-

Posts

73 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Primosand

-

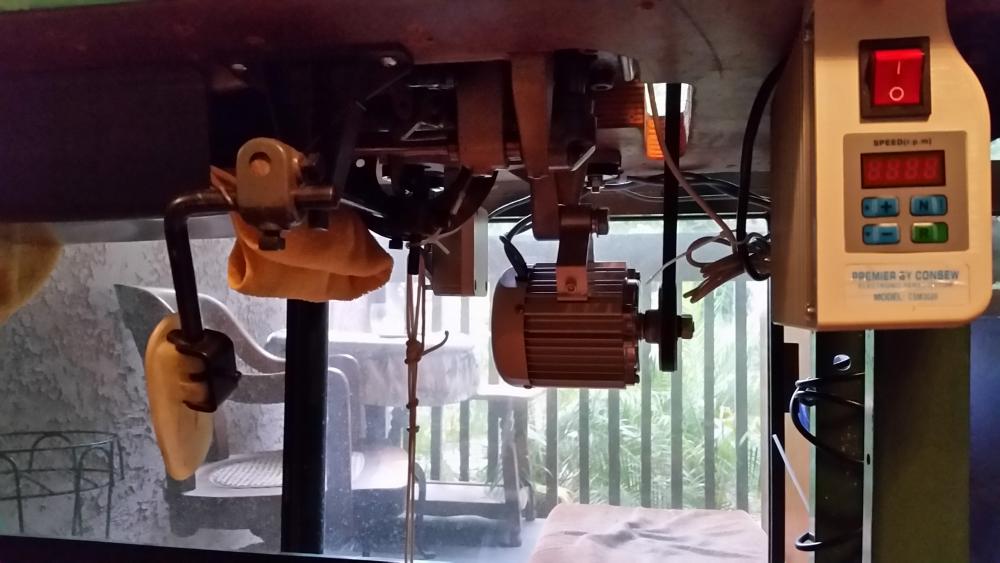

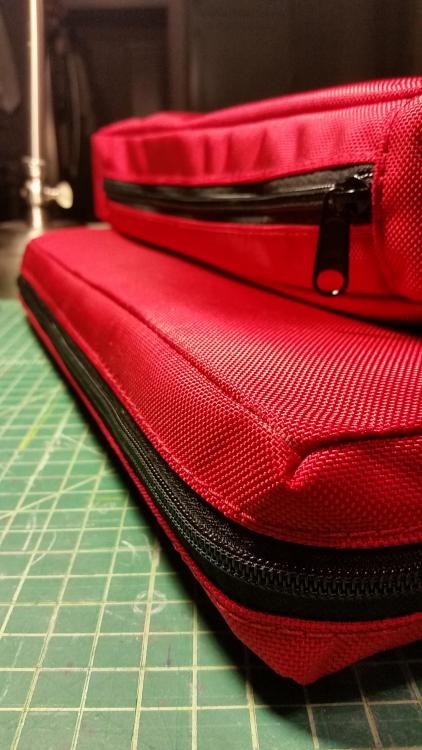

Dialing in a machine the way "you" like it. This is the set up that works best for me ..... on my Consew 226 I have a Consew Premier CSM550-1 (550 watt) servo motor with a speed reducer. The reason this Consew servo motor works so well for me is that I was able to open it up and disable the brake. With the brake disabled (I think I just removed the brake shoe pads, it's been a while) I can start to feather it up to speed so slowly that I can clearly see the thread being pulled or dragged through the the needle. I can also control the speed well enough to take 3 or 4 steps (stitches) forward with "no jump at all" and 3 or 4 back to lock in the start of a seam. I can also slow it down when coming to the end of a seam where I have to put the needle on a specific mark and then carefully/slowly back stitch it again to lock and finish the seam. I usually sew with a bonded nylon and or poly thread T-69 , T-90 and T-138 and 18, 21, or 23 needle for reference but it shouldn't matter what you use. The other thing I love is it has the power to push through a knot of just about any fabric at a dead crawl. Leather or like this last job with ballistic nylon where it's folded over a few times at a seam/corner and you need to sew through as many as 5, 6, 7 or 8 layers. It will slowly drive the needle through it like butter. Reminds me of tiny hydraulic press. No doubt the speed reducer is contributing to the desired slow speed, torque and control. Another really nice touch are the 4" casters with brakes that I've put my tables on. I can easily move the machines over to my cutting table (dinning table) if I'm doing a large canvas boat cover for instance so that the table can support the weight of the heavy canvas or roll the machines out on my patio to work outside. It makes the tables much taller than normal but I've found that with my bad eyes it just brings the work up a bit closer to where I can see it. The problem I have with this new Consew CSM 3000 (750 watt) that I just bought for my double needle Pfaff 142-6 is that I can't figure out how to disable the brake. So when it starts up it's like it "jumps into motion" all be it to the slowest speed (200-500 spm) rather then the needle slowly starts to move. Same thing with the stop it just comes to s screeching stop instead of letting me slow it down. This CSM 3000 is a newer style of motor (with digital speed control out front on the on/off switch box ... very nice) but does not have the mechanical brake that my older CSM 550-1 has. I've googled "servo motor brakes" a bit and these newer Consew servo motors may have a magnetic brake. I've opened up both ends of the motor and was still unable to figure out how to disable the brake. If any of you folks out there that know what you're doing and can shed some light on this servo motor brake business I'd like to hear from you. If I can't figure out how to disable the brake and get control of this newer servo I'll have to return or exchange it for the older Consew model or buy a different brand that has much more control over startup speed and stopping. Looks like I'll probably have to pony up the money for a speed reducer pulley as well, something I was hoping wouldn't be necessary this time around. jeff

-

Hi Elizabeth, Today I'm finishing a rush job that must be done to by 3:00 so I can't talk much. But wanted to let you know I have a Consew 226 and love it. Servo motors ...... yes. Clutch motors .... NO !!! I'll show you my set up with servo and speed reducer pulley when I have more time. It's dialed in and perfect for leather. My new Pfaff 142-6 twin needle that I just got isn't dialed in because I just bought the wrong servo motor. (don't buy a Consew Preimer 3000, 750 watt) Does a Singer 111w155 have reverse? I know the consew 226 does. You want reverse. jeff

-

Thanks for the input gentlemen. I've ordered a 750W motor rather than a 550W. I'm going to try it out without a speed reducer or needle position and see how it works. I figure I can add the other items later if needed. Interesting that a speed reducer screws up an add on needle position device. I had not considered that. thanks again for the help.

-

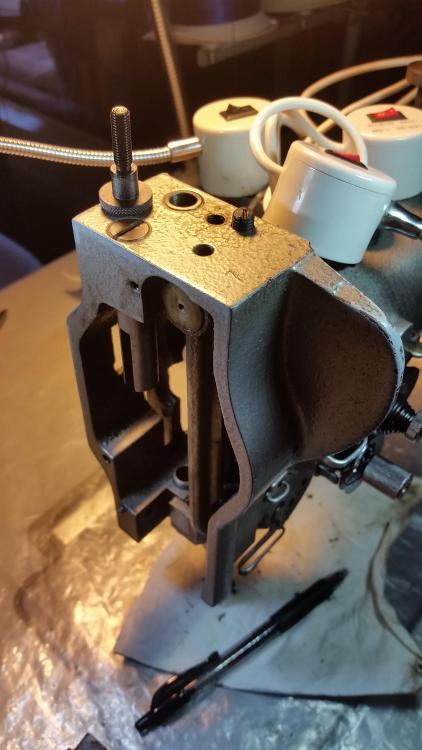

Hi Folks, I'm looking for a little advise before I spend my money. I recently bought a Pfaff 142-6, twin needle upholstery machine that came with a clutch motor. I want to upgrade it with a new servo motor. I'd like to know a couple of things before I spend my money.. 1. 550W or 750W ? I have Consew 226R with a 550W Consew servo motor and a speed reducer pulley set up similar to the way Cowboy or Cobra cylinder arm machines come new. It works great but would a 750W work even better? 2. Does adding a speed reducer pulley add torque (piercing power) at very low speeds? Leather sewing speeds. 3. What particular brands are the best deals (bang for your buck) on a servo motor these days? (are all brands the same?) Check out my new Pfaff 142-6 pictures below. I'm so proud, always wanted a twin needle machine but that clutch motor is down right scary and has to go. What is a perfectly good clutch motor good for in a re-purposed kinda way? I was thinking a polisher for cleaning up vintage sewing machine parts that have a bit of rust. Thanks in advance for any advice you'd care to share. jeff

-

Interesting machine. I will start watching for Singer 114W103's Good luck

-

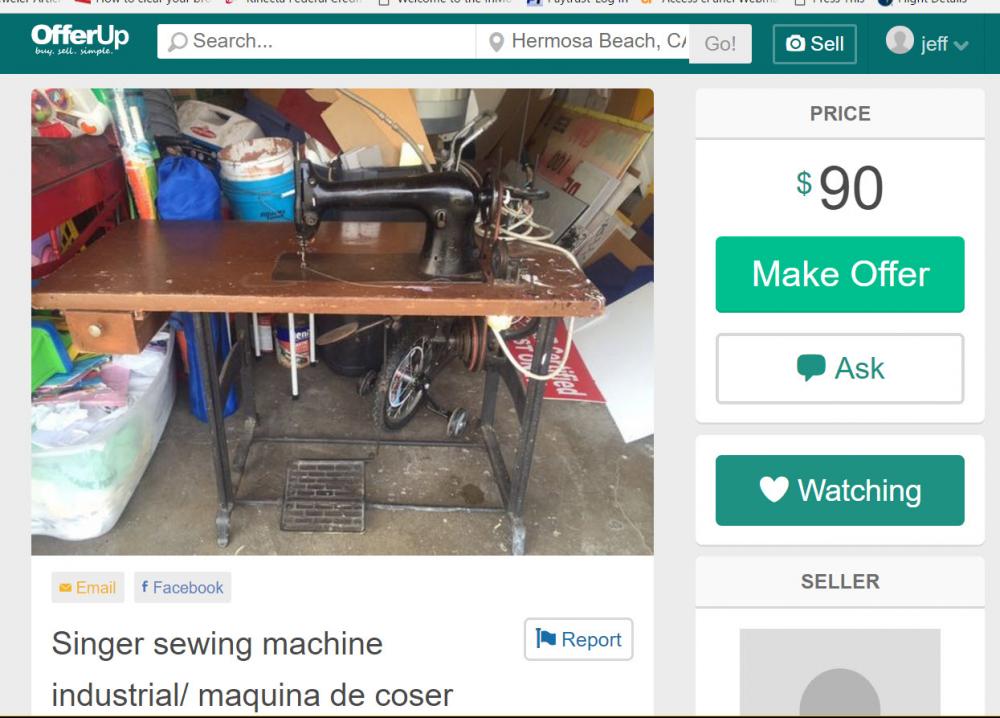

Dennis, sadly your machine is out of my budget at the moment and shipping it across country would really put it out of my budget. So I'd like to ask you a couple questions about Singer if you don't mind. I've never owned or used a Singer before. I've recently started restoring Italian made, vintage 1950s Necchi sewing machines. These are marvelous, very well machined, but little (domestic) sewing machines. If I'm not sewing with #138 or heavier thread I'm just not happy. While scouring Craigslist, estate sales and the like for vintage deals you run across a bunch of old Singer machines. Both large and small (industrial and domestic) some some like new and some a pile of rust and neglect. Prices are sometimes very low .... like $80-$100 for an industrial that needs a lot of work. I can't tell if your machine has a reverse on it. I'd like to identify one or two models of industrial, American made Singers that can do what your machine does as easily as your machine does it but with "reverse", maybe even a zigzag feature although zigzag is not really that important to me. A straight stitch machine that can calmly walk through a 1/2" of tough leather so slow that you can see the thread being pulled through the needle is what I'm looking for. I'm guessing that Singer parts are far more available than say Adler or Pfaff just based on how many you see up for sale so I'm guessing that restoring an old Singer would be the quickest way to wind up with a fine old machine like yours at a price that I can afford. What model/models of older Singers can do what your machine does, has a reverse feature, with replacement parts being relatively easy to obtain? thanks for your time.

-

wow ..... that is gorgeous

-

very creative, very nice

-

-

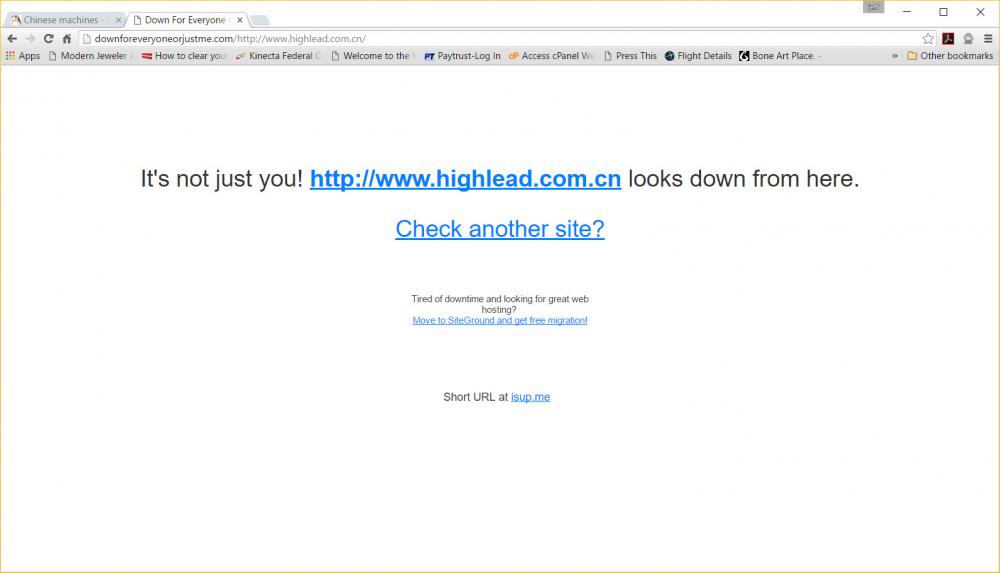

Thanks for the reply Mike. We read you're post above and then tried http://www.highlead.com.cn/ on both our smart phones, my wife's macbook and her apple desk top and we can't get through to the site on any of our devices. We noticed you're in France and I'm wonder if that may be why you're getting through. Can someone here in the US check this website link and see if it's working? http://www.highlead.com.cn/ thanks jeff

-

Can anyone tell me whats up with the current Chinese Highlead website? http://www.highlead.com.cn/ It no longer works, does anyone know whats going on? Do they have a new website? thanks to anyone that can help. I'm looking for a : Highlead GC20638-25D SP2 this is a split, twin needle, 25 Inch long arm with pneumatic controls thanks in advance to anyone that can help jeff

-

very nice work.

-

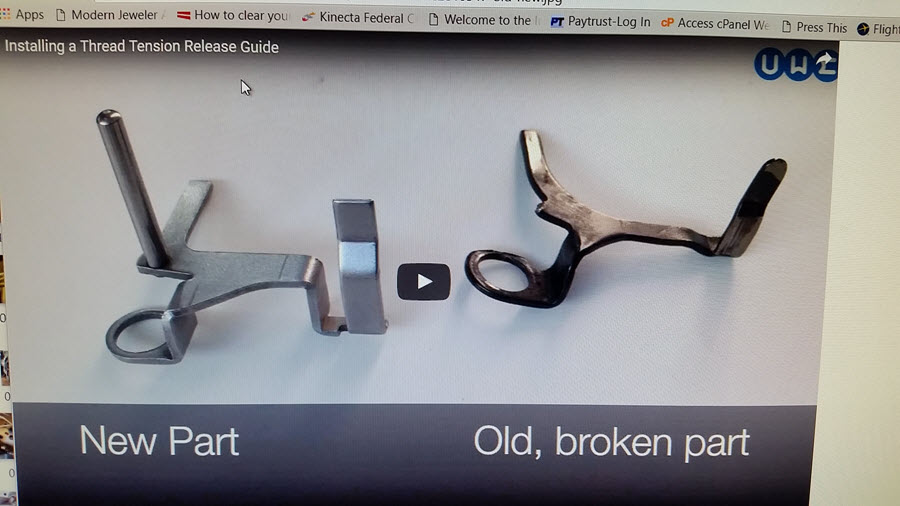

So it been a while but did get the replacement parts in and was able to fix my “thread tension release slide” with (Seiko part #10546). Uwe thanks again for making your videos. You really do a fine job. I have little to NO experience with sewing machine repair. But with your video I was able to order parts, open up the belly of the beast and make the fix. My “thread tension release” on my newly purchased, "used", Consew 226 is now working as it should. Thanks again for your help Uwe. Also I’d like to says thanks to Gregg over a Keystone Sewing Machines. Gregg finally sent me the correct Seiko part after I ordered the wrong (Chinese made) part from two other local LA parts venders.

- 20 replies

-

- tacsew t1563

- juki lu-563

- (and 6 more)

-

I like you LED light strips .... good luck on the sale.

-

Slide plate pin ........ thanks again guys. I'll look this up in the parts list diagram and see where and how it goes and see about the missing spring. So my replacement "tension release slide" part came in the mail yesterday. It was shipped in a soft side bubble wrap envelope and the bendable part #10546 was sticking out the side of the bubble wrap. The arm broke off the part as I removed it from the bag. Before they sent this to me I talked to Sean at Aberoni sewing and he told me that this is a quality Japanese made part that they use all the time. Another guy at the store said that of the two styles of parts the old style with the arm simply bent up at a right angle was the supirior part. He said that the one with the post added, the post will break off and was an inferior chinese part that runs about $3.00. When I asked why they mail of a bendable part in a softside bubble wrap envelope and not a box he said that other part venders ship the part in regular envelope (no bubble wrap) and that there method was better and saved money.

- 20 replies

-

- tacsew t1563

- juki lu-563

- (and 6 more)

-

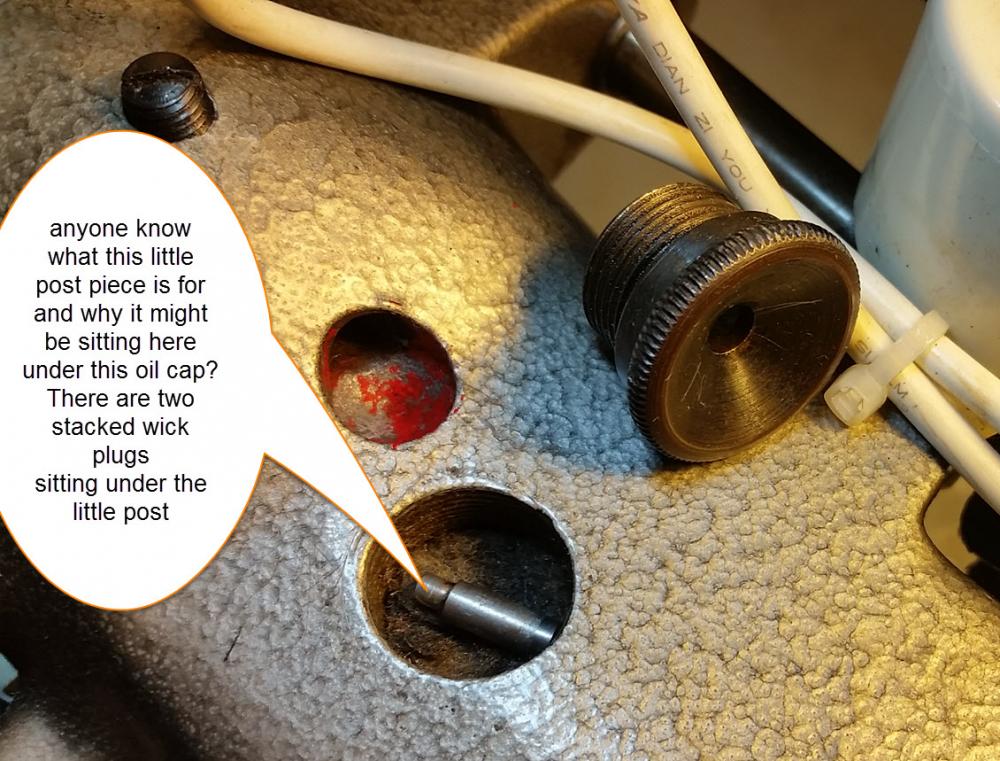

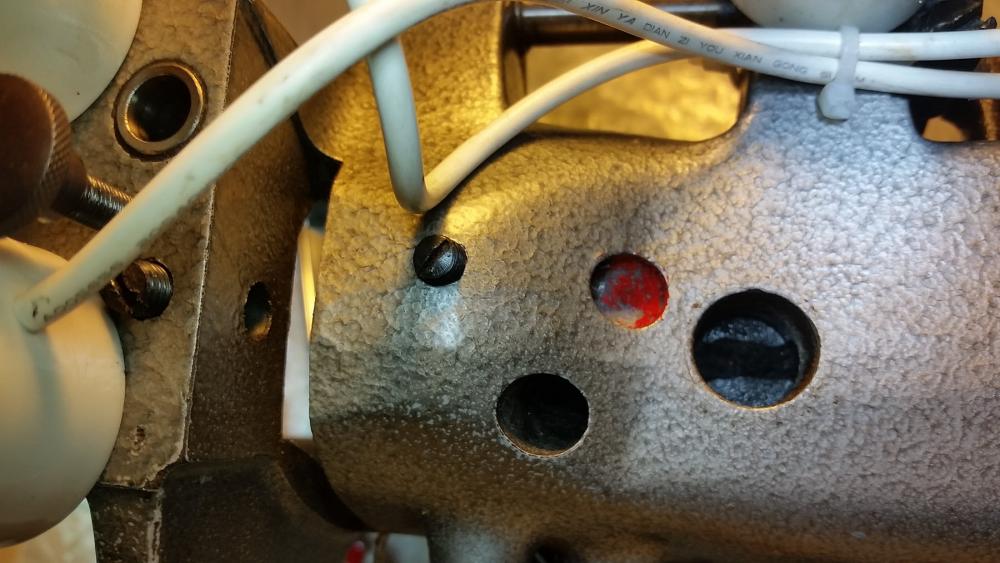

So I opened this oil resiovor cap (I think it's an oil resiovor) and this little pin was just sitting there on top of two stacked wick plugs It doesn't seem to belong. Does anyone know what it is for and where it goes? thanks

- 20 replies

-

- tacsew t1563

- juki lu-563

- (and 6 more)

-

- 20 replies

-

- tacsew t1563

- juki lu-563

- (and 6 more)

-

- 20 replies

-

- tacsew t1563

- juki lu-563

- (and 6 more)

-

- 20 replies

-

- tacsew t1563

- juki lu-563

- (and 6 more)

-

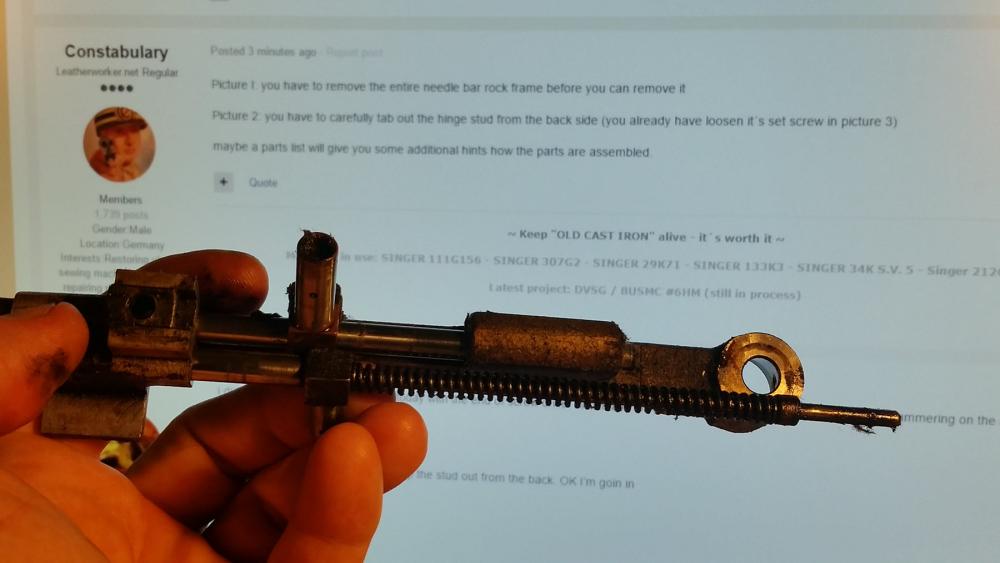

I did tap that little stud at one point today with the end of screw driver and it didn't move so I stopped thinking it unwise to start hammering on the machine when I clearly didn’t have a clue. So take the set screw out and then tap the stud out from the back. OK I’m goin in Thanks so much for the help.

- 20 replies

-

- tacsew t1563

- juki lu-563

- (and 6 more)

-

nice work

-

after watching Uwe's video, I got into my recently acquired used Consew 226 to check why my tension release didn't seem to work properly. The thread tension release arm was missing with only the small ring portion of the part still around the shaft. I managed to get everything I need out of the machine and a replacement part ordered. So I’d like to get the machine cleaned up inside as much as possible while wait on my replacement part to be shipped. Does anyone know how to get the needle bar and the middle presser foot bar out of the head? There is a set screw on top that I took out but then nothing moves. any help would be greatly appreciated.

- 20 replies

-

- tacsew t1563

- juki lu-563

- (and 6 more)

-

Best Machine For Thinner Leathers (Purses, Wallets,etc)

Primosand replied to horselady21's topic in Leather Sewing Machines

Yes the seat is very nice. -

Sewing Machine tweaking: Consew 226 and Cobra 16" cylinder arm

Primosand replied to Primosand's topic in How Do I Do That?

Tom I opened the linkage cover on my servo and there it was a ........... "motor brake" I disengaged the break and now my Consew 226 hand wheel rolles over like butter. Thanks for the help Tom.