-

Posts

358 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Yetibelle

-

I suspect that it skipped a stich and then caught on the next one, that made it look extra long. That's just a guess.

-

My picture is now "Bob" approved!

-

New Cowboy 4500 - Need some help.

Yetibelle replied to internetcowboy's topic in Leather Sewing Machines

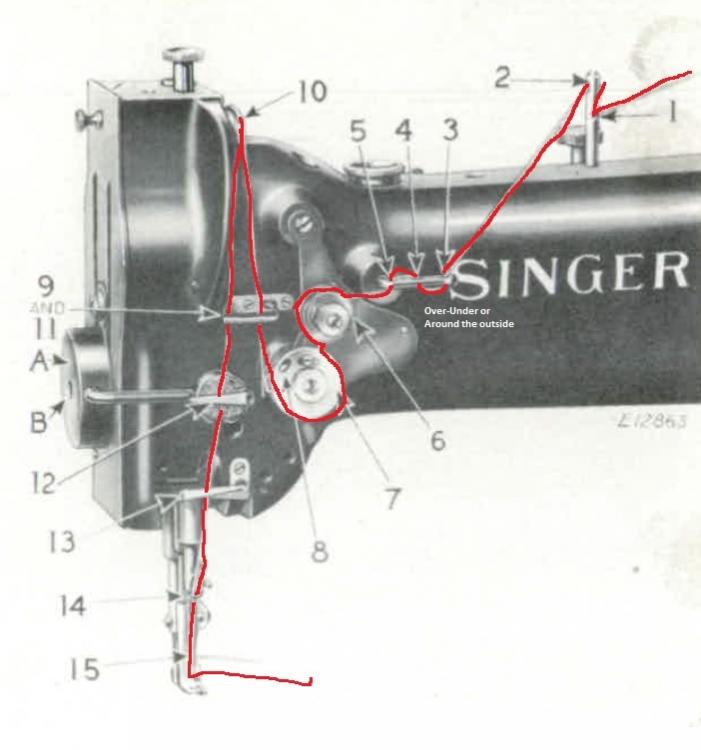

The pictures also show the thread-path and I see that you looped it back under the thread-guide. I don't think I have done this should I be? -

For a while I was threading the tension disk through to the tab, like in the video. It clicks in there so naturally that your positive that is what it's meant for. If your breaking thread, your needle and thread size may not be paired correctly, too big of thread for the needle maybe? What sizes are you working with?

- 22 replies

-

- 111w155

- threading the tension disks

-

(and 1 more)

Tagged with:

-

Singer 29-4 Stitch Length And Foot Pressure Adjustments

Yetibelle replied to Kako's topic in Leather Sewing Machines

That stitch length is good at 6.5 some are much worse. As part of the test, when your sewing turn the bell and if the stitch gets smaller in certain positions that mean the track is worn. Here as a nice slide show on the parts after the head is taken apart. I am not sure if the 29-2 head has the exact parts as this, but the idea is the same. You can is from this side (looking upside down) how the bell moves in the track, once that gets worn I recommend you replace them both. Take a look at the blog and see if that helps, it's a fair amount of work to get it all apart, clean it then put it all back, but not impossible. http://northants-restoration.blogspot.com/ -

You can always get a Flat-Bed table for the Cobra-4? Or if your looking for the similar machine in the flatbed the Consew 733r, HEAVY DUTY, this gives me a good excuse to drop in one of my favorite sewing videos - AKA - How to Sew with a Hammer!

-

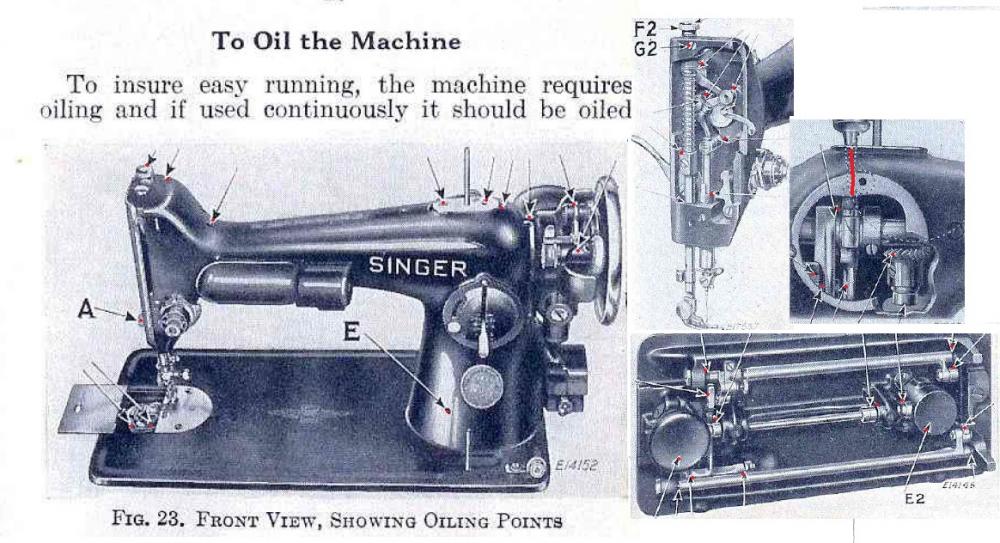

The 201-2 while a great machines is still just a home machine and not going to sew leather very well. Here are the general guidelines to oiling - Oil anything that moves other than the motor and belt, since this is a direct drive, the belt is a non issue, but you get the idea.

-

Machine foot for Hat with Wire Brim Edge

Yetibelle replied to Double Daddy's topic in Leather Sewing Machines

WOW - very nice hats! You should make a short production video so we can see how its done. I know mine would end up looking like floppy mess. -

If its the solid wood table and standard H-legs with a clutch motor still attached it will be heavy and awkward. I put some cardboard down and slide it on top of that they look bigger in pictures than the actually are, I figure the table is 48 long by about 20 wide, easy for a big SUV. you will have fun they are nice machines and easy to maintain.

-

Well it says Chandler on it but it looks like a Mitsubishi DU-105. Like this one. I suspect if its in good shape it would be a great light\medium weight machine.

-

I typically see "The Boss" sell between $800-950, mind you I mean sell. The Boss packages I see listed every few months start out at $1200 and then after a few month drop and sell in the sub $1000 area. I went with the CB4500 and really love it. You can always start with the base package and then add to it as you go. I found I like Uwe's flat top table a lot more than the standard table as an example. Really it does seam like a lot of money, but after messing with 80-100 year old machines having a new machine that works each time you step-up to it is a real pleasure. Plus unlike most other technology this machine will probably last 80 years also. In fact I will even go so far as to say if you get one you will soon find yourself wanting a second one (and totally justifying it also). HAHA

-

Stitch unbalanced every few stitches

Yetibelle replied to the deacon's topic in Leather Sewing Machines

I suspect the bobbin tension is off, could be you need a new bobbin-case-spring? It may look correct, but just not have the right pressure on the thread anymore? If you can load some pictures of your bobbin and case and hook, maybe someone will notice something? -

Question? Great looking machine, but you always have great looking machines! How are you getting the reverse function? Is that a feature of the motor?

-

You turned the corner as the needle was in the up position and when it came back down it stretched the stitch. To form a right-angle corner, when you get to the end, you leave the needle in the full-down position and then press lightly on the lifter pedal to raise the foot enough you can turn the project. Then you roll the balance wheel by hand to make the next stich. This should form a correct right or left angle. The pros can predict the path of the needle on the turn and form a round corner the same way, by feathering the lifter-foot and needle-down position to keep the stitches even. Just takes a lot of practice and a steady hand, oh and a speed-reducer helps a lot.

-

I think Solar Leather has a good videos and documentation on the CB-4500. http://www.solar-leather.com/supporthelp/

-

I understand its a good price but if you really want a leather machine look for a 111w155. The 31-15 is tailor machine not a leather machine, but it is old cast iron so whatever fits under the foot it will probably sew. I assume it will have an old clutch motor on it and this will be the hard part, since you wont have any control, you will tap the pedal and it will take-off like a rocket. You could put a roller-foot on it and a servo motor and that would give it more control, however then your spending more money and may as well look for a 111 machine that already has a servo motor.

-

Stitch unbalanced every few stitches

Yetibelle replied to the deacon's topic in Leather Sewing Machines

When you see the bottom on top - that is typically to much top tension that's pulling the bottom up. Your not far off. That is just 2 layers, does it still do that on 4 layers? Handy chart. -

It has reverse, so it would be on the higher end of the price scale. I really liked the one I restored a few years ago. They are very heavy, and not that easy to move around so I bolted casters on the feet. Still if you have larger canvas project it is a great machine.

-

I think we should take a moment to define what a "electronic needle positioner" does. In the most basic sense it allows you to program repetitive work-flows. So you place your item under the needle and press the button and it drops the foot and needle sews/backstitch sews 10 more inches backstitch, lift foot cut thread move on to the next piece. This can save a lot of time if you are making 50-100 pieces at once. This Pfaff 2545 has this built-in, plus it has larger bobbins. Some other "EPS" systems setups essentially do the same thing but you can change the patterns and stitch style (if you have zig-zag) and get really complex fork-flows to the point it is automated and you don't even need to guide the project the machine will do all the work.

-

Yes I hear that "click' when I go in reverse , glad that is normal. Also depending on the leather and layers I sometimes hear it "squeak", but realized that was the leather and not the machine.

-

Yeah he know everything

-

That is a very nice looking machine, it may not be a walking foot, but a roller foot machine is also very good. I suspect it is close cousin to the 45k53 machine? But I will leave that to the others to figure out. Depending on what your project is that would be a very good medium weight leather machine. Plus that treadle is a rare one, I would buy the machine just for that (depending on the price). Nice find.

-

Well my first "rule of thumb" is, restore it and use it as it was originally built. So if the machine started as a 45k64 then it should be used and restored as such. I only recommend this because to change or modify a machine is a considerable amount of work if it is possible at all. Finding the correct parts to just get a Singer45k running again can also be a challenge. So rather than putting in all that effort into a Frankenstein your better off just looking for the correct machine for your projects.

-

any issues with putting a servo on a Singer 153W103?

Yetibelle replied to ELeBlanc's topic in Leather Sewing Machines

No issues, swapping the clutch motor for a servo motor, assuming the clutch motor was mounted in a standard 3 bolt standard setup. If not you may have to drill a few new holes but that's not a big deal. The Servo motor is a huge improvement over the clutch motor, you wont regret it. -

You don't want this to be your first industrial sewing machine, if your goal is to sew leather. First this is not a leather machine. Second I don't like any "oil-pan" machines. I am sure some people out there love them, and if I was running a factory of these machines I'm sure it was great just filling them up and checking the window and topping them off every so often. However as a hobby this is a pain. If you ever move the machine oil will slush all over. Sure you can swap out the motor with a new Servo motor and that will slow it down, but its still not a leather machine. Keep looking