-

Posts

358 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Yetibelle

-

Help! I'm reaching the end of my tether!

Yetibelle replied to Cymro29k3's topic in Leather Sewing Machines

I sold this machine a few years ago, it was working when I sold it. I'm sure that part could have been wrong, if I ever come across another one I will have to compare. -

Help! I'm reaching the end of my tether!

Yetibelle replied to Cymro29k3's topic in Leather Sewing Machines

Correct that is the 51. They are all 80 year old puzzles and figured any tricky thing to look for may help out a little. When I put that head back together it was stiff and didn't spin smoothly, I took it apart 3 more times and then finally got it to spin smooth and I still have no idea what I changed. Does that k3 have an internal presser foot spring? Or is it getting foot pressure from the bar? -

Help! I'm reaching the end of my tether!

Yetibelle replied to Cymro29k3's topic in Leather Sewing Machines

There are a number of items that can keep the 29k from making a stitch. A few are really simple and frustrating. Some include worn parts on the inside of the head, but lets assume they are ok. From what I understand its sewing "in place" and not advancing the leather. So even if it was not threaded and you just blank stitched you would not get even stitch holes? Or are you getting very small stitch holes in a line? Here are a few things to check. On the back of the 29 there should be a wing nut sliding adjustment, move that all the way to one side and the other. When you raise and lower the foot, that spring should compress and release. Sometimes it gets stuck and wont release so you don't get any pressure on the foot. You may need more oil in there and not even know its stuck until you hear it click release. But if the foot has no pressure and not moving its probably the spring. So check that tension on the spring and see if it is actually doing its job, and you feel pressure when you raise and lower the foot lever. That little screw in the front middle under the second tension assembly is annoying and I'm not sure of its value other than to frustrate. So loosen that and it makes the machine work. If the machine is feeding correctly and you have the right pressure on the leather and getting spaced holes and its still not picking up the bottom thread. Flip the needle plate around. It has 2 sets of holes, again not sure why, one set works and the other does not. This can also be frustrating. Once you find the side of the plate that works mark it with a dot. Last thing, since the head can rotate by turning the Wings, there may be one direction it prefers and it will start sewing. I guarantee that direction is not directly forward like you think it should be. So turn the wings that rotate the foot to the right slightly and then left slightly and see if you find that point it actually picks up the thread. This also means that you have a worn track in there and a few parts need updating. -

Singer 111w155 stitch length selector “wacky”

Yetibelle replied to Googledave's topic in How Do I Do That?

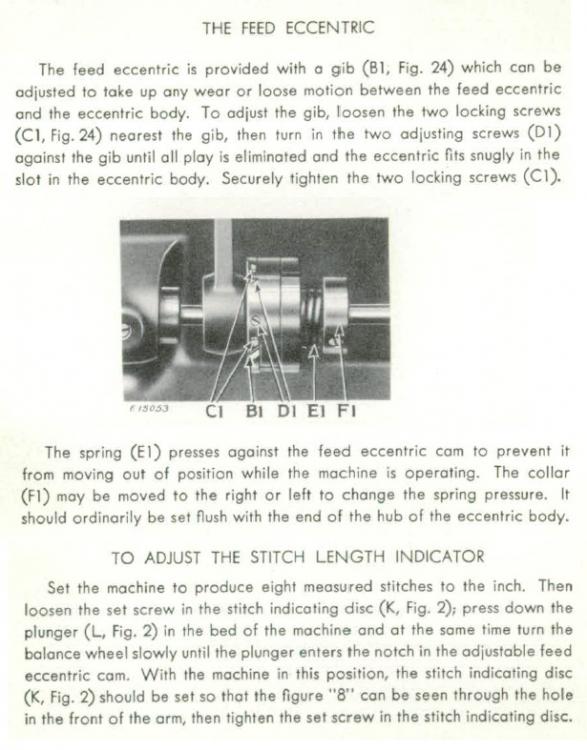

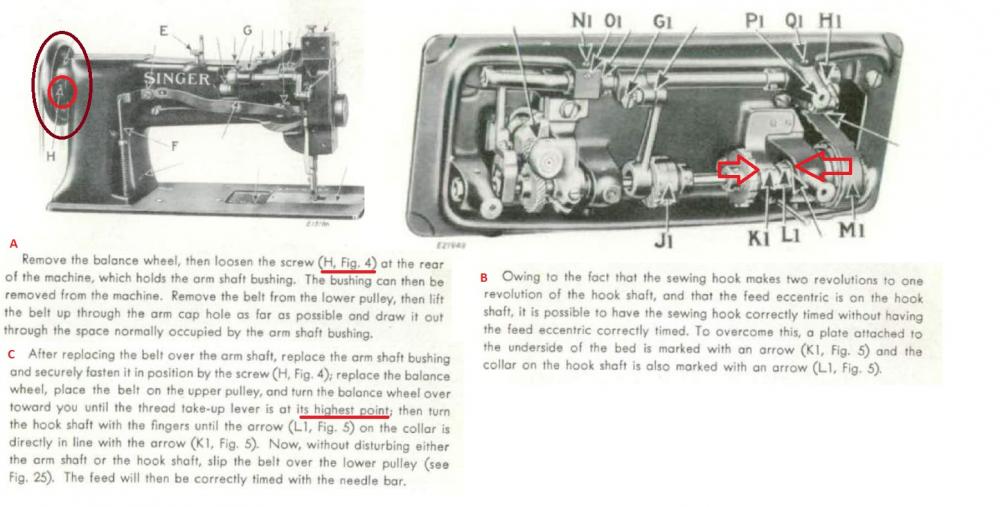

That is tricky. If its not adjusting the "normal way" take a look under the hood. Tip the machine back and rest it on a block if you don't have a tilt-knob there, this way you can use both hands. Watch as the plunger pops in place, the eccentric lever arm then should move smoothly in/out as you turn the wheel. I am going to guess that its not moving or slipping and the feed eccentric needs to be reset. Here are the Singer instructions. -

I think once you added the "homebrew" oil/wax product (depending on how well it set in) I don't think you going to want to cover that with a finish. The leather will breath from the rough side and your olive oil mixture will start to mold and using the bag-kote will then trap the mold in, it wont be pretty. So you would clean that off as best you can with a leather soap, then use a leather dressing\conditioner. The "food based" oils are not good, your project will get sticky and mold-up. You can experiment with your own formulas, and process but I would stay away from the cooking oils.

-

WOW - he did cover a lot in that video, and I'm glad that works for him. I would recommend you don't follow those instructions. I do recommend finding a basic leatherworking class before you start. They will go over what you need and what you don't and the correct order to making a project. In the mean time watch the videos from Weaver Leather, they do a great job of how to get started.

-

Singer 111w155 stitch length selector “wacky”

Yetibelle replied to Googledave's topic in How Do I Do That?

You pressing the stitch-selector release button/plunger just to the right of the inner cover plate and you turn the hand wheel slowly till you feel that button drop into place. Then you turn the hand wheel and read the stitch selector window numbers, and hope they actually line up with the correct count. If they don't its not a huge deal, you just figure out the math as you set it. Then release the button and its all set. -

I will bet its a 29k51. A great machine other than the small bobbin size that is common on 29 machines. I like the hand wheel on the side, those parts are harder to find.

-

When you get a freight quote, they give you a few options. You can have it delivered directly to your house or place of business, but if you don't have a loading dock (like at home) then they charge you an extra $50-$80. So it is less expensive if you pick a freight terminal and you then pick it up. The tricky part with that is then you need to unpack it and load it yourself, these machines are heavy so bring help.

-

Are sewing machines worth the money

Yetibelle replied to Horsewhishper's topic in Leather Sewing Machines

The machine will last a lifetime, unlike my computer or phone, and if I wanted to sell it they really hold there value. One of the less discussed benefits of this investment is the ability to quickly prototype new projects that I was not willing or able to tackle before. I can grab some low grade veg-tan, trace out a project and sew it up in 20-30 minutes and typically the first draft looks pretty good. This is a really big deal, it helps you flush out ideas and concepts that you would never want to take 2-3 hours and hand-sew. So your skills and designs will improve very quickly. This flexibility is really amazing you will be making things left and right just because you can and it become rather addictive. I grab some scrap from one project and make a small leather case out if it, pound a snap on it and give it away as a gift. Also people will start bringing you there stuff to fix and unlike before when you had to hand-sew, you will be excited and patch a bag or a backpack in a few minutes. Its really great feeling. -

Singer 7-34 Manual and Needle Type

Yetibelle replied to Sambishop16's topic in Leather Sewing Machines

Here is the PDF. Singer 7 CLASS_all_instructions.pdf- 4 replies

-

- singer 734

- needle type

-

(and 4 more)

Tagged with:

-

I wonder how far it traveled, is it still in the same State it was shipped to? I think it became self-aware and escaped off the tuck, we can call it Johnny-4500!

-

Once motor is removed place in bag and recycle it. You will want a Servo motor. That is a good looking machine.

-

-

Singer Age by Serial Numbers Slide Chart

Yetibelle replied to Gregg From Keystone Sewing's topic in Leather Sewing Machines

I agree get back in there that is a great find! -

I didn't read all the comments, since I'm tired and lazy (and honest), so forgive me is this was mentioned... As startup cost go I think a leather craft business is very reasonable, the 441 clone while it appears expensive is a great investment. It will last almost forever, unlike a most other modern day tools and equipment, and thus it will pay for itself very quickly. The learning curve isn't that complicated; now I can make 2-3 items a day that use to take me 2-3 days to make 1 item. The product design, marketing and order fulfillment, just like any other business, would be a struggle to master.

- 22 replies

-

I know this will sound rather basic and silly, but there are 2 sets of needle holes on the swivel cover plate. Even though they both look rather similar my machine will only sew correctly on one side. So have you tried the other side of that plate?

-

Also you may want to use a stitch-grooving tool to create a channel to sink the stitches into. It all depends on the look you want, but the "sunk" stitches look really clean.

-

I think after any one hand-sews leather, while sometimes relaxing and meditative, it can also be frustrating and slow. This also applies to learning to sew leather with a machine, hand crank, treadle or motor; it will take you some time to get the hang of it. So if you pick the hand crank Boss machine, you will be learning to sew with one hand cranking the other holding the project. If you get a treadle you will learn how to move your hand back and forth from the hand-wheel to the project and get a foot-rhythm. Now if you get a the Cowboy CB4500, both hands are holding your project, the needle can move at brisk pace or a single stitch at a time due to the servo motor and speed reducer pulley. I believe the slower speeds, using both hands and the edge guide reduce the learning curve significantly. I would also add that unlike a 2K computer that is good for maybe 5 years, the industrial sewing machine may be immortal, since some of my machines are well over 100 years old and in perfect working condition.

-

Good looking machine. I suspect with that puller attachment you wont be tipping the head back very often. My point is that you could just set the machine into the table and have it sit in the routed-lip of the cutout without the hinge brackets. Just an idea. To tip or not to tip? That is the question.

-

reconditioning Singer 144W305 motor Cat # S53216E-G

Yetibelle replied to tketcham's topic in Leather Sewing Machines

I suggest getting a Servo motor, it will save you time and money. -

-

Not sure what my problem is... any insight appreciated!

Yetibelle replied to RaptorBravo's topic in Leather Sewing Machines

- 14 replies

-

I can almost identify the machine for you, from one of the pictures. They did an excellent job of hiding most of the machine and narrow your vision to the sewing foot area, and the sewing actually doesn't look half bad. Anyway it looks like a Singer 15 clone maybe a Deluxe 100 or Deluxe 30. It may be a capable little home machine, but its not worth what they are asking, and its not a leather machine or close to anything industrial. I call these misleading adds "quarter-stackers" since they always try and sell you the machine based on how many quarters they can stack next to the foot. Whenever you see a smaller "home-style" machine sewing leather, and stacking-quarter beware. The 31-15 is an industrial tailor machine. However the 16-188, that is called a 16-18 in the add, is a light leather machine - your better off with these for less money! sure they need some cleaning, and probably a new servo motor. https://cosprings.craigslist.org/for/d/2-vintage-sewing-maxhines/6553220337.html

-

That's not an outrageous price for the machine. Just note you may have to put more time and money into it. Possibly a new hook ($80-$120), possibly a servo motor ($100 or so) and Speed reducer ($100 or so). So the costs can add up.