suzelle

Members-

Posts

490 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by suzelle

-

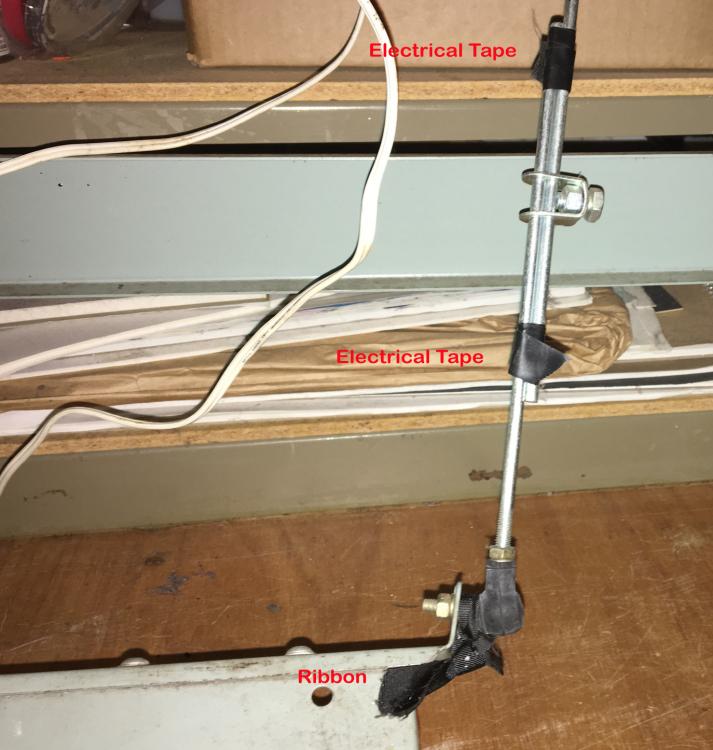

Previous Owner fixed a couple things. Trying to add more pics because I wanted to show the paper clip wrapped around the top of the rod that connect to the motor. Anyhow, I'm unable to post another photo, but use your imagination. I am sure this is part of the reason the machine had never really been used at all. I have Mickey Mouse to thank. So glad the head is in such great shape. Really just a few small adjustments all over the machine and it will be a great workhorse for standard sewing in the table. I'm thinking I will go ahead and use the clutch motor in the table, that makes sense. Later, when I get the table all set up (taking my time) I will work on making the machine portable too. It has the kind of hinges that allow you to just lift the machine right out of the table without any unscrewing or anything. Love that!

-

-

Airplaneguy, Great work on the machine! Looks really nice and very functional! Like the work on the shoe too! Thanks for sharing. Always warms my heart to see one of these old machines put to good use.

-

kgg, I have mostly bonded polyester thread myself, as my commercial sewing experience began with Sunbrella fabric, canopy covers, awnings, patio furniture, that type of thing, all for outdoor use. I'm going to be experimenting with nylon thread myself, as I'm moving into leather work too. I say experiment! get a couple small cones and see what you think of the bonded poly. With sunbrella fabric and the ideas you have for your dog collars (which may be outdoors quite a bit?) I say you probably will like using bonded poly thread. However, how long the threads can withstand the outdoors will also have to do with what part of the country the products you make are used in. In other words, do these Sunbrella dog collars and sch get exposed to the Arizona sun? For how long? All things to consider. Perhaps the items that you make are just for yourself and you will only have to think of the climate/temps in the area where you live, whatever that is, and how many hours a day the items will be outdoors in the hot sun. However, if you are making these items for others and sending them to different climates, I would consider going with a bonded poly for sure. Just my opinion. If your products would be subjected to extreme heat you may even want to consider kevlar thread - which is quite expensive. I have had Customers request it, then change their mind when they find out how much you have to add to your "Materials" fee. I have only had to use that a handfull of times and have just one cone of it, in black. LOL. By the way, Ferg recommended a great website (sailrite.com) for information on threads. Good luck!

-

Well it has been a year since I posted this question about the weight of the Singer 20U. I took my time shopping and really wanted an older 20U, made in Japan. Well, I got one! It was available in Seattle, via Craigslist. I already posted something about the machine but wanted to come back to this string and thank all those that responded to me! Thanks for answering all my questions! These older machines don't come up to often around here and the one I found is in pristine condition. I will use it for leather work too, Nothing heavy, just garment weights. I'm can sew heavier weight leathers on my Pfaff 545, so got that covered. My Commercial Embroidery machines are capable of sewing through leather too, which I've been doing for about 12 years now. I do a lot of bulk heads and auto interiors for other businesses. They hire me to design and embroider their panels before they install the interiors. I also design and have sewn many aircraft covers. I don't do much of this for myself, it is my work so usually done for others, or done Commercially. I'm taking my time setting it up the Singer 20U. I'll be using it mostly at home I think for my own creative projects. I want to be able to easily lift it out of the table and put it in a portable carrier to use on a job or at the shop where my other machines are. I'm thinking of cutting the Original table back to about 38" and putting a piano hinge on it so I can use the full length of the table now and then for bigger items. I've got an older Industrial table too (with the H legs) and I want to add wheels to it and use it under the Singer 20U. That way, I should be able to store it inside our home, and roll it out of the way easier. Thanks for all your thoughts and ideas, I've really enjoyed reading this forum and although I've been sewing for many years, I think I learn something new each time I visit here. This is a great forum! Thank you all!

-

Not any inadequacies really, I keep them oiled regularly. A commercial embroidery machine mechanic recommended it.

- 28 replies

-

- grease

- industrial sewing machine

-

(and 1 more)

Tagged with:

-

Just a thought: Have you removed the feed dogs and cleaned around that area with the part(s) removed?

-

Guitar Strap For a Big Guy- Advice Needed

suzelle replied to Firewalker's topic in How Do I Do That?

Nice job! I would like to make a guitar strap too. Loved seeing the result. Thank you! -

Great to know Eric! Although I have a 1 lb. can of grease that came with every commercial embroidery machine we own (LOL) I always feel weird smearing that stuff all over the gears because I know how get dark and gunky it is going to get. I always clean up previous grease before applying new, but that is a messy job! Have thought of getting some TriFlow, now I think I will. Great discussion here everyone! I think I'll donate all that grease! One thing I started doing a couple years back with my sewing machine oil is adding Marvel Mystery Oil to it. Mix is 50 Marvel/50 Lily white. The Marvel Mystery Oil is reddish in color, so mixed in with the Lily oil, it appears orange. Smells good, I like that! What I really like though, is that it seems to keep my machines running smoother and cleaner. I've thought of using it on the gears too, think I'll go ahead and do that now since there were a few comments about those who just oil the gears.

- 28 replies

-

- grease

- industrial sewing machine

-

(and 1 more)

Tagged with:

-

P.S. Gregg - I mean to say good eye! You caught that - 2nd photo included shot of back of the machine with "made in Japan" That is why the 2nd photo was included. Other wise, who cares? When you have a chance Gregg, let me know if you have parts for these 20U machines. I'm going to make her portable. Looking for parts that are missing. I think previous owner moved parts off for another machine, either that or it just never had them in original table set-up? The motor is old (Arrow brand) but looks unused like the machine. I do have a nice portable motor I bought a few years back that is heavier than a standard household motor, I think 1/4 hp or something like that. Going to mount that to the motor boss, or back, we'll see. Also, need a decent box to put her in. Something like what Sailrite has on their website. I don't want plastic. If you have things, let me know please. Or if you have used parts from the old machines I'd be interested in that too. Thanks!

-

Crackle Coating Singer 111G156, 107W1...

suzelle replied to Constabulary's topic in Leather Sewing Machines

Okay Evo, thank you! That is all that I found, but online. Thought I might walk in to a Harley store and see what they have. I will post if I find the stores stock anything. I might just go back to the hammered paint idea & reserve the texture for another paint project. I tend to like my sewing machines to be lighter colors lately, as it is easier on my eyeballs these days. LOL. -

You should be proud, your work is Lovely.

-

Crackle Coating Singer 111G156, 107W1...

suzelle replied to Constabulary's topic in Leather Sewing Machines

Evo, I really like the "Texture" paint. Nice! Years ago, I bought a couple of those flat black, or textured paint machines. Lately though, my brain has been entertaining playing with a "hammered" finish paint. I want to re-paint another of my old Singer machines. This one is a blue-gray singer 188K. She might look cool with a textured paint too though, do you know if the paint you mentioned comes in other colors? -

Greg, Thanks very much! Yes, I have wanted one of these Singers for some time. The advantages for me are: I can mount it in a portable case and take it on jobs with me when my projects call for any work on the spot. I may not be able to use the heaviest of my threads (v92) in that situation, but I can with confidence use a Bonded Poly v69 thread for my proto-type aircraft covers, knowing it won't damage my machine. The v69 thread is strong enough to hold my fabrics together and to get approval on the fitting, but this is not the thread I would use in the final product, nor would the Singer 20U be the sewing machine I'd use for the final product. It's at least an answer to travelling equipped, and getting a good fitting initial pattern. Another advantage: This machine was manufactured in Japan, and although it's an older machine, it is like new. After fully inspecting it, I've found that it just hadn't been run, hadn't been oiled or greased either. These older Japan made machines seam to be very dependable. Again, parts are plentiful and affordable! Oh, and this type of machine is still being manufactured today, under various names. I think my $350 investment was a smart one. In fact, I know it was! Money well spent. In my experience, it has been a challenge finding a versatile machine I can use on a job or at the shop, one that is portable and takes the industrial needles and threads I commonly use. When travelling to a job, it just makes sense to have a machine with me so I can make the best use of my time and travel. One thing I won't do again is ship a machine to a job, have had some damage in shipping. I have also purchased machine(s) when having to travel to another State and that's not fun either, never know what you will end up with when you get there. So these days, I don't go too far. A day trip, maybe a weekend, and I can pack my Singer 20U with me! I am sure the Singer 20U will handle much of my smaller stuff, upholstery work and most uniform work with ease, it won't even sneaze! I have 6,12, and 15 needle embroidery machines and make large, pretty densely embroidered jacket back patches that are sewn onto garments, I think this machine will handle that task with ease as well. I won't have to tie up my Pfaff 545, which I keep set up to sew over the street banners. It's not the thickest thread available, but I use Bonded Poly v92 on this machine and I don't like to fuss with it since it needs to be ready to run banners immediately after running them on our HP Latex Printer. My banners can go up to 60" wide and any length, so no screwing around here! LOL. I keep that area set up with extension tables needed to sew long banners, and use these tables for some of my portable machines and sergers when I NOT on a banner job. I also use these tables to spread out/sort paper work and pack orders. this is the most efficient use of that area in the shop. Above a section of the tables that are against a wall, I keep the portable machines. They are ready to pull down and use for whatever orders I've got. Also, assortment of threads, needles, velcros, banner making supplies, etc... The Singer 20U takes industrial needles, you can even set it up as a "twin" needle (I just learned) which can be helpful with a double-stitch look. I'm sure not a true double stitch as it's not a double bobbin machibne, but it's somethi'n! It has pretty good reviews for it's wide zig zag stitch and people do comment on the lovely Satin Stitch, beautiful straight stitch. I know it's got more oomph than a domestic/household machine. I'd call that Glorious! I mean Glorified! Since I really put my sewing machines through the paces, it's a great plan to have a couple of Home/Domestic machines in my shop too! After all, we make and fix garments too! I think that the making of a fine garment is the most intricate work I do. I feel that every machine is a tool and like a set of socket wrenches, it's good to have them in various sizes. After 32 years in business, I've gathered up a few of these tools! Love them, have never lost my excitement over getting a new one. Correction: New/Old one!

-

DrmCa, Machine is not an "upgrade" for me, actually it fills a gap in my herd. I have what you called a "full blown industrial" lol. So don't worry 'bout me, k? Oh, and thanks for the encouragement.

-

Constabulary, This is very much important, and much appreciated information! Thank you. Then gentleman I purchased the machine from said he had (3) machines and I bet they were all the same machine style, but saw just this one. He had a business (garment repair and construction) and had employees, then when through some hard times and had to sell machine(s) to afford a move. When I asked him about parts, he would go back into his home and fish out what I'd asked for: a bobbin to test machine, a needle plate, thread, lol. I realized he was trying to hang on to whatever he could, probably for his other machines(s). So the machine is in excellent condition, but she does need a few things. One of the reasons for purchasing this machine is that I have about 400 various sized needles in packets of 50 each that will all fit this machine. I got them along with a Consew 217 machine I purchased a few years back. I sold the machine though, because the hook broke, and I'd only paid about $200 for it, but the replacement hook was going to cost far more than the machine at the time. I think hook prices have come down on those since then, because those machines are being manufactured again now, under a different name (Global???) in Germany (???). I priced out new ones about a year ago. Wished I'd hung onto the 217. Oh well, I live and learn. Learning is fun. Thanks again for the help! I am not selling this Singer, parts are cheap and plentiful. I have loads of bobbins, needles, and feet already that fit it. Thread too, mostly v69 in many colors. Great for uniform repair, which I seem to do a lot of. I have a lot of v92 thread too, I use poly in both these sizes, bonded. I'm pretty sure this Singer can handle the v92 thread, as long as I don't use it all the time? Please feel free to comment on those ideas, I want to learn. Matt at Sailrite posted something a while ago on his forum that you can use v92 thread on the Singer 20U, as long as you have the correct foot, needle plate, and feed dog. He recommended the zig zag set for the v92 thread.

-

Dikman, THANKS! Yes, except for a couple nicks and dings, it's in pretty new condition although manufactured years ago. maybe 1980s??? Not sure yet what year, but that will be fun to find out.

-

Crackle Coating Singer 111G156, 107W1...

suzelle replied to Constabulary's topic in Leather Sewing Machines

Love that Godzilla! -

Yep, you guessed it! Another Singer! Picked her up in Seattle today, Seller had it listed on Craigslist for $400, and it looked pretty good in the photos. I didn't see that it came with extra feet, straight stitching plate and feed dogs, or any tools, so I offered $350. I could see everything was turning, so it wasn't jammed up in anyway. However, something was goofy with the feed dogs and they were not moving the fabric. Figured if everything else was moving, I could fix that! Got back to the shop and put the Singer up on the table to inspect and found that all it needed was a couple of adjustments and screwing down the feed dogs! Now she sews! Been wanting one of these pretty bad, I'm going to be testing this machine with some lighter weight leather projects, sewing up some western garments for Grand-Daughter Emma, at last! Emma rides horses (thus the leather garments) and I am spending time with her teaching her to design her own clothing. She's very creative and it's a really fun time for me too! I cannot think of a better machine for her to learn on. However, I think I'm going to get another motor so she can start out slow. Emma likes to ride horses, but I don't think she's ready for the Horsepower this thing puts out. LOL

-

Look, a hat for your machine!

-

Great Question here on the weight of the thread, and good to know (Thanks Wizcrafts) that these machines may possibly be able to sew 138 thread! I had one some time back, but ended up just getting it running, then sold it. I didn't think the one I had was capable of sewing heavier than v69 thread and that wasn't really adequate for my needs. I'm wondering if anyone can advise on what serial numbers to look for when you are searching for the one that can sew the heavier weight 138 thread. I think I may have to look for one again! Thank you! Oh - Jaybogg... good luck on your search. I'm not ready to buy one of these just yet, but would point you in the right direction if I did find one. I think I'm about another 1-2 years out before I can fit another machine in my work space.

-

Great news! Thank you for sharing.

- 4 replies

-

- pfaff 145

- servo motor

-

(and 1 more)

Tagged with:

-

Yes, Congrats! Looks like a hefty machine. That handwheel is huge!

-

Pfaff 545 industrial sewing machine overview and video

suzelle replied to gavingear's topic in Leather Sewing Machines

Bob, I'm ready for that motor now! I will be giving you a call!