-

Posts

358 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Yetibelle

-

That machine is massive. It's a wish list machine not a great machine for daily use. Back to your problem.... you don't need to spend $1000. You can find them for a few hundred or less sometimes. Granted a $50 machine may need work, but I have found some $150 machines in really good order. To break down the Wiz masters post - you need a walking foot machine. I regular home machine does not have a walking foot. Plus a home machine uses a tiny needle and thin thread that does. It work so well sewing leather. So you probolly don't want the big class 8, but I think a model 111w155 would be good. Watch how the foot walks.

-

Well - while they are great machines (I love every Singer Machine), they are all home machines and not really setup for leather sewing. I am sure some are very strong machine, but you may get frustrated with them as you sew leather. Read Wizcrafts post on the first page of the forum, about "The Type of Sewing Machine you need to Sew Leather", he does a great job going over how it all works. Singer Dream Machine would be a model 97-10 or a Class 8 DARN you beat me .... haha

-

WOW - a yard sale. That is a great find.

-

I have few of them, I will check the part numbers when I get home tonight.

- 22 replies

-

Here is what I think....if it is a good price and you like the idea of working on 80 year old sewing machines, then go for it. If you just want to sew a project and move on, then don't put to much time into it. They can be really fun, and they also can drive you crazy. One day it may sew fine then the next it may not sew at all. You may need 5 parts, but you can only find 3 of them and the other 2 parts cost more than you paid for the machine. 1) Any idea of the $ value? A "typical non-SV" 111w155 machine is about $350-$600 depending on the condition and if it is working or not, motor type and extras, like needles, bobbins, lamp, thread holder, ect. 3) Is there a better operating manual or service manual I should be looking at? I suspect that any 111 guide will be a good start, show you how to thread it and see if you can get it stitching. 4) Replacement parts: Who is a reputable source? 111 parts are fairly common on e-bay, and sometimes you can find "donor machines" without tables and just strip the parts, but it can be frustrating looking for parts at a good price. 5) I have done some searching and this model # comes up blank. What model number is most similar that I should use to order parts? I have a 111W155 and it looks almost the same. I am sure someone know the exact model it is related too.

-

Here in the Midwest, I see the 31-15 all the time, sometimes they are $50 bucks, sometimes they want $400. I would say if you look for a while you will find one at the $50-$150 price.

-

HAHA I was just thinking ...I wonder if I could ship a few machines over for a full auto-body re-paint..

-

-

Basically every place there is a joint, or turns. Here is an bad manual that points to just about every part haha. Typically any place you see a hole or a tiny brass lid oil goes in there. http://parts.singerco.com/IPinstManuals/7 CLASS 2 NDLS.pdf I can post some pics tomorrow, I have to shrink them so they are small enough to post.

-

-

Well you have 4 post in here, but I suspect someone will combine them. I clean mine with a tooth brush and some Zep Foaming Degreaser, I found that works well. If you take it apart a section at a time and clean it then put it back together that helps you from forgetting how it all goes back. Once you get most of the dirt and grease off you get some steel wool and some fine sandpaper like 400-600 grit and just start working in sections. I take the head apart and clean all that but I don't take it out the main shafts. With a little effort they clean up very nice. The skipped stiches could be just an old needle. Replace it and see if that helps. When you say "get smaller needles" they really don't get small for this machine.

-

Every tool has its use, I think the BOSS gets picked on because it's in the $1200-$1400 price range and there are many used and new sewing options (with motors) that compete in that space. So from that mindset we want to compare them directly against one and other. While the BOSS is really in a category by itself. I love all heavy stitchers and if I had the money and the space would have them all.

-

Just picked up a Singer 211G165 - Couple Questions

Yetibelle replied to y2k600f4's topic in Leather Sewing Machines

Sometimes the stitch length numbers in the window don't line up with what the machine does. this can be because someone replaced the internal belt and did not line it up with the numbers. I suspect if it is stitching that the timing is set correctly. If your at the lowest setting and you sew a row, and measure the stitches on a test strip how far off are they from what the machine setting is? You can also check the needle bar and make sure it is set coreectly and then check the feed dogs and see if there is nay play or wiggle in them. It appears your not off by much. 3-4 SPI is are really big stiches. -

You should contact Service Thread - they will be able to help you get the correct thread for any heavy project. - You may also need a hammer. haha love this video

-

That is a great Idea. I wanted to mount a machine and motor on top of a workbench that would solve the pedal problem. I suppose you could also convert that to a pedal with the extra long flexible cord, then you could move it around like a pedal system on a home machine. Now your not limited to a fixed-link or chain pull pedal system .

-

Have you looked or thought about a rolling-foot post bed machine? They would be good for 3D work.

- 9 replies

-

- industrial sewing machine

- leather wisdom

-

(and 1 more)

Tagged with:

-

Good test advice. It should work smooth and the stitching should look good on both sides of your test. Check out some Juki 1541 videos on YouTube and it should give you an idea of what they run and sound like. They have a really nice purrrrrr sound to them.

-

I don't own one, but I always liked the concept. A simple machine, with a small footprint that can sew really heavy leather. My first issue was, wow they are really expensive, even used they are typically average $800, however if its the right tool for the job then who care what it costs. The second issue was a crank arm vs. a foot pedal. Most of the time I wish I had a few more hands to help me out, so loosing one hand to cranking is a drawback for me. I think I would have bought one of these if it had come in a foot pedal kick-press version. Then I can just stamp out the stiches and use both hands. My last point would be speed, since you crank-out the stiches they are not very fast but if your not concerned with speed of production its no big deal.

-

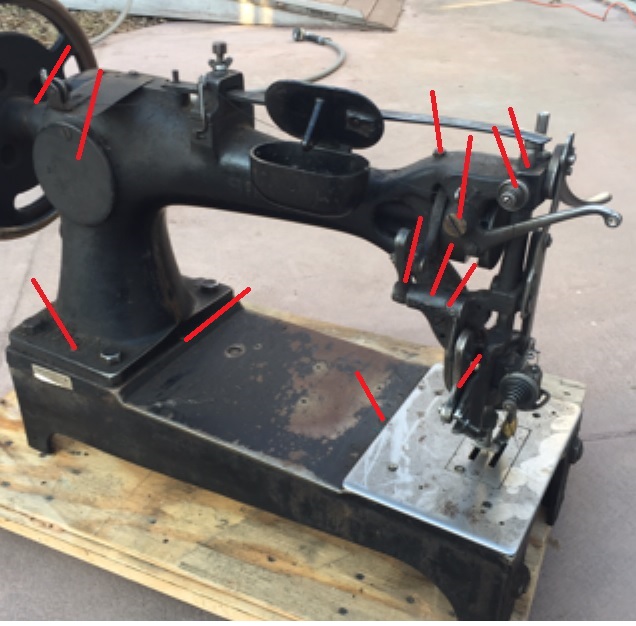

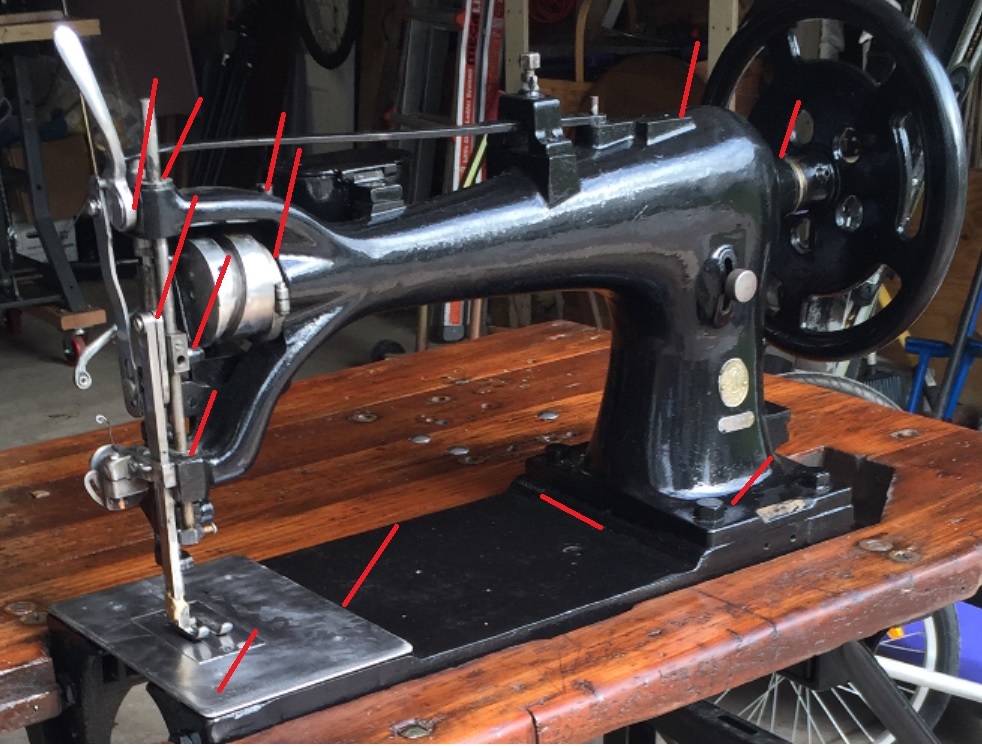

Can anyone identify this machine?

Yetibelle replied to bikermutt07's topic in Leather Sewing Machines

I have a hard enough time getting the 80-100 year old machines to work the way they are meant too. I suspect most of these machines we restore had been in service for 50 plus years before they end up in the back of a barn or basement for another 20 or 30 years before I find them. So restoring them is reward enough for me. -

Can anyone identify this machine?

Yetibelle replied to bikermutt07's topic in Leather Sewing Machines

It works great. Since I sew canvas and leather most of the time it's fine, but they are right with the big foot and being a flatbed it's harder to accomplish detailed work on smaller projects. It all depends on what your making and how many turns and corners you will have. I love the look of 346 and 415 thread but it's not really necessary for most projects. -

Can anyone identify this machine?

Yetibelle replied to bikermutt07's topic in Leather Sewing Machines

only forward----------> no reverse. You stop lift the foot up with the needle down, turn the project 180 then put the foot down, then sew over the last few stiches. While they are tough machines it will be hard to get them to sew an inch thick. -

Reverse is typically just for backstitching the end and start of the row. So you go forward 2-3 stiches and then backstitch over that 2-3 stiches then continue on forward until you get to the end and then reverse for 2-3 stiches and done. You don't typically drive the machine in reverse for very far. Try and run with 138 on the top and 92 in the bobbin and see if that makes a difference. Also with a new machine it should work correctly I would contact Tecsew support and see if they can help get it adjusted right.

-

Can anyone identify this machine?

Yetibelle replied to bikermutt07's topic in Leather Sewing Machines

-

I suspect if it only runs a few minutes at a time - with the belt off - it has issues and you should contact the company.

-

Could it be that it is just getting overloaded? It says something about that on the PDF. Reduce the load? Not sure if that means your belt it to tight, or the wheel to heavy? Or maybe the project to thick? But I am sure it is one of them CSM1000.pdf