-

Posts

366 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by rdl123

-

I believe I have actually burnished the leather - The door knob bouncer is convex - Next time I will be definitely using the protective leather pad. I have attached pictures for you to look at - Let me know if this looks recoverable. I guess the other question I have is will this affect the ability of the seat to absorb neatsfoot oil? Bob & Goldshot - I appreciate your help on this. Many Thanks, Ron

-

From the album: first saddle project

-

From the album: first saddle project

-

I have a question - When I glued my seat in I used a ceramic doorknob bouncer to really press the leather into the cantle face. It left some rub marks - Can anyone comment if these are permanent or if there is a way to minimize them? I will take some pictures. Ron

-

Bob: Timberline. Here is the seat fitted. Few things I will do differently next time that's for sure... Still have to glue this rascal in. R

-

From the album: first saddle project

-

From the album: first saddle project

-

From the album: first saddle project

-

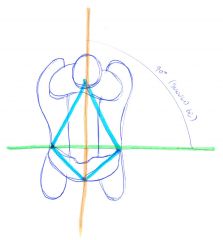

Randy: Glenn Christman (tree maker) made me aware of this potential issue. The biggest problem is if your cantle is not square it will push you off center when you lope trot etc...I am not sure how common this problem is - When Glenn explained this to me I immediately checked square on the saddle I am building and it was off...Strange thing is I've never heard of checking this in any books or DVD's...Guess it should be common sense to check it but it sure never crossed my mind. I had marked center on my cantle and horn. I marked center on the cantle by coming off of the bars - Not dividing the width of the cantle. From there I used the nail and string method. One from cantle center mark and one from horn center mark. The right side of the tree - The cantle sat further back by probably a good 1/2" off square. I was told to try and get it within 1/8" of square. Luckily I was able to get it bang on... When I have a minute I will take a pic of the leather neck piece I installed to make up for it. Here is a pic showing the measurements I took... Funny thing is - I had noticed previously that when I sat in the saddle I didn't line up with the center line on my ground seat. It always seemed like I was sitting at a minor angle. Anyhow, after the fix If I just jumped up I'd wind up being perfectly centered automatically. On Saturday I fit my seat - Went fairly well - now I just need to glue it in. Will post pics when I take some. Ron

-

From the album: first saddle project

-

Thanks Gold Shot: I will try to hide the divider mark - Have also been practising my decorative cuts as well... I have bought a larger lifter and it seems to work a lot better - Last one was so small it kind of got lost...Also lifting the lifter like you mention sure helps too! Anyhow, I am planning of putting my seat in tomorrow. I have watched the Jeremiah Watt DVD's and will use his layout method for putting the seat in - Does anyone have advice for a compete newbie on installing seats? Also, I have the new skirts blocked on - They fit this time and look ok...I will try to post pics for critique on Monday... An interesting thing, I discovered the cantle on my production tree was off square by probably 1/2" - I fixed by adding a chunk of heavy neck and skiving it out till both sides matched. Not much fun - Took me a whole afternoon of carefully checking balance...Anyhow, I am about to order a second tree and this one will come from Glenn Christman out of Alberta. I like the fact that he uses rawhide he personally prepares over factory produced stuff...

-

Randy / Harrington - Thanks for compliments - Harrington - Yes, I haven't done decorative cuts yet - Need to study up on them as so far I've never made a decorative cut I liked! Do you have some tips? I need serious help with my tooling - I think what I need to do is spend the time to study Sheridan/floral style carving in detail, get a feel for how it's supposed to flow etc. The slight point to the otherwise round horn is something I picked up from Dale Harwood - He does it to break the monotony of round caps on larger horns - I like it too although I think I'll order my next tree with a Guadalajara style horn... Roughed out the fenders last night and have made patterns for the second set of skirts - I'll cut them to size once they are blocked on tree this time. R

-

Randy - I really like the Barry King awl handle - I get my blades from Douglas Tools - Sheridan Leather sells them: Vandy, I believe, is Bob Douglas's daughter and will help you pick which size to get... I have found that the combination of Douglas awl blades and the Barry King handle is very controllable - I purchased the flattened side handle - Gives me a refererence point every time I pick up the awl... One douglas blade has lasted several pairs of chaps, my first saddle project is half done w/it and it is still perfect, just strop the tip once in awhile. Ron L.

-

Have been busy with other projects so not much time for this one - However did stamp and install my horn cap last night - Finished at 5.25" dia. R

-

From the album: first saddle project

-

From the album: first saddle project

-

From the album: Chinks-Buffalo Hide

-

I am thinking of going with exposed stirrup leathers on this saddle. Any one have insight in to the pros and cons? I've searched quite a bit and haven't come up with anything definite. My current saddle has exposed stirrup leathers and I have had no issues... Thanks! R.

-

Here is this past weekends progress: Swell cover on, hand hole finished and horn capped and wrapped. Horn still requires the final, top piece. Had the horn cover fitting perfectly but when I glued it and then put it on I managed to get it up from the swell a bit... Horn on this tree was 100% flat so I made a 4" circle that skives to zero from middle to give it a dome effect - This is nailed and glued over the horn filler. Also, to all who have helped and given me needed insight and corrections - Thanks very much...I am looking forward to the second saddle project and avoiding mistakes I have made on this one. Ron

-

From the album: first saddle project

-

From the album: first saddle project

-

I'd like to know - Do you install your riggings over swell cover or under swell cover?

-

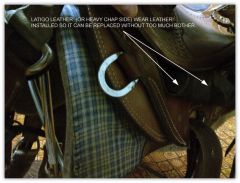

Here is a picture of the wear guard I was talking about above. Bob - I'd appreciate your thoughts about this - And, I will definitely be using plugs on saddle #2. rdl

-

From the album: first saddle project

-

Bob - I appreciate this insight - Being a complete amateur I was not aware of this - However, set out like you have explained it I can see the issue. I know of a maker in Maple Creek Saskatchewan who rectifies this issue by running a piece of 5oz latigo as a wear guard - I hadn't realized why he did this until now...It is easily replaceable and obviously he does this so it takes the wear - Not the rigging plate. I think I will do the same for this saddle. I will try to find a photo of the wear guard I am taking about... And, thanks Bob for the information - Proves that no matter how much you study this, there is always more information and tips to be had! Ron