Sovran81

Members-

Posts

324 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Sovran81

-

Ringwork is another name for fancy plaiting. A pattern that goes around the braid. Often multiple rings of varying patterns strung together. Commonly found on whip handles or anything else that doesnt do a lot of flexing. Because of the possibility for several overs without an under to lock the strand, most ringwork is kept short with other ring patterns used to lock long runs of over.

-

I dont think you will have that long. Fantastic work.

-

Packer reopens again on the 14th. I am ordering grade 1 k-whip(various colors). Price is $120/m2( about $12USD per sf). Anyone interested? Get with me by PM. Final hide pricing is determined by size printed on the hide. I am ordering grey species myself. Smaller square footage but thicker (1mm) hide.

-

I called Atlanta and gave them all the pertinent info. They wanted me to ship a machine head to them. MFG I have a 206rb-5 and they wanted my machine to make the binder! I was less than impressed. They are evidently geared to working with factories that have machines to spare or someone that has the cash and downtime to ship their lifeblood. I have no problem paying a little more for something I know will work, but if they cant cover the common machines themselves..... ahh nevermind, this will turn into a rant.

-

Yes that is the pic I was referring to. I agree looks like a standard lock stitch to me. I cant even see a third shaft denoting a walking foot.

-

Old post I know but I read the OP link and have a question. "Machines that sew a saddle stitch"? Are there any? I am not sure what a needle and awl makes. I doubt any of them fit the picture of the flatbed machine in the link.

-

I am unsure of rawhide, but I tried some veg tan horse butt because I had it lying around. Maybe it had too much flank on it, but I was not impressed. I didnt even bother splitting it down to braiding thickness because the 5/8" strand broke twice while stretching it. I ended up finishing it to 7/16" wide and giving it to a friend for his renfair projects.

-

Isnt that like teaching an old dog new tricks?

-

@GrampaJoel lower right hand corner when you view it. Mouse around and a graphic menu bar appears. Click the floppy disk.

-

Great presentation Leatherpownder. Thank you. Brian you may want to check your link. It doesnt seem to be working.

-

I use 138 and 207 bonded nylon on my 206RB-5. I sew between 4-18oz. I have to adjust the top thread tension when either changing thickness or leather type to keep the knots in the middle. Make sure your needle size is matched to the thread and is installed properly. Make sure you dont have lint or other debris in the bobbin or feed dog areas. Make sure your thread path is correct.

-

Thanks for the info everyone. I wasnt saying anyone's method or choice was wrong. I am just trying to understand the relation of soap to adding extra tallow to it. Understanding glycerin addition is easy. It is a humectant and attracts moisture to help keep the leather from drying out. Tallow I am unsure of because no further chemical reaction should occur since what ever passes for lye in todays soap has already been consumed in the soap making.

-

Let me get this straight. You mix a chemical based soap, Ivory(they changed the formula from pure soap to a deodorant bar some time ago) and (Castille)a vegetable based soap, add a little glycerin and water. I know you braid rawhide so using a straight soap kinda makes sense. The thing is, We havent changed our tool designs much in a hundred years(the old timers had already figured it out). They used real soap and fat(oil) mixes. What more do we know about braiding soap that makes modern formulas better? Since soap is a surfactant, does it cut the surface tension of water repelling properties of fats and oils? Does it allow moisture penetration through fats(oils) while still maintaining the slip we need when moist and the hold we need once dry, or at least atmospherically dry? Does it impart and initial conditioning of the leather and allow application of further conditioning without it "sitting on top"? I am not really after recipes, more a how and why of then and now.

-

I have read everything I could find here, at AWPA and anywhere else google has sent me but these questions still has not been answered. I hope someone can shed a little light for me. Braiding soap s a mixture of tallow and pure soap, sometimes with other additives such as glycerin in it. Soap is a compound of tallow and lye. What is the purpose of adding additional tallow to the soap? OR Why not use straight soap or straight tallow? Please note if you are a rawhide or leather braider.

-

projects adult section

Images added to a gallery album owned by Sovran81 in Our Leatherwork Galleries

-

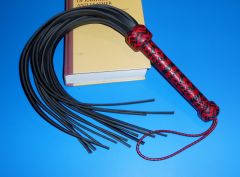

From the album: projects adult section

-

Thank you all for the compliments. @Peter T Thanks for the critique. That was exactly what I wanted. People to be very picky and provides some tips. Like rolling it to see if its straight vertically. I never thought of that even though I rolled it to compress the strands. Some of the strands stretched a bit even though they were prestretched. I used the belly and flank strands.This was a first time cutting a roo hide. While aware of belly and flank stretch, I couldn't bring myself to waste leather that is $19 per square foot. The upside is now my two hides are pretty well trimmed, so the next attempt should be better. I wasnt sure how much space the pattern would take so I made the pattern short then measured the pattern after braiding it. I discovered just enough room to repeat the pattern. Even though I had marked the first strand something went wrong(this has been bothering me). That line came out 1-2 diamonds off the line. I reworked at several times until finally I got it to line up for the most part. I sure hope Santa brings me some pattern books this year. I keep making patterns that dont fit evenly to the plait count.

-

24 plait handle, red and black roo. Experts please critique so my next one is better. http://leatherworker.net/forum/index.php?app=galleryℑ=23050&size=medium

-

From the album: projects adult section

-

WOW! I understand pull tight and plait loose, but that pic right there is making me think you sleep with the fid. LOL Thanks for showing a pattern. I am still curious as to how you split the pattern into sequences. Now I am thinking the sequence is the complete 'ring' no matter how long it is. Do I have that right?

-

Absolutely beautiful Peter. A couple questions if I may. When mapping your pattern I assume you end each sequence with an under to lock it in. Do you have a set number of over/under to make a sequence, or is a sequence set as 1" of finished work? I have worked with up to 12 strand but never done any fancy ringwork. I am graphing a 24 plait handle with ringwork and am unsure how to divide the sequences. I for one would love to see some of your sequences graphed out and posted. Thank you.

-

Tracy, it is that both part and bight cant be divided by the same number. GCD= Greatest Common Denominator. The GCD of the numbers 9 and 7 is 1. No other number can divide both of them.

-

Anyone got a copy they want to sell? Ramskull Press only ships airmail which makes it too expensive for me.

-

The osborne style splitter is nice but overkill for lace. The Dene Williams is a great splitter for lace. You dont need anything more and has the added advantage of using disposable blades. If you want to rig up a homemade jobber for almost nothing, Youtube leather splitter. The difference between a splitter and skiver as in the link you posted is splitting keeps the leather the same thickness through out the cut. Lap skiving is designed to taper the cut so the leather blends into itself better when folding, Such as belts for the buckle fold. Beveling is paring the edge of the strand so it lays smoother next to another strand. On a side note: Some people have luck using a lace cutter such as the Lace Master or cheaper Yknot lace cutter to split lace by turning the lace sideways. It never worked for me though.

- 14 replies

-

- kangaroo lace

- braiding

-

(and 1 more)

Tagged with:

-

Bob did this newb sewer right. I received a pallet and 2 boxes IIRC. The pallet held an assembled stand with motor attached securely bolted to the center of the pallet. Box 1 held the machine head with test swatch( what I had told Bob I was going to sew) under the foot. Box 2 contained the accessories that came with the stand and that I had ordered separately. It truly was "plug and play". Set the machine in position, drop on belt, skip belt guard install(sue me, I was excited), thread machine, plug in and sew. Thanks again Bob.