers make parallel lines. Beaders are a fixed width tool that rounds up between the tracks to make a rounded bead line.

- 9 replies

-

- tandy

- since tools

-

(and 1 more)

Tagged with:

-

Got done early with some shop stuff tonight and pulled out some handy Danny Duncan stuff. Two of the "lever punch" machines, two svivel knife sharpening jigs, and one of the wooden handle lace punches. I'll probably just leave them out and put them in the Old Corner Museum of Cool S**t Leather Tools.

-

Beveling ... slowly ... and badly

bruce johnson replied to AEBL's topic in Floral and Sheridan Carving

It isn't speed to start with but practice, muscle memory, and getting a rhythm. To avoid chatter marks I probably don't move more than 1/3 of the stamp width at any stroke. I am also not holding the maul like a hammer, I am rocking it like a see-saw and letting the weight do the work. I hold the stamp slightly above the leather and relax my last two fingers to allow the hit and rebound. I am holding my maul with the thumb and index finger/middle finger doing most of the gripping. The last two fingers are loose and that allows the rebound. I rotate my wrist and the maul dead falls in a rocking motion, the last fingers rock the heel of the handle and raises it up for the next stroke. Between the right and left hand being "loose" i am not striking, I am rocking the right and moving left. Speed comes with wider stamps for me. -

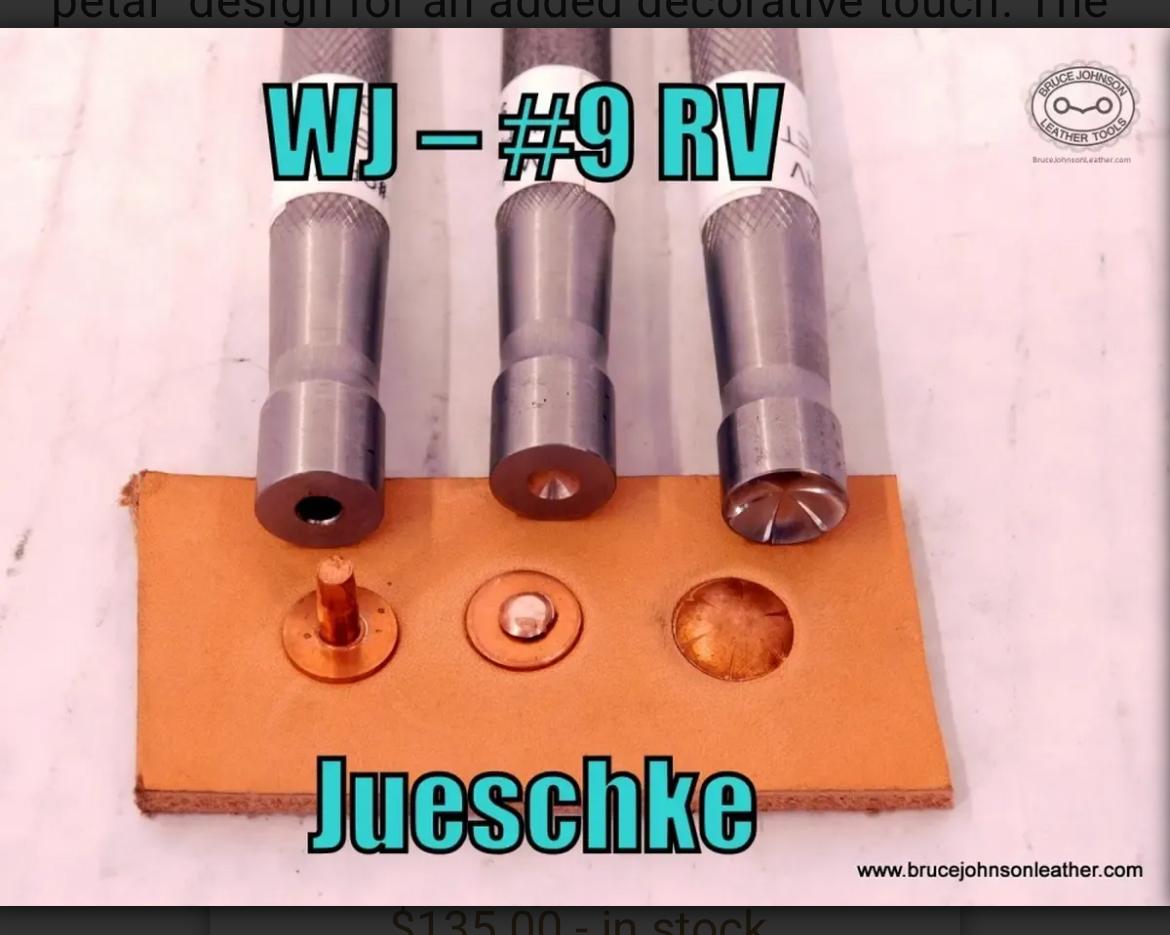

Mark, I get them pretty often, and have new ones from Wayne Jueschke - https://brucejohnsonleather.com/products/stamping-and-carving-tools/border-stamps - Bruce

-

Yessir, I am in Oakdale

-

Decide what you are interested in first. People say “I don’t like basket stamping patterns” but you can learn a lot about casing and ideal moisture with a basket stamp and a border. Want to carve? Then get the basic stamp set and play with it, that will help you decide if you like it. It will also give you a basis for which stamps to upgrade and the sizes that fit your projects. As you go along you will find a whole range of stamp makers, some priced more than others. Barry King is still a pretty good bang for the buck. You may decide this is not for you or you got a stamp you just don’t use. The resale is generally good for Barry King and higher end stamps.

-

They could have came that way or sharpened that way. Some styles of edgers come sharp to the tips - CS Osborne fine edgers and Gomph common edgers were sharp at the tips and several old guys called them "finger stabbers". Pretty good edgers and great for trimming a binding near a stitch line. Yours are a pretty common style edger and it is no crime to round the tips. Sometimes those are purposely narrowed at the tips to allow them to get into the edge on thinner leather. Wider tips will hit the surface underneath unless the leather edge is raised up otherwise. If your tips are hitting inside curves and you like this style edger then grind the tips back closer to the edge. That will let you swing them in a narrower radius without the tips hitting as much. With sharpening edgers and French edgers as you wear and sharpen the edge back the tips get longer and working them from the bottom will make the tips more pointed. I round over a lot of tips when I am done squaring up a French edger and then sharpening French edgers and edgers. You want some tip to serve as a guide but you don't need a bunch in front usually. Another tip - Test on scrap first. Hold the sharpened edger at the lowest angle you can and try to "feel the cut"- keep raising it until it cuts smoothly and then don't go higher. Higher angle and it still may cut but longer tips may raise the edge up and the blade wont engage as much and cut full width. The other thing with shorter tips is the edge can dig in and chatter and bounce. That will dull an edge a lot faster. When I have people test edgers at shows, i commonly see them try to push the edger at way too much angle. It surprises them how that edger they tell everyone is dull at 45 cuts like butter when I show them the sweet spot is 15 or 20 degrees. Think of it as micro-skiving. Bob Douglas used to say "You have to make friends with your tools".

-

When you say the best that opens it up some. I don't really know of any braiders that would say "best". It comes down to what you get used to and comfortable with. There are probably at least 10 different makers of string cutters if I thought hard enough here right now. Most braiders trade around string cutters some until they settle on one. Some like one better for rawhide and another for kangaroo or latigo and have a couple. First off you mention splitter function. Some of the cutters with built in splitters work OK and some don't without tweaking. The angle that the blade meets the string can vary by depth and that can make a difference. I will just throw this out - I don't have numbers to back this up, but my guess from shop visits and talking is that over half of the braiders I deal with have a dedicated splitter. Usually it is either a Chase pattern splitter or more commonly the tried and true Osborne #86 splitter. A few folks like the little old Tandy splitter that sold for around $100 for rawhide. String cutters - There are several makers. I have new ones from Wayne Jueschke with two bars for $500. I also have new ones from Y-knot Lace. The three way Y-Knot cuts string and can bevel 30 and 45 degrees for $230. I have the handheld lace splitter from Y-Knot that runs $230. They work differently but the Y-Knot cutter behaves more like a Hansen, the Jueschke is like the LaceMaster. I get used ones through here too. Like I said - braiders tend to trade these around. Haughts, Hansens, Neuberts, LaceMasters, Vaqueros, Budds, Joe Benner, Tim George, JSE, home mades have all been through at times. They never sit long. Here is a link to what I've got now - https://brucejohnsonleather.com/products/braiding-and-lacing-tools/lace-cutters

-

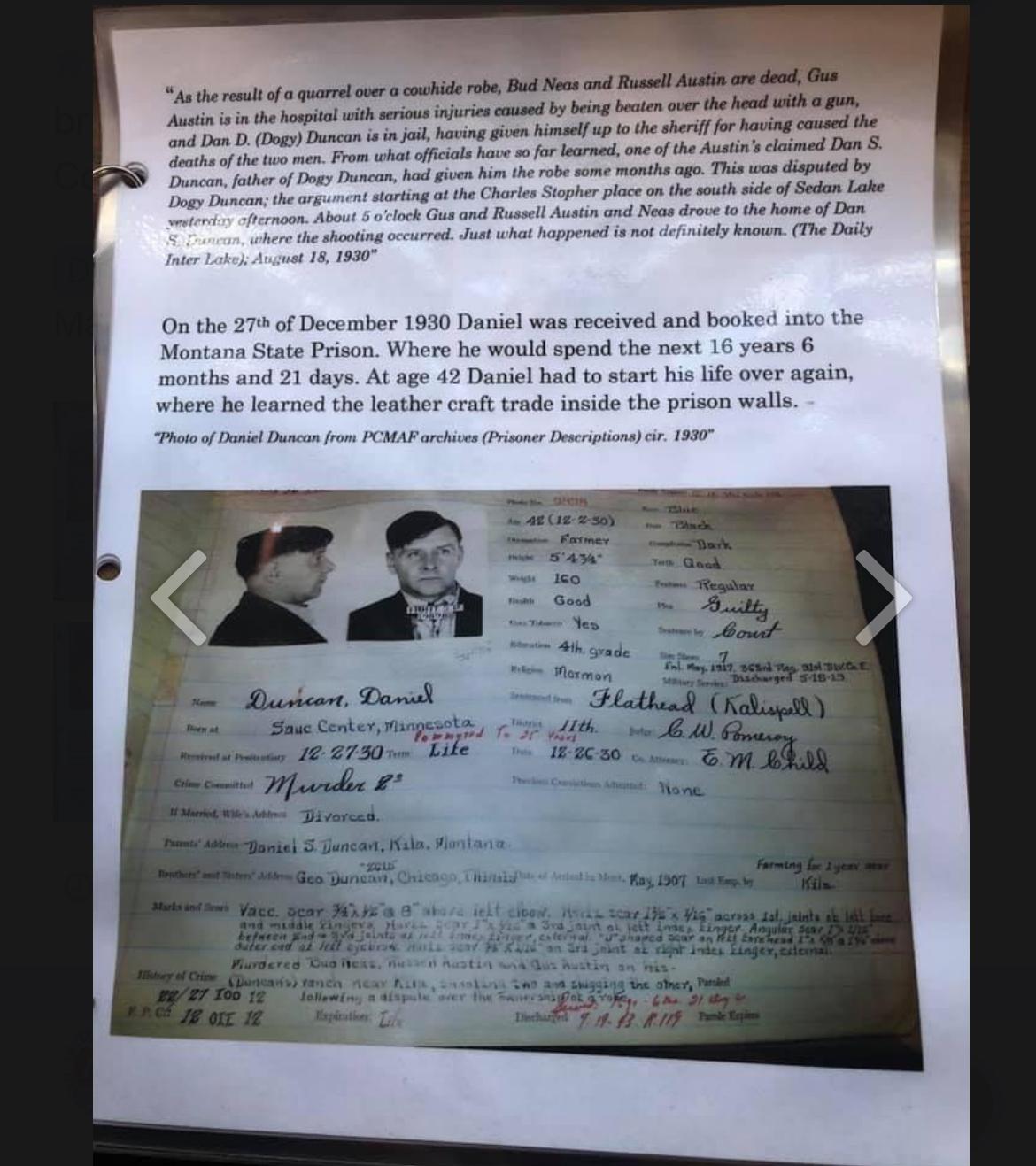

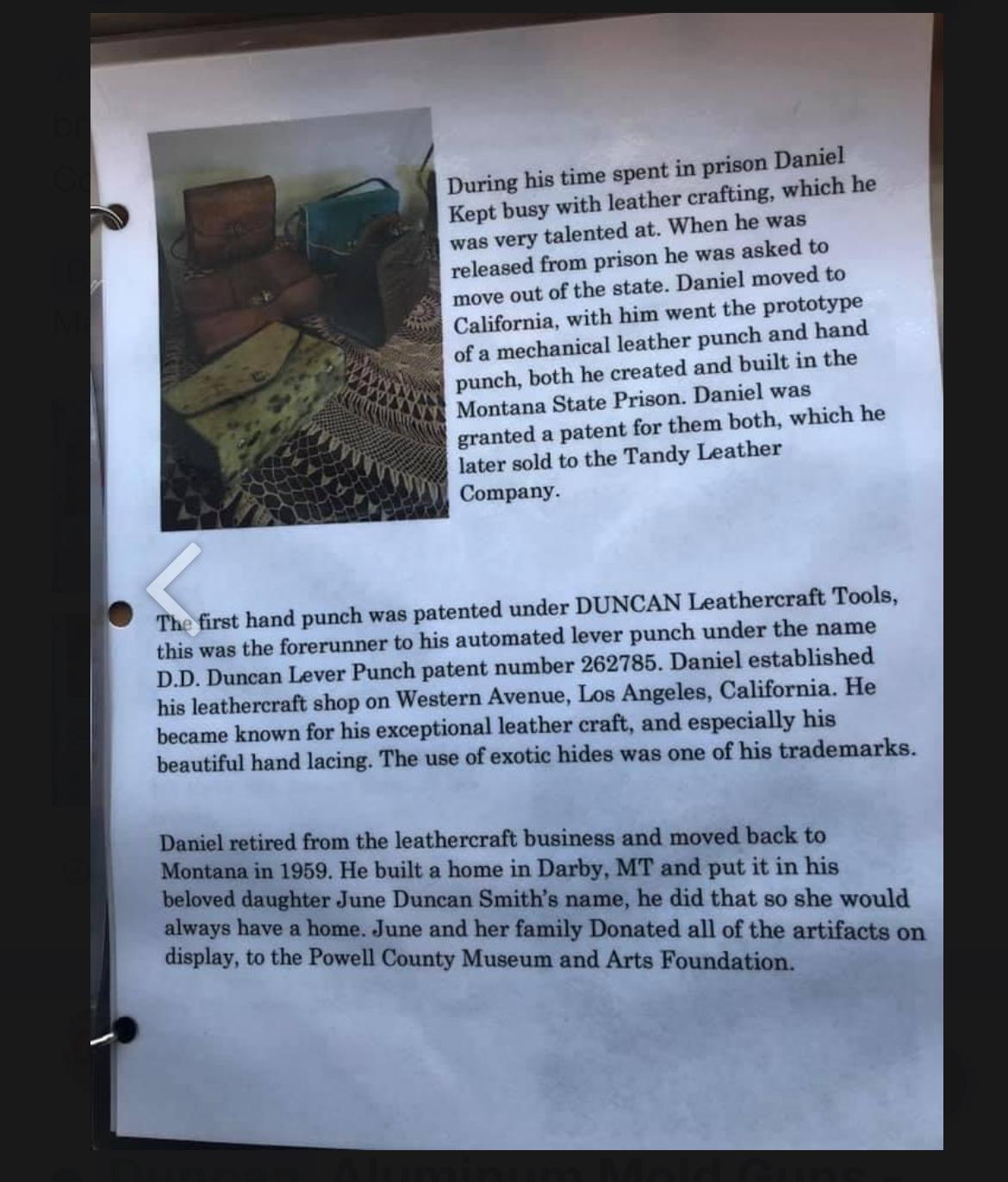

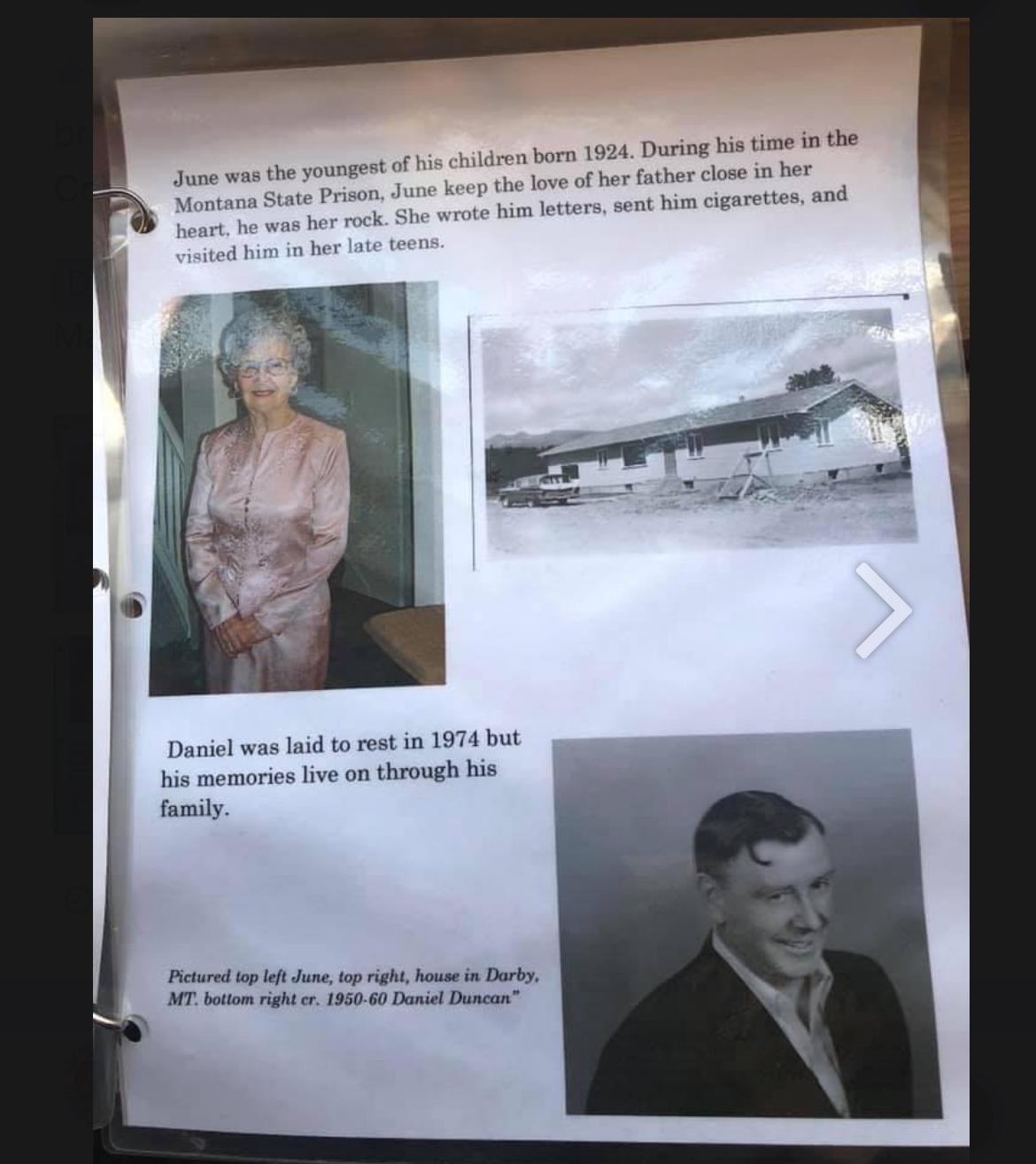

Thank you! There is always a story behind something. One thing I found interesting was on the intake sheet he was listed as a 4th grade education. Life sentence originally too. He did well. A friend told us we needed to go the prison there in Deer Lodge and then the craft shop. At the prison craft shop the makers price and describe their items themselves. Especially with the hitched horsehair you can see quality and skill differences. One belt jumped out at me, really clean tight work, excellent color transitions, and priced about $200 more than most others. He described the size, colors used, and his comment section was "27 years experience hitching hair". He had been there a while. Hope he got some good commissary with his proceeds from me. I bought a bag with 5 hitched key fobs. One had a pink heart hitched into the pattern. Tag said "Give the heart to a sweetheart, mine left me - why I'm here". How can you not buy that? I am not sure how other prisons operate. I know at one time in Colorado the inmates working in the Canon City leather shop produced stuff that went into interstate commerce and by federal law were paid minimum wage. Huge money for a prison job. The guy that used to run that program said almost zero disciplinary issues because the guys did not want to lost those jobs. One guy got out and buys from me for his own shop.

-

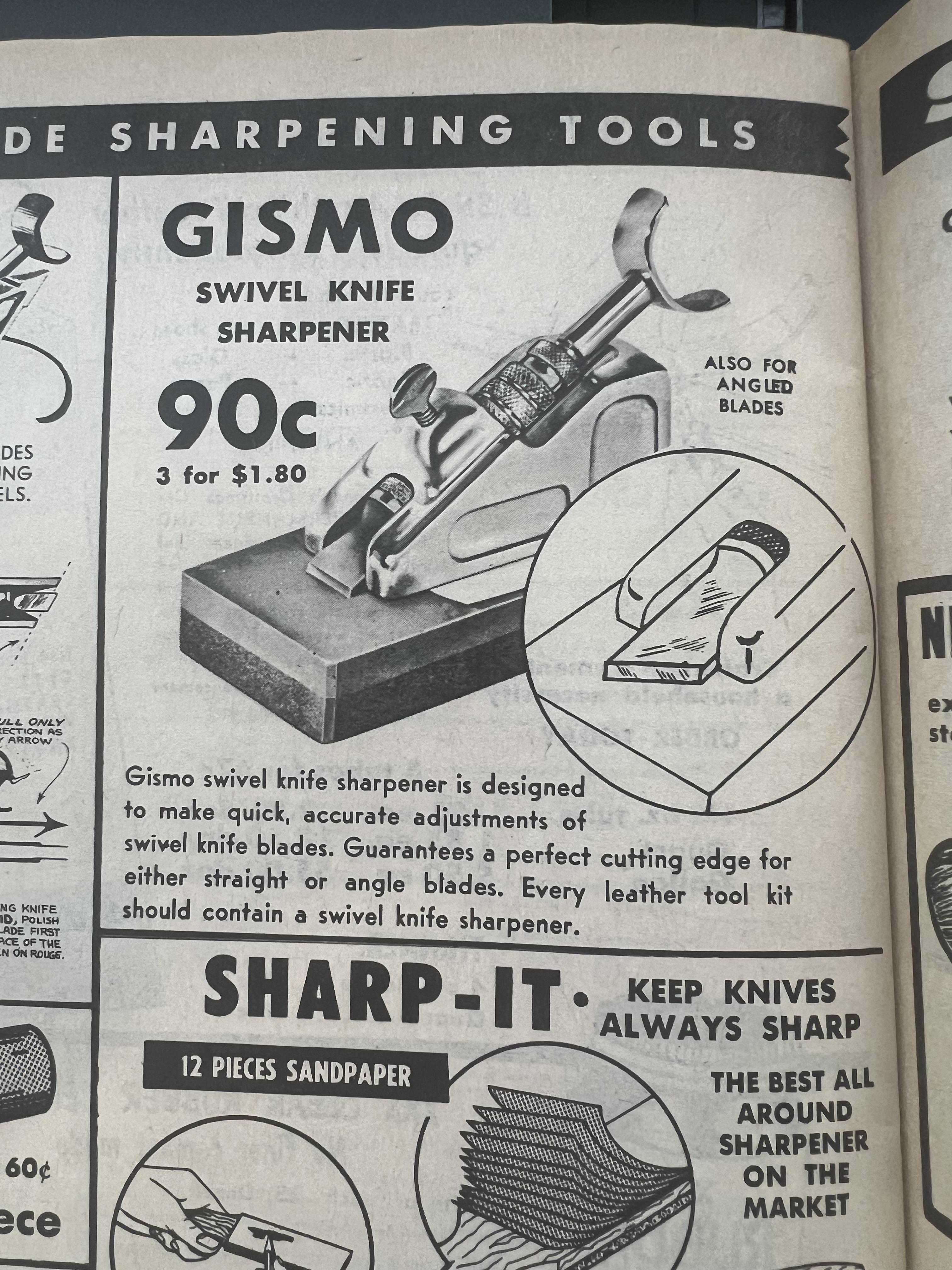

If you rotate the barrel so the width of the blade contacts the media evenly then a straight or angled blade will sharpen. That is the problem with illustrations, they skew things. The angled blade drawing shows that angled blade sitting in there parallel to the stone. Lay it in so the blade edge contacts the stone evenly and the blade edge will sitting at a bit of an angle but sharpen evenly. The old timer trick for this particular resharpener Is to loosen the set screw in the swivel knife barrel and let the blade rotate freely. A light finger pressure on the blade ensures the blade stays flat on the media. Then you just rotate the blade to the other side and leave the barrel alone. The angle of the barrel hasn't changed = even angles on both sides. I have some other sharpening fixtures for swivel knives that operate on a similar principle and even though some have a set screw, I never tighten them either. Finger pressure and push strokes only. One exception is the flat shank blades like Gomph-Hackbarth, those I would tighten.

-

Danny Duncan was mentioned in another thread about a swivel knife sharpener he patented. He also came up with a handheld lace punch and a punch machine called the “Lever Punch”. I learned a bit about Mr Duncan when we toured the old Montana State Prison in Deer Lodge. I’m just going to say if you find yourself in that area - well worth the visit. The prison has a large craft program and across the street is the craft shop where these folks can sell what they make. Part goes to a victims fund, part to maintaining the store, and the remainder to the inmate. Leatherwork, horsehair hitching, and more. I came across a display case of leather tools and this history on Danny Duncan. They had a few versions of the Lever Punch on display. Chuck Smith knew Danny when he was in Southern California and we had a good talk about him. There are several good leather workers trained in prison. Some still there. Texas has a good program and so does Colorado. Sometimes these guys have to go through a lot of steps to get tools they need and some are provided in the prison shop. I’ve got a lot of respect for these guys and the officers who run the programs and teach these guys.

-

-

Danny Duncan was the one who came up with this swivel knife sharpener. He also made a wooden handle lace punch. He patented the lever handle punch machine that punched lace and stitch holes. Tandy bought the rights to that and sold them 40 or more years ago. Chuck Smith had a version of it a few years ago called the Punch O Matic or something like that. Chuck knew Danny in his later years.

-

Sharpen 3/5 in 1 round end cutter blade.

bruce johnson replied to Kfd518's topic in How Do I Do That?

You already figured out the trick for doing the round blade in place. The touch up will be easy now with an ultra fine stone or diamond stick as needed. Depending on the machine you can use a tapered diamond round file and not remove the feed wheel if there is enough space. Just have somebody crank while you hold and eyeball the file and edge. The skiver blades are way easier. Most have a double bevel although a very few are single bevel. Jigs or angle guides designed for wide chisels on stones, paper, or machines will work for them.