-

Posts

300 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by chriscraft

-

I'm looking to build some tool belts along with a double 2-way radio shoulder harness for a few friends that are in Oil Refinery field service work. I did this type of rough neck work myself sometime back in the Houston Texas area. While working for the Koch oil field company based out of Houston, my company would pay us extra to travel within the US to other oil refineries to install and service oil field equipment. I would often run into Refinery Plant Operators that were wearing custom leather radio harness and leather tool belts. Some of these looked home made but some were top knotch custom rigs. I know that some were just a customized inexpensive carpenters tool belt but some were built specific to only hold a few basic operator tools. I've seen Similar built leather tool belt rigs in the Forestry Tree service industry. What it needs to carry: Radio harness- these carried 1-2 two-way Motorola radios similar to a Firefighter radio harness but looked more vest like. They had pockets to carry paperwork, pens and small items such as Lock-Out-Tag-Out tags, keys and zip ties. Tool belt- They resembled electrician line man tool belts that carried basic tools such as scrapers, ball peen hammer, channel locks, flash light, glove sling, tape measure, leatherman knife and a few slots for metal marking markers and pencils. With all the different oil refinery plants spread out throughout the United States, I'm wondering if anyone here has built anything like this? Looking for ideas while I take the plung at building one of these niche market leather rigs. .

-

Joseph, I Defiantly would love to make a living doing this myself. It all takes time, materials, equipment and of course... Skill. I've decided to keep this craft in the hobby stage for a long while. Will slowly aquire more tools and equipment as I tinker around honing my craft. Good luck and keep us posted if you decide to build one..

-

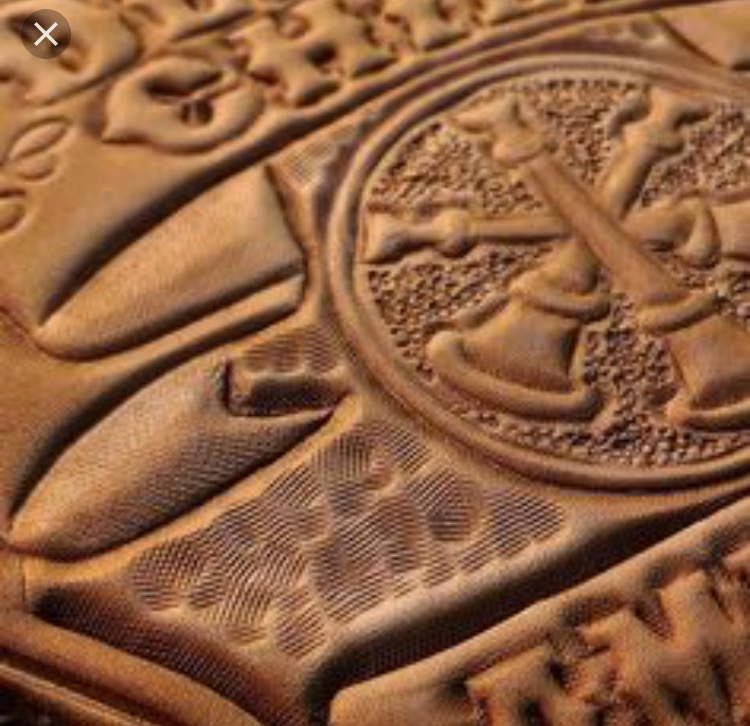

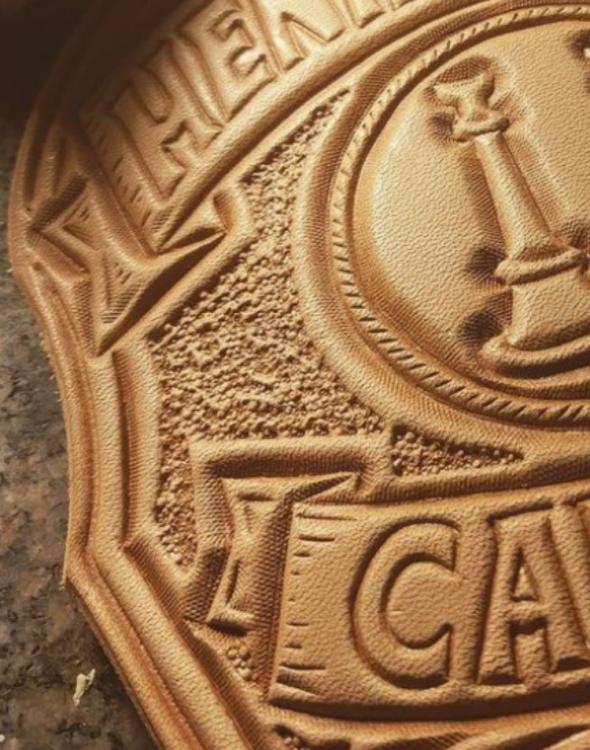

This was a side job I did for another company. They charged the customer $1,350 for 9 shields. Ouch!!! Not only did I provided the design layout and the build specs to be made out of quality HO leather but I also built the first sample shield at no charge. This ended up landing me this small order but it was a gamble on my part. If you're building one shield for a close friend, then pricing gets difficult. Im not sure if charging for your time is possible but you will gain knowledge out of the build experience. Billing friends for just materials will at least pay for the hobby. As always, try to use the best materials your friends can afford. This makes life easier on you.

-

Like JerseyFF said, most custom shield makers don't use them. It's definitely not a FF standard to include a curve stiffener or not. It's just one of those "overkill" add-on items that you may or may not ever need. I just wanted it to be hidden within my shield build and not look like it was added as an afterthought.

-

Nice, was it all hand brush work? Looks like a little airbrush work was used. Nice that it's not over hand tooled. I think that is what makes painting these stand out more. Too much tooling can overwhelm the piece. But you didn't so great job.

-

Jason I really don't have a ton of experience sewing or even ordering thread. I've purchased thread from Bob Kovar over at Toledo Sewing Co. and I've ordered from The Thread Exchange. Looking through my 1 pound thread spool labels I wouldn't be able to tell where each spool came from as they all look the same. Most have a Made in USA label on them. I do recall ordering this Dark Gray thread color from TTE, it was listed in the clearance section and they only had a hand full of spools left. The color looks darker on the spool than compared to the finished stitched color.

-

Hey Jason, I used 346 thread with a 5 spi setting on my Cobra leather sewing machine. I've noticed not all thread lays down the same. Some are a little more flexible and some thread is stiffer. I've gotten best results with the stiffer threads like this dark grey thread I used. I was trying to find Kevlar thread for this small run of shields but it's not available in many colors and have read mixed reviews about Kevlar cutting through leather. I'm not looking to produce these for the active fire service. I wouldn't mind making some for decoration, wall hanger type of shield so no issues with using bonded nylon thread. Havent been doing much leatherwork for a while now. Just need to get back at it.

-

I haven't done much leatherwork in a while and need to get back at it. I'd like to try out some different distressed backgrounder tools or matting tools on. Does anyone know what tool is used to accomplish these different hammered textured effects? I have the Hidecrafter pebbler 3pc. set and these don't look like they were used on these projects. Thanks in advance, Chris

-

Firefighter Radio Holder

chriscraft replied to rtesterman's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Very nice clean brush work on the stamped logo. Thumbs up.. -

Jim, I used the 1/4" set. Depending on what size leather circle patch your planning on making you could get away with 1/2" letters. Sorry for the late reply as I don't get on here too often. I'm usually on during the winter. That's when I start tooling and messing around with leather again.

-

Ray Pohja Master Leather Carver Floral Belt Found

chriscraft replied to chriscraft's topic in Floral and Sheridan Carving

My wife purchased this small wall mount shadow box for my Ray Pojha belt. Its been hanging in our wall for a couple years. -

Ray Pohja Master Leather Carver Floral Belt Found

chriscraft replied to chriscraft's topic in Floral and Sheridan Carving

I finally had a opertunity to have this beautiful belt appraised. My wife and I just got back from the St. Louis, Missouri Antiques Roadshow filming. It was our first time attending the AR and the waiting lines were long as to be expected. 6,000 admission tickets were issued for this location. The appraiser wasn't able to tell me anymore than what I already knew about this unique leather belt. He seamed to think it was incomplete and missing the buckle. I mentioned that Ray Pojha was not a jeweler or buckle maker. He only worker with leather and it's the way you would receive it from him. I said that to me, this belt was as complete as it gets. The belts craftmanship and detail did get the appraisers attention as he had not seen one with free hand scroll work on the lining. They passed it along the booth to get second opinions. The belt was then taken to another side enclosed booth for furthur evaluation while I waited. Finally one appraiser returned with my belt and was able to tell me that he felt confident one of Ray Pojhas belts of this quality had sold in auction for $1200. He was able to apprised my belt in the $800-$1200 range but felt it may go for more if in the right market. I was able to get him to agree that this belt was complete and not missing any parts. However he still insisted on me finding a suitable era correct buckle to better showcase this belt. The average person would view it incomplete. Funny that the same consignment shop that sold me this belt felt the same way. I wasn't picked to get filmed on center stage but I have suspicion I was filmed during the final appraisal. The only way to find out is to wait for the three episodes of Antiques Roadshow 2017 St. Louis to air on television. -

Sorry for the late reply Lakejumper. I'm using a new pro series Hidecrafter pebbler 3pc set. Thanks for the compliment.

-

I decided to buy it. Its confirmed, single loader press. I will not be mass producing anything here so it will do.

-

Has anyone used one of these older rivet kick press? Im thinking about buying this as an alternative to a newer Heritage kick press. It's made by The Tubular Rivet Co. Boston Mass. Looks to be well built but it might be a single loader. Maybe one could retrofit a new side tubular rivet loader.

-

Looking for a Heritage foot press for rivet setting. I'm in Milwaukee, WI.

-

I was lucky that my grandfather had a set of swivel knife fine and course hair blades in the figure carving tools I inherited from him. I don't know how old these are but most of his tools were from the late 50's to mid 60's. I would be lost without these two swivel knife hair blades. My fly fishing lures wouldn't look the same without them. I also would like to try and make my own blades with some fine jewelers files.

-

I quickly found out that I needed to tune these letters. The casting on the letters have rough edges that made laying some letters beside others difficult. I filled away each rough edge and rounded them a little. I didn't do them all at once as this would take some time. Just thought I'd mention this for those having issues lining up these inexpensive alphabet sets.

-

Sheridan leather has the Douglas Tool Versa Groove. It can be used right or left handed.

-

Estate Sale Tool Collection Find

chriscraft replied to David Bruce's topic in Floral and Sheridan Carving

What a find!! an autograph by the Stohlmans. You covered the previous owner's name, anyone famous? I've been going to local estate sales hoping I too can run into something like this. Also keep an eye out for framed wall art. Maybe an original tooled item from Al. One day. -

Thanks. Yes this stitch groover has some bite and tucks the stitch away. Its a Douglas Tool brand called the Versa Groover and I ordered both tip sizes. Think I'm using the smaller of the two cutters. It's a Great quality stainless steel tool.

-

JerseyFF, just find yourself a quiet place to practice tooling after your station duties while at the station. I can tell you that I wanted to construct one of these leather shields back in 2010 when I was at the station and never did. Here is a link where I did a step-by-step on this blacked out shield. Maybe this will inspire you to get started. leatherworker.net/forum/topic/69922-alphabet-stamping-on-a-firefighter-shield/

-

Mechanic Belt

chriscraft replied to DS STRAPS's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

This would look cool with the entire open wrench set on each side. smallest to biggest ending with the larger wrench toward the back leaving space for name or initials. -

TSes, this isn't a copy off any pattern and I didn't have an actual sample to look at to just trace. That would have been much easier if a pattern was submitted. I designed the tooling layout. I did a web search on antique leather FF helmets and from all the different shaped shield pictures I found, I took the one I liked the best. This new layout had to fit within the measurments I was given. Most of the antique leather helmets I found pictures of used a "High Eagle" mount. This mounts the shield slightly taller than the top of the helmet making the need for a tall shield. I needed to design a shield to mount below the hieght of the helmet. Having a standard mass produced production shield in hand was a good base to start laying out my new outline for this shield. Now I had to design the inside layout, again looking at photos I picked out the number style that looked appropriate. I came up with the top banner as it resembled a firefighter metal badge. The pebbled background is a good filler that makes the rest pop. I like this design and hope to use it again on a different Dept. Shield. Some of the projects we work on take on a special meaning. I was a volunteer firefighter so this was a fun project to work on. I don't know if leather shields were originally part of the helmet or if the shields used to be hand tooled by leatherworkers. I would imagine it was a skilled trade one would specifically learn for this purpose. Today a few top FF helmet companies still produce leather helmets such as Paul Conway, Cairns and Phenix. These companies also provide a shield for an additional cost but it does not come close to what a private individual can produce. I've seen a few small companies that focus only on building leather FF shields, radio straps, radio harness, duty belts and truck belts. Depending on the skill level of the leather shield maker, each shield can range from a basic $80 to a fully custom hand tooled/painted $400 presentation leather shield. I'll let you know when someone pays me close to $400 for one. The first sample shield took me a total of 20 hours to build including making the layout and design. This last one pictured took me 4 hours to build as I already knew how to go about building one. I think with much practice and a few speedy tools one might be able to build these in less that 2 hours.

-

Since 2010, blacked out FF leather shields have been becoming popular at fire houses across the US. Even if you have a colored numbered or white shield, it becomes smoked black during a fire and one must keep scrubbing away the dark smoke stained shield. So having a blacked out version to begin with wont make you look like a rookie anymore. Besides having a brightly painted number on a shield as identification that was great 100 years ago. Today every FF carries a two way radio, GPS, Personal Alarm Safety System and other reflective FF turnout gear. Traditional Firefighter's wore leather helmets that had leather hand tooled shields back in the day. Today they are still making traditional leather FF helmets but they don't come with a leather shield, Craftsman not included. Most Fire Dept. issue a mixed pleather/composite material front. These flimsy fronts belong on a plastic composite firefighter helmet and not on a Traditional Leather Helmet. This is why I was sought out to build a few quality leather shields. I chose to use Hermann Oak 7/8 oz for the tooled front and backed it with 8/9 oz. Makes a beefy leather shield.