-

Posts

358 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Yetibelle

-

Good looking machine. I am not sure of were to buy that would be local to you? You can save some time and shipping just look for some heavy kite string, or nylon twine at the local store. If its just a test for "size" to pass through the machine, they are going to be close to 415 or 554, maybe a little thicker. You will have an issue with the needle size before the thread size, so whatever you can fit in the largest size needle you have (the 27). They do go up to size 28 I believe ? I think they use to make a size 30-31 in a 7X5, but they may be hard to find. When trying this I would use the handwheel, there is a chance you engage the motor and it just just spins a nice nest that will be a pain to get out of the hook. Yes this is as large as it gets for the Class 7. The Singer 97-10 would be the largest needle machine similar to the class 7 in the way it works, but can sew up to an inch thick. After that you need to look at needle and awl machines they use in shoe making and heavy horse tack. Sill the thread size doesn't change that much just the ability to sew thicker.

-

Sewing machine sewing without thread

Yetibelle replied to PAMuzzle's topic in Leather Sewing Machines

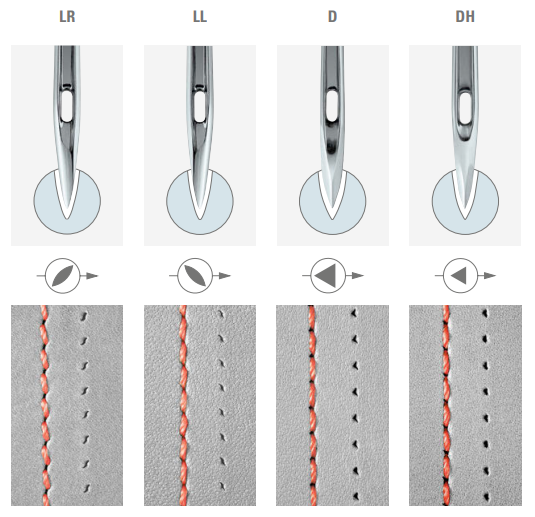

I think most of us use 277 thread, 24-26 needle, still looks heavy and strong but not as pronounced as size 346. If you want that "thicker" thread look use 346 thread, both top and bottom, needs a larger needle 794 LR or DH size 26-28 Bonded Polyester is UV rated for "full sun" like a umbrella. Nylon works for most regular outdoor exposure products, with leather items you have to condition them regularly so both will work. Zig/zag stich that refers to the needle moving side to side as it moves forward, think embroidery . These machines are not zig-zag machines. Depending on the needle point it will make what looks like an "offset" stitch with the LR point. The D or DH point needle makes a straighter looking stich. -

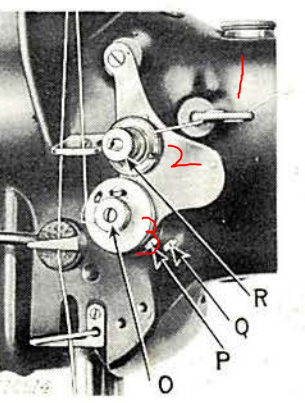

Singer placed that tab in such a way it totally looks like its part of the thread path. I know that most of us no longer use the thread lubricator, and the machines still sew correctly. We have figured out little tuning methods to balance the tension thread path (1-2-3) so that it works, sometimes that includes looping the tab. Plus it helps that we have bonded nylon\poly thread that moves smoother than the older linen threads. Its only a problem, when its not working, and thread on that little tab is annoying the thread controller spring and it starts to skip or bunch. That is when we become our own enemy and start to tighten\loosen the tension nuts, bobbin spring, then when all else fails start to look for timing videos on YouTube, when all we really had to do was unloop the tab. r

- 22 replies

-

- 111w155

- threading the tension disks

-

(and 1 more)

Tagged with:

-

I’m sure I have posted the pros n cons of the The Boss before but in a nutshell - pros - really small footprint, it’s a hardy class 7 system so big thread and needle for heavy work. Portable since it’s so small. cons - you need to crank with one arm, and you need to crank consistently the same way. If you get lazy cranking you may skip a stitch. Think about cranking 500 times for a belt or bag strap stitch line - my arm is already tired. Other cons are small throat depth, and the last is the cost, it’s pricy. Spend the extra money and get a Cowboy 4500, you will not regret it.

-

The Class 7 is like owning and driving a classic car, its more about the experience than the actual usefulness of the machine. I could watch this all day in a loop. https://www.youtube.com/watch?v=periHrxK-6Q

-

Yes they are very similar machines, I thought the Adler was a Singer Class 7 until I got the dirt off. After I got it clean, I realized that most of the parts in the head are Singer, so at one point it was rebuilt with class 7 parts. I think the machine in the listing looks in good shape, however too expensive.

-

There is a very inexpensive magnet laser marker sold at Harbor Freight tool. The magnet is not very strong but its $6. While the level is nice, you better off mastering the edge-guide. Once its set, all your work should follow that path.

-

Sewing Machine Purchases and Questions

Yetibelle replied to MzVictoria's topic in Leather Sewing Machines

Your not that far away from The Leather Machine Co I believe? Take a look at the Cobra's, you wont want anything else after that. https://leathermachineco.com/ -

WHERE on the table do I want my machine?

Yetibelle replied to kevinkay's topic in Leather Sewing Machines

I don't think there is a set rule if your going to make your own table-top. You just have to make sure it all lines up from the bottom to the top, so the motor and belt are not in the way of the table legs, plus it is heavy and you don't want it to lopsided so it tips over. They are typically offset to the right like in your picture to give you a little more room on the side for the project to float around as your sewing, and still access to reach the hand wheel. Looks like a nice table top. -

Sorry no not a leather machine, but you could make a nice pair of jeans.

-

Is it the correct needle for the machine? Is it a new needle, sometimes the needles get bent slightly and that's all it take to rub and skip stiches this is a good video showing how the needle passes down and meets the hook at the right distance and time, to make a stich. This machine he is using is similar to yours. https://www.youtube.com/watch?v=Og1hM8iS22Q

-

I suspect it's a Randall, but its missing some parts.

-

Here is a video of the 111g156 running, do you see the part in the video? or is it not part of the needle and foot area? https://www.youtube.com/watch?v=R8zxFHHChlo

-

I don't think your picture got added, can you try and add again.

-

the Forum makes it a little tricky to upload the manual, if you Google - Singer 111g156 pdf - the parts manual comes right up as the first hit. Henderson is also a great place to find manuals. https://www.hendersonsewing.com/manual.asp?page=42

-

This is also the issue with the Tippmann Boss (that is way more expense), its hard to sew long runs, belts and straps, with just one hand and keep them looking good. Sure it can be done, its just tricky. That is a Chinese shoe patch machine. Similar to a Singer 29-4 in the operation, but that's about it. I don't think you will be happy with this machine if your going to try and actually make something and want it to look good. Save up a little more money and get a machine with a motor. It will give you much better control of your project and they will look better.

-

Welcome to the group. I love that cast-iron base! I will give you my 2 cents, that is probably not worth even that. The big motor (yours is a newer one not original) once plugged in spins up to a some crazy RPMS and sounds like a small jet taking off and runs at full tilt as long as it has power. That front antique clutch has a spring that keeps your machine disk away from the spinning disk until you press the foot pedal, it then pushes the machine disk side into the spinning side to engage spinning and start sewing at warp 10. Once you take your foot off the pedal it the machine side pulls away from the spinning madness and the machine stops. If you look at a new clutch motor it will have a little arm that drops down from the pulley end that you directly connect the foot pedal, the newer motors have this cutch ability built in. The down side to this setup is clutch motor noise, the zippy fast speed, and the potential bump in the electric bill. I recommend replacing both with a new Servo motor, silent, speed adjustable, take less power, overall a much better user experience.

-

*** Basic Disclaimer *** This is a simple collage of vintage Singer Leather Sewing Machines. I am sure I missed something, I can always add more. I just borrowed these pictures from the Internet for reference purpose only, not rights reserved bladdda bladda.....enjoy.

-

Singer Industrial Sewing Machine Screws

Yetibelle replied to shoepatcher's topic in Leather Sewing Machines

WOW that's great thanks. -

Singer Industrial Sewing Machine Screws

Yetibelle replied to shoepatcher's topic in Leather Sewing Machines

Here is the Singer Screw guide from 1890 on the Smithsonian page. It is a scan of the book but I bet someone can convert it to a PDF. http://www.sil.si.edu/DigitalCollections/Trade-Literature/Sewing-Machines/NMAHTEX/2734/index.htm -

New Tandy Craftool Pro Stitch Master made by Sailrite

Yetibelle replied to Treesner's topic in Leather Sewing Machines

Here you can see a Sailrite in action! -

Not exactly a Leather sewing question... BUT

Yetibelle replied to SilverForgeStudio's topic in Leather Sewing Machines

-

New Tandy Craftool Pro Stitch Master made by Sailrite

Yetibelle replied to Treesner's topic in Leather Sewing Machines

This machine reminds me of my Ferrari! I think I should have done a little more research before I spent all my money. -

I really like the concept of The Boss, small footprint can be made portable, sews thick leather, no power needed ect. That's also what its drawback are. Since its so small its not great for larger projects, since you have to hand crank you loose one hand to the crank vs a foot pedal and two hands on the project. Hand cranking and clutching (like a motor cycle) is tedious. Someplace between 50 and 100 cranks you will loose patience with this process and your cranking may get a little lazy and not complete your follow-through up\down correctly and the machine may bind up. It' funny in the Cowboy Outlaw video he actually says "run this machine like your angry at it". In the demo videos they typically run the machines with small scraps of firm veg-tan, rather than actually making something. As your making your decision look for some videos of people actually making things and watch how they use the machine and their hands. Then picture yourself making the same project, you can crank-it-out -angry style, or gently guide it along peacefully. Good luck.

-

Singer 111W153 & table resto project

Yetibelle replied to Sugarkryptonite's topic in Leather Sewing Machines

Looks great! I want a sandblaster! You should get a Servo motor for it. That giant clutch motor while they look great there is really nothing great about them. The Rex Servo is about $100 buck on Amazon, I have got a few and they work great. The best upgrade you can do for the machine, other than a sandblaster.