-

Posts

5,806 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Constabulary

-

I'll get a new left toe foot but have to place a new order - thats okay for me considering the fairly low price of the feet. They for sure have something I could use. I also found some interesting cheap feet for the Adler 67, 167, 68, 168, 69, 169, 267 and so forth "line" in their store: https://de.aliexpress.com/item/1005008687919538.html nutin for me Singer Idjit but looks like a good deal for the Adler folks 😉

-

Here is a parts diagram of the Adler 20-20 - hope it helps Adler_Parts_class_20-20.pdf

-

I may have a hard copy of the 20-20 parts list, not sure though. I´ll check that in the days to come... stay tuned... 😉

-

They have arrived! Took 10 days from China to Germany and no extra charge. I´m using them on my 111G156. First glance.... The "fork" foot set works fine and line well with my feed dog - no issues. The right toe foot is touching the thread guide but the one I have installed is not the "original" one I have one from a 211 so that is on me. The left toe foot does not fit into the foot bar. The end that goes into the foot bar fork is a bit thicker than on the other feet It also has a different finish, the other feet fit well. Maybe I´ll do some grinding but I´ll check with the seller first. The scissors are sharp a hell. I ordered them for just having a pair in my tool box. REALLY SHARP!!!

-

Need reverse feed parts for Singer 211G156

Constabulary replied to Art Bailey's topic in Leather Sewing Machines

since you are in the USA I´d contact a sewing machine dealer in you area. I´d probably check with Toledo sewing machines https://www.tolindsewmach.com/parts.html They for sure can get you the parts you need or even have them in stock. -

Be as you are - why faking around on dates? No rules IMO. If it´s not working then its not working. Was not working at the 1st time, right? So do not put too many expectations into a date, let it happen and see where it ends. You never know (as you have experienced). Just don´t be rude and not excessive friendly.

-

here is a parts list that tell you what it originally was designed for. Its basically is a tailoring machine that is surely able to sew some garment leather. if it need parts google the part numbers or post pictures of your machine so we try to figure what could fit from other machines. Feet seem to be the type that is used on 107w, 143w, 457w and so forth (straight stitch). singer 150w104 parts list.pdf

-

machines can be set up for different needle systems by adjusting the needle bar height but I would start with the system that the manual states. when you have figured the system make a small sticker that reminds you of the needle system and stick it on the machine somewhere. beside that needle bars rise a little bit with the time so maybe it needs a little adjustment of the needle hook timing / adjusting the NB height (most likely lowering a tiny but).

-

Singer sewing machine identification

Constabulary replied to Rob3rt's topic in Leather Sewing Machines

Singer industrial machine serial numbers are always stamped into the machine body. "Chinese sellers" sometimes mix up TE-6 (left stand) and TF-6 (right stand). IMO you need parts of a TE-6. Here is a SEIKO TE-6 parts list, maybe it helps to figure more. PARTS_TE-Series.pdf -

Oddball sewing machine question

Constabulary replied to catboatguy's topic in Leather Sewing Machines

roller foot is not the same as walking took with a walking foot you can sew other thicknesses much easier. So it depends on your work. -

Just wondering what prices are shown to the folks in the US (due to tariffs and stuff). F.I. the double toe set is 11.19€ + 4.03€ shipping on my end - thats approx $17.77 I have ordered a complete double toe set, a single left toe foot and a complete right toe set for 36.98€ incl shipping and VAT - thats $43.18. (EDIT II) and a pair of scissors is included too: https://de.aliexpress.com/item/1005009076526433.html? Not sure If I got charged with other import fees but yet I have not paid anything on top when I ordered on AE. They seem to "re-pack" the orders when they arrive in the EU so my shipping labels so far had a EU sender on it (yet). EDIT: I think I posted these 153w / 227R / CW-8B needle plates earlier but I´m not sure: https://de.aliexpress.com/item/4000301291692.html I think I haven´t seen the "left sided plates" elsewhere.

-

Oddball sewing machine question

Constabulary replied to catboatguy's topic in Leather Sewing Machines

Bernina 217 is the smoothest ZZ machine I ever used. I owned one with a pattern cam. Super nice, super smooth. Looks like yours is an 8mm Zig zag - most ZZ machines (in general) have 4-5mm some have 6mm but 8mm is quite hard to find. Price depends on your local market. I think 500 for just the head is not really cheap but on the other hand 8mm ZZ is something you don´t find every day. Keep in mind that you sell it as a private person and not as a dealer who gives some kind of warranty. I think it would sell better when completely set up with table and servo motor. But if you need a ZZ machine then with the 217 and 8mm ZZ you pretty much have bought the "icing on the cake" machine alreday. If you have work for it - keep it! -

A lot of folks for sure have seen the "birth of a sewing machine" film from the Singer plant. https://www.youtube.com/watch?v=bIMxwy8CLkw Here is another one from the Rast & Gasser sewing machine plant in Austria. https://www.filmarchiv.at/de/filmarchiv-on/video/f_030ALPaJwVeL9AgoOj7NwW Turn off the sound, its annoying. 🤪

-

Singer sewing machine identification

Constabulary replied to Rob3rt's topic in Leather Sewing Machines

needle plate and feed dog are missing, not sure if the shuttle race and cover are complete but I´m almost certain that Singer 17 hooks would work IF the shuttle race is complete. So since you are from Hungary (former east block / soviet influenced) I would bet that it is a East German / GDR made Tetxima 17 or Köhler 17 (or maybe even a PODOLSK of some kind). But I only can guess. Best bet or parts - try Singer 17 parts or Seiko TE-6 parts. -

Singer sewing machine identification

Constabulary replied to Rob3rt's topic in Leather Sewing Machines

I don´t think it is a Singer only because it has Singer tag. If it is a Singer look for the serial number an post it here so we can try to figure more. Pfaff, Adler and Seiko made similar machines of this class. If it was a Singer it would be a Singer 17 but again I personally doubt it is Singer made machine. The stitch length lever look kinda Pfaff-ish - like from Pfaff 25 machines but not exactly the same.... I would almost say it is a Japanese made machine of some kind / brand. -

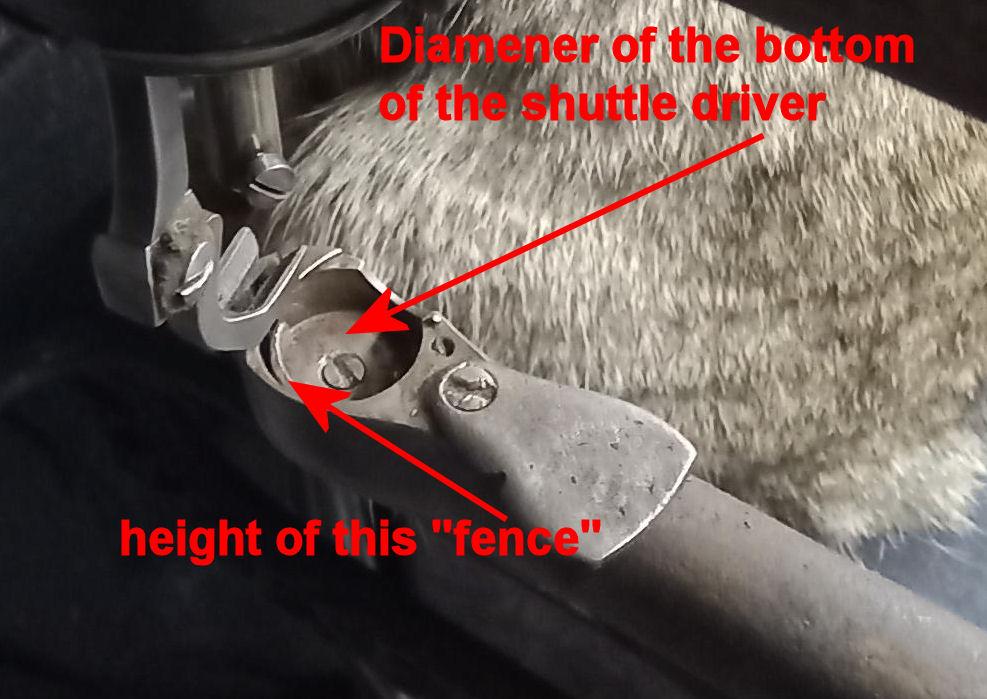

Definitely a clutch system. The machine it self is a jump foot machine. The jump foot system is similar to what you find on Adler 4 or Adler 5 machines (and later models).

-

true - as on most machines. Problem is IIRC that the shaft bearing (272142 I think) is inside the hand wheel or the casting and my buddy said the bearing is THAT tight on the shaft or inside the hand wheel / casting (glued or shrunk fit) that you cannot pull it of w/o damaging other parts. Maybe CowboyBob knows better 😉

-

I don´t think it is possible except you drill a hole in the shaft and cut a thread. but IIRC it is almost impossible to remove the hand wheel from a 211. I have a 212 and was not able to remove it. A friend tried to pull off the hand wheel on his 211 with a gear puller and bent some parts around the thread lever. However, maybe you can make a sleeve or spacer ring that goes over the "hub" on the hand wheel.