suzelle

Members-

Posts

490 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by suzelle

-

Fraying/breaking top thread on 111-155

suzelle replied to blue duck's topic in Leather Sewing Machines

Kathi, looking at your pics and reading again what you had written... I have a couple questions. 1- When did you send the machine to get the hook replaced. Was it years ago or recent enough that they will help you? What brand hook did they put in the macine? Is there a part number for it? Asking because I personally would want to know if the hook was one that is of a higher quality? Is it HEROSI (?) Is it another High quality brand? If it's not a high quality hook, exactly what is it? Did the Company who replaced it put that information on your Invoice for reference? 2- Are there any other parts that were replaced during the repair(s) and if so, what are the part numbers for those? 3- What bobbins do you have in it? Are you using one that is made for that hook? In other words, does it fit perfectly in the bobbin case? Is the bobbin thread stitching with no problems? If problems, what is happening to the bottom thread now? -

Fraying/breaking top thread on 111-155

suzelle replied to blue duck's topic in Leather Sewing Machines

Good Morning Kathi (Blue Duck) I hope you are making some progress with your machine. Just checking on you. I'm wondering if you have cleaned everything in that bobbin area. Try to remove all the dust, lint, stray threads. Then oil what needs oiling. Might help the parts to function better? If you can remove that bobbin case you may find some dried oil and some stray threads underneath. I'm not a mechanic, but it's always the first thing I will do, before anything else. -

Adding my Thanks to the moderators! Love this place.

-

Oh Yes, MORE CHOCOLATE please! Hang in there, feeling your pain. Still dealing with regrouping after having to move out of my shop that was on a main street in the middle of town, open to the public. I'm transitioning still, working from home and also at a friend's (Customer's) shop. Hang in there! Stock up on Chocolate!!!!!!!!

-

Pfaff 545 bobbin case opener jams the catch hook

suzelle replied to John D's topic in Leather Sewing Machines

Uwe helped me with finding correct part # - thanks Uwe! It got ordered! The part number is 91-000699-15 -

Maint1517, At last, remembering to post a pic of my newest old sewing machine. LOL. Consew 255RB - I didn't pay much for the machine and working with it now, trying to get it to work perfect! The saga continues. How's it going with your machine? What's the thickest thread you were able to successfully sew with it? Also, is the stitch length acceptable to you? I mentioned higher up in the thread that I'd used a Pfaff machine similar to the one you purchased. The machine belonged to my friend and it was a Pfaff 332 Zig zag. It was about the same era as the one you have, just with zig zag and free arm. I really liked the consistency of the stitch, that was a solid machine and the reason we used it was for the zig zag feature when needed. However, the max length of the stitch was a bit short for straight stitching. So we never used it that purpose (canopy covers). We did all the straight stitching on the Industrial machines which were Juki machines and Consew 206 (?). Anyhow, the little Pfaff free arm made me a Pfaff lover. What I remember this friend using to stitch with was #92 poly bonded thread in the top and it worked just fine. I can't say if it could have sewn any thicker thread than that though, as #92 was the only thread size in her shop. I liked the stitch on that old Pfaff so much that I later purchased my own Pfaff zig zag, but the one I got was Pfaff 138-6. They are hard to find, but nice machines. It was able to do a much longer stitch than the domestic Pfaff when straight stitching and bed size was a standard Industrial size. I got the machine at a real bargain, put a little time and very little money into it and got it stitching perfect. Then I sold it for double what I spent. I was later sorry I sold it because I loved it so much. So, I bought another Pfaff 138-6 last year. I paid 3x the price for that one (!) and it is now set up to sew #69 to #92 thread, that one will be with me hopefully forever. Love it! If you are a Pfaff lover, thought I would share. I also have a Pfaf 545-H4. That one is capable of a thicker thread (so I am told) and it's just a straight stitcher. I have always used #92 thread in this machine and initial setup of the machine was with this thread weight in mind. Recently, I've been trying to sew with #138 thread on top and the machine had some fits! A part was damaged (only $10 part) but the real expense of that mistake is now she needs a complete tune up! I figured she is due for that and plan to have her set up to sew the #138 thread now that I'm doing more Auto Upholstery work. Previously I'd been using the machine mostly for very long vinyl banners and various other jobs. The lift is pretty high, I love it for lots of layers of upholstery fabrics and vinyls. Some of the little screws and things can sometimes be a challenge to find. But worth it to me if I can keep them running! It's been a good stitching and faithful machine for nearly 10 years now, I think. No special attention, just oil and regular use and she's happy! Hope that helps a little.

-

Yes! I do the same. I saw my own Mom do that too. My daughter did it twice! I have felt my finger begin to go under the foot a few times and pulled it out just in time. Once I bruised my finger pretty good, but didn't get the needle! No thanks! I don't like those kind of needles! Yuck and Owie! I was reading another post on this forum about needles popping off and hitting your face and the need to wear safety glasses or some kind of glasses when you are using the heavier needles. Not a bad idea! I must confess there as well, my own glasses have saved my eyeballs a few times!

-

JUKI 563 thread snagging on bobbin case

suzelle replied to matcanada's topic in Leather Sewing Machines

So much great information in this thread! I know it's an older post but much appreciated! I'm going to use all of it to try and fix same issues I'm having with my own machine. Mine is a different machine than the one here, but issues are same. -

Pfaff 545 bobbin case opener jams the catch hook

suzelle replied to John D's topic in Leather Sewing Machines

Thanks John for posting this diagram! Does anyone have a part number for the screw shown in above diagram pleasee? It's Marked "2" in diagram. Thank you! -

Fraying/breaking top thread on 111-155

suzelle replied to blue duck's topic in Leather Sewing Machines

blue duck, Oh good, I'm glad you at least have the instructions and can go over them. I was looking for a manual. But I think I have enough info now printed out from different places online. I have a manual given to me by the Seller, which is the poor copy I started with. Yikes! LOL. -

Fraying/breaking top thread on 111-155

suzelle replied to blue duck's topic in Leather Sewing Machines

blue duck, Do you have a manual that clearly shows how to thread the top and bottom? I know this is frustratiing, I'm dealing with some shredding issues on a machine now too. Trying to read everything I can and finding some poorly illustrated instructions on an old machine that is new to me. -

Oh yuck! Your poor Mom! I think these old Pfaff domestics are nice machines. I did sew on one ocasionally when a friend had one at her shop. I thought it was a sturdy little machine and the stitches were very consistent, even through about 4 layers canvas and sunbrella fabrics.

-

Consew 206-RB4 oiling mechanism and sewing speed?

suzelle replied to sojourner999's topic in Leather Sewing Machines

sojourner, I just found that site too, https://www.diamondneedle.com/ I'm going to place an order too, was excited that it appears they have lots of Pfaff parts too! -

Speed Reducer Mount made from Clutch Motor Mount

suzelle replied to Constabulary's topic in Leather Sewing Machines

Creative thinking! -

Big Barb - The Consew! (255 RB2 - I think!)

suzelle replied to suzelle's topic in Leather Sewing Machines

Hi Sark, Thanks so much for your thoughts! I no longer care too much for clutch motors, although my Pfaff ran just fine on the one that came with the machine. I had sewn on a lot of clutch motor machines when I used to make aircraft covers. We did sew long stretches of fabric, wing covers, engine covers, entire canopy covers, and smaller parts too like intake and outake plugs. Not just one cover at a time, but many of the same pattern. Those machines were a pain in the butt though, when we did the smaller pieces. I used to wish I had a servo on my own machines at home and got one. It was one of the earlier models and I don't think I got even a year out of it. So I stayed away from them for a while. I hear they are much improved over the earlier models and certainly plan to use them again. For now though, using what I have to make some $, then will invest in the clutch motor. That 3450 RPM motor that came with my $400 Consew 255 - it went straight to the dumpster. Not trying to sell, I couldn't even give the thing away! LOL. A controllable clutch motor I feel is a useful thing, if I can put it on a machine and sew with no issues, and I didn't have to pay extra to get it. But if I have to buy new motors, they will be the new Servo motors and I'll be buying one in a few weeks or months for sure. I have dumped a few bucks into parts (screws, feet, other little things that add up) for both my Pfaff and the new to me Consew. I do have a question about parts... I have bought parts from Ebay and have also gotten them from Certified Dealers of the machine brands I have. I am wondering if I should focus on parts being sold by certain manufacturers that may be of higher quality than others? Some say OEM, some say they are aftermarket. Some don't say what they are. Do you or anyone reading this see a difference in quality? Just curious. I have in the past bought an after market Hook (entire assembly) for an old Singer 31-15 that had parts that flat out would not fit. I ended up being able to use some of the parts from that assembly but had to keep some of the parts with it that were OEM and on the machine already. It worked out, but I was disapointed that all the parts of the assembly didn't fit. Couldn't return it as a whole because I'd used some of the parts. Even still, I got the job done and got the machine running very well. It was kiind of an easy machine to fix, not complicated. As I am buying parts for my old Consew, I'm just wanting to get the highest quality I can find. Thankfully, Consew is still making this machine. So I am hopeful I can find most of the parts from them. Pfaff machine, can't find every part, but so far I've been lucky to get what I really needed and have taken some parts off another machine or two. Although I've done very little Auto Upholstery work and some Aircraft interior work (like Auto Upholstery but FAA approved materials), I have much more to learn. Always learning and I'd consider myself really more of a beginner in this field. I have a lot more experience with furniture upholstery which can be done with a domestic machine or semi-industrial machine. I appreciate all your comments (advice) and will go back and read again when I'm changing out the small parts and the motors on these machines. Thank you Thank you! -

Woehlk, that's a fine lady indeed. Just stopping to say congrats!!! I like everything about her. The old needle envelopes are cool with the vintage Pfaff logo! Can you find a serial number anywhere?

-

Big Barb - The Consew! (255 RB2 - I think!)

suzelle replied to suzelle's topic in Leather Sewing Machines

Okay Wiz, THANKs again!!! I will go and find one of those anti-backlash springs I put away! LOL. I'm already threading the bobbin case the way you suggested, so hopefully backlash spring will help. Yeah, I figured yours probably didn't have the self-oiling. It's not that hard to oil them. My industrial embroidery machines have oil reservoirs too, but I still have to regularly oil many points on the machines, and grease a few gears once in a while. Just part of regular maintenance. My Sewing Machine Man told me to just use a nail or something in as an oil gauge, works the same. No biggie. Have a great rest of the weekend Wiz! -

Big Barb - The Consew! (255 RB2 - I think!)

suzelle replied to suzelle's topic in Leather Sewing Machines

Yes Wiz, you may call me Suz! My Sis does. Notice I shortened your name up as well. Thank you for sharing your trick, I have to say it makes me feel better as I have found myself doing exactly as you suggested. I noticed that my luck is a bit better when I hand walk (or try to sew slowly which wasn't possible with the 3450 motor) the first couple stitches, carefully holding the tail, and did notice the difference of the top thread tugging different than the bottom thread. I think with my Pfaff machine, I hold both threads pretty evenly and as long as I am holding them, not too many issues. I appreciate knowing it's a common thing with these machines. So thank you! Great tip. FYI - Yes my machine does have a safety clutch and I learned how to use it. It's like my Pfaff 545 when you get a jam, but different method of resetting. The problem I caused, I believe, is that I had loosened the screw to the presser bar lifter. I think that should probably have been left alone. That may be what the timing issue is. I reset it best I could. The Sewing Machine Repairman told me it was not very much out of time, but he adjusted it all anyhow. It was stitching pretty good when I brought it to him, but occasional looping, not looping with every stitch. But I can't have any loops, especially when I am top stitching every inch (24 rows) down each seat panel. Bench seat has a total of 48 rows on bottom cushion and 48 rows on the back cushion. Yikes! With all that said, I only had to remake one panel. Yes, you are right, that is exactly how the thread got so jammed up and the timing went wacko. I had to pull out stuck thread and had to take out the gib and the whole bobbin case. I really should have left the But I also assumed it could have been the bobbin spinning in the bobbin case with herky jerky movement of the crazy 3450 RPM motor. This machine also hadn't been run since at least 2017, so she needed lots of love and oil. I think timing was probably good til I got ahold of it. LOL. I'm learning how to operate this one and it has been very humbling. I whipped through a couple of projects on the machines at the shop and on my Pfaff, but Pfaff did need to see the Sewing Machine Man too, I knew it was just a matter of time. I was doing so well getting things done, then had some major down time with both machines needing adjustment. Wiz, do you think it would be smart to have a bobbin tension spring ready just incase I need it? I found one that looks pretty good, it's a star shape that sits at bottom of bobbin case I believe. I think I like the design of it better than the standard ones I have seen. I generally don't like them, but it may be wise to pay attention to that too? Let me know your thoughts. Also, do you have an oil check gauge in your Singer 211G156? I see it listed on your '"Current Crop of Machines" list. I looked up your machine and it does look very much like mine. These are nice machines with a beautiful stitch. I'm not sorry at all I bought Big Barb. We're just going to have to get better acquainted. -

Big Barb - The Consew! (255 RB2 - I think!)

suzelle replied to suzelle's topic in Leather Sewing Machines

Thanks again Wiz! Okay, I'll find out just what I can do with her when Monday rolls around. I did sew with the machine last week and made a couple bench seat covers. The bobbin area got jammed up and I had to totally disasemble and put back together. I lost a gib screw, ordered a few extras and magnetic screwdriver after that. I didn't get it put back together exactly right, but close. I think the timing was thrown off just enough that I decided she was going to get a full tune up by a Pro. Not me! I spent my day yesterday (it was a fun day) taking a Ferry to the Sewing Machine Repair Man. I left machine with him a few hours and he had it all tuned up, good as new. Looking forward to really putting Big Barb to use next week. Crossing my fingers she will run flawlessly and earn some money! I just know the fast motor wasn't helping either, glad there is a slower motor on the machine now!! -

Big Barb - The Consew! (255 RB2 - I think!)

suzelle replied to suzelle's topic in Leather Sewing Machines

Okay Wiz, thank you so much! Will stick with the G refillables if I order again then. Much appreciated! -

Big Barb - The Consew! (255 RB2 - I think!)

suzelle replied to suzelle's topic in Leather Sewing Machines

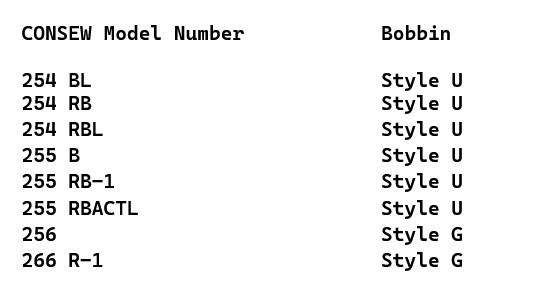

https://www.thethreadexchange.com/miva/merchant.mvc?Screen=CTGY&Category_Code=sewing-machine-bobbin-style-info I hope it is okay to post the link above. Let me know if it's not. I order thread from this place and have always found their list of bobbin sizes that correpond to each machine model very helpful. I get my cones of thread here usually, they've had most of the stuff I have used so far. I haven't oredered the pre-wound bobbins from them, but refer to this chart when I am looking for machines. I went back to it today just to verify if my "Big Barb" is a 255RB machine, since she's missing her original badge. If the machine's bobbin case didn't get altered and I can verfiy what model a machine is, that can make it much easier to find other parts too, which I'm doing now. Hope it helps somebody else. -

Multi-functional - Yes! I try to do the most with what I got. LOL. Let's not call that cheap kgg. That's just smart.

-

Big Barb - The Consew! (255 RB2 - I think!)

suzelle replied to suzelle's topic in Leather Sewing Machines

Yesterday I took the advice of Dikman and Constabulary and changed my motor out. However, I did not replace it with a Servo, I'm really fine with clutch motor that runs at a reasonable speed. It's what I have on hand and I need to get this machine running quickly so I can work and make some money now with it. I removed the Consew machine's 3450 RPM motor by removing the sewing machine head and tilting the table with motor back so the motor was laying against the floor. Using a couple of pieces of wood, I was able to prop the motor and the side of the table up as needed to remove (3) support bolts and the control switch from the table. Then I did the same with the 1700 RPM motor on my Pfaff 545 machine. I then installed the 1700 motor and adjusted all the bolts and screws, belt, and foot pedal to fit. The Consew is now set to sew at a speed I'm used to. This motor is a little louder than the other one, but I can easily tell when I need to switch it off. I should probably do some maintenance on the motor and it will run a little quieter. There is a good youtube video on how to do that - Alexander Dier I think. The 3450 is getting a proper sendoff - to the dump! I tried to give it away but nobody wanted it. Today, Big Barb is headed off to visit my Old Sewing Machine Repair Man. He's going to give her a good checkup. I figure why not spend a little and have a Pro look her over and make the right adjustments. Then I'll just maintain the machine. He will do the usual tune up stuff and I asked him if he could replace all the tension springs and check springs too, along with any stripped or missing screws. Well worth it to have him look things over! Oh, forgot to mention... I am going to order a Servo, but it's going on the Pfaff 545 that I have at my home shop. The Consew is getting set up at my friend's shop and I will use it there. -

Daman, I think you could easily sell that machine if you decided not to try and convert it to a straight stitcher (great ideas others posted here). Looking at the foot, I'd say that is a spoon foot for embroidery. Or spoon glider. I once bought a very old Singer (241-12_ that had one of those feet on it. The machine used to be a regular straight stitcher, but the feed dogs had been dropped or removed and put on a longarm frame for quilting. It was heavy, but it worked for the purpose. It was my first real Industrial machine. It was not pretty but it was a Singer and I do love Singers! Anyhow, I bring this up not because I think your machine could be used in that way, but because I think it might make a good machine for an Artist who made wall hangings. The Artist could just sit down in front of it and move the work around in any direction to create designs. You could use it with hooped fabric, or create a flat table for it and push an unhooped piece of fabric around on the table. If you knew you could use various weights of decorative threads and such, it could possibly be a good machine for that type of work. Maybe make an example of something like that to show a potential Buyer/Artist who might buy your machine. There are many lovers of the old Singers out there who would find a way to use it and display it, simply because it is a beautiful piece of Sewing History! Wish I had room for it myself!

-

Big Barb - The Consew! (255 RB2 - I think!)

suzelle replied to suzelle's topic in Leather Sewing Machines

Dikman, Thanks for the "Nice Find"... I think you bought an old Singer a while back that I was drooling over. Flad you like Big Barb! Okay on Servo!!!! I think you are right, I won't regret getting one. The clutch motor on this machine is rediculously fast! kgg, thanks for that link on pulley and speed reduction!!! Good stuff there! Yesterday, I bent the bobbin tension spring a bit to go back into a curve shape. It had flattened out so much I could not tighten the tension screw any further. That provided a temporary fix, but I expect it won't hold long as metal was compromised when it went flat. So better get that part now! I dropped one of the three gib hook screws first time taking apart the bobbin case to fully clean and oil. Man was that crusty! Gib screws ordered! She's functioning on just 2 screws at the moment. Got to remember, magnetic screwdriver for those screws!!!! Didn't have one with me that day. I've been ordering small parts and replacement parts to keep the Consew 255 running happily. She hasn't been run for a long time, so I am discovering what she needs and what is worn out or needing replacement as I go. So far, I have some stripped screws, probably a beehive tension spring, perhaps the whole top tension spring assembly (?), also bobbin tension spring and screws, some hook gib screws. Gotta get her a dip stick/oil gauge too!

.jpg.d60258221c476480a6e073a8805645bb.jpg)